1. Introduction

Laser brazing is suitable for a fast joining process with low heat input and thus minor distortion, compared to laser welding. A current industrial application is the joining of zinc-coated steel parts in car body. Besides the structural abilities, here, a high optical quality is required, because the seam is in the visible range of the customer. In this application, defects in the form of edge notches on the seam occur, caused by an inconstant wetting of the substrate [

1]. A periodic melting of the zinc layer is assumed to be the explanation for that [

2]. The wetting frequency is in relation with the process parameter such as processing speed [

3]. Furthermore, it could be shown that the wetting frequency can be influenced by the oscillation of the laser beam in the process direction and thus the quality of the solder seam can be improved [

4].

In addition to the beam modulation mentioned above, beam shaping can influence process dynamics and thus wetting. When parameterizing the soldering process, the intensity profile of the laser on the workpiece has a decisive influence on the formation of the seam surface. Compared to a defocused laser beam, a top hat intensity profile can, for example, significantly reduce the frequency of edge notches [

5].

However, laser brazing, and therefore its benefits, is not yet utilized for aluminum alloys. The reasons for this are the presence of an oxide layer, which has to be removed in an additional step before brazing, the high thermal conductivity, and primarily, the low melting point [

6].

Aluminum brazing can be achieved with aluminum-based filler material due to a good corrosion resistance and high joint strength. However, in this case the temperature interval between liquidus temperature of the filler material and the solidus temperature of the base material is critical [

7].

A process window for joining pure aluminum (melting temperature 660 °C) with AlSi12 filler material (melting temperature 575 to 585 °C) exists but is small and thus sensitive to temperature instabilities. An alternative solution is the usage of filler materials with lower melting points by the alloying with copper and zinc, but there are disadvantages in terms of the ductility and formability [

8].

Since melt pool oscillation is a known phenomenon in laser brazing, inconstant wetting behavior could cause a periodic partial melting of the base material in aluminum brazing.

Previous research used high-speed cameras as well as thermal 2D and 1D pyrometer sensors to investigate the wetting behavior of molten braze material. Grimm et al. published a possibility for online process monitoring by analyzing various regions of interest (ROIs) in recorded images. They also described the melt pool propagation as periodic. Depending on the misalignment of the wire or the brazing speed, the frequencies are in the range of 15 to 40 Hz [

1]. By observing the area of laser interaction with a single spot pyrometer, it also seems that specific frequencies are present in the process. The pyrometer signal frequencies increase with higher brazing speed, but become equal to the scanning frequencies when the laser is scanned superposed to the feed in a longitudinal direction. Heitmanek et al. relate this to the thereby modified temperature field in the fusion zone. Based on simulations, the melt pool elongates due to increased laser deflection [

4]. These melt pool propagation instabilities are related to the evaporating zinc coating of the steel and the inconsistent wire feeding. Furthermore, using manual high-speed image analysis of the wetting front, Heuberger et al. identified an unsteady spreading of the melt pool front related to seam defects [

9]. Reimann showed the relationship between an inconstant wire feeding and the melt pool frequency by comparing a pyrometer signal with the wire feed rate. He discovered that a stepwise spreading of the melt pool front, caused by external influences such as the system technology, results in V-shaped flakes on the seam surface [

10].

2. Materials and Methods

2.1. Materials

The materials used in this study were pure aluminum EN AW-1050 in H24 condition with a 2 mm thickness as the base material and aluminum–silicon eutectic alloy AlSi12 with a 1.2 mm diameter as the filler wire. The specimens were cut to sheets of 150 × 50 mm, whereby the length was oriented 90° to the rolling direction. Fontargen F 400 NH brazing flux was applied with a brush after forming an emulsion with purified water.

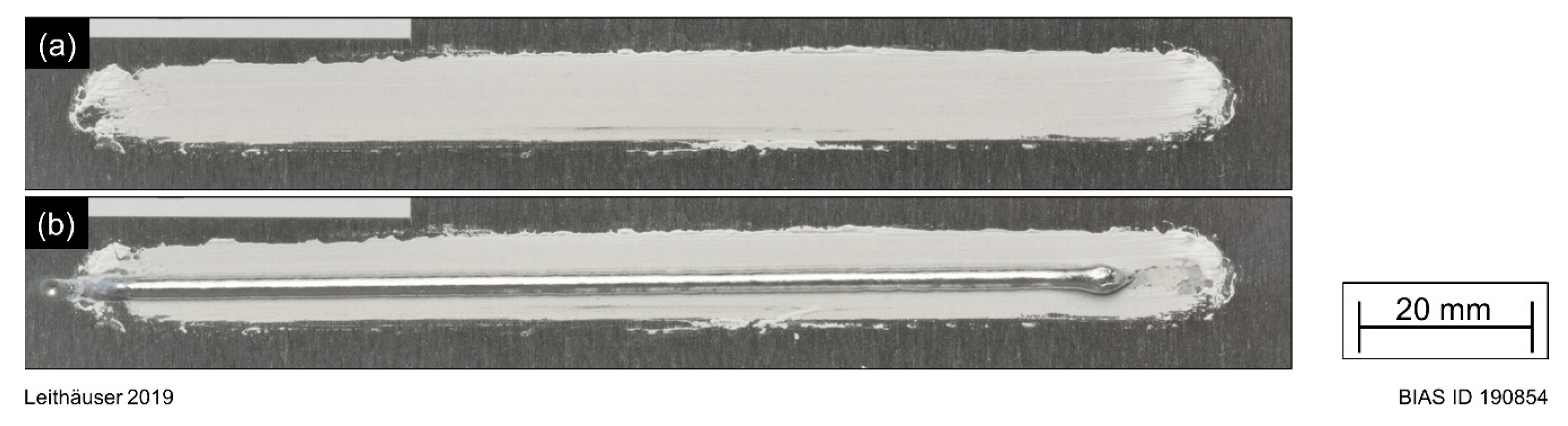

Figure 1 shows the sheet after the flux application and subsequent brazing.

