Chip Morphology and Delamination Characterization for Vibration-Assisted Drilling of Carbon Fiber-Reinforced Polymer

Abstract

1. Introduction

- High-frequency vibration-assisted drilling (HF-VAD); frequency is in the range of 1 KHz to 18 KHz.

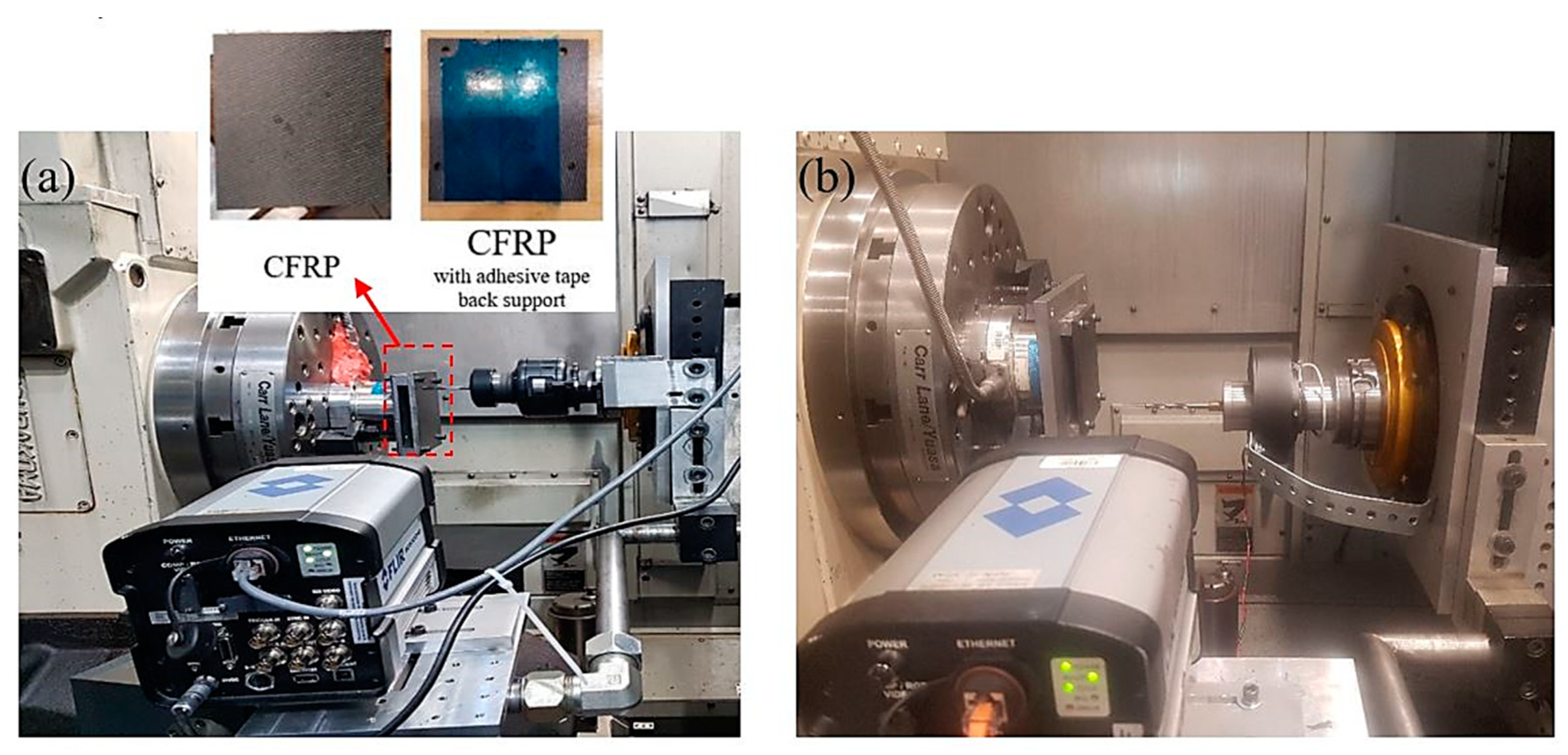

2. Experimental Setup

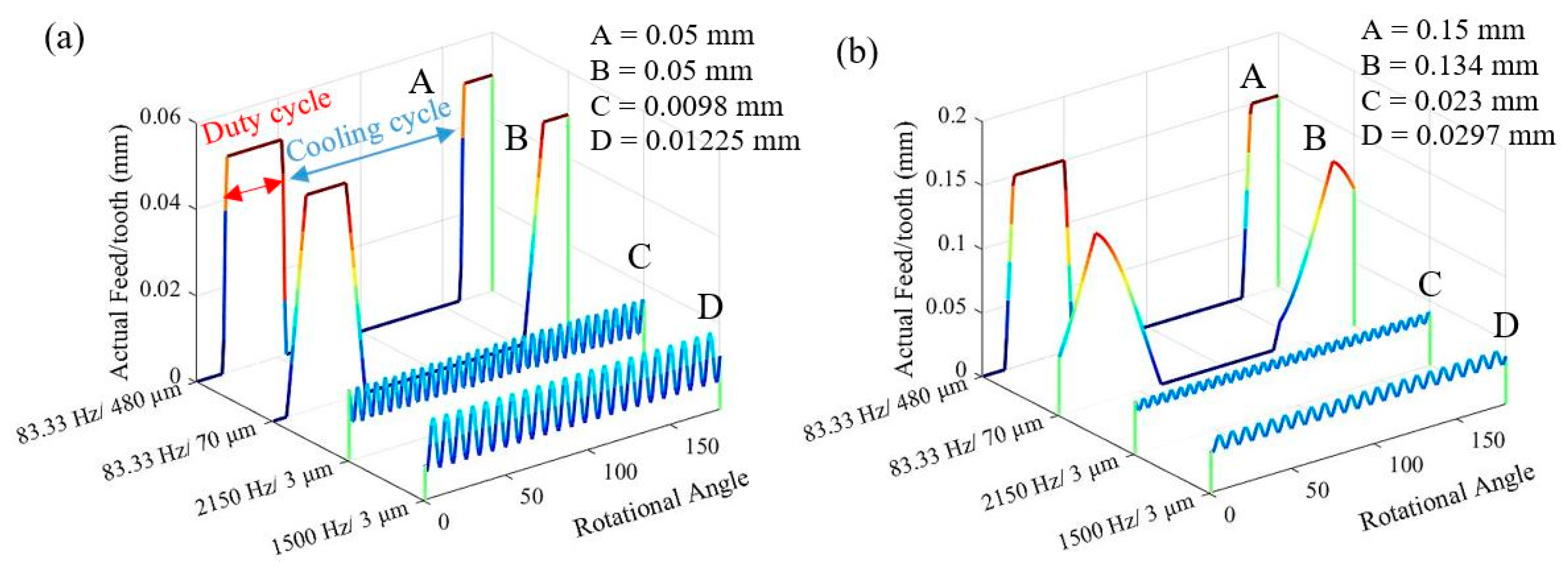

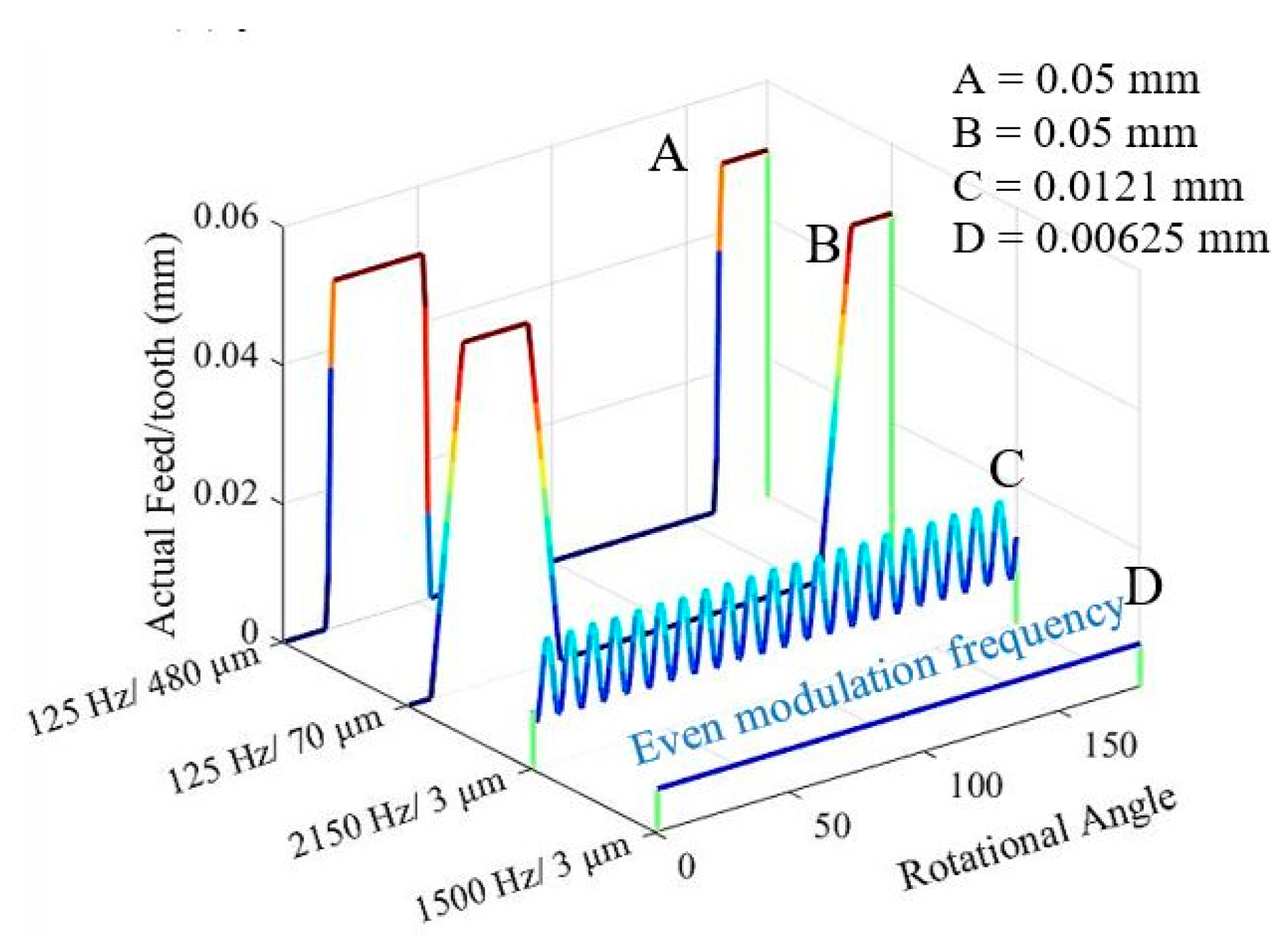

3. Kinematics of VAD

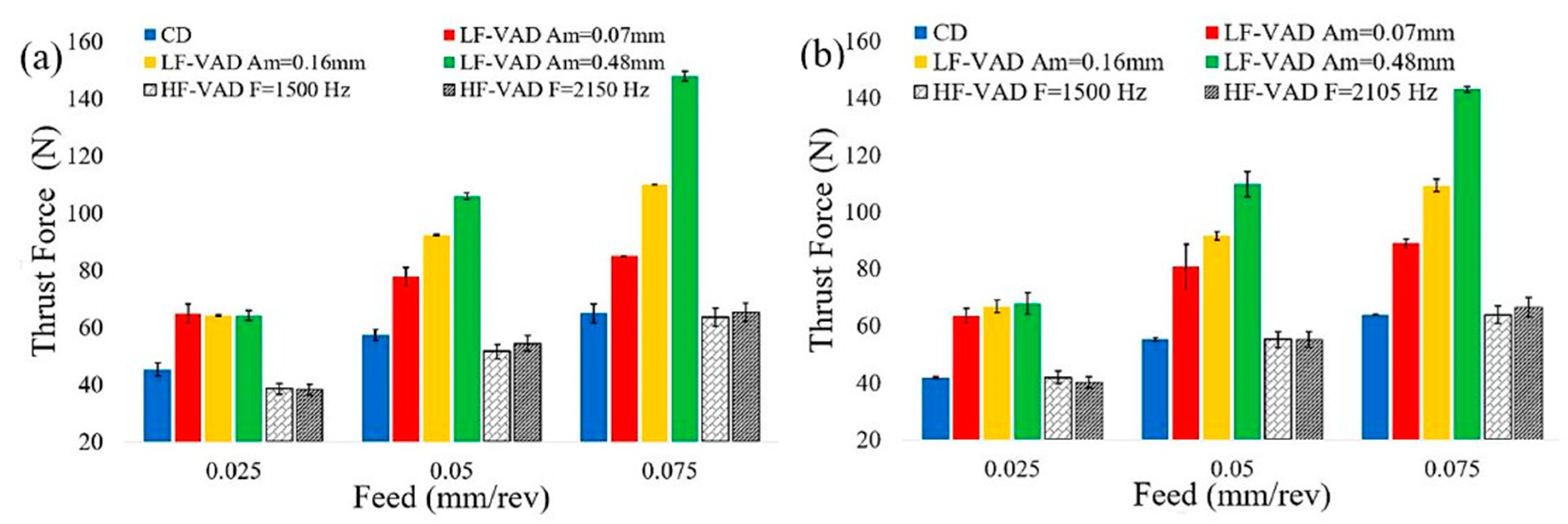

- HF-VAD has the lowest mechanical load compared to LF-VAD and CD.

