2.2. Model Description

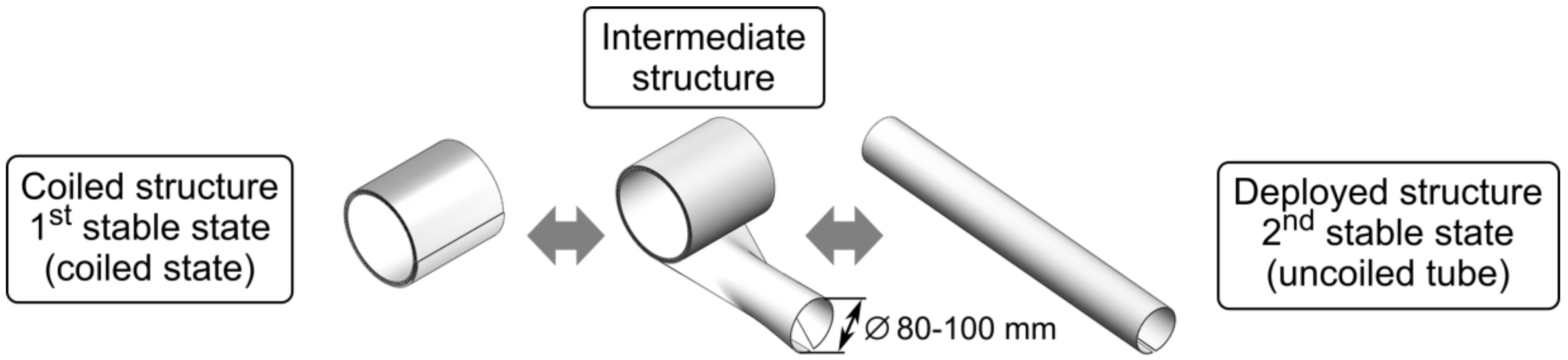

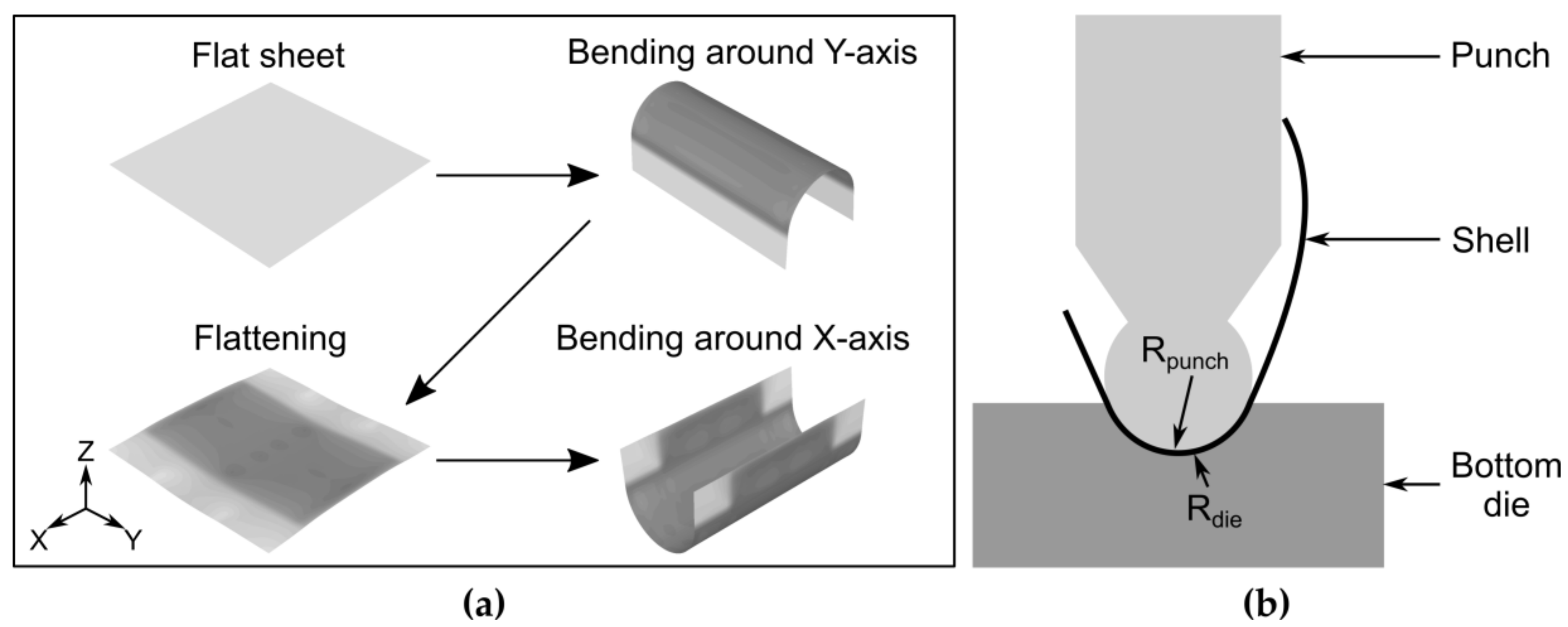

In order to describe the phenomenon of bistability, the semianalytical model needs to cover the whole process of two subsequent bending operations over two different axes in two opposite directions. The metastable states are identified by searching for a minimum of the bending moment resulting from the residual stresses acting in longitudinal and transversal direction of the shell.

As a starting point, an already published model aiming at the production of bistable metallic shells by Kebadze et al. [

7] is used. The model introduced now enhances this model by considering bending of already prebended and annealed cylindrical shells over perpendicular axis in opposite direction and gives a more detailed description of the kinematic and isotropic material hardening which are considered.

Contrary to the Kebadze et al. model [

7], in the following paragraphs the model is explained following the production process, starting with pure elastic bending of the flat unbent shell, moving to elastic–plastic bending, first springback after unloading, second bending operation, including elastic and plastic deformation, and final elastic springback. Moreover, for the model verification, a 0.1 mm thick shell of annealed beryllium–copper with an initial yield stress of 650 MPa was used by Kebadze et al. [

7]. Along this explanation, equations given by Kebadze et al. [

7] are stated as far as they are necessary to understand the general concept. A more detailed description can be found in the publication of Kebadze et al. [

7] itself.