2.2. Laser Processing

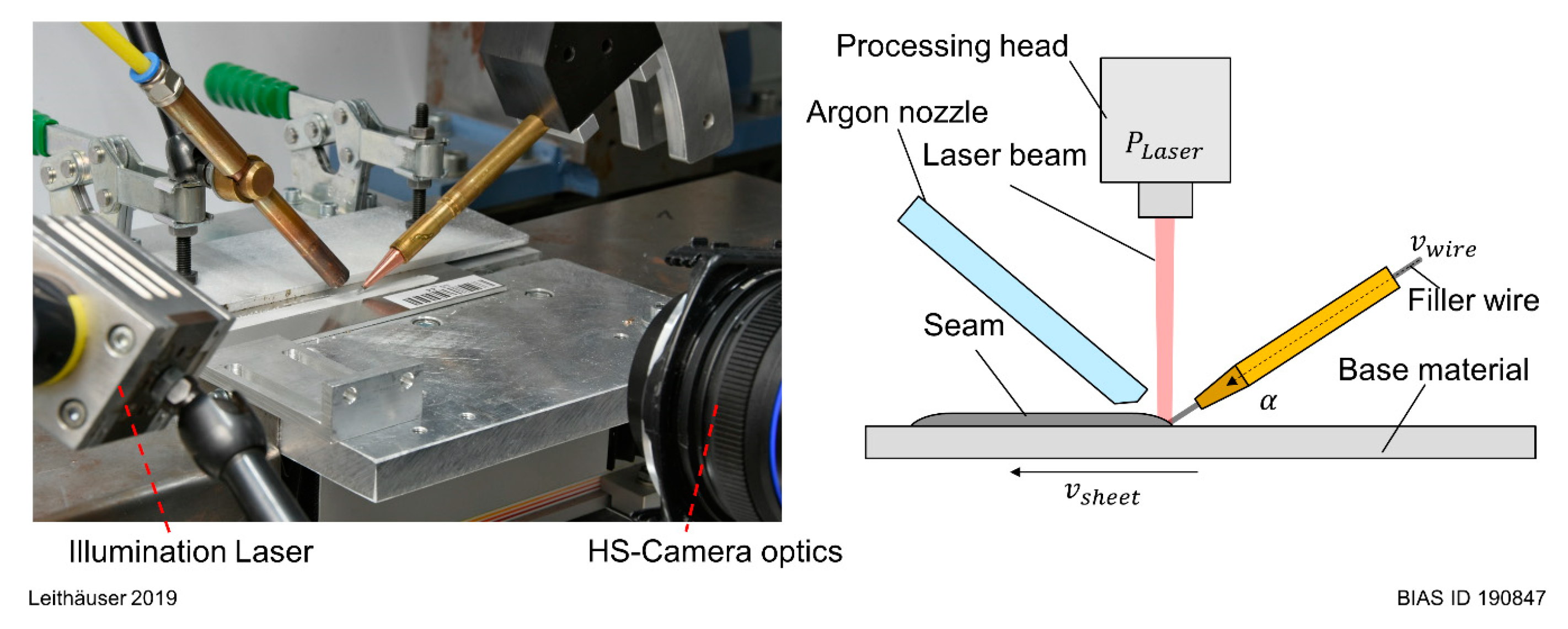

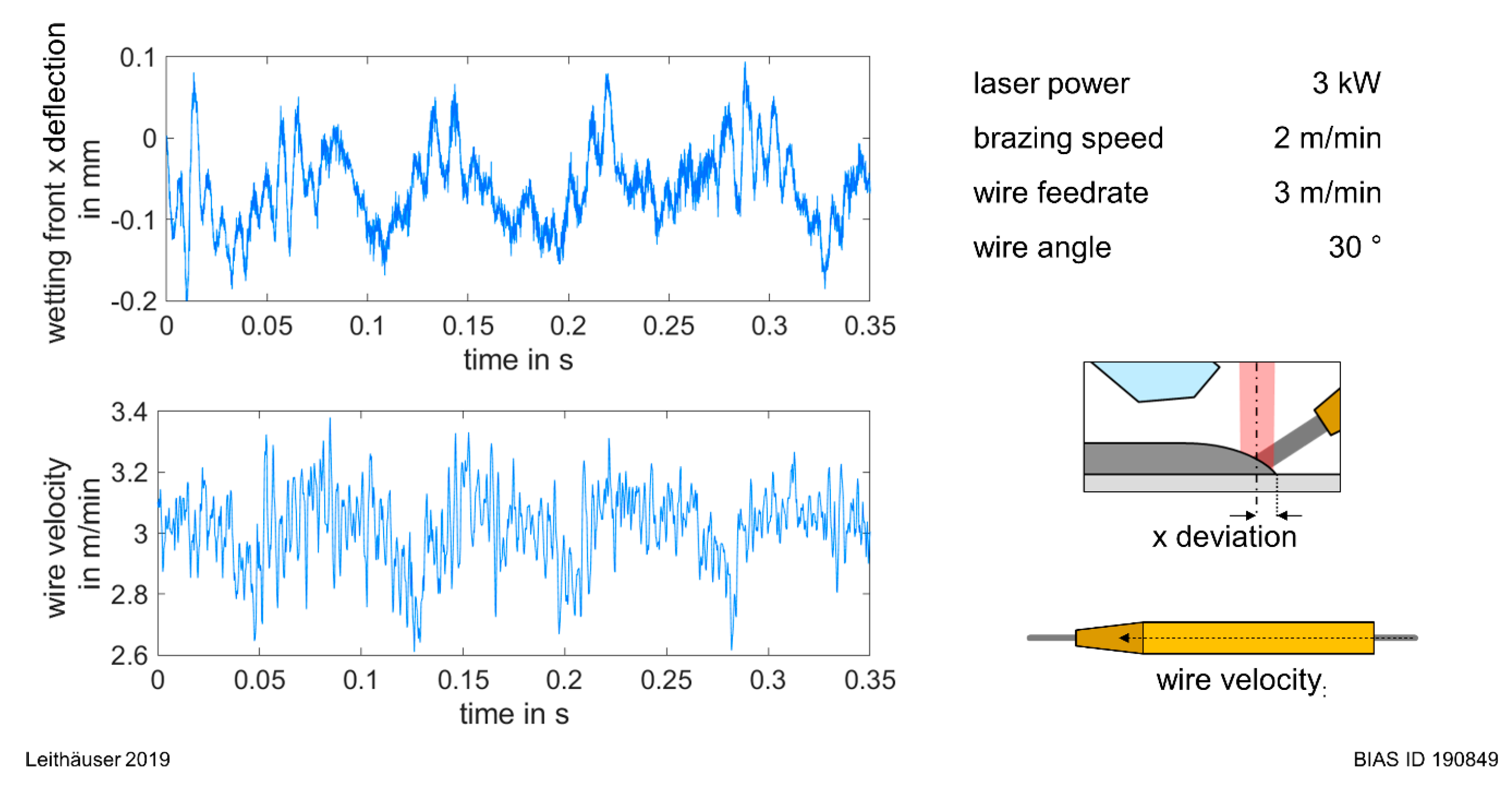

The braze was done in a bead-on-plate configuration on a custom Power Automation CNC table with a moving specimen holder. An Nd:YAG laser (Trumpf HL 4006D, TRUMPF GmbH + Co. KG, Ditzingen, Germany) was used as the laser source, emitting at a wavelength of 1064 nm. The beam, guided with a 600 µm optical fiber, was focused perpendicular to the base plate. A Trumpf BEO D70 optics was used, with a 56 mm collimator lens and a 280 mm focus lens, creating a spot of 3 mm in diameter. The filler wire was supplied laterally through a wire rope and a copper tip to the workpiece by a Dinse LK 60 E drive unit. Argon was used to shield the braze from the counter orientation, regulated by an Omega FMA6526ST digital mass flow controller to 12 L/min. The laser power was 3 kW, the brazing speed was 2 m/min, and the wire angle was 30°. The wire feed rate was modified from 2.5 m/min to 3.5 m/min in 0.25 m/min increments. The setup is visible in

Figure 2. The created seam has a length of 100 mm.

2.3. Process Observation and Post-Processing

The process was recorded with a Phantom VEO 410L high-speed camera, recording 768 × 312 px images at 18 kfps. The camera was angled 4° to the horizontal plane. A CAVILUX HF (Cavitar Ltd, Tampere, Finland) illumination laser, emitting at 810 nm, was used as a light source for the recording, combined with an 810 ± 10 nm bandpass filter in front of the optics. This provided a controlled illumination of the process without disturbances from the surroundings.

