Collaborative Infrastructure-Free Aerial–Ground Robotic System for Warehouse Inventory Data Capture

Highlights

- A fully autonomous, infrastructure-free UAV–UGV system for warehouse inventory is designed and validated: the UGV performs global localization via EKF + scan-to-map using only a 2D floor plan, while the UAV uses ArUco-based relative localization to autonomously take off, follow the UGV, and execute precision landings; results are validated in simulation and real-world trials.

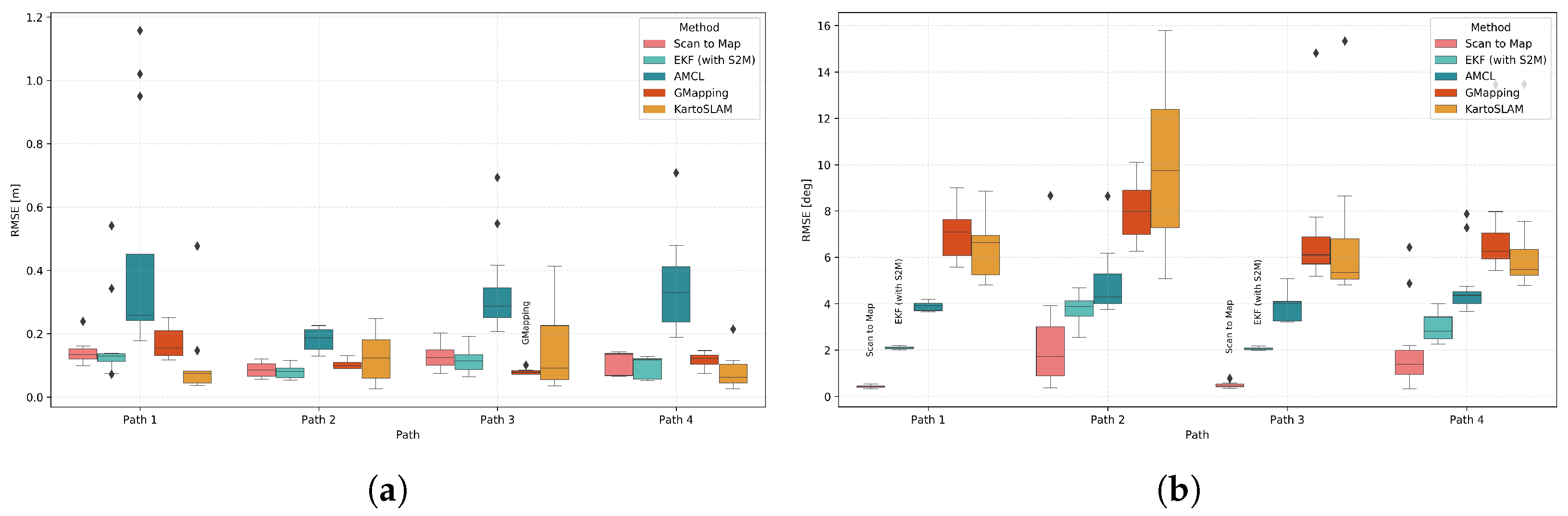

- The proposed UGV localization yields consistently low translational error and the lowest orientation RMSE across scenarios, outperforming AMCL and remaining stable during a 45-min warehouse run where AMCL diverged; the UAV reliably follows and lands using a lightweight controller.

- Enables rapid, low-cost deployment in GPS-denied, symmetric warehouses without prior 3D mapping or external infrastructure, remaining robust to shelf-occupancy changes and dynamic clutter.

- Provides a practical path toward scalable cycle counting by coordinating UGV motion with UAV shelf scanning; the open-source implementation facilitates reproduction and adoption by industry and academia.

Abstract

1. Introduction

Innovation, Scope and Contributions

- Development of a lightweight, accurate, and robust UGV localization method that combines an EKF with an optimized scan-to-map matching using only a simple 2D floor plan of the warehouse layout. This approach eliminates the need for prior mapping operations or external infrastructure, while remaining robust to dynamic shelf occupancy.

- Implementation of a practical UAV localization pipeline using ArUco markers combined with other data sources.

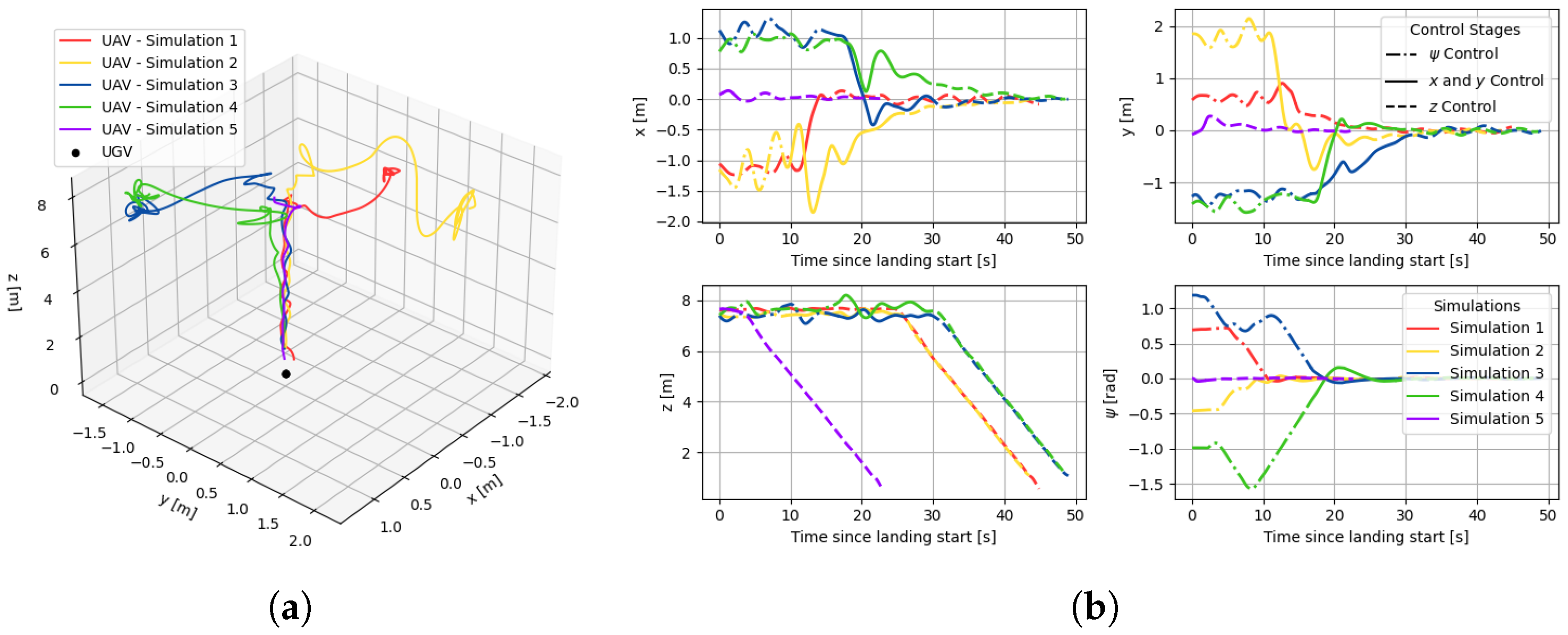

- Deployment of a UAV motion control pipeline that enables the UAV to autonomously take-off, follow a moving UGV and execute reliable landing procedures in indoor warehouse conditions, ensuring robust UAV-UGV collaboration without external navigation systems or commands.