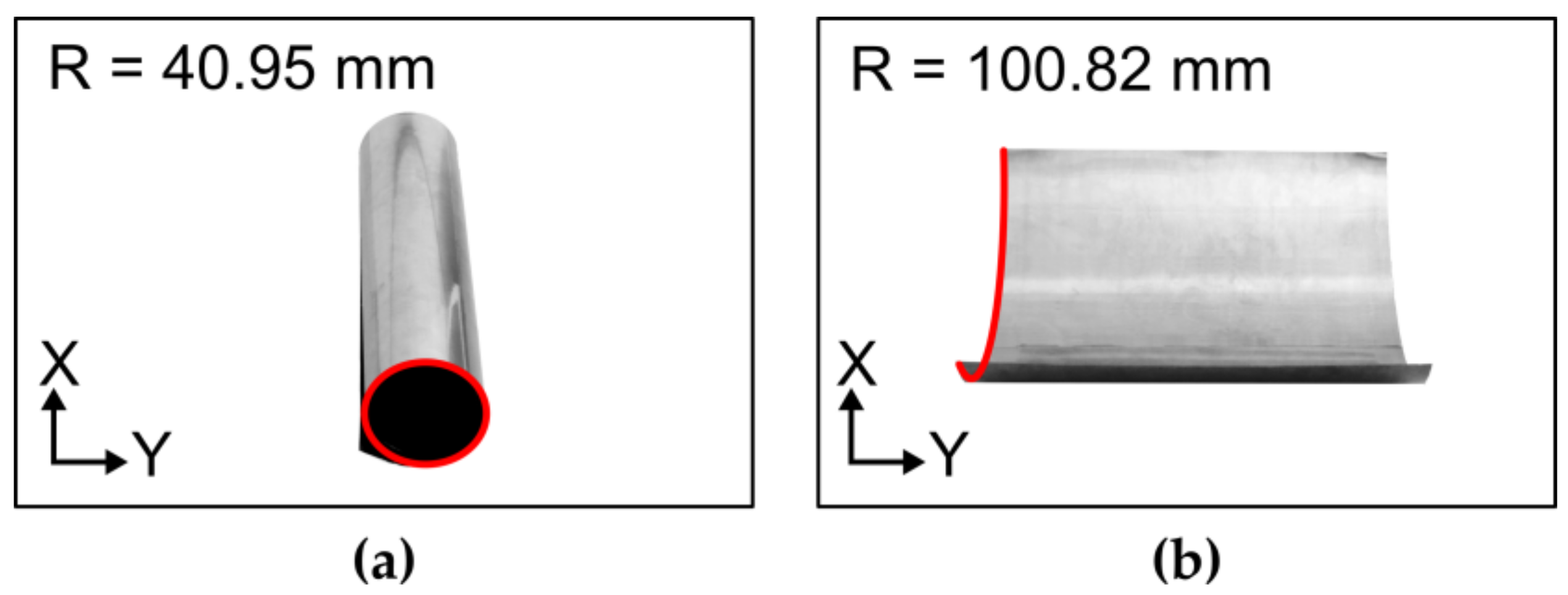

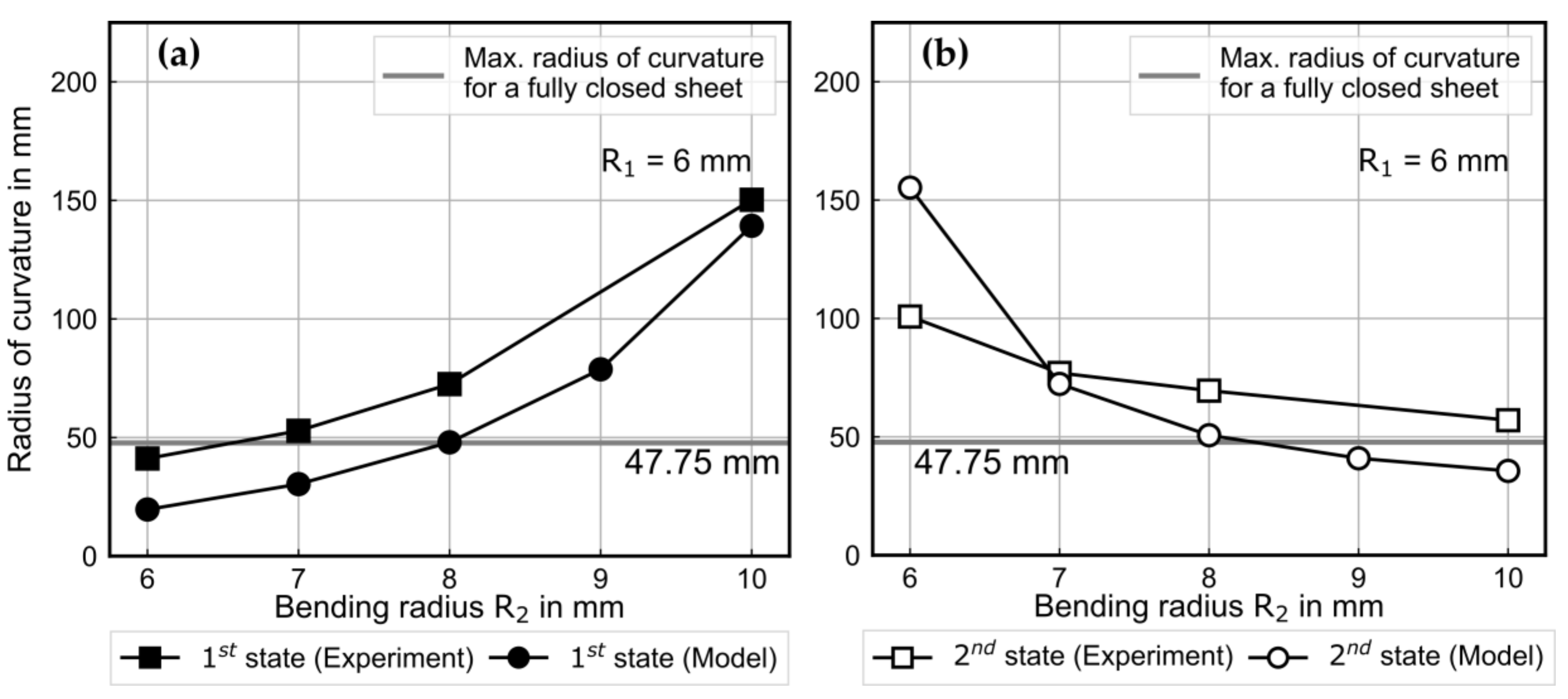

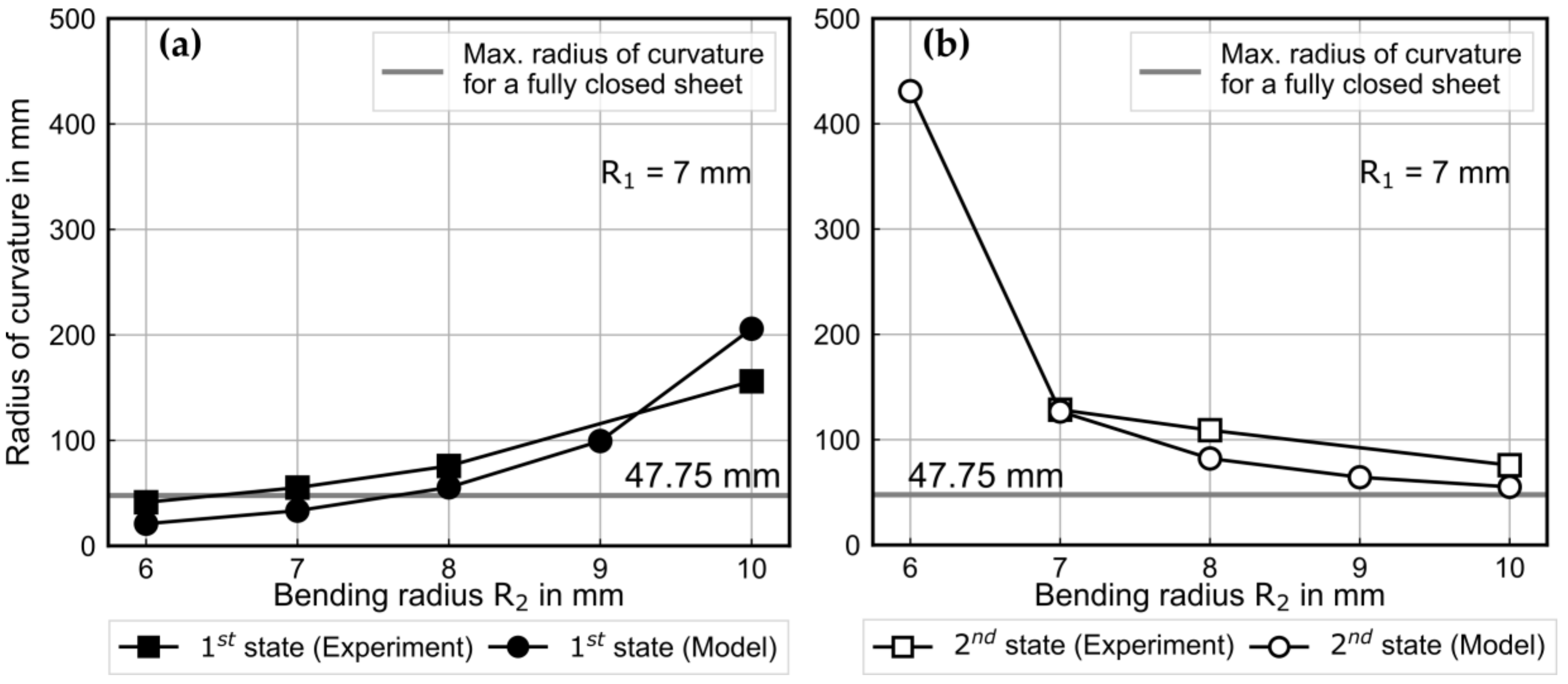

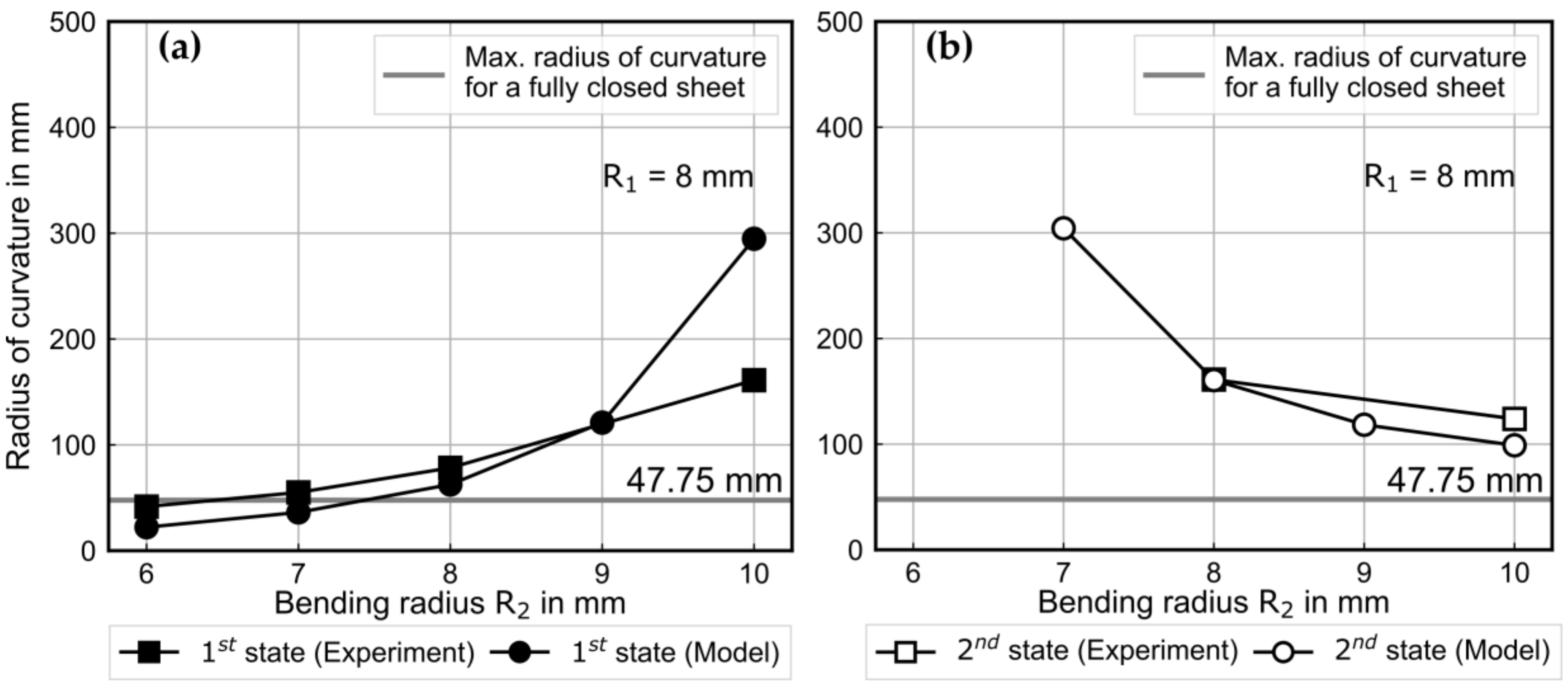

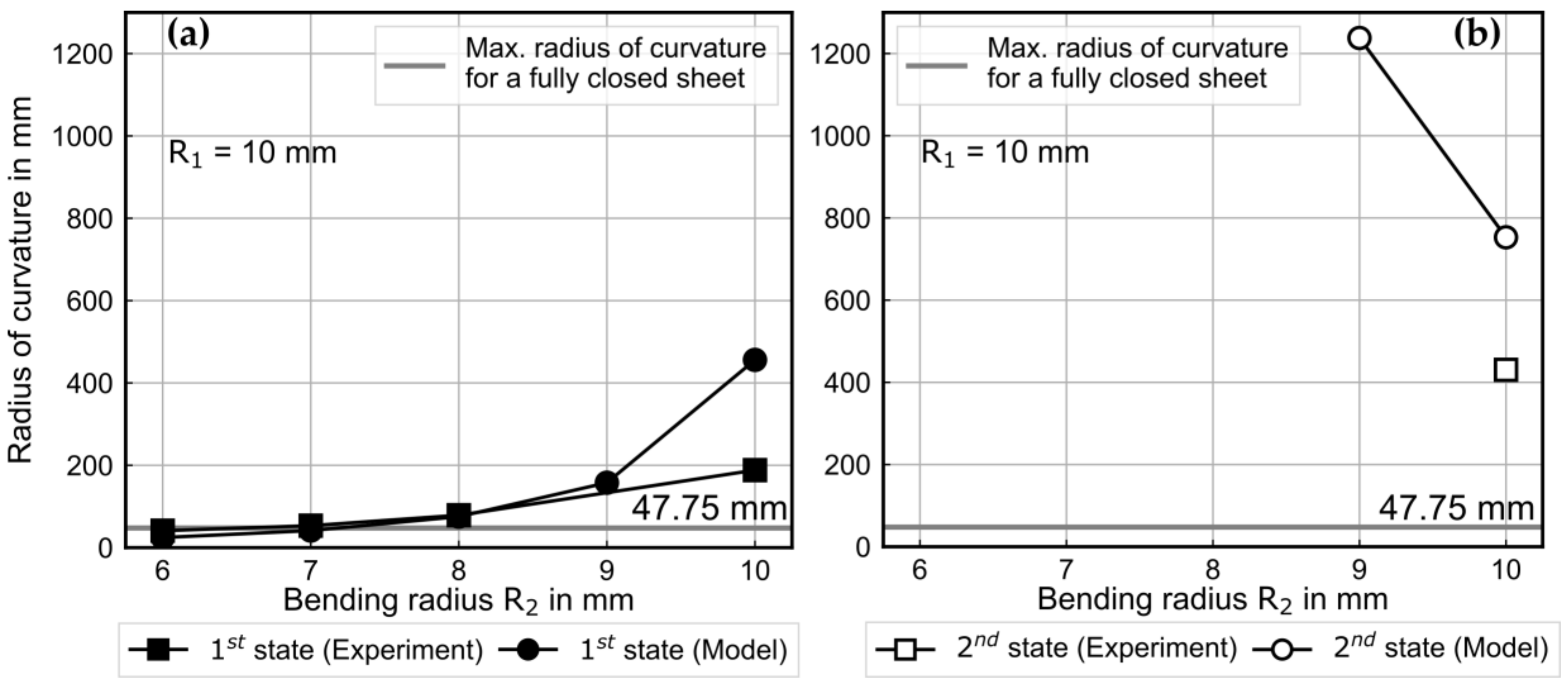

The preliminary experiments of manufacturing bistable metal shells using an incremental die-bending process indicate that in case of equal bending radii in the two consecutive bending operations, the springback radius after the second bending is always smaller than the springback radius after the first bending. This can be attributed to the displacement of the yield locus instead of increasing the yield locus and, therefore, to kinematic hardening. However, after switching between the first and second stable state, the springback radii do not change. Therefore, no plastic deformation occurs during the change between the stable states. Based on these observations, kinematic hardening in the first bending operation followed by isotropic hardening in the second bending operation is assumed. A similar approach is employed by Kebadze et al. [

7], who refer to a work of Crisfield [

10] regarding details on the calculation scheme. Since this assumption satisfies the experimental observations, it will be applied for the analytical model in a first step.