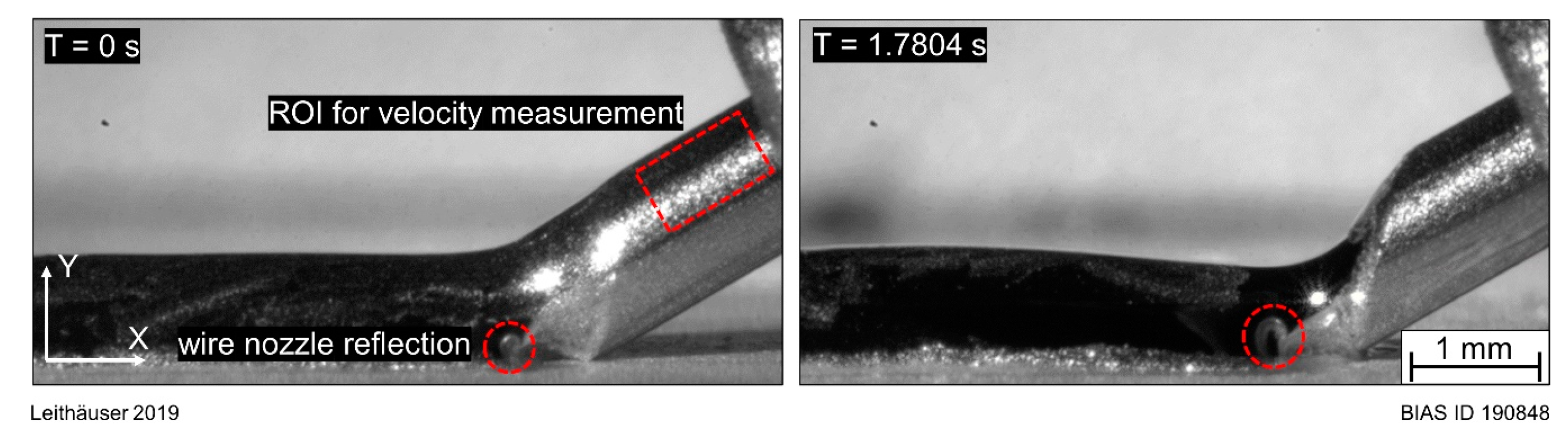

The tracking of the wetting front, as well as the capturing of process parameters such as the wire feed rate and wire angle, was achieved with image processing in MATLAB. In

Figure 3, a circular object is noticeable at the front of the wetting melt pool. This can be recognized as the reflection of the wire nozzle. The fact that the melt pool is forming a spherical geometry at the wetting front brings the reflection to the camera. This circular shape was used for tracking the wetting front with a circle detection algorithm that uses a circular Hough transform. The outputs are the center point coordinates and the approximated radius of the circular reflection. The front deviation in the x (horizontal) direction of this circle represents the wetting front.

An appropriate stability for the front detection was achieved through the dynamic adaption of the adjustment parameter, the binarization threshold, and by using a smoothing filter for the cropped ROI.

To determine the wire feed rate, the Kanade–Lucas–Tomasi (KLT) algorithm was used to track the multiple eigen features of the wire. The quantity was between 60 and 100 features per tracking cycle. With the coordinates, the x- and y-velocities were calculated for each feature by polynomial curve fitting and then totalized. The mean value of all feature velocities was used as the wire speed. A tracking cycle of five frames was used in this study as it has a good statistical accuracy as well as high sampling rates.