- Validation through simulation and real-world experiments, demonstrating the feasibility of the system’s modules in warehouse-like scenarios.

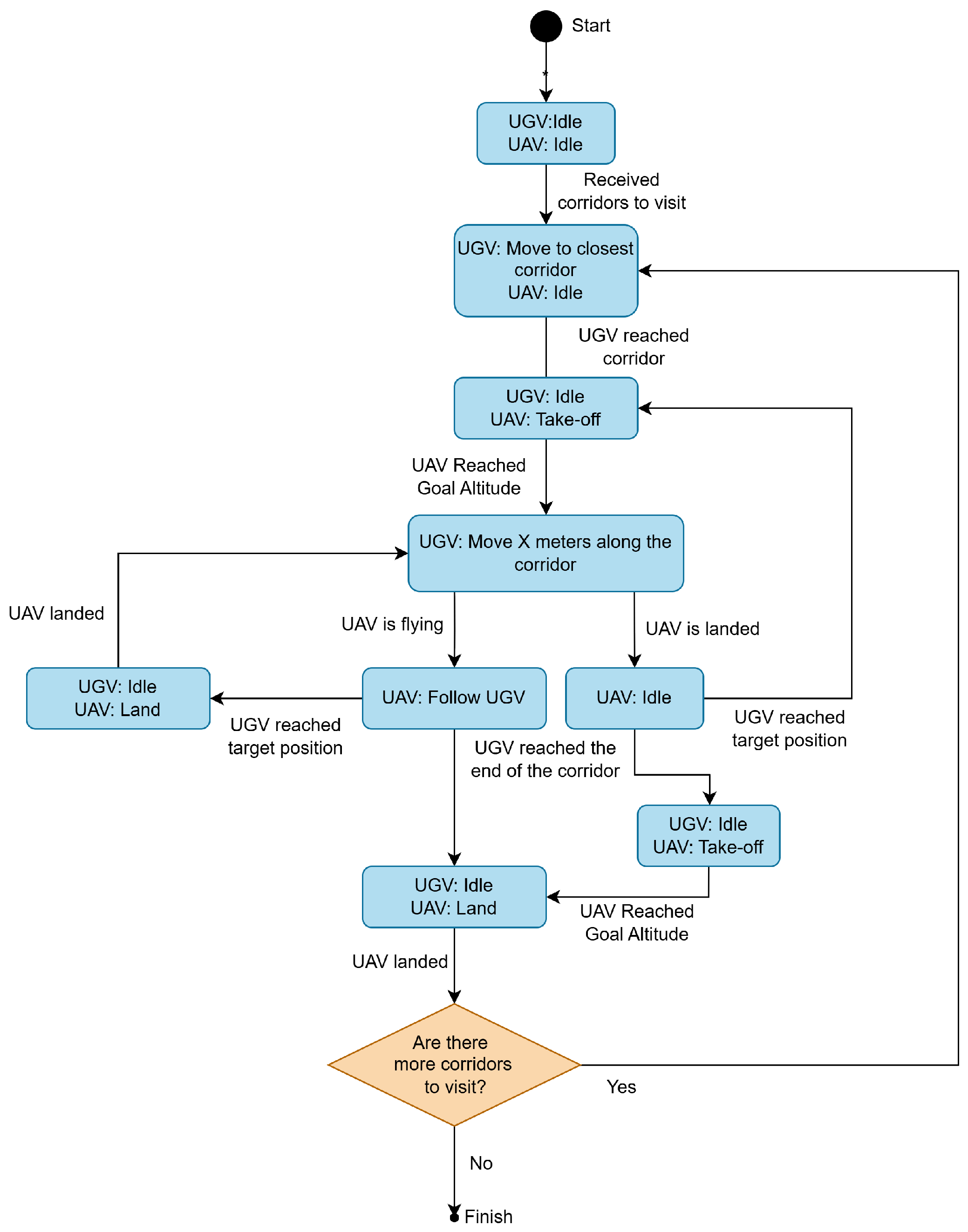

2. Proposed System