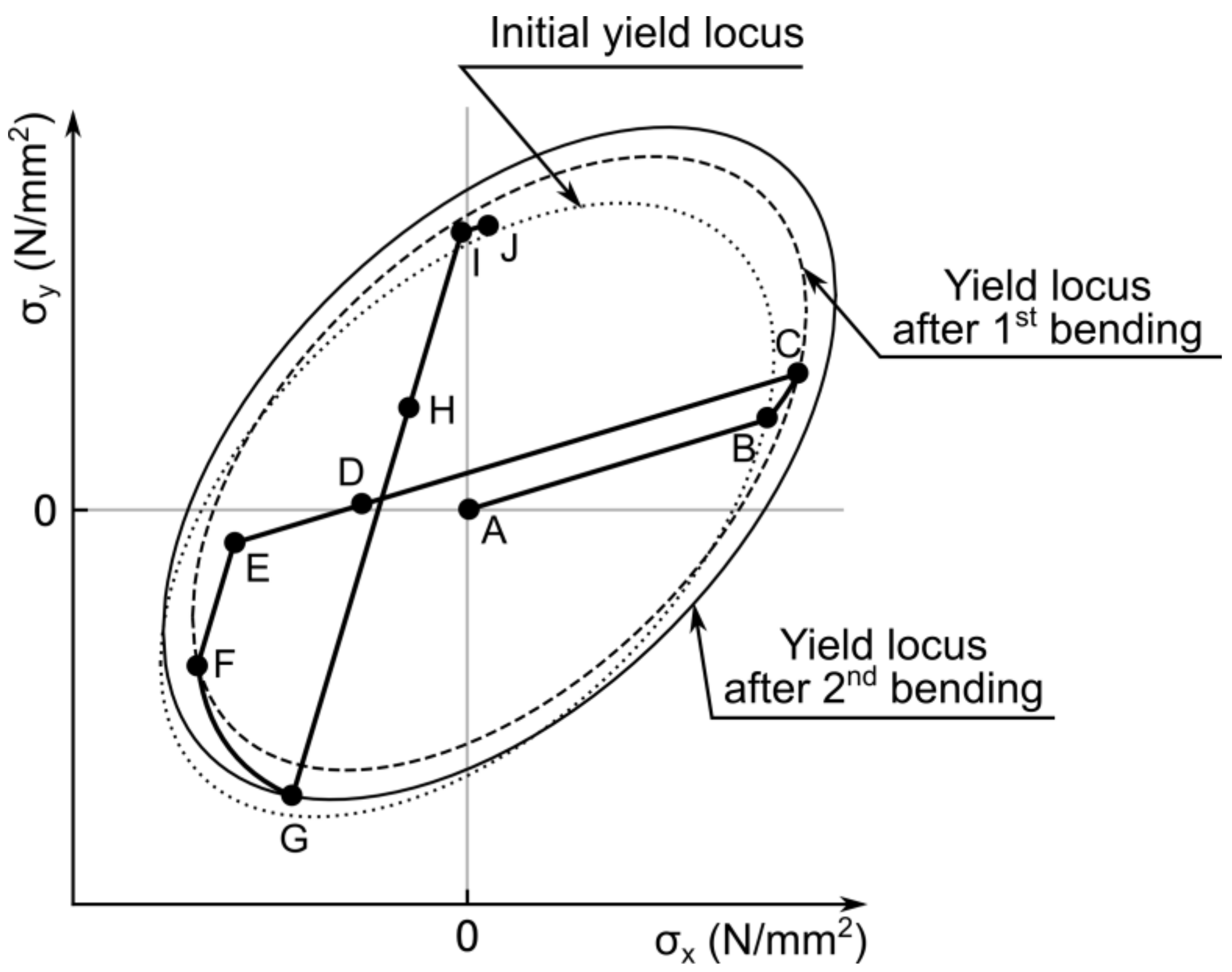

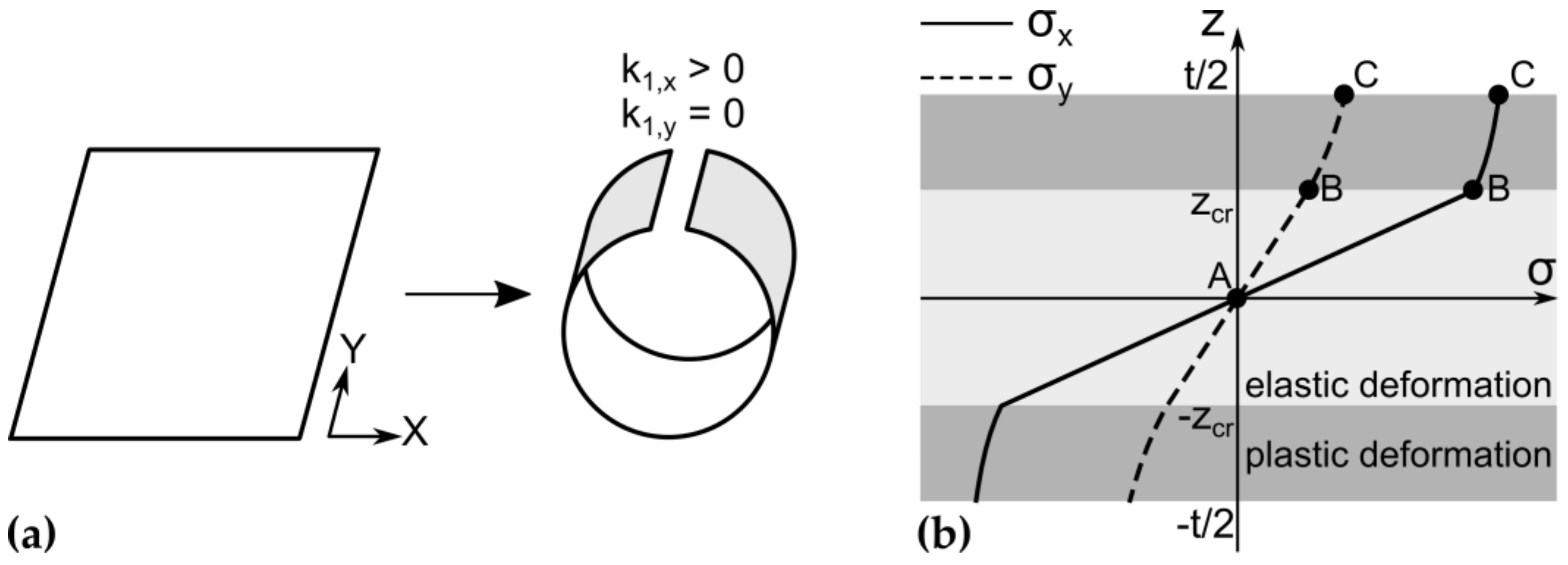

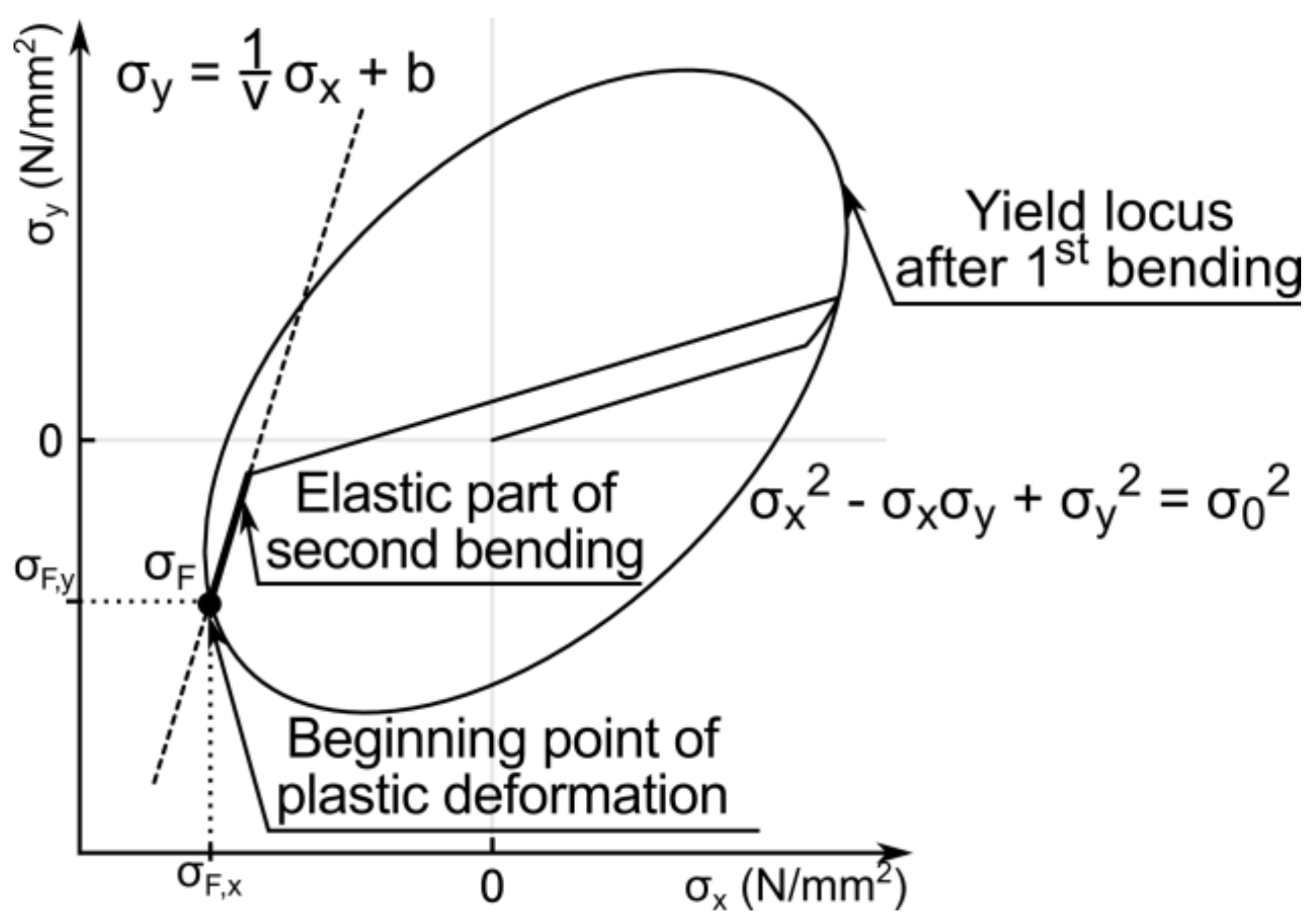

The whole chain of the bending process is depicted by means of the stress state and the von Mises yield criterion in

Figure 4. The yield locus represents the stresses on the surface of the shell. Point A corresponds to the unstressed flat shell. After the start of the first bending over the Y-axis, the shell initially deforms elastically until the stress state reaches point B. Subsequently, plastic forming takes place until point C. After the first bending, the shell has the curvature of

k1. During plastic forming, kinematic hardening occurs and the yield locus is translated from the original position by an amount equal to the vector of plastic stress accumulated during plastic forming. After plastic forming, the material unloads linearly until point D, which corresponds to the springback configuration with the shell curvature of

ksb. After springback, the shell is bended further until the flat state (point E). From the flattened state, the bending over the X-axis starts. This step also consists of elastic deformation until point F and plastic forming until point G. After the second bending, the shell has the curvature of