2.4. Signal Processing

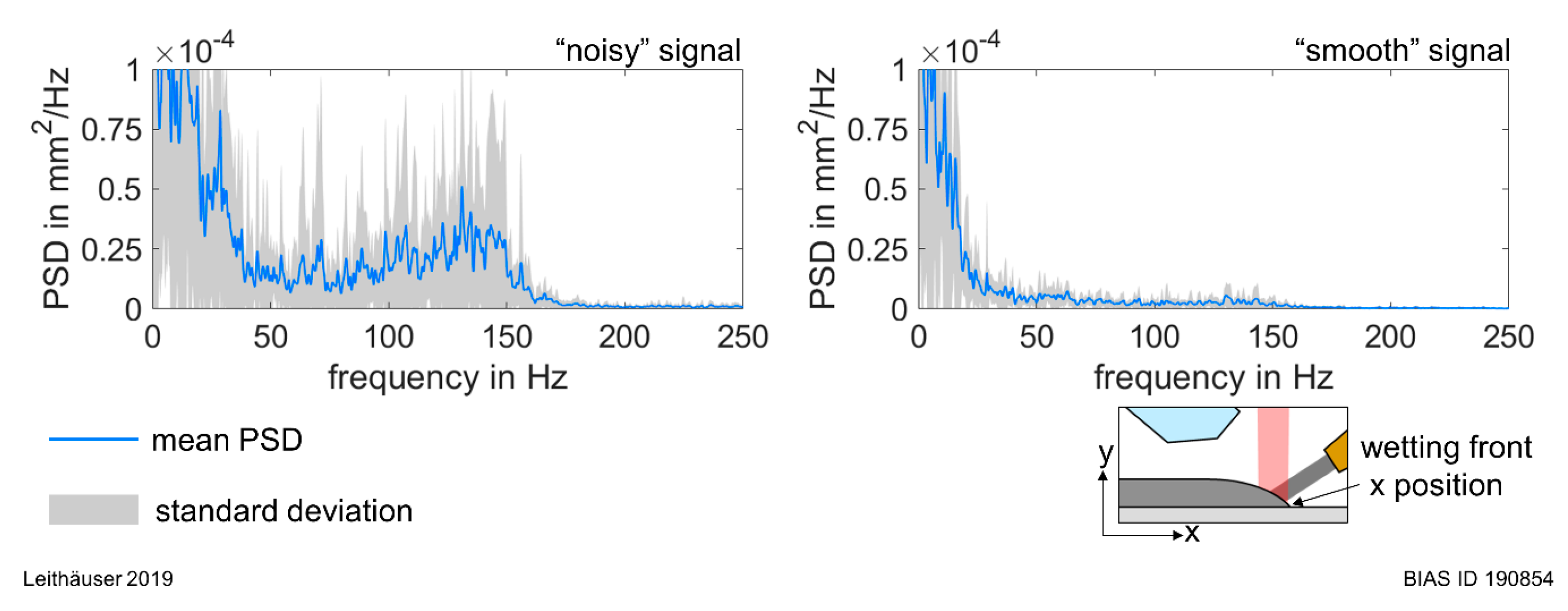

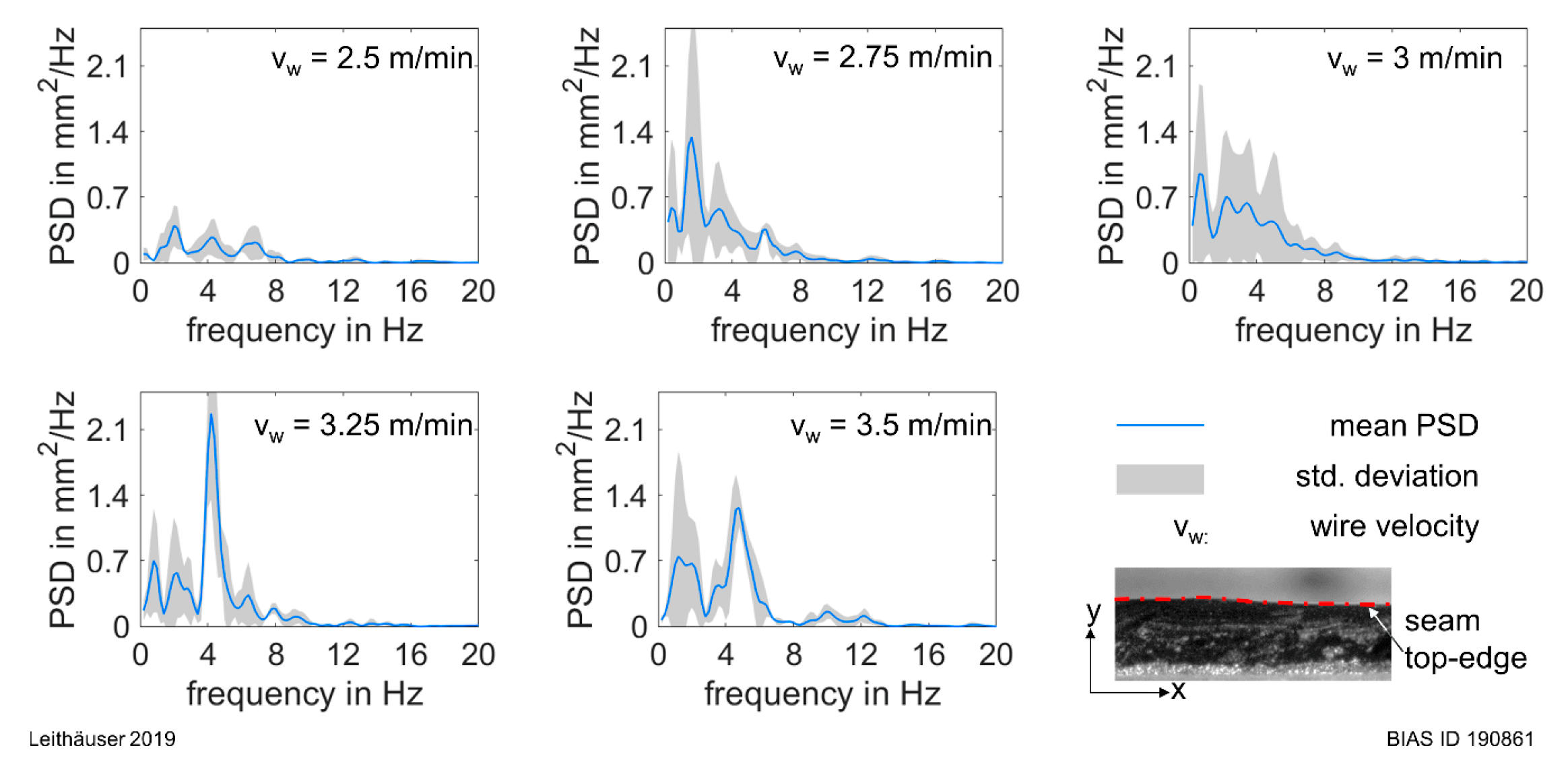

For a frequency analysis of the signal, the power spectral density (PSD) was calculated as the Fourier transform of the biased estimate of the autocorrelation. This is suitable for stationary random processes. Therefore, the “periodogram” function in MATLAB was used, applying filtering with a hamming window. Prior to this, the signal was detrended by subtracting a best-fit line from the raw data. The mean and standard deviation of the PSD were generated by calculating the mean and standard deviation values for each frequency increment. Finally, the seam height over time was generated by detecting the top edge of the seam in the high-speed video, where the melt was already solidified.