2.1. Solution Overview

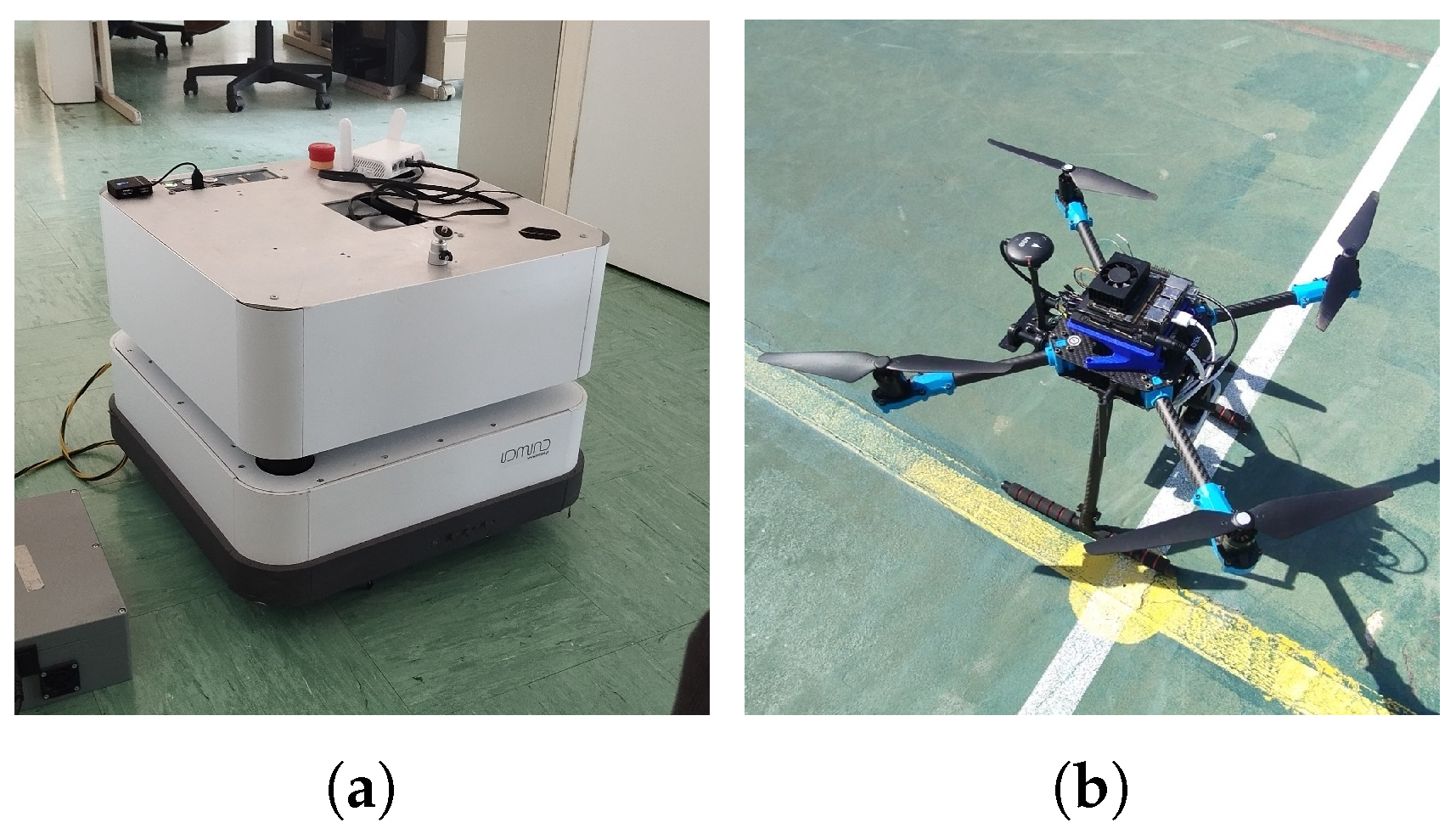

2.2. System Hardware and Setup

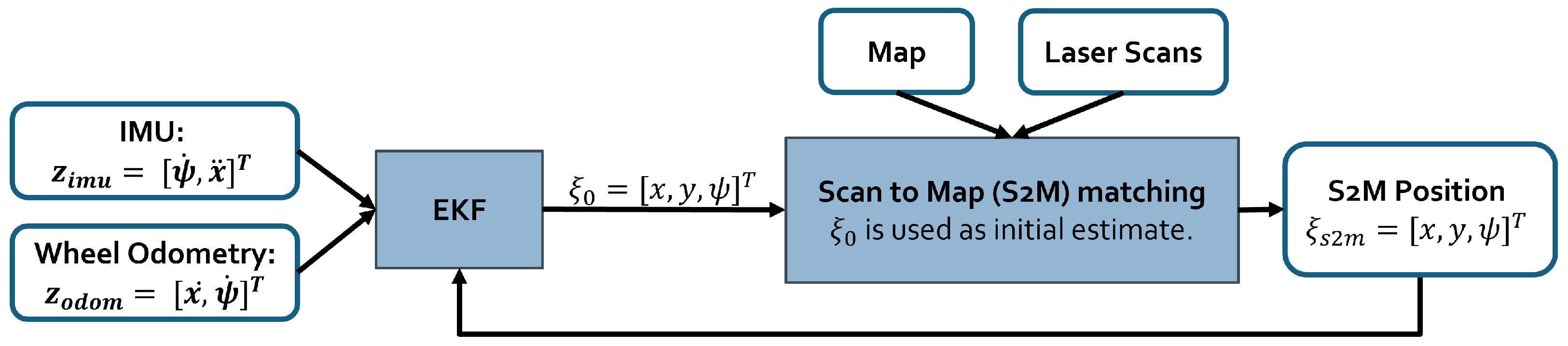

2.3. UGV Localization

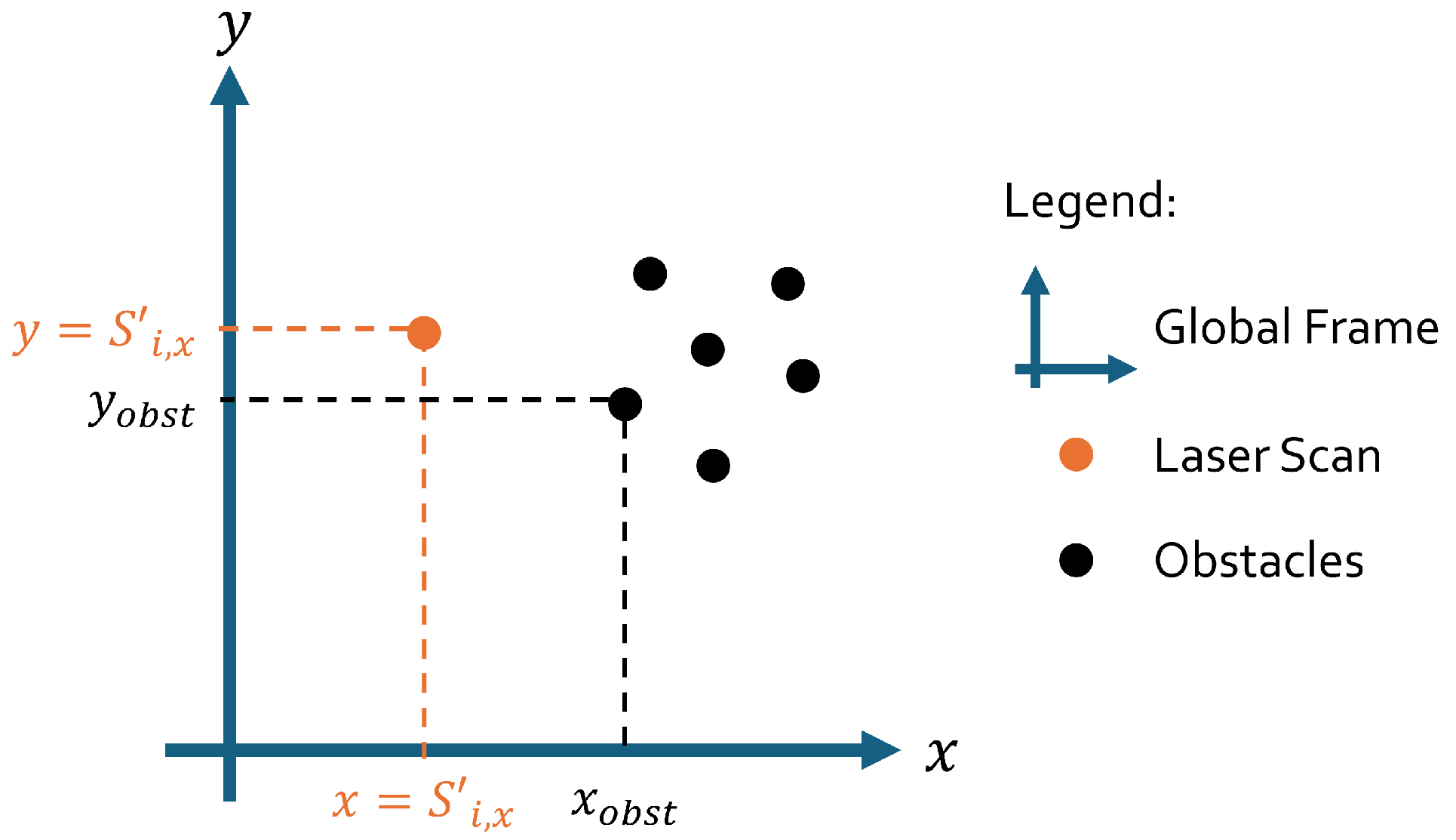