k2. Unlike the first bending, plastic forming at the second bending operation leads to isotropic hardening [

7], and the yield locus grows. Point H corresponds to the springback configuration after the second bending operation, which is equal to the first stable state with the shell curvature of

k1.geom,y. By bending the shell to the flat geometry (point I) and further bending in the opposite direction over the Y-axis, the second stable state could be achieved at point J with the shell curvature of

k2.geom,x. In the next sections, this bending sequence will be described in detail for each single step.

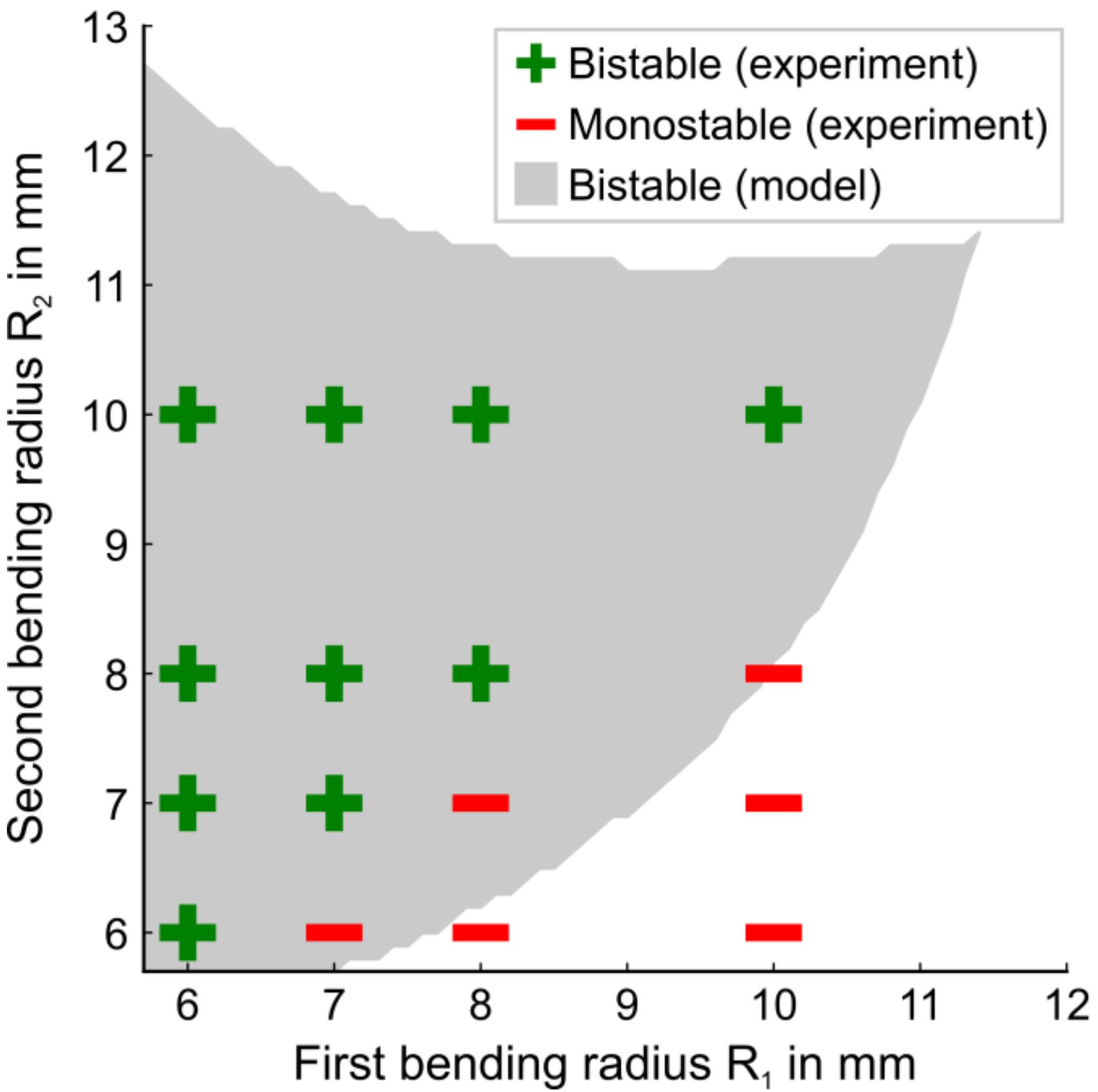

It is defined that after first bending and springback along the Y-axis, the shell curvature is positive (k1,x > 0). After bending the shell in reverse direction along the X-axis (k2,y < 0) and at the first stable state, the curvature has a negative sign (k1.geom,y < 0). At the second stable state, when the shell is bent along the Y-axis, the curvature again has a positive sign (k2.geom,x > 0). Taking this into account, an assessment of the stability of the shell geometry becomes possible. If the first and second geometry have an opposite sign in curvature other than defined, there is no stable geometry along the given axis, and, correspondingly, the shell is not bistable.