- LF-VAD has a higher mechanical load compared to CD. Moreover, increasing the amplitude resulted in higher impact energy during the periodic tool engagement mechanism.

- Based on the uncut chip thickness analysis, VAD has a lower thermal load compared to CD.

- A reduction in the cutting temperature was achieved during LF-VAD cooling cycle.

- Lower thrust force and thermal load are the main reasons to achieve a delamination-free process for utilization of VAD technology.

4. Results and Discussion

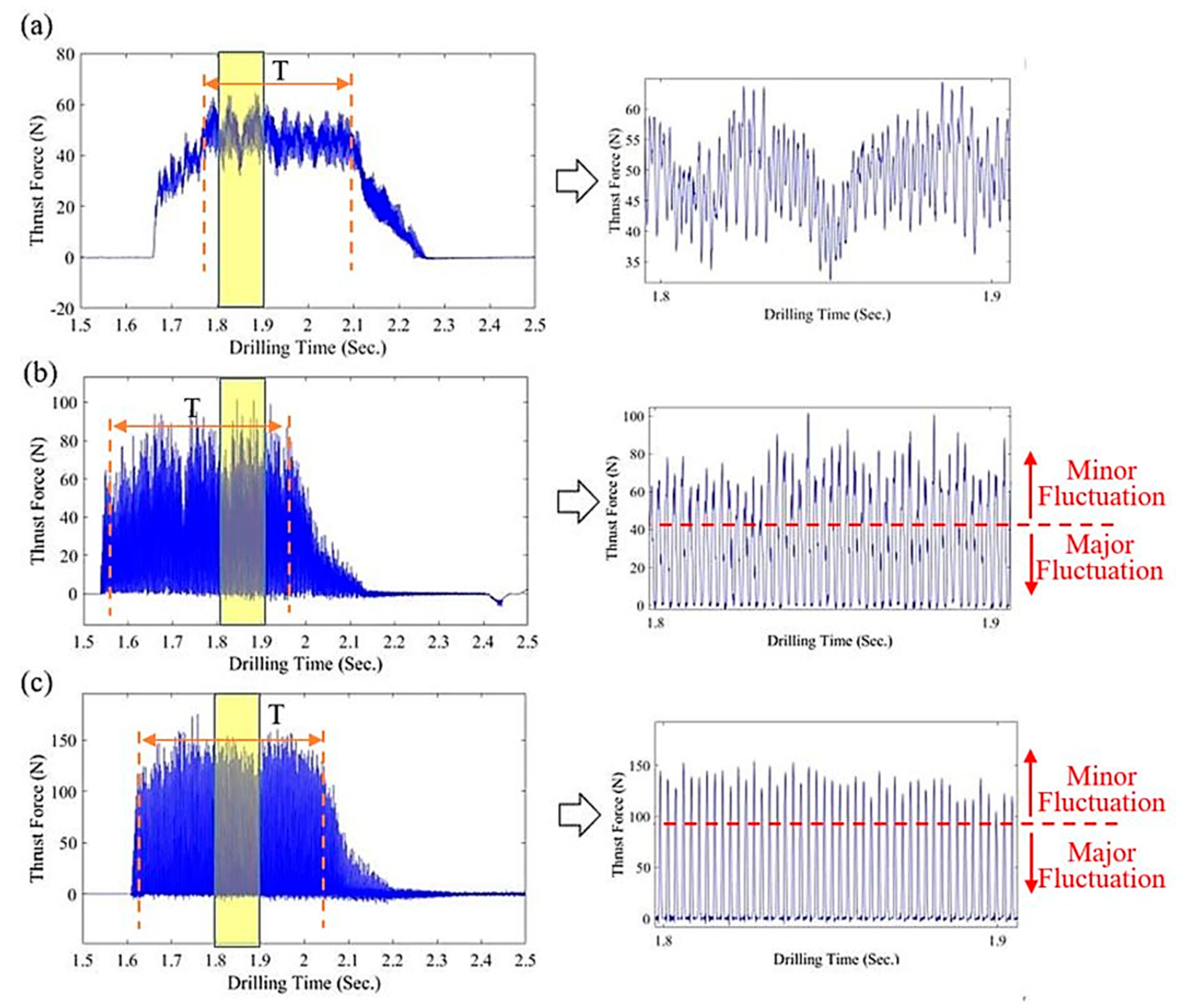

4.1. Effect of VAD on the Thrust Force

- Lower uncut chip thickness compared to CD, as described in Section 3.