Scan to Map Matching Algorithm

2.4. UAV Localization

2.5. UAV-UGV Coordination and Trajectory Planning

3. Simulation Results

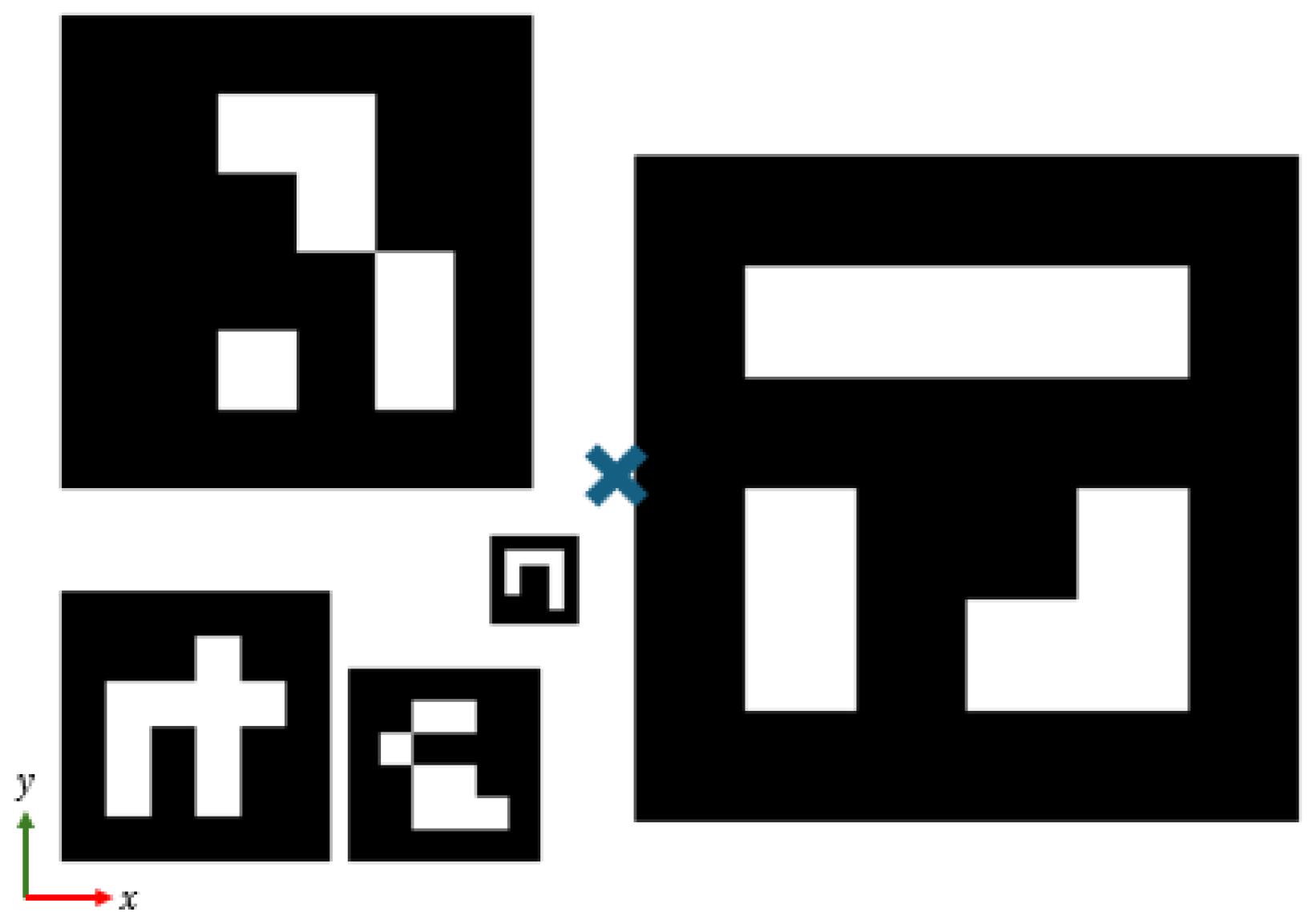

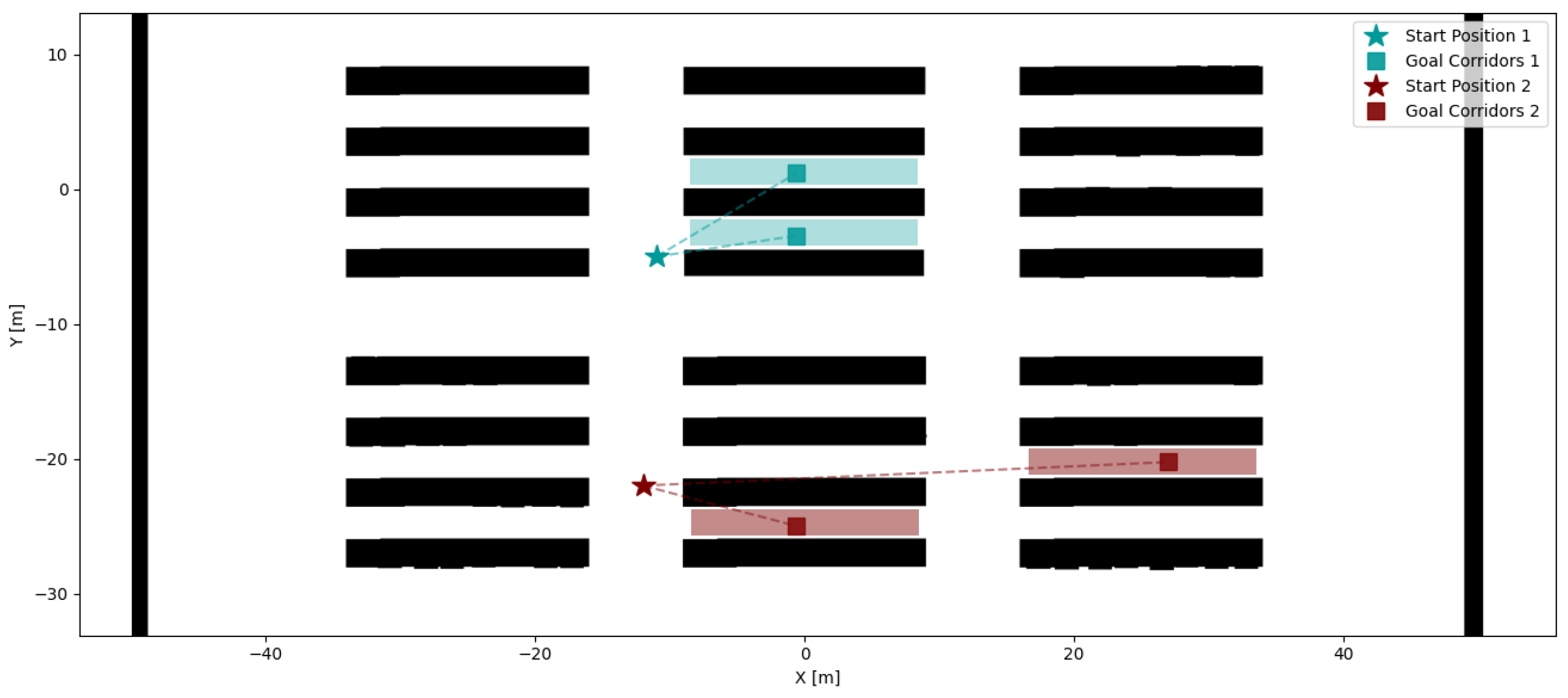