2.2.1. Elastic Deformation during the First Bending

The stress state after the first bending σ

C could be divided into two parts: elastic stresses and plastic stresses (

Figure 5b). The starting point of the process is an elastic bending within the first bending operation. In general, stresses and strains are considered in two dimensions according to the above-mentioned assumptions. For means of simplification, a vector notation is used as given in Equation (1).

Due to the assumed similar stress–strain behavior of material under tension and compression, only half of the shell thickness must be taken in account. The stresses on the other half could be assumed the same, but with opposite sign.

Generally, the thickness of the shell at elastic and plastic part is divided into n layers each. Accordingly, the stress state of each layer is calculated subsequently using 2n increments. For this research, a value of n = 200 has been determined to give suitable results.

It is necessary to define the transition from elastic to elastic–plastic bending. Thus, a critical depth measured from the neutral axis can be defined below which the shell does only deform elastically under a given curvature (see Equation (2)).

within this equation,

E is the Young’s modulus,

k1 is the first bending curvature,

v is the Poisson’s ratio,

σ0 is the initial yield stress of the material, and

z gives the distance from midsurface of the shell. The maximum elastic strain and elastic strain increment follow accordingly and are given in Equations (3) and (4).

where

n is the number of increments.

The accompanying stresses can be calculated via the material stiffness matrix

C as stated in Equations (5) and (6) [

7].

2.2.2. Plastic Forming during the First Bending

In the Kebadze et al. model [

7], the stress–strain relationship of the shell was represented as tabular data. In this work, since the transition point between elastic and plastic bending is known, the stresses under bending load are described via the extended Voce equation [

11]. Furthermore, the equivalent stress according to the von Mises yield criterion can be calculated utilizing Equation (7) [

7].

where

A denotes the auxiliary matrix for the given stress state for pure bending (Equation (8) [

7]).

Knowing the stress state at which plastic forming starts, it is necessary to describe the evolution of the stress state under load. The consistency criterion is applicable in that case and can be written in the form according to Equation (9) [

7].

In order to describe the evolution of the yield locus, the so-called strain hardening parameter

H should be calculated (Equation (10) [

7]). The strain hardening parameter consists of the tangent modulus

Et, which gives the slope of the yield locus at a given stress state.

In this work, the tangent modulus is derived by differentiating the extended Voce equation [

11] as stated in Equation (11).

where

θ0 is the initial hardening rate,

θ1 is the asymptotic hardening rate, and

(σ0 + σ1) is the back-extrapolated yield stress, with

σ0 as the initial yield stress. After plastic forming starts, the stresses acting on the material can be calculated with the help of the material tangent stiffness matrix as given in Equation (12) [

7].

within this equation,

I denotes the 2 × 2 identity matrix, and

a is the normal vector to the yield surface (see Equation (13) [

7]):

Along plastic forming, the direction of the tangent to the yield locus changes along with the evolving stress state. Thus, it is necessary to conduct an iterative calculation of the change of the yield locus. Therefore, the total plastic strain is divided in

n increments. The plastic strain increment can be calculated via Equation (14):

where

t is the thickness of the shell. The given stress increment and the total stress under load can be calculated according to Equations (15) and (16) [

7]:

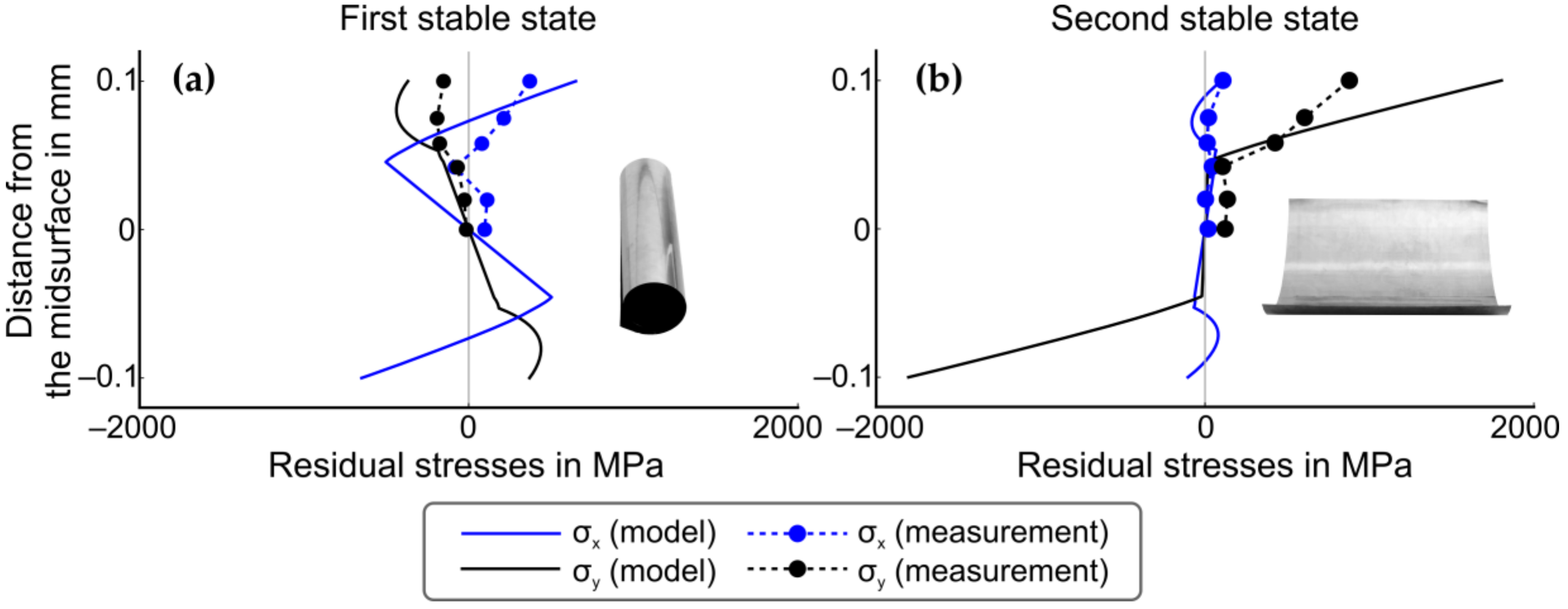

The plastic stress distribution after first bending is shown in

Figure 5b. The evolution of the stress state is assumed to be caused by kinematic hardening. Thus, the evolution of the stress state in direction of the normal to the tangent at the yield locus is imposed as a shift of the yield locus from the origin of the stress space. This way, the back stress evolving during kinematic hardening is equal to the vector of plastic stress accumulated during plastic forming (which is used as well in the work of Kebadze et al. [

7]). Thus, kinematic hardening can be described without using material-dependent coefficients.

2.2.3. First Elastic Springback

The shell is in a mechanical equilibrium if one of the resulting bending moments per unit length, induced by the residual stresses, is close to zero. The specific bending moments can be calculated as given in Equation (17) [

12].

within this equation,

z gives the material thickness,

mx and

my are the resultant bending moments per unit length in the unit Nmm/mm, and

σx(z) and

σy(z) are the residual stress distributions along the given axes. In order to determine the remaining curvature after springback, the linear relationship between bending moment and resulting shell curvature [

12] can be applied according to Equation (18) [

13]:

where

k is the shell curvature and

m is the resultant bending moment per unit length. Assuming that curvature of flattened shell (

kE,x) and bending moments along X-axis at springback curvature (

mD,x) are equal to zero, the springback curvature can be calculated according to Equation (19).