- The ability of the axial tool oscillation to discard the non-cutting process under the chisel edge.

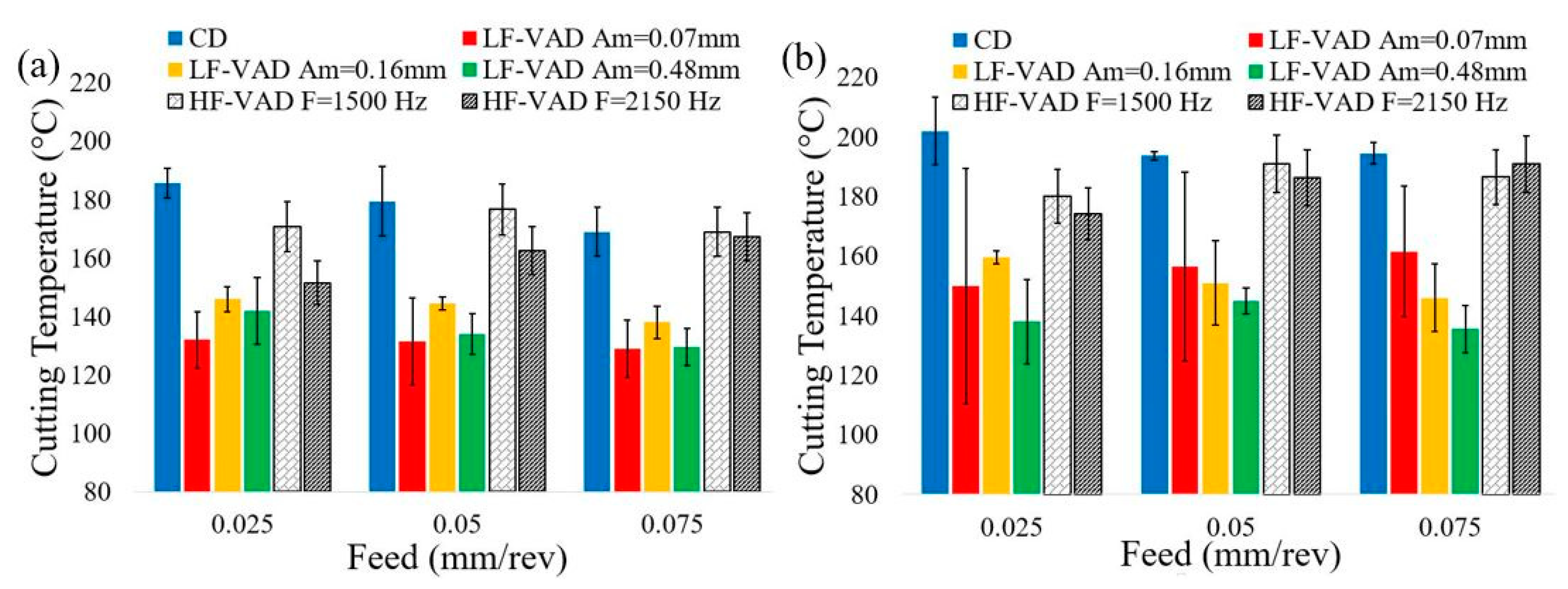

4.2. Effect of VAD on the Tool Temperature

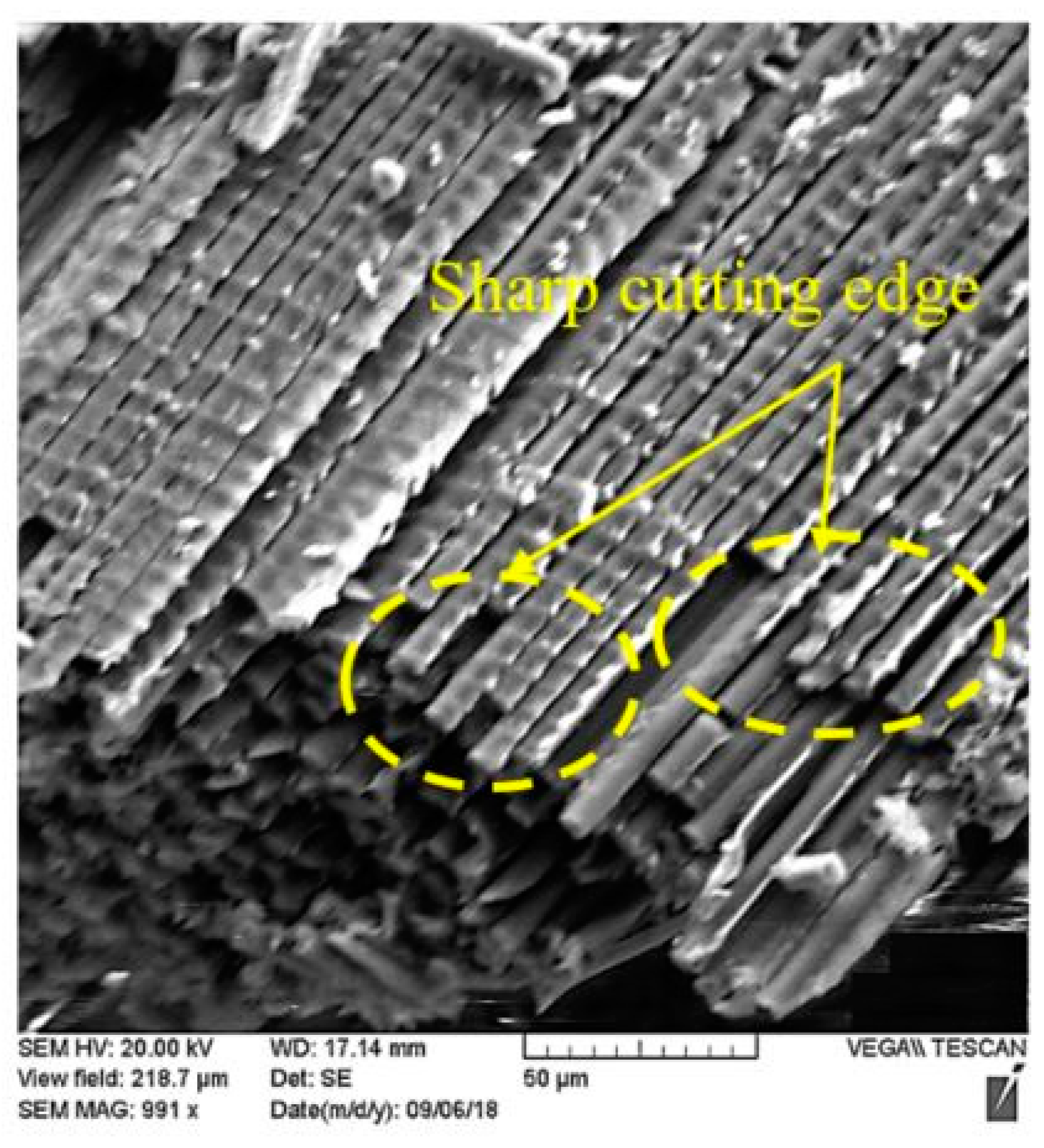