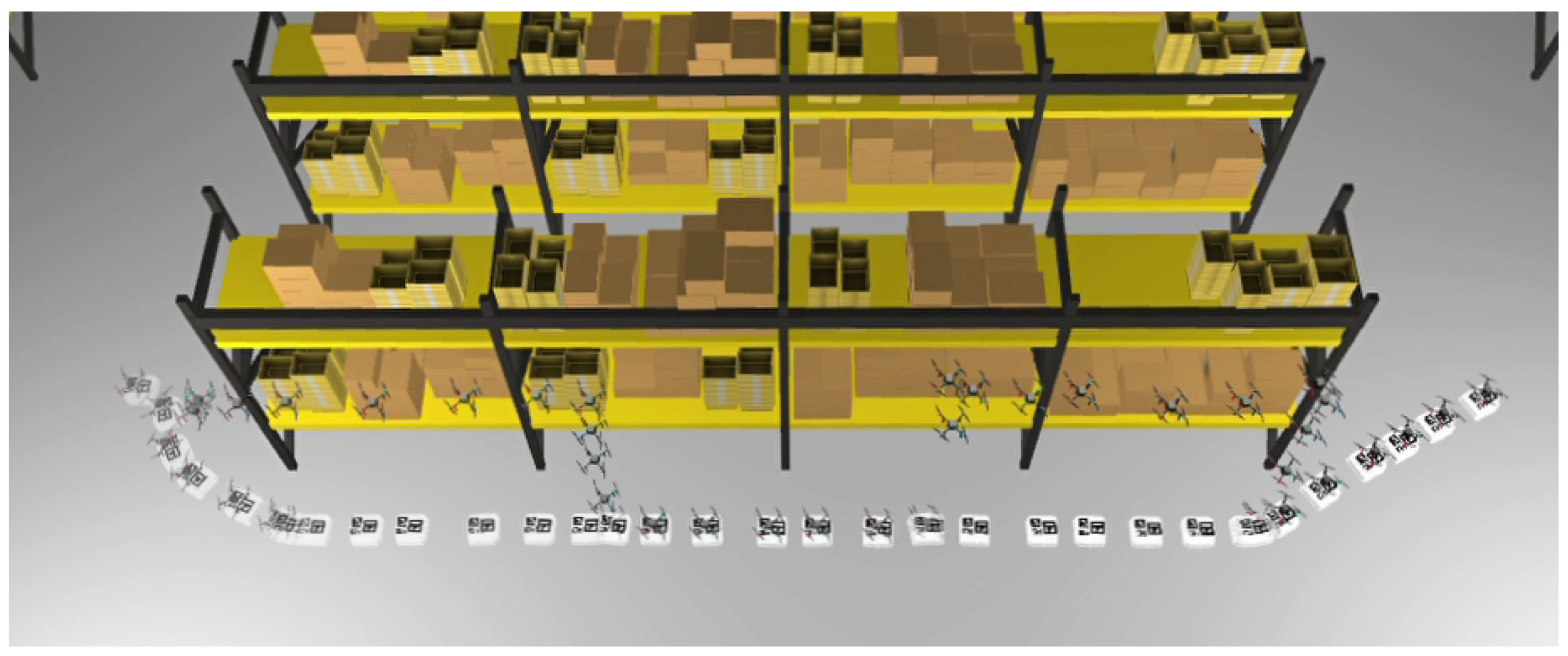

3.1. Simulation Setup

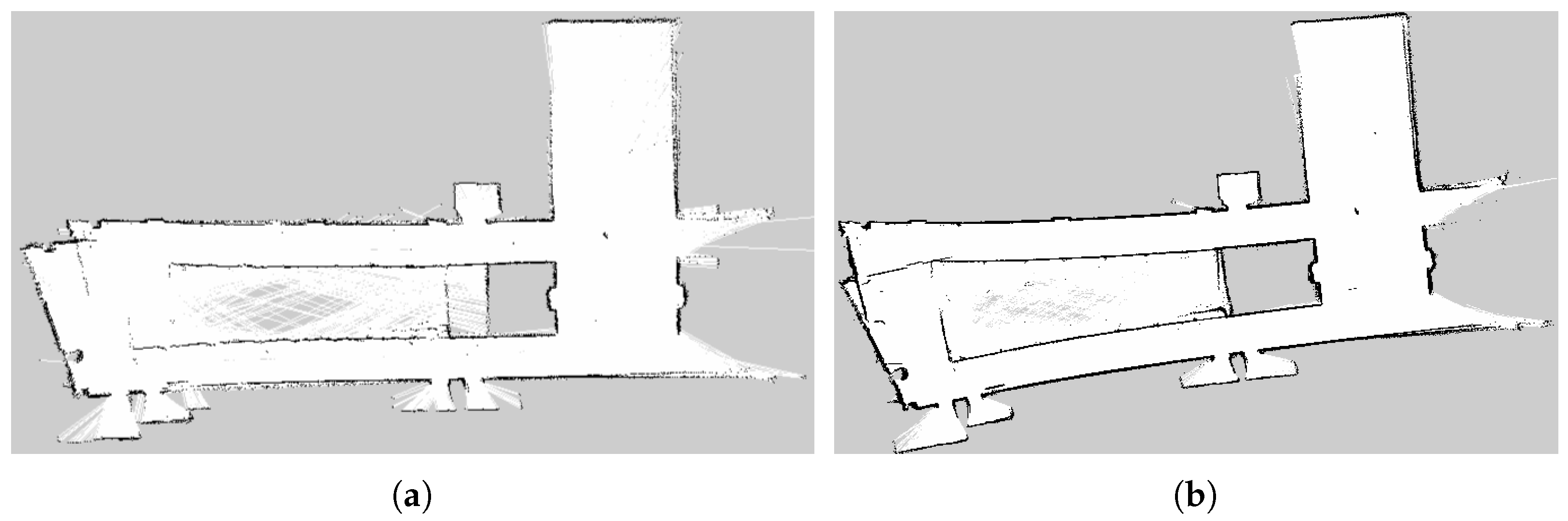

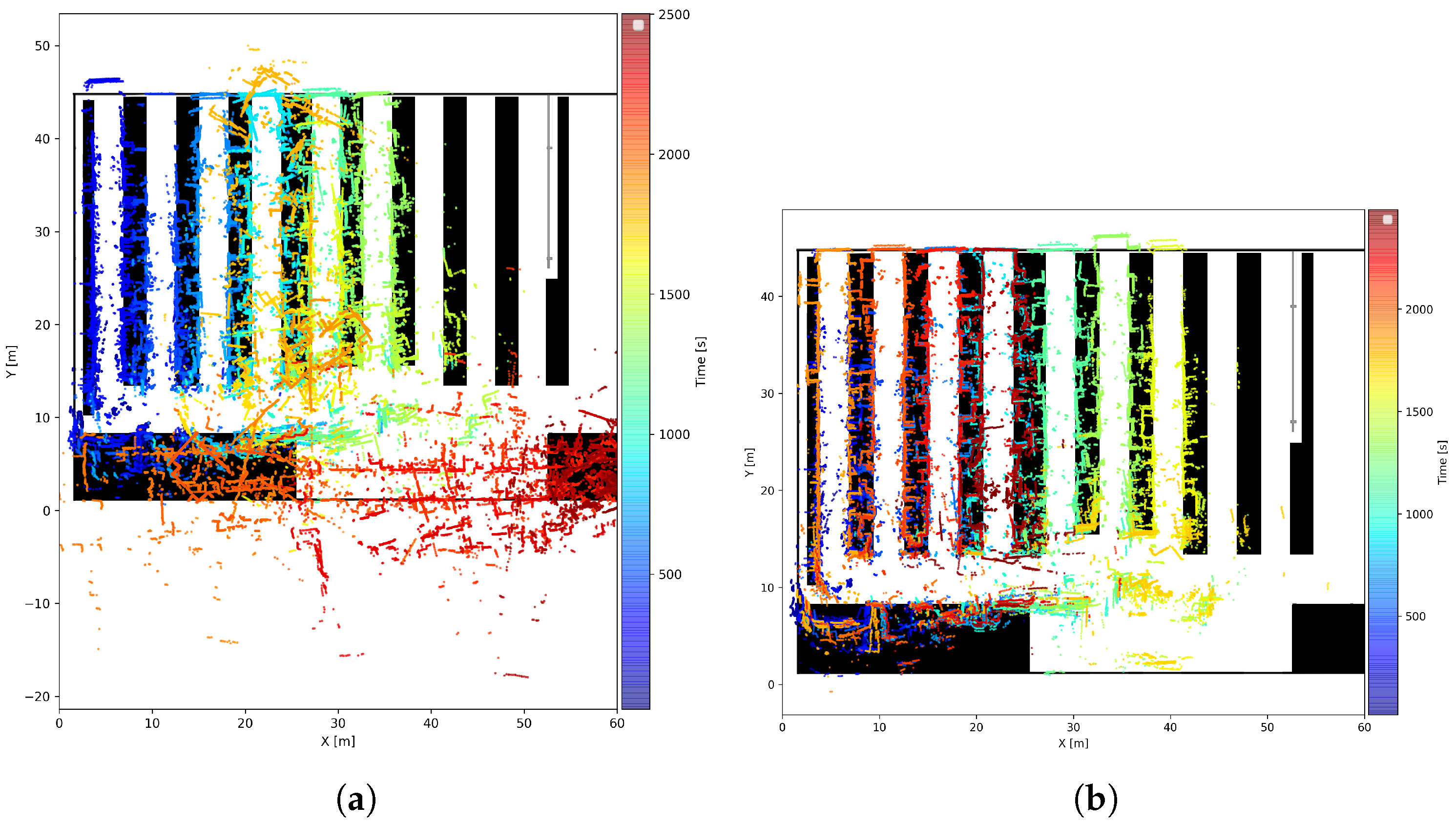

3.2. UGV Localization

3.3. UAV Landing

3.4. UAV-UGV Collaboration