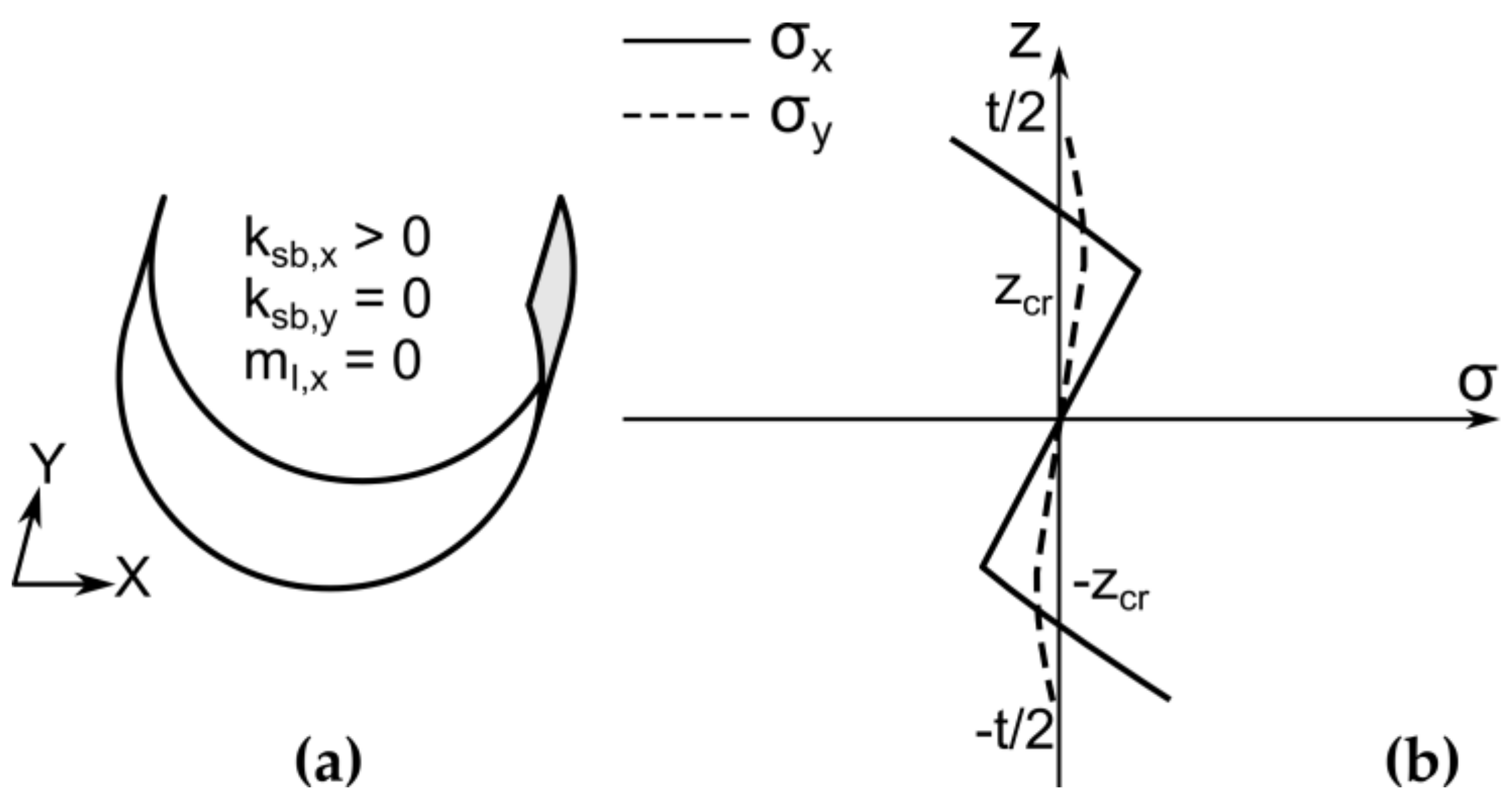

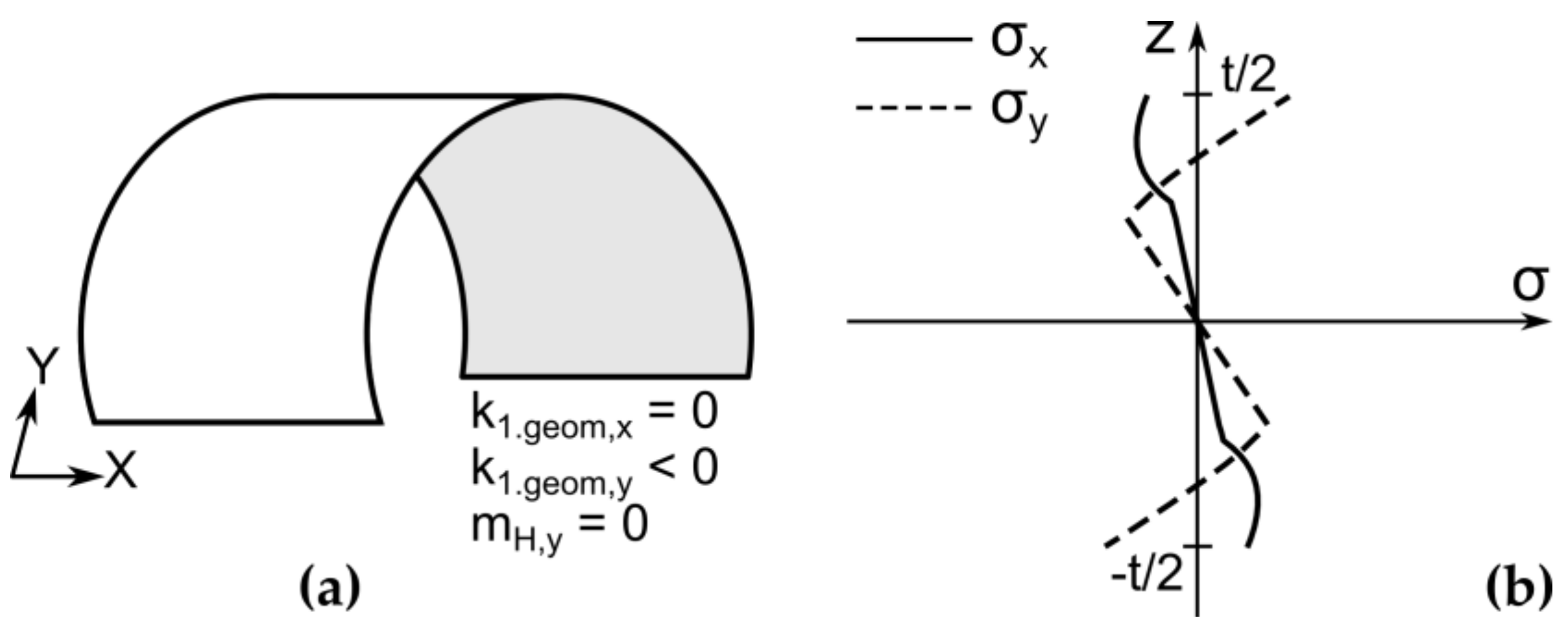

The shell geometry and stress distribution after first springback are shown in

Figure 6.

2.2.4. Elastic Bending in the Reverse Direction

First of all, the stress distribution for the flattened shell should be calculated. For this purpose, the elastic stresses calculated for bending of the shell by curvature

k1 should be subtracted from the stresses after first bending (Equation (20)):

Afterwards, the

x and

y components of critical stress values, at which the plastic deformation starts (

σF), can be determined by solving a system of two equations (Equation (21)):

where

b is the offset of the elastic part line relative to the Y-axis.