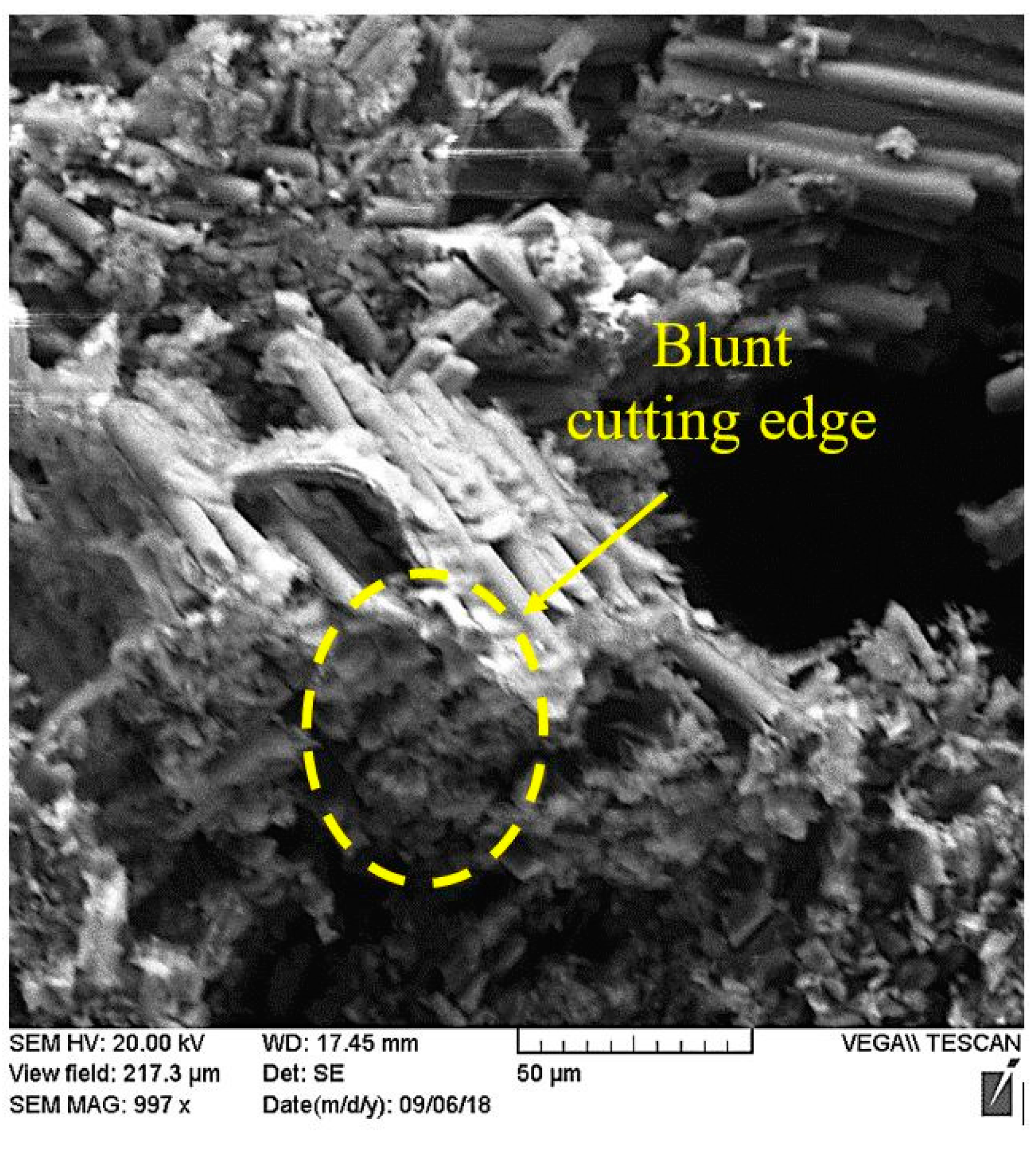

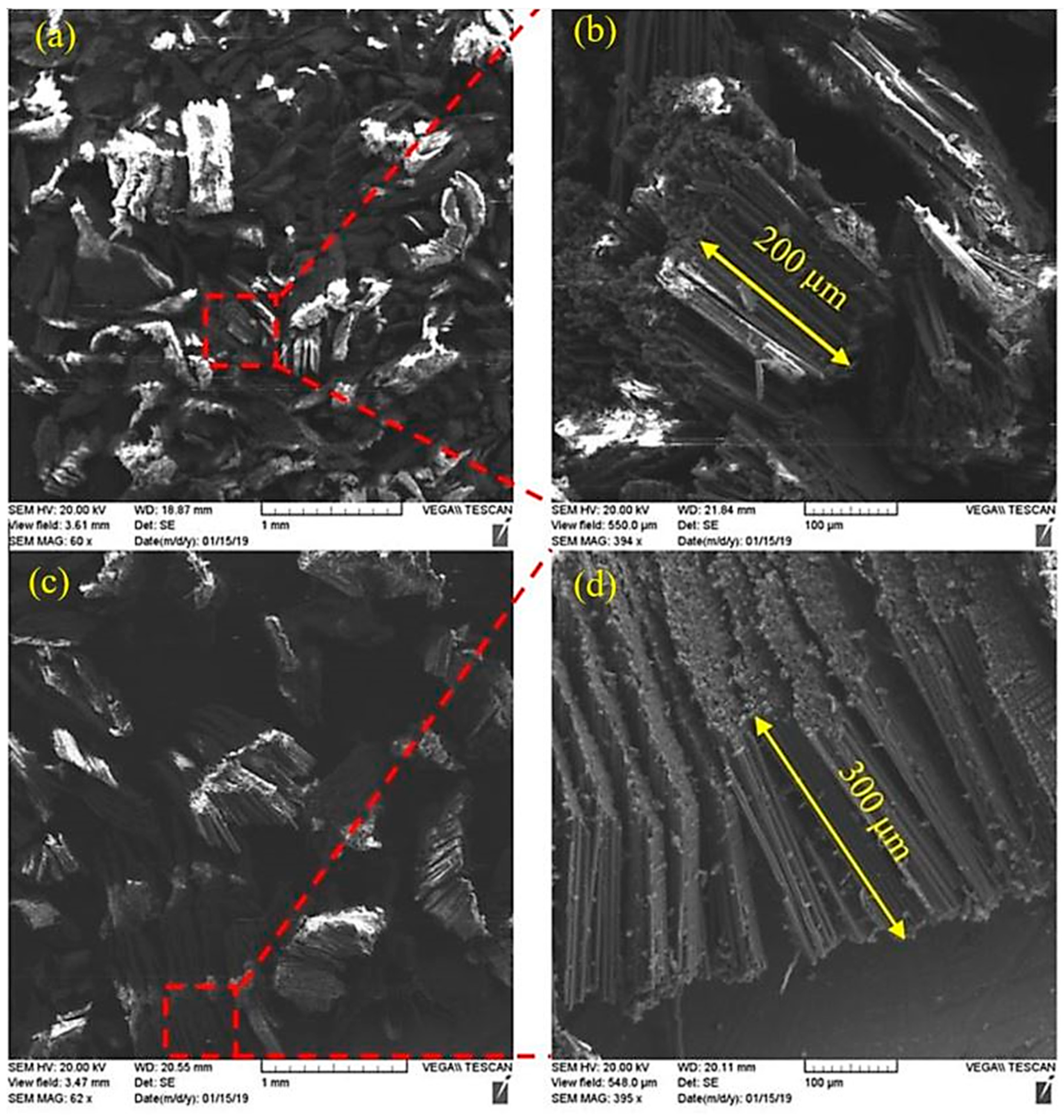

4.3. Chip Morphology

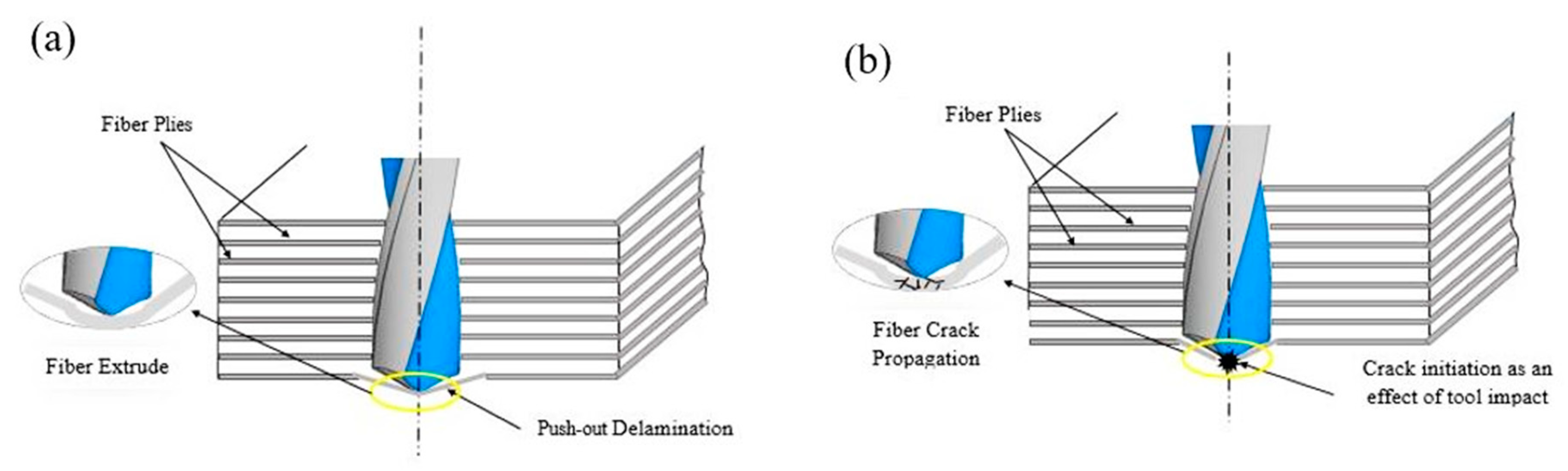

- The non-cutting process under the chisel edge is discarded through the axial oscillation mechanism.