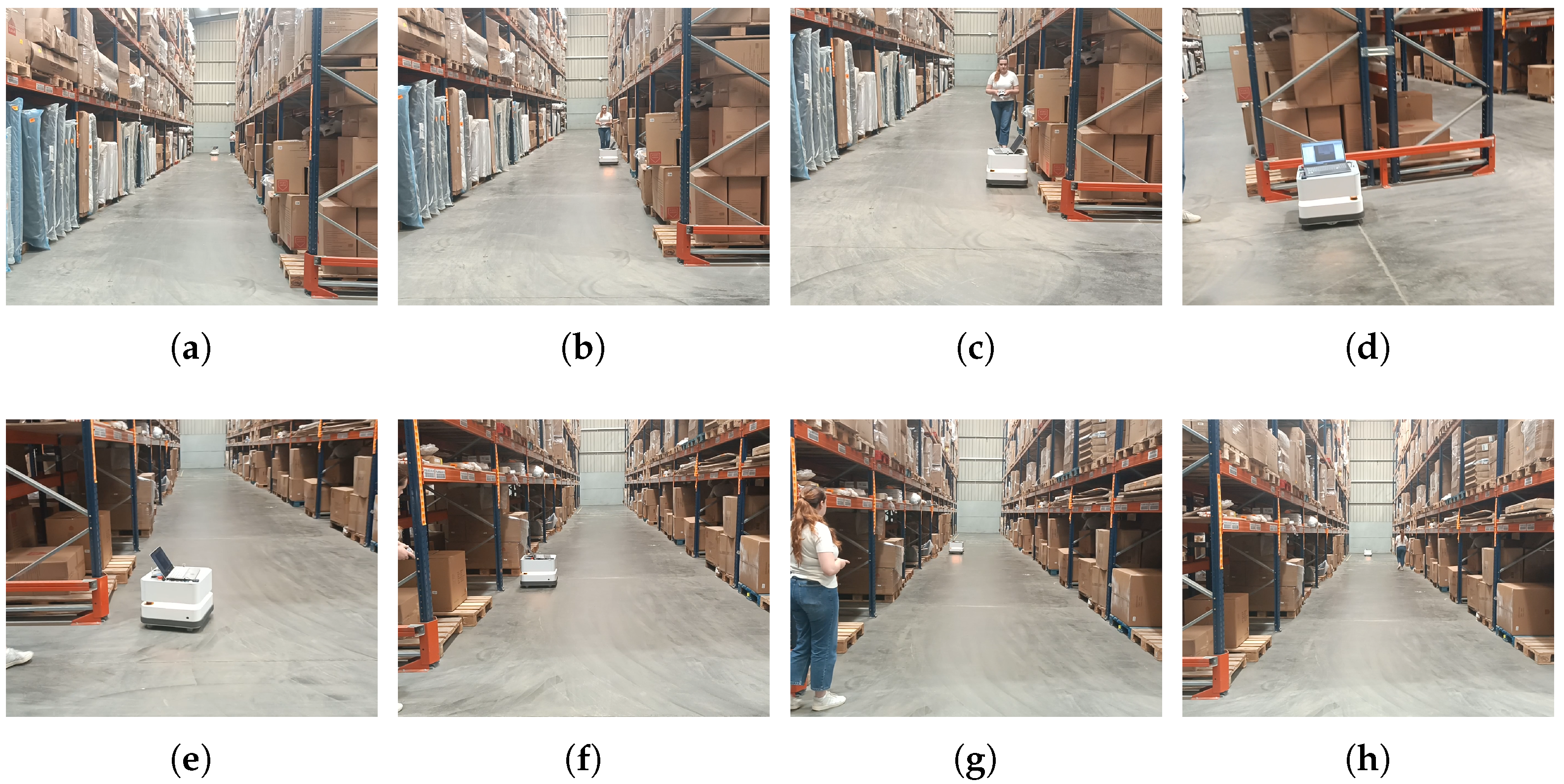

4. Real-World Experiments

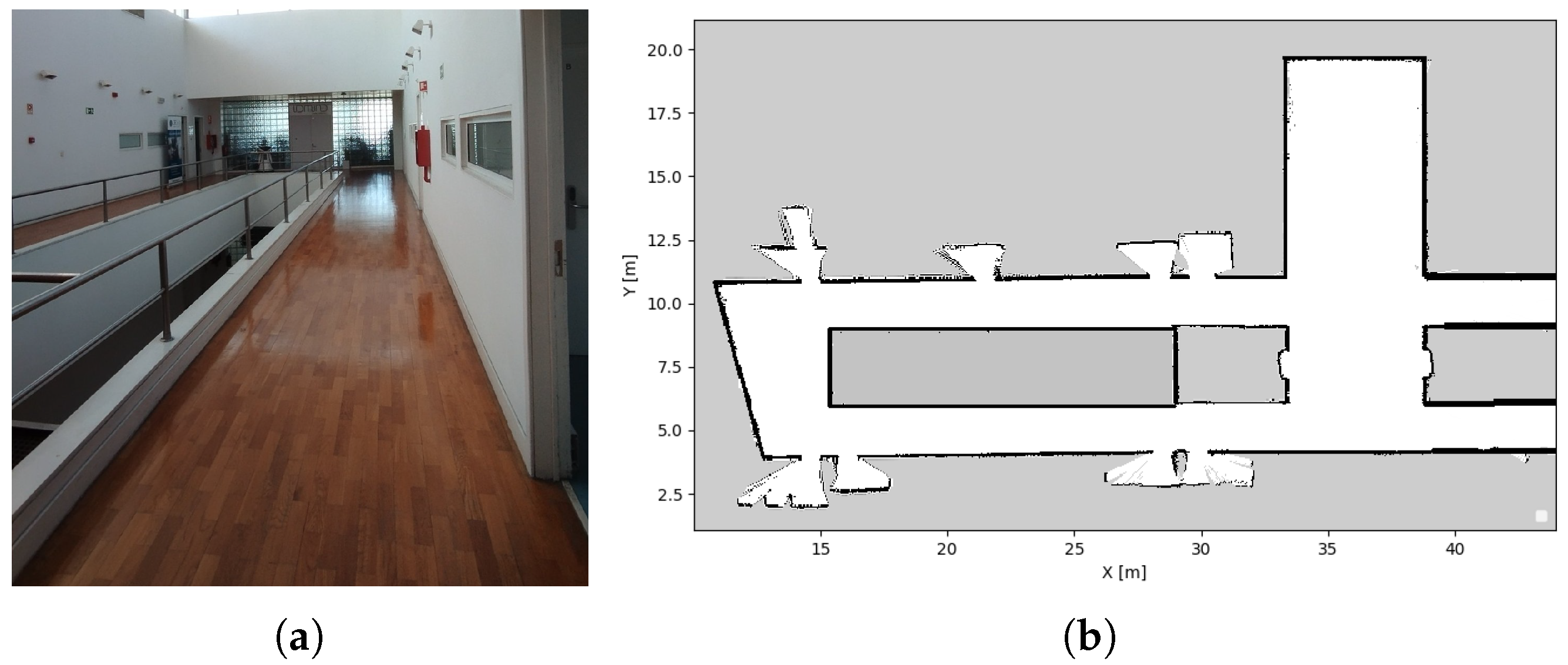

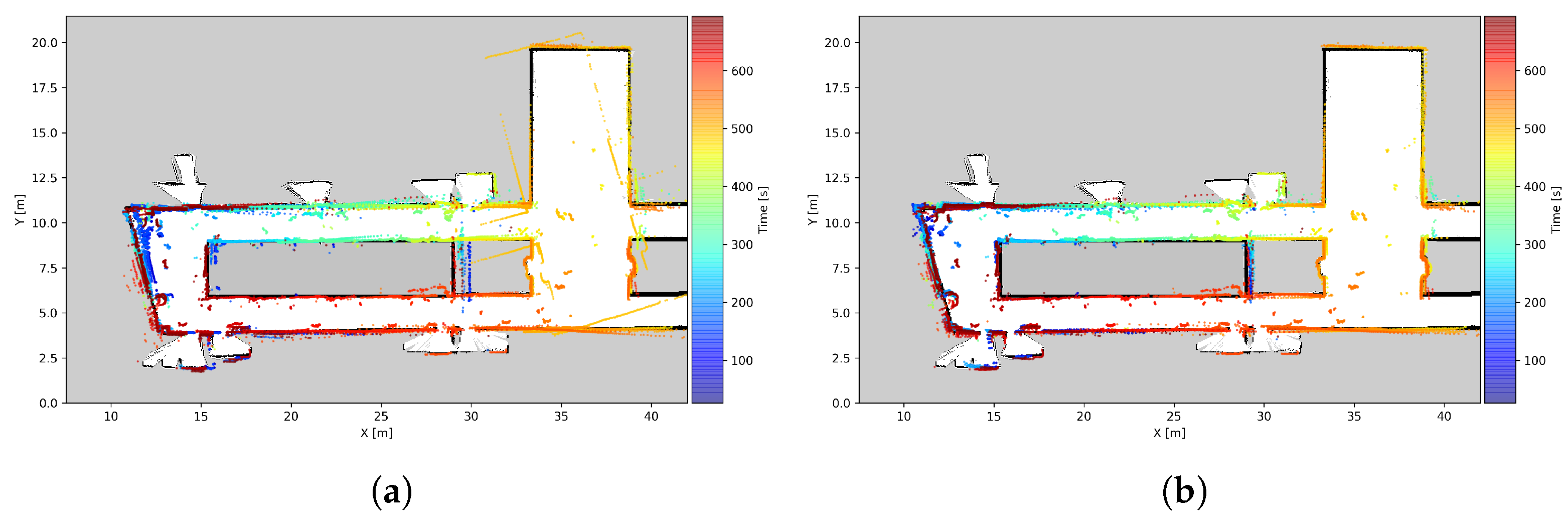

4.1. UGV Experiments

- Test (1) Open-loop tests, in which the UGV was manually teleoperated using a joystick. These tests focused on evaluating the real-time performance and consistency of the localization system across varying trajectories and viewpoints.