4. Discussion

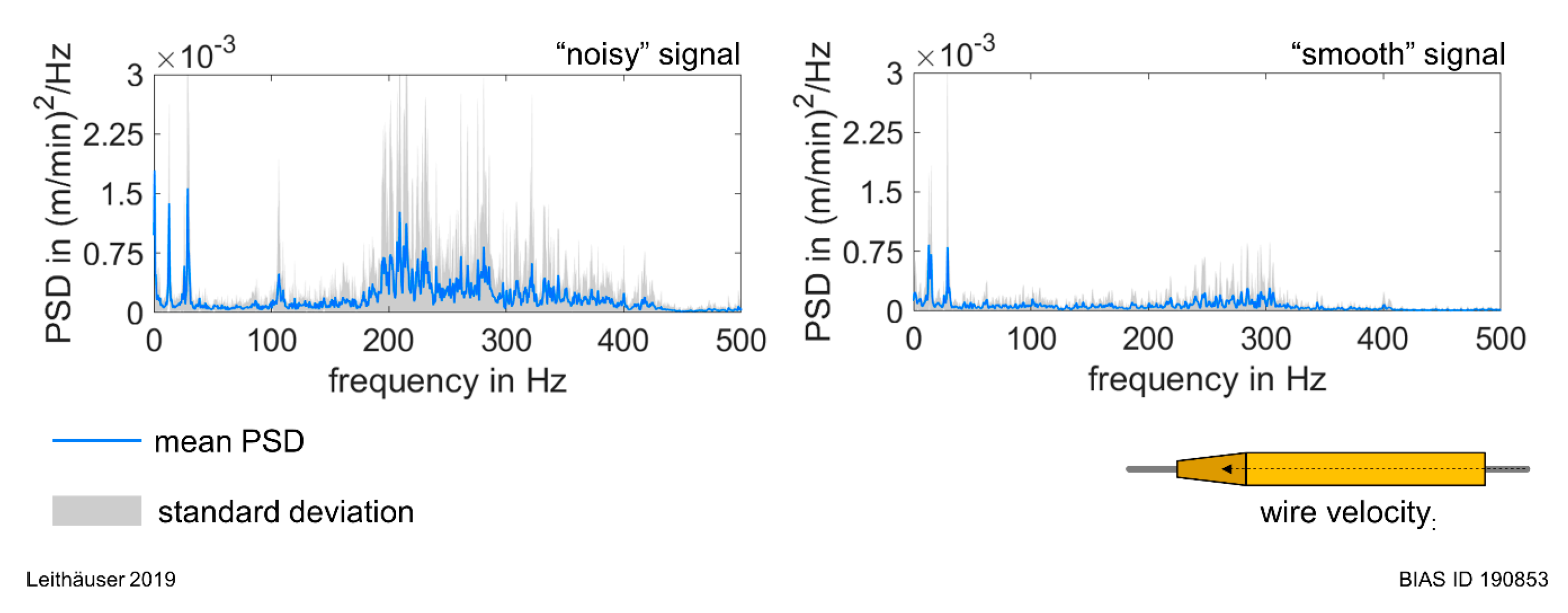

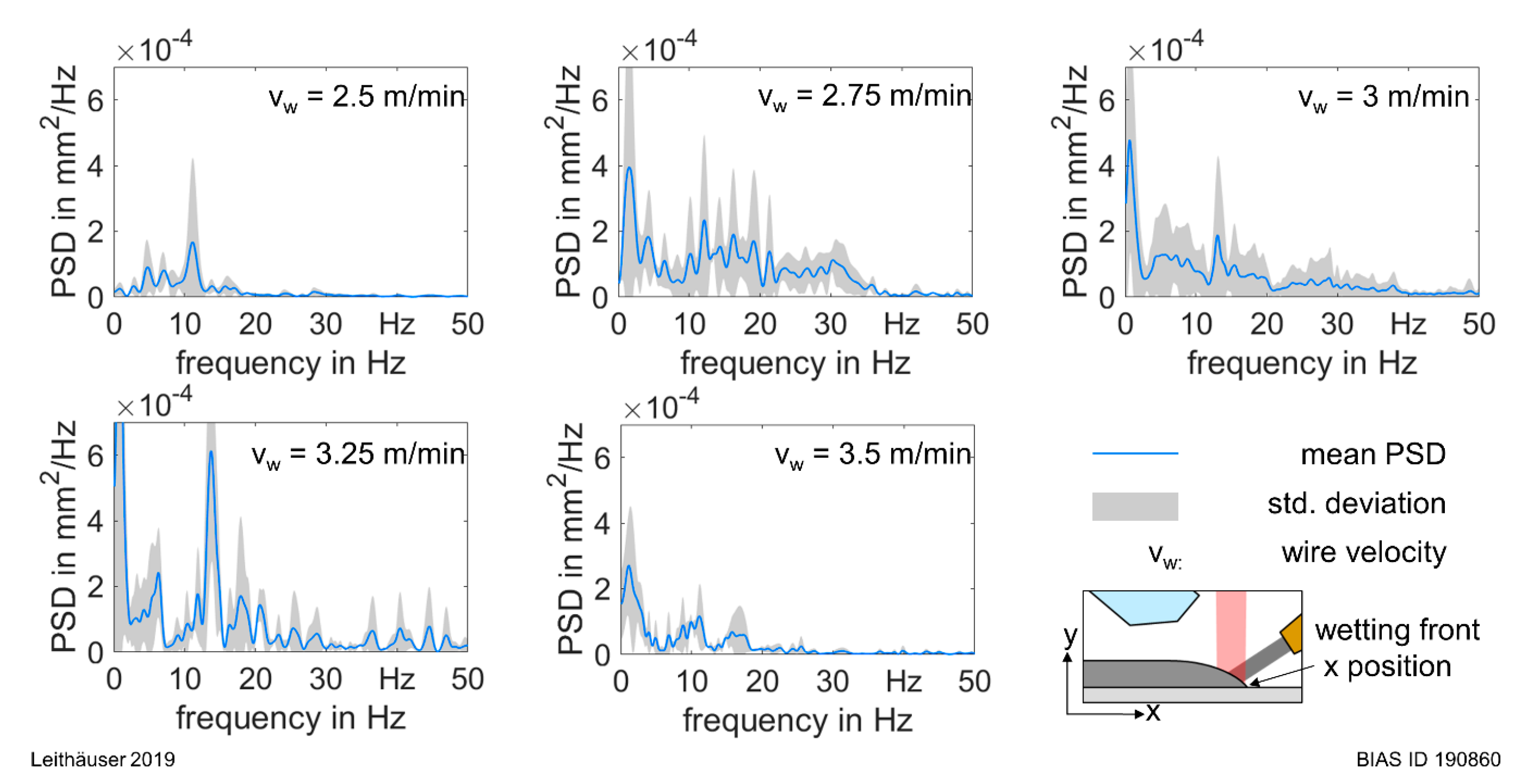

With the introduced method, it is possible to capture the wetting front of the melt pool over a long time, generating statistically verified data and proving periodicity in melt pool propagation. It can be shown that, as already known from the state of the art for steel brazing, the wire feeding has a direct influence on the melt pool oscillation in aluminum brazing.