- A conically-shaped shear zone is created at the impact point (the chisel edge) [36].

- Changing the cutting mechanism under the chisel edge to periodic impact.

- Lower cutting temperature at LF-VAD resulting in maintaining the material stiffness, and consequently resisting the fiber matrix debonding mechanism.

4.4. Geometric and Surface Integrity

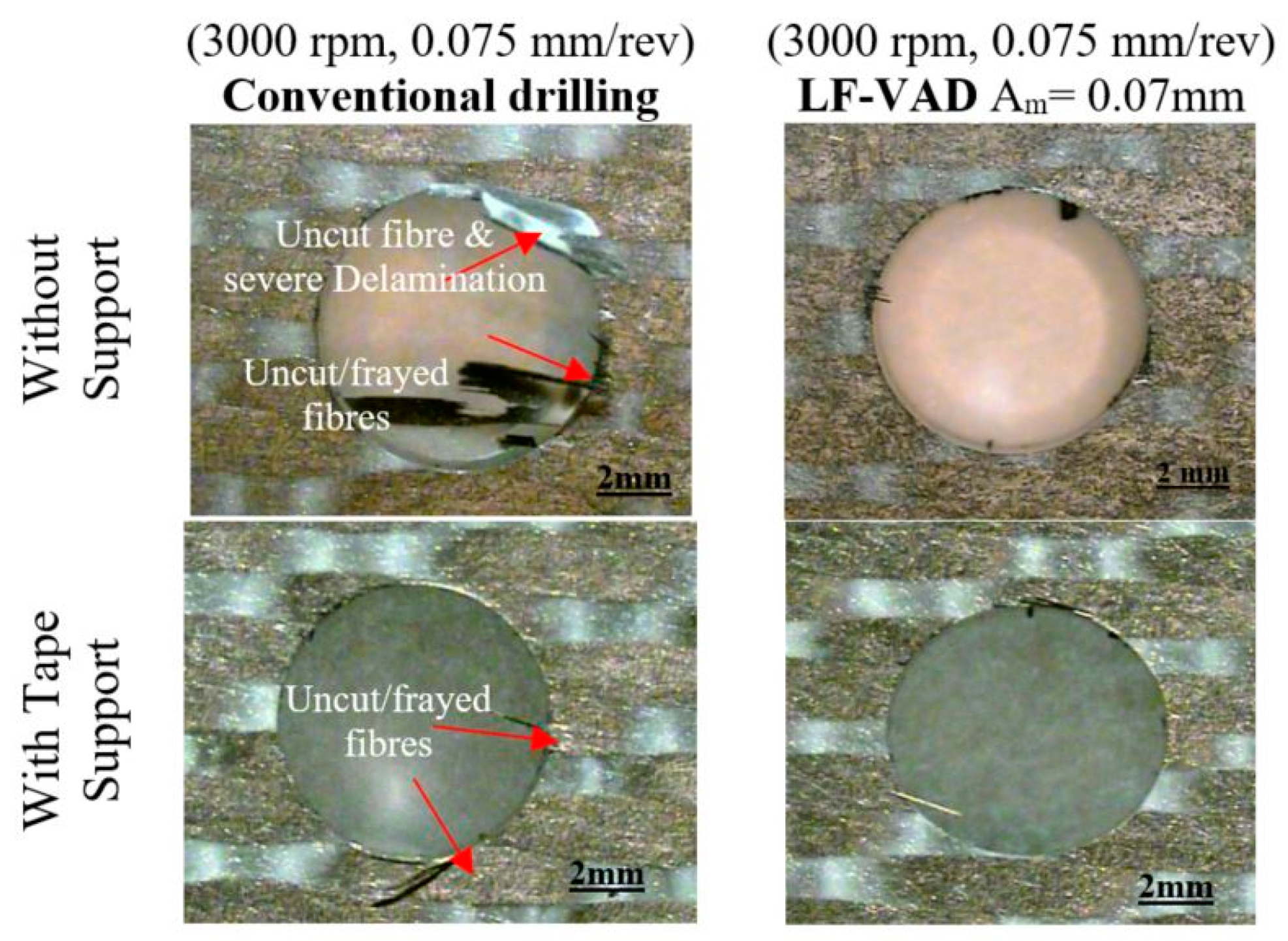

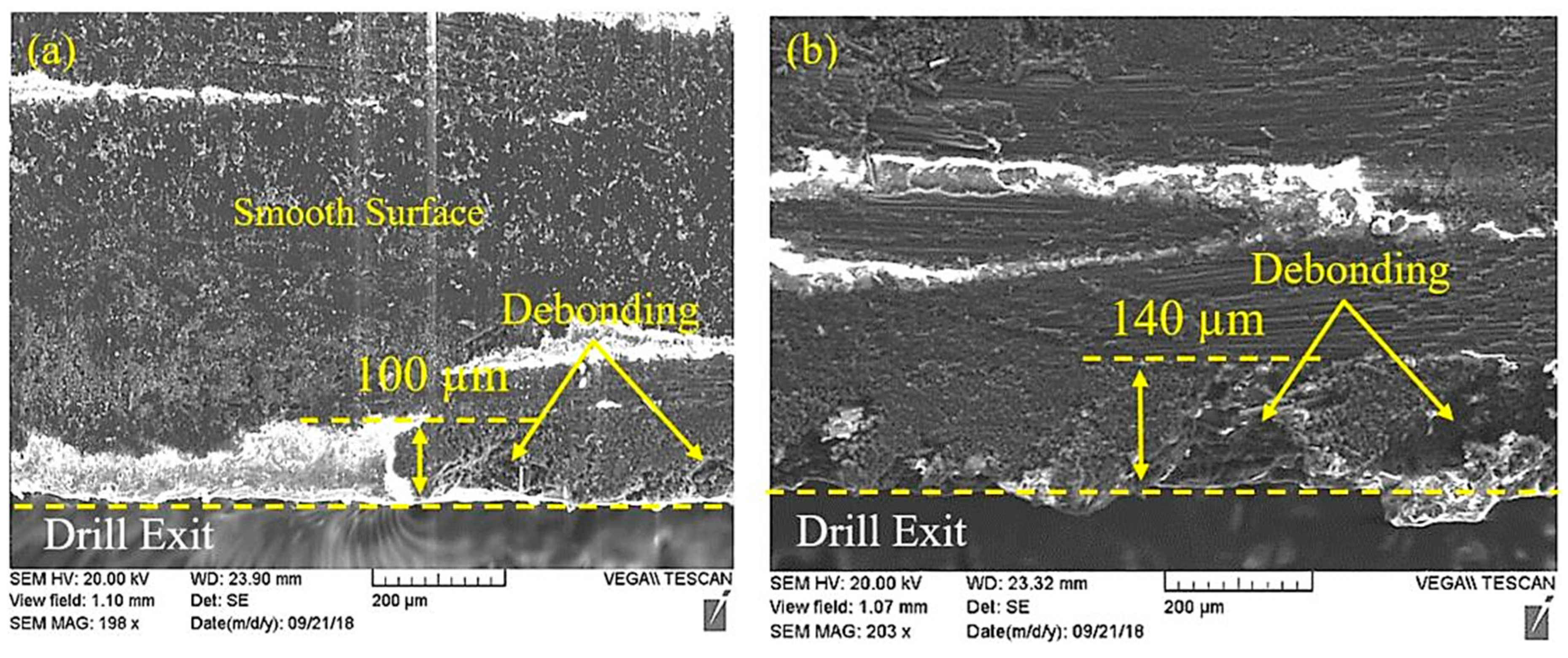

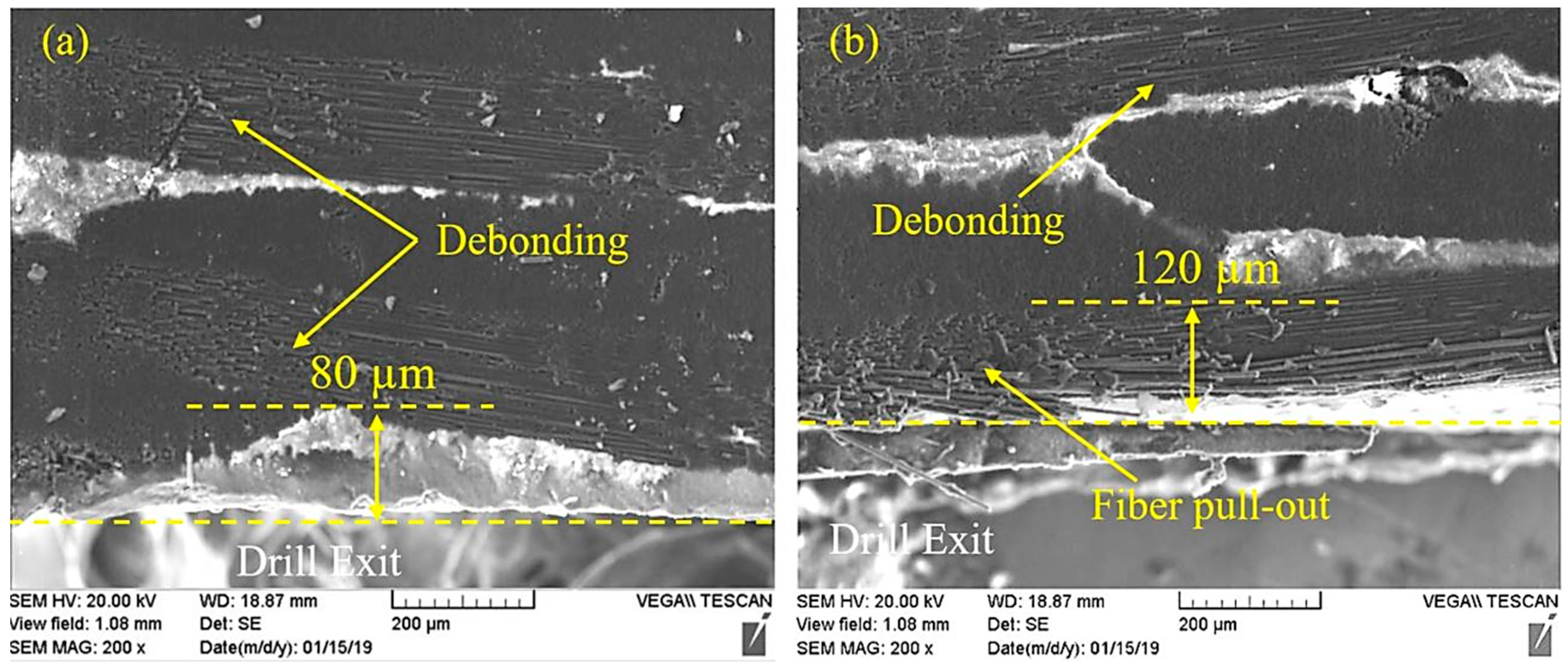

4.4.1. Delamination

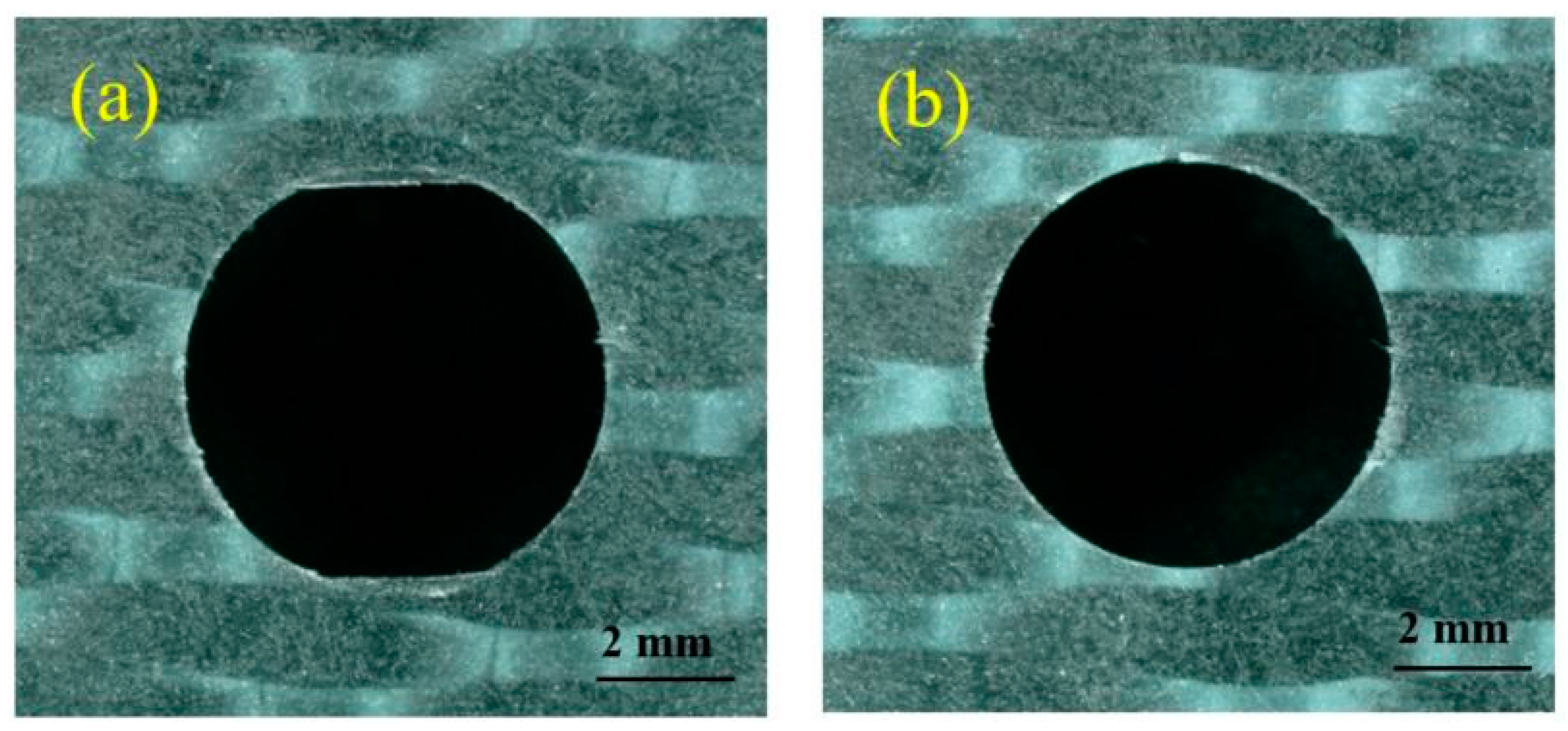

4.4.2. Exit Hole Wall Quality

- Lower cutting temperature (Section 4.2).

- Lower duty time (Section 3).

- Proper fiber-cutting process under the chisel edge (Section 4.3).