- Test (2) Closed-loop tests, where the UGV was commanded to autonomously navigate to predefined goal points. These trials aimed to verify the effectiveness of the motion planning and control modules in achieving accurate and reliable navigation towards desired positions when using the proposed localization solution.

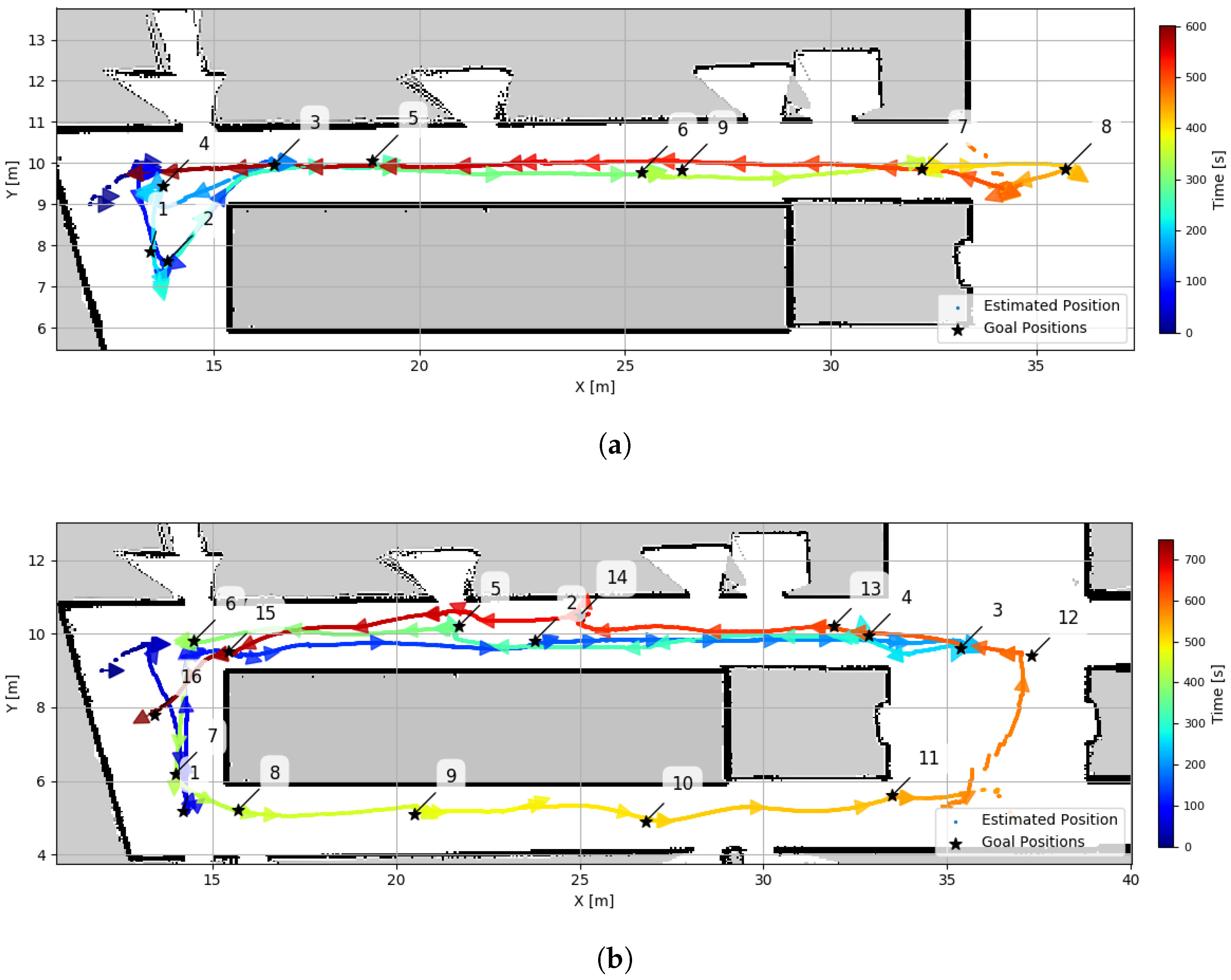

4.1.1. Experiments at IDMind

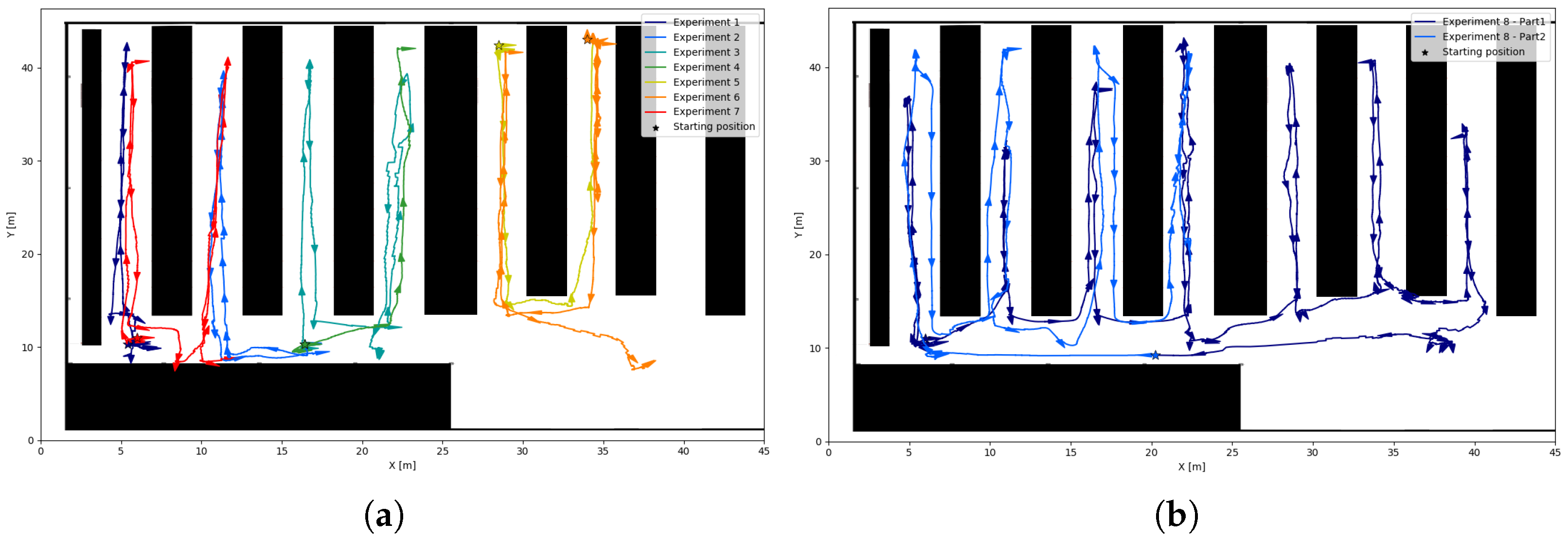