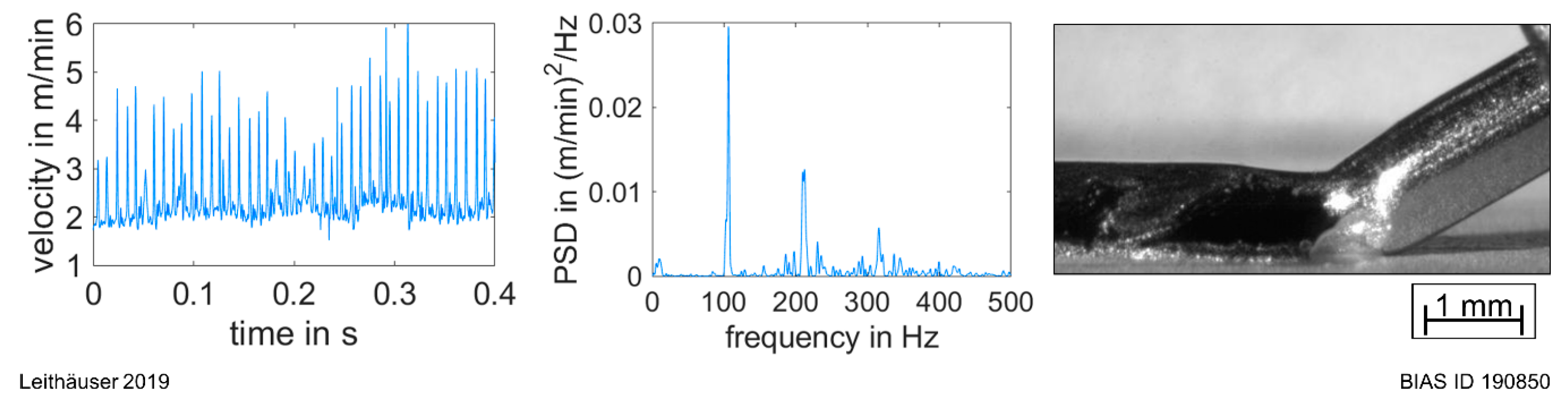

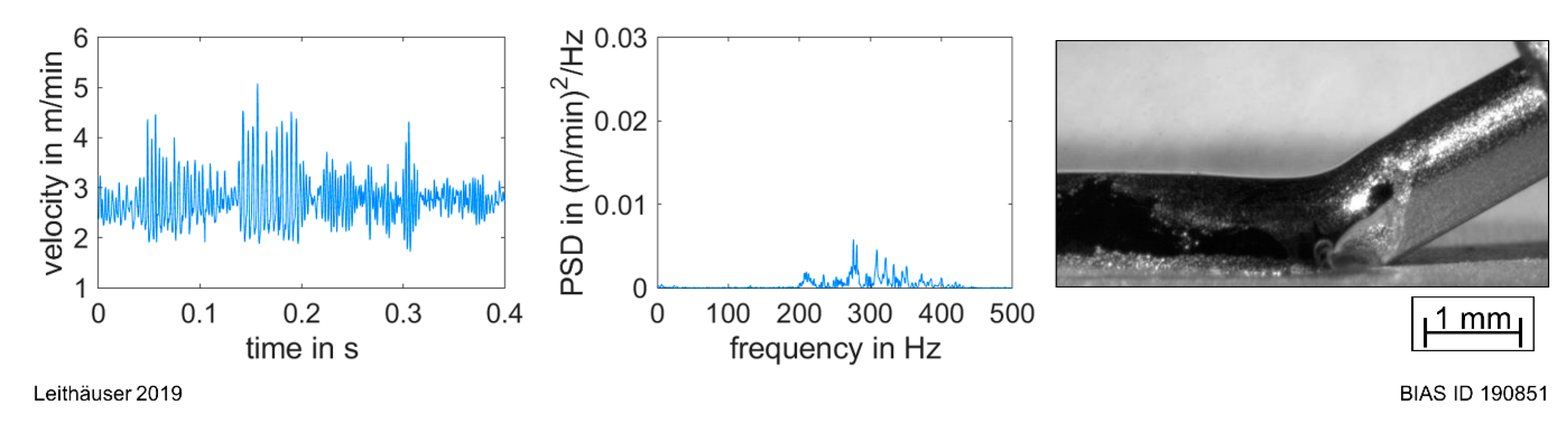

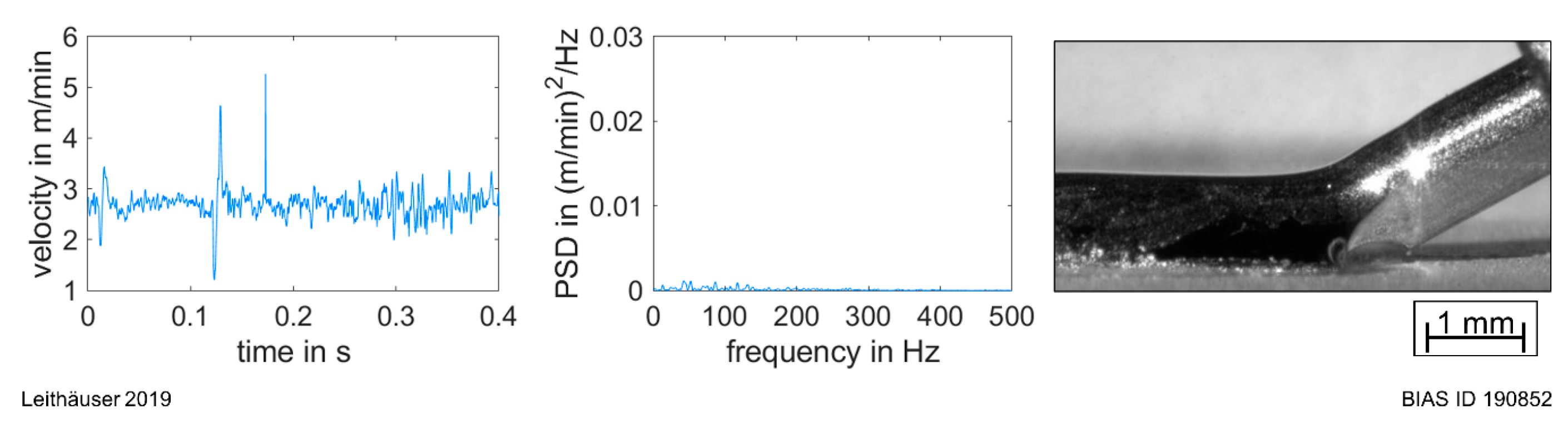

It is demonstrated that the wire feeding is not constant during the laser brazing process due to the nonuniform melting of the wire. This effect occurs randomly and does not depend on the tested wire feed rates. Therefore, another inhomogeneity must be present, such as a misalignment and an unequal laser absorption, which was mentioned by Reimann [