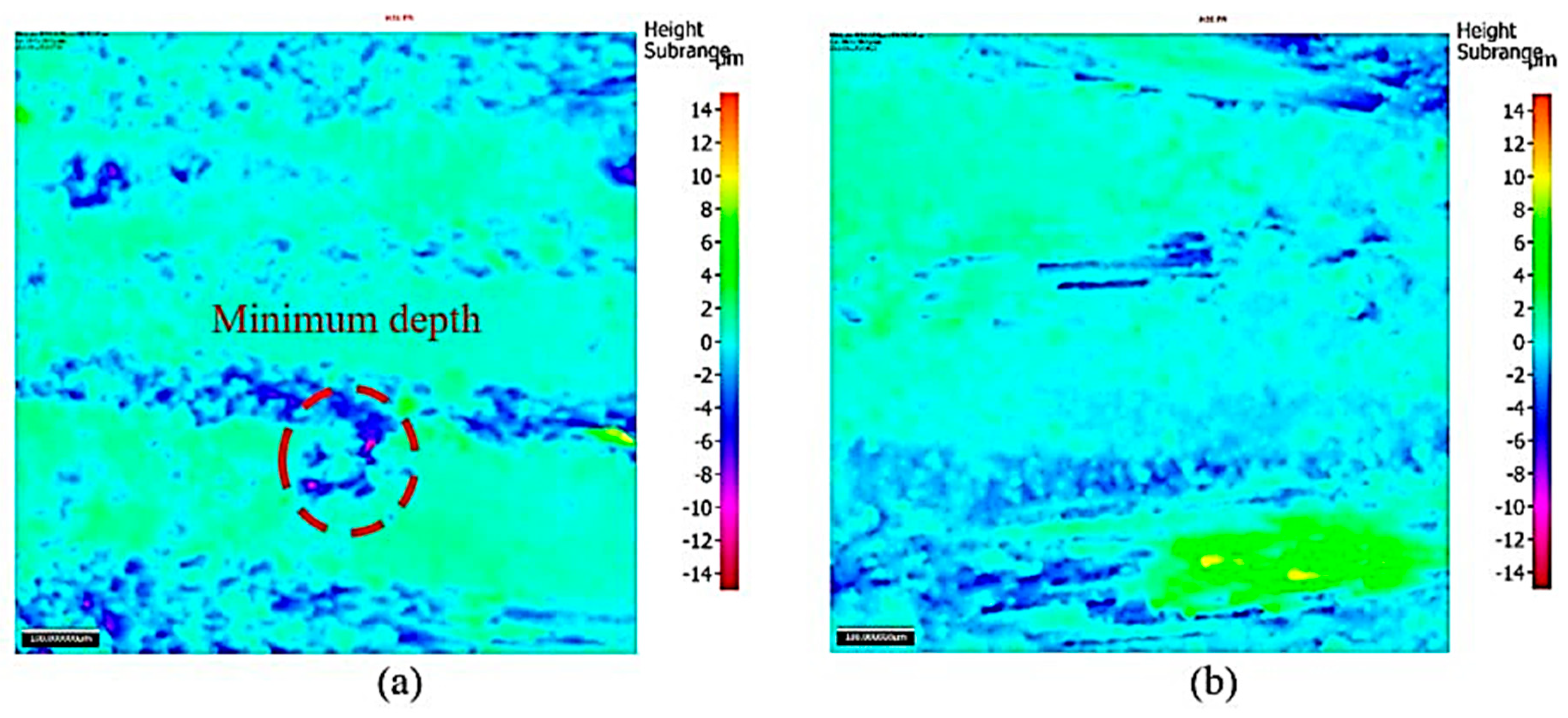

4.4.3. Surface Roughness

5. Conclusions

- For all machined parameters, LF-VAD showed higher thrust forces compared to the CD. This increase is due to higher uncut chip thickness and tool impact.

- HF-VAD showed up to 16% reduction in the thrust force compared to CD.

- VAD showed a significant reduction in cutting temperature compared to CD. The cutting temperature reduction was 31% for LF-VAD and 13% for HF-VAD.

- Free delamination drilling was successfully achieved by using VAD due to lower thermal load. The delamination factor for CD was ≤0.5 at N = 2000 rpm and ≥0.5 at N = 3000 rpm respectively. On the other hand, the VAD resulted in delamination factor ≤0.2 for all machining conditions.

- The adhesive tape back support reduced the delamination factor for CD to ≤0.5 for all machining conditions.

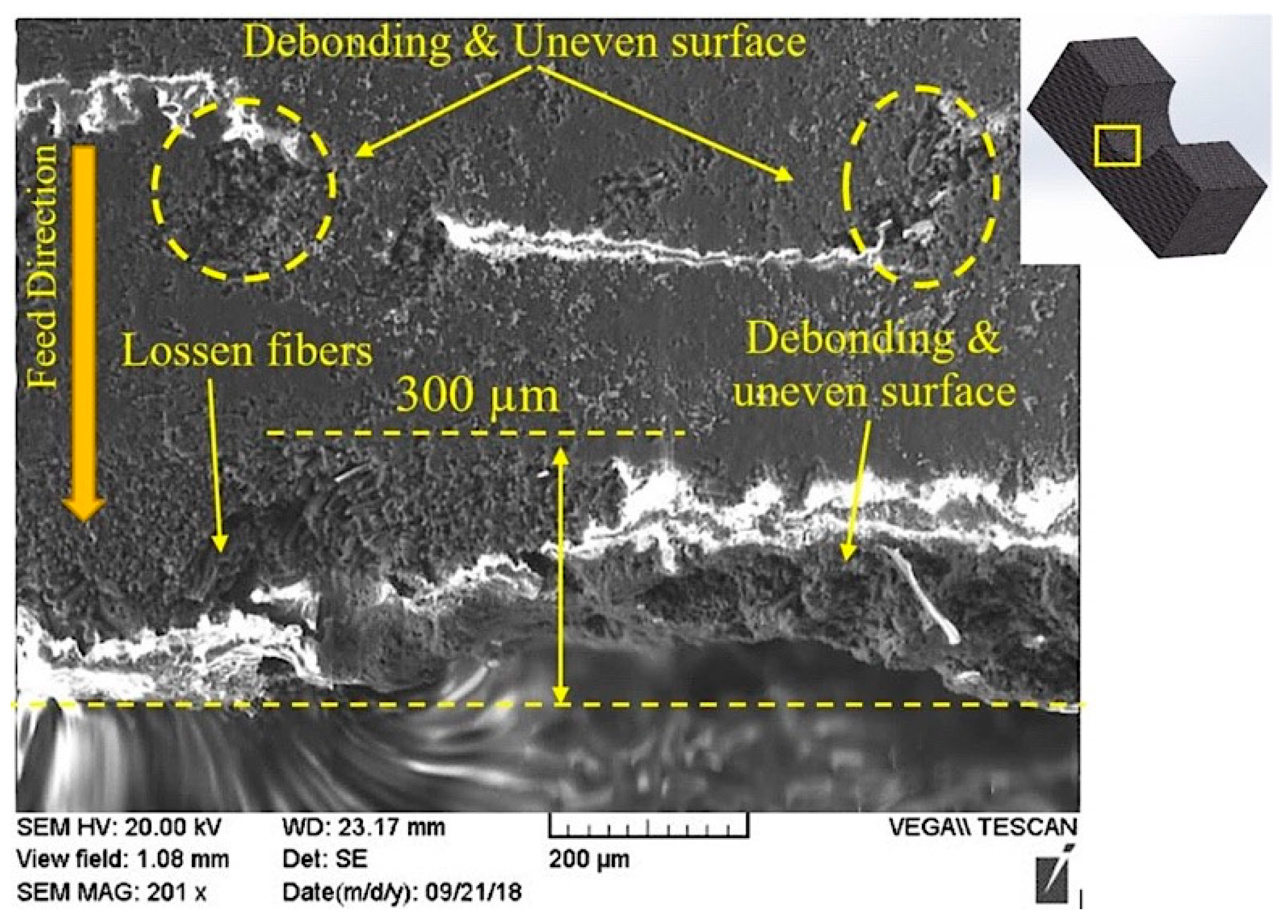

- LF-VAD resulted in a longer machined fiber compared to CD. The fiber length increased from 80 µm at CD to 300 µm at LF-VAD with Am = 0.48 mm.

- Based on the SEM examination of the machined wall surface, VAD resulted in a significant enhancement to the machined surface quality compared to the CD.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Soo, S.L.; Abdelhafeez, A.M.; Li, M.; Hood, R.; Lim, C.M. The drilling of carbon fibre composite–aluminium stacks and its effect on hole quality and integrity. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 233, 1323–1331. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Janssen, R. Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. CIRP Ann. Manuf. Technol. 2002, 51, 87–90. [Google Scholar] [CrossRef]

- Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M. Low-frequency vibration-assisted drilling of hybrid CFRP/Ti6Al4V stacked material. Int. J. Adv. Manuf. Technol. 2018, 98, 2801–2817. [Google Scholar] [CrossRef]

- Debnath, K.; Singh, I. Low-frequency modulation-assisted drilling of carbon-epoxy composite laminates. J. Manuf. Process. 2017, 25, 262–273. [Google Scholar] [CrossRef]

- Che, D.; Saxena, I.; Han, P.; Guo, P.; Ehmann, K.F. Machining of carbon fiber reinforced plastics/polymers: A literature review. J. Manuf. Sci. Eng. 2014, 136, 034001. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Y.; Cong, W. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Fu, R.; Jia, Z.; Wang, F.; Jin, Y.; Sun, D.; Yang, L.; Cheng, D. Drill-exit temperature characteristics in drilling of UD and MD CFRP composites based on infrared thermography. Int. J. Mach. Tools Manuf. 2018, 135, 24–37. [Google Scholar] [CrossRef]

- Persson, E.; Eriksson, I.; Zackrisson, L. Effects of hole machining defects on strength and fatigue life of composite laminates. Compos. Part A Appl. Sci. Manuf. 1997, 28, 141–151. [Google Scholar] [CrossRef]

- Chen, W.-C. Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int. J. Mach. Tools Manuf. 1997, 37, 1097–1108. [Google Scholar] [CrossRef]

- Gaitonde, V.; Karnik, S.; Rubio, J.C.; Correia, A.E.; Abrao, A.; Davim, J.P. Analysis of parametric influence on delamination in high-speed drilling of carbon fiber reinforced plastic composites. J. Mater. Process. Technol. 2008, 203, 431–438. [Google Scholar] [CrossRef]