The curvature at which plastic forming begins can be found using Equation (22):

Figure 7 shows the determination of the starting point of plastic deformation at the yield surface.

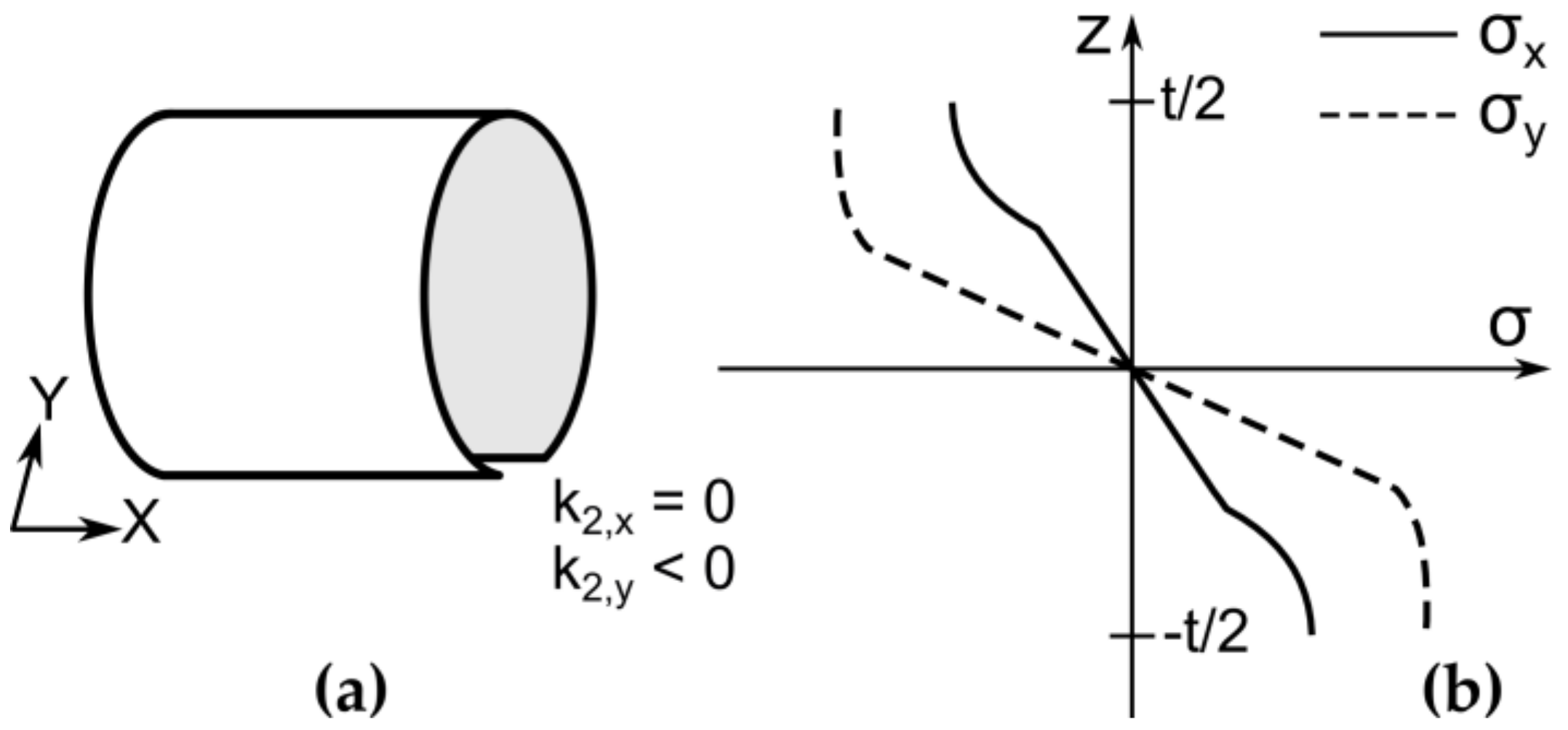

2.2.5. Plastic Bending in the Reverse Direction

Plastic deformation during the second bending can be calculated using the approach from

Section 2.2.2. The shell geometry and stress distribution along the shell thickness after the second bending are shown in

Figure 8.

2.2.6. Elastic Springback and the First Stable State

The curvature and the stress distribution of the first stable state can be calculated with the help of Equation (23).

where

k1.geom,y is the curvature of the first stable state and

mI,y is the moment along the Y-axis at the flattened shell after the second bending. The shell geometry and stress distribution at first stable state are shown in

Figure 9.

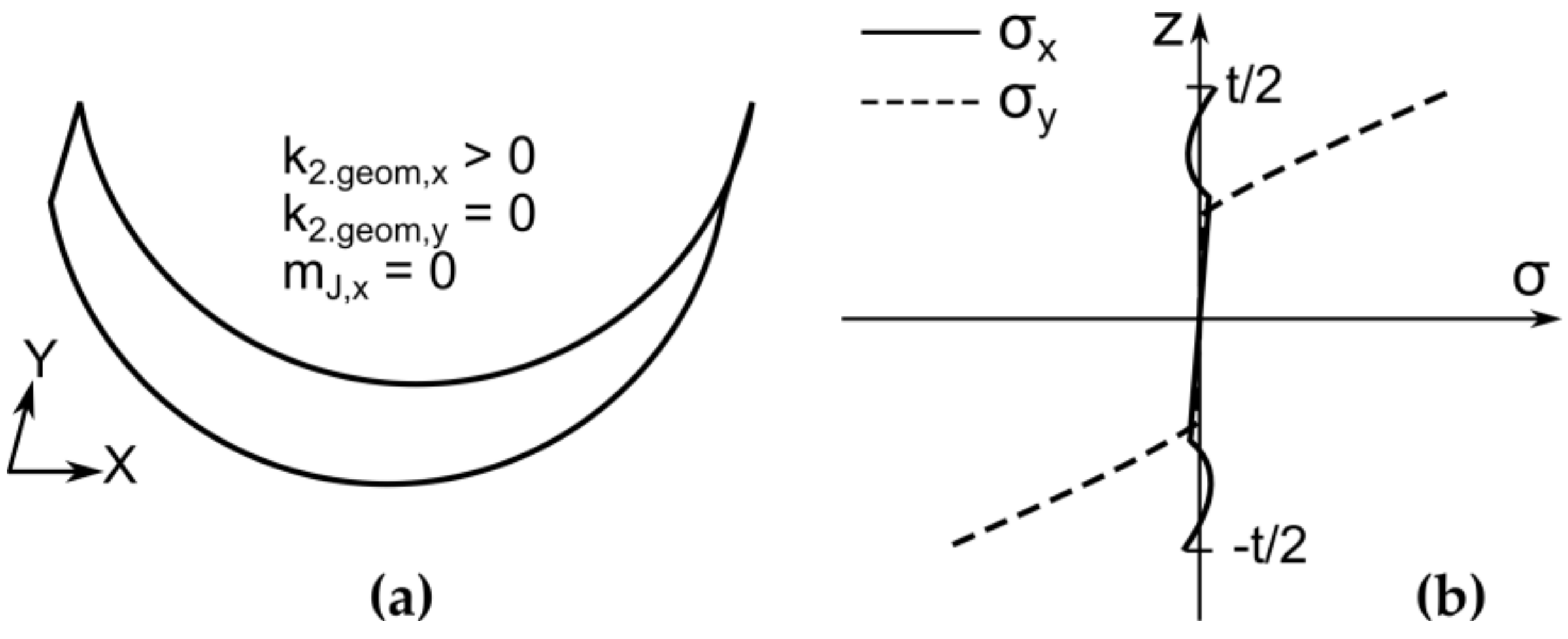

2.2.7. Second Stable State

The curvature and the stress distribution of the first stable state can be calculated with the help of Equation (24).

where

k2.geom,x is the curvature of the first stable state and

mI,x is the moment along the Y-axis at the flattened shell after the second bending. The shell geometry and stress distribution at second stable state are shown in

Figure 10.