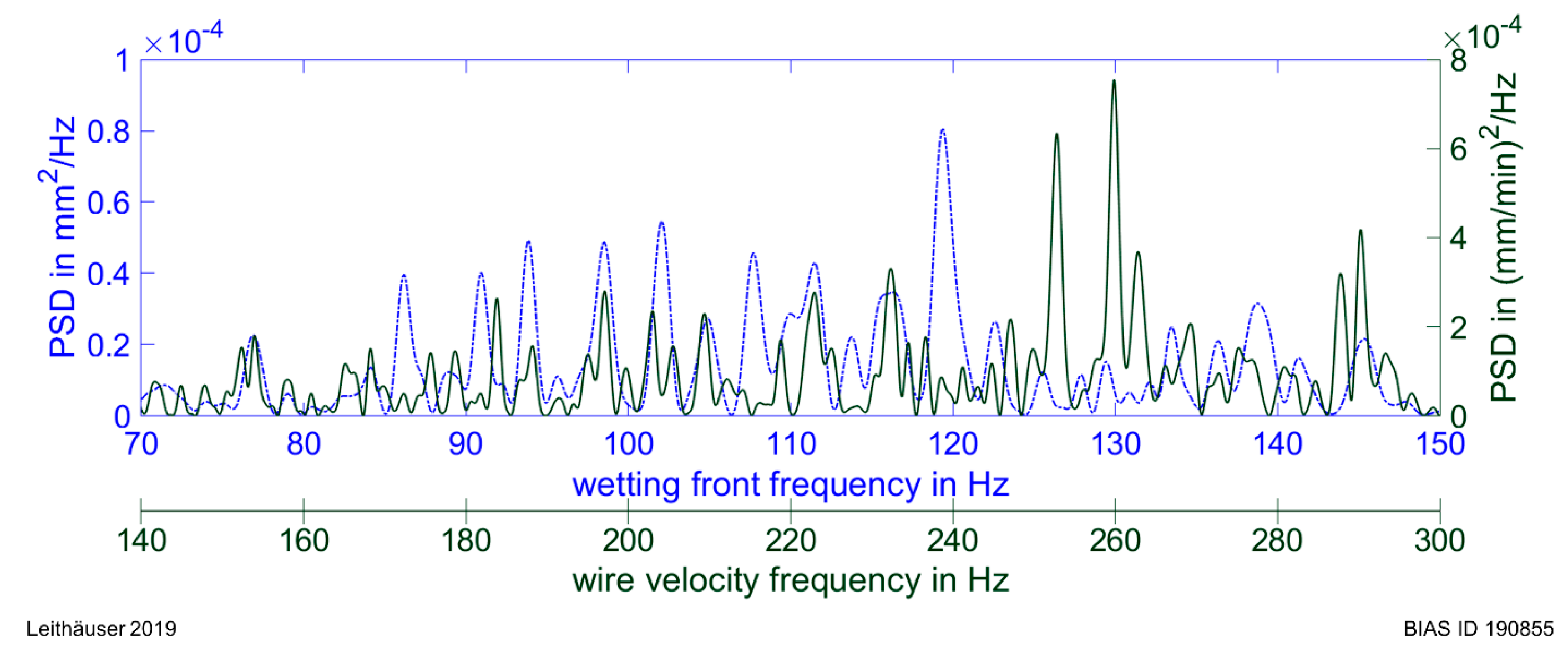

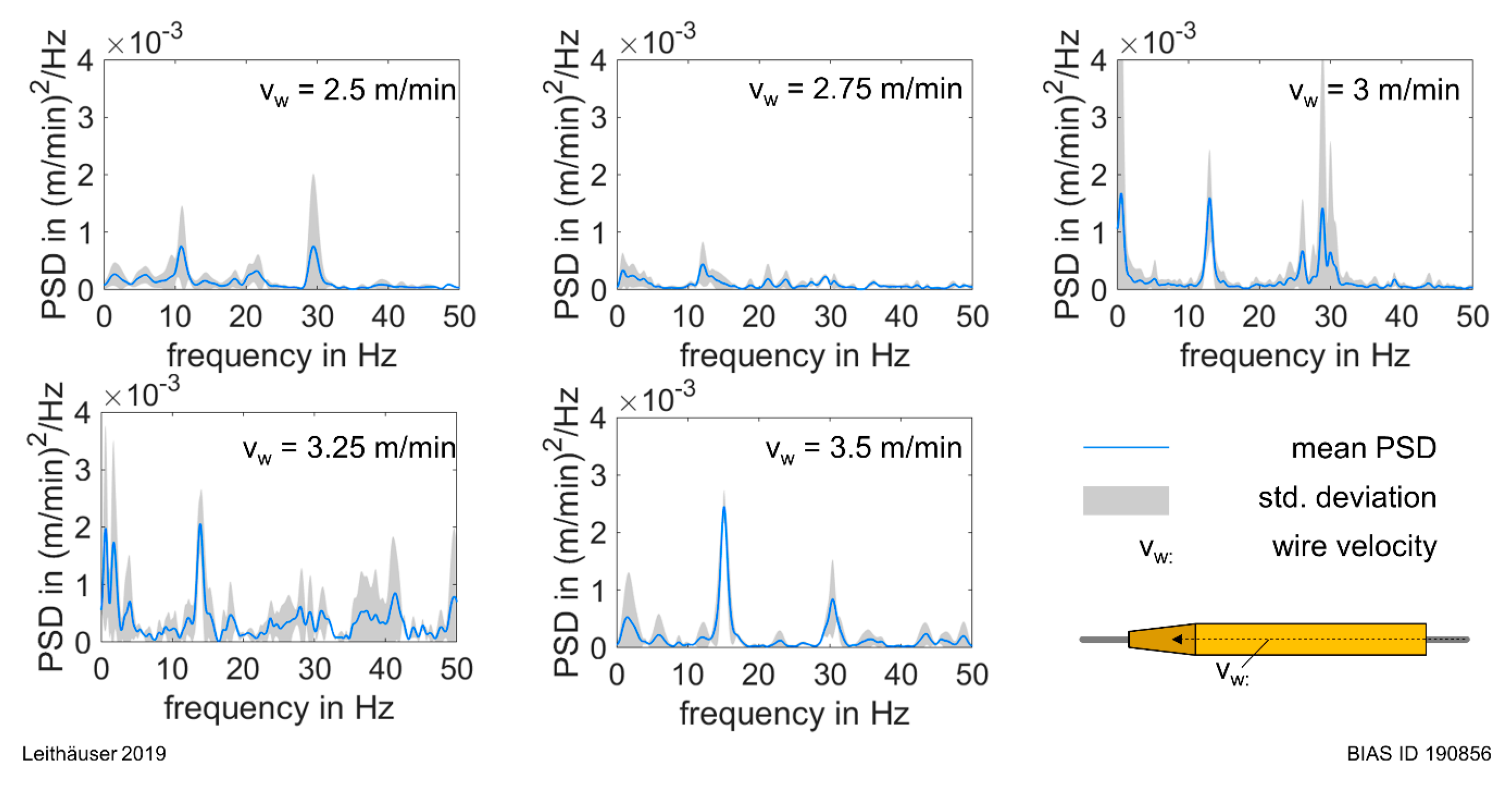

10] as a cause for inhomogeneities in the melt pool. The wire feeding is mostly affected when the unmolten wire stabs into the base material. In this case, the feeding has periodic characteristics with frequencies between 160 and 400 Hz. The vibrational frequencies are rather changing in time, thus leading to a broad spectrum. When the wire collides with the base material, the resulting vibrations are transferred to the melt pool at half the frequency. These disturbances are nonexistent when the wire is sufficiently melted prior to touching the base material.

Independently from the previously discussed oscillations, in the setup, some periodicity appeared in the wire feeding, which might have been caused by the wire feeder itself because it is directly related to the feed rate. The frequencies are lower at 11 to 15 Hz and are transferred to the wetting front in phase. This oscillation has an amplitude which is in the range of 2.5 times greater than the higher frequencies.

An irregular surface height of the seam can be identified with a periodic characteristic in the frequency of 4 to 6 Hz; this becomes more distinct when the wire is fed with a higher velocity, but no direct correlation can be made to the appearing wetting frequencies as the period length is from 6 to 8 mm at brazing speeds of 2 m/min, which is significantly higher than the oscillating length of the wetting front.