- Romoli, L.; Dini, G. Experimental study on the influence of drill wear in CFRP drilling processes. In Proceedings of the ICME 08, Naples, Italy, 23–25 July 2008. [Google Scholar]

- Linbo, Z.; Lijiang, W.; Xin, W. Study on vibration drilling of fiber reinforced plastics with hybrid variation parameters method. Compos. Part A Appl. Sci. Manuf. 2003, 34, 237–244. [Google Scholar] [CrossRef]

- Tagliaferri, V.; Caprino, G.; Diterlizzi, A. Effect of drilling parameters on the finish and mechanical properties of GFRP composites. Int. J. Mach. Tools Manuf. 1990, 30, 77–84. [Google Scholar] [CrossRef]

- Ho-Cheng, H.; Dharan, C. Delamination during drilling in composite laminates. J. Eng. Ind. 1990, 112, 236–239. [Google Scholar] [CrossRef]

- Xu, J.; Li, C.; Mi, S.; An, Q.; Chen, M. Study of drilling-induced defects for CFRP composites using new criteria. Compos. Struct. 2018, 201, 1076–1087. [Google Scholar] [CrossRef]

- Durante, M.; Boccarusso, L.; De Fazio, D.; Langella, A. Circular cutting strategy for drilling of carbon fiber-reinforced plastics (CFRPs). Mater. Manuf. Process. 2019, 34, 1–13. [Google Scholar] [CrossRef]

- Shyha, I.S.; Soo, S.L.; Aspinwall, D.; Bradley, S.; Perry, R.; Harden, P.; Dawson, S. Hole quality assessment following drilling of metallic-composite stacks. Int. J. Mach. Tools Manuf. 2011, 51, 569–578. [Google Scholar] [CrossRef]

- Shyha, I.S.; Aspinwall, D.K.; Soo, S.L.; Bradley, S. Drill geometry and operating effects when cutting small diameter holes in CFRP. Int. J. Mach. Tools Manuf. 2009, 49, 1008–1014. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, M. A novel variable-dimensional vibration-assisted actuator for drilling CFRP. Int. J. Adv. Manuf. Technol. 2018, 99, 3049–3063. [Google Scholar] [CrossRef]

- Sadek, A.; Attia, M.; Meshreki, M.; Shi, B. Characterization and optimization of vibration-assisted drilling of fibre reinforced epoxy laminates. CIRP Ann. Manuf. Technol. 2013, 62, 91–94. [Google Scholar] [CrossRef]

- Wang, X.; Wang, L.; Tao, J. Investigation on thrust in vibration drilling of fiber-reinforced plastics. J. Mater. Process. Technol. 2004, 148, 239–244. [Google Scholar] [CrossRef]

- Makhdum, F.; Norddin, D.N.P.; Roy, A.; Silberschmidt, V.V. Ultrasonically Assisted Drilling of Carbon Fibre Reinforced Plastics; Solid State Phenomena; Trans Tech Publications: Leicestershire, UK, 2012; pp. 170–175. [Google Scholar]

- Makhdum, F.; Phadnis, V.A.; Roy, A.; Silberschmidt, V.V. Effect of ultrasonically-assisted drilling on carbon-fibre-reinforced plastics. J. Sound Vib. 2014, 333, 5939–5952. [Google Scholar] [CrossRef]

- Gupta, A.; Barnes, S.; McEwen, I.; Kourra, N.; Williams, M.A. Study of cutting speed variation in the ultrasonic assisted drilling of carbon fibre composites. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; p. V02BT02A038. [Google Scholar]

- Makhdum, F.; Jennings, L.T.; Roy, A.; Silberschmidt, V.V. Cutting forces in ultrasonically assisted drilling of carbon fibre-reinforced plastics. J. Phys. Conf. Ser. 2012, 382, 012019. [Google Scholar] [CrossRef]

- Phadnis, V.A.; Makhdum, F.; Roy, A.; Silberschmidt, V.V. Experimental and numerical investigations in conventional and ultrasonically assisted drilling of CFRP laminate. Procedia CIRP 2012, 1, 455–459. [Google Scholar] [CrossRef]

- Sanda, A.; Arriola, I.; Navas, V.G.; Bengoetxea, I.; Gonzalo, O. Ultrasonically assisted drilling of carbon fibre reinforced plastics and Ti6Al4V. J. Manuf. Process. 2016, 22, 169–176. [Google Scholar] [CrossRef]

- MITIS Engineer MITIS Tool Holder. Available online: https://www.mitis.fr/ (accessed on 20 October 2017).

- Panju, J.; Meshreki, M.; Attia, M. Design of a Retrofittable Spindle Attachment for High Frequency Vibration-Assisted Drilling. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; p. V02AT02A034. [Google Scholar]

- Airtech Advanced Materials Group. Flash Breaker Data Sheet. Available online: https://www.freemansupply.com/datasheets/Airtech/flashbreaker125.pdf (accessed on 16 July 2018).

- Pecat, O.; Meyer, I. Low Frequency Vibration Assisted Drilling of Aluminium Alloys; Advanced Materials Research; Trans Tech Publications: Zurich, Switzerland, 2013; pp. 131–138. [Google Scholar]

- Sadek, A.; Meshreki, M.; Attia, M. Effect of Tool Kinematics on the Drilling Forces and Temperature in Low Frequency High Amplitude Vibration Assisted Drilling. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014; p. V02AT02A035. [Google Scholar]

- Zhang, D.; Wang, L. Investigation of chip in vibration drilling. Int. J. Mach. Tools Manuf. 1998, 38, 165–176. [Google Scholar] [CrossRef]

- Sadek, A. Vibration Assisted Drilling of Multidirectional Fiber Reinforced Polymer Laminates. Ph.D. Thesis, McGill University Libraries, Montreal, QC, Canada, 2014. [Google Scholar]

- Chen, Q.; Guan, Z.; Li, Z.; Ji, Z.; Zhuo, Y. Experimental investigation on impact performances of GLARE laminates. Chin. J. Aeronaut. 2015, 28, 1784–1792. [Google Scholar] [CrossRef]

- Cantwell, W.; Morton, J. Comparison of the low and high velocity impact response of CFRP. Composites 1989, 20, 545–551. [Google Scholar] [CrossRef]

- Cantwell, W. The influence of target geometry on the high velocity impact response of CFRP. Compos. Struct. 1988, 10, 247–265. [Google Scholar] [CrossRef]

| Machining Parameters | ||

| Cutting speeds N (rpm) | 2000 and 3000 | |

| Feed f (mm/rev) | 0.025, 0.05, and 0.075 | |

| Cooling medium | Dry | |

| LF-VAD | HF-VAD | |

| Amplitude Am (µm) | 70, 100, 160, 250, and 480 | 3 |

| Frequency F (Hz) | 83.33, 125 | 1500, and 2150 |

| Cutting Tool | ||

| Material | Tungsten carbide | |

| Diameter | 6 mm | |

| Point angle | 118° | |

| Helix angle | 20° | |

| Number of flutes | 2 | |

| Workpiece Material Specification | ||

| CFRP | 5.8 ± 0.02 mm of 42 × L-930(GT700) woven plies with the configuration [[0,90]21]s, and flame-retardant modified epoxy prepreg. | |

| Flash breaker | AIRTECH flashbreaker® 1 with a thickness of 64 µm [30] | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussein, R.; Sadek, A.; Elbestawi, M.A.; Attia, M.H. Chip Morphology and Delamination Characterization for Vibration-Assisted Drilling of Carbon Fiber-Reinforced Polymer. J. Manuf. Mater. Process. 2019, 3, 23. https://doi.org/10.3390/jmmp3010023

Hussein R, Sadek A, Elbestawi MA, Attia MH. Chip Morphology and Delamination Characterization for Vibration-Assisted Drilling of Carbon Fiber-Reinforced Polymer. Journal of Manufacturing and Materials Processing. 2019; 3(1):23. https://doi.org/10.3390/jmmp3010023

Chicago/Turabian StyleHussein, Ramy, Ahmad Sadek, Mohamed A. Elbestawi, and M. Helmi Attia. 2019. "Chip Morphology and Delamination Characterization for Vibration-Assisted Drilling of Carbon Fiber-Reinforced Polymer" Journal of Manufacturing and Materials Processing 3, no. 1: 23. https://doi.org/10.3390/jmmp3010023

APA StyleHussein, R., Sadek, A., Elbestawi, M. A., & Attia, M. H. (2019). Chip Morphology and Delamination Characterization for Vibration-Assisted Drilling of Carbon Fiber-Reinforced Polymer. Journal of Manufacturing and Materials Processing, 3(1), 23. https://doi.org/10.3390/jmmp3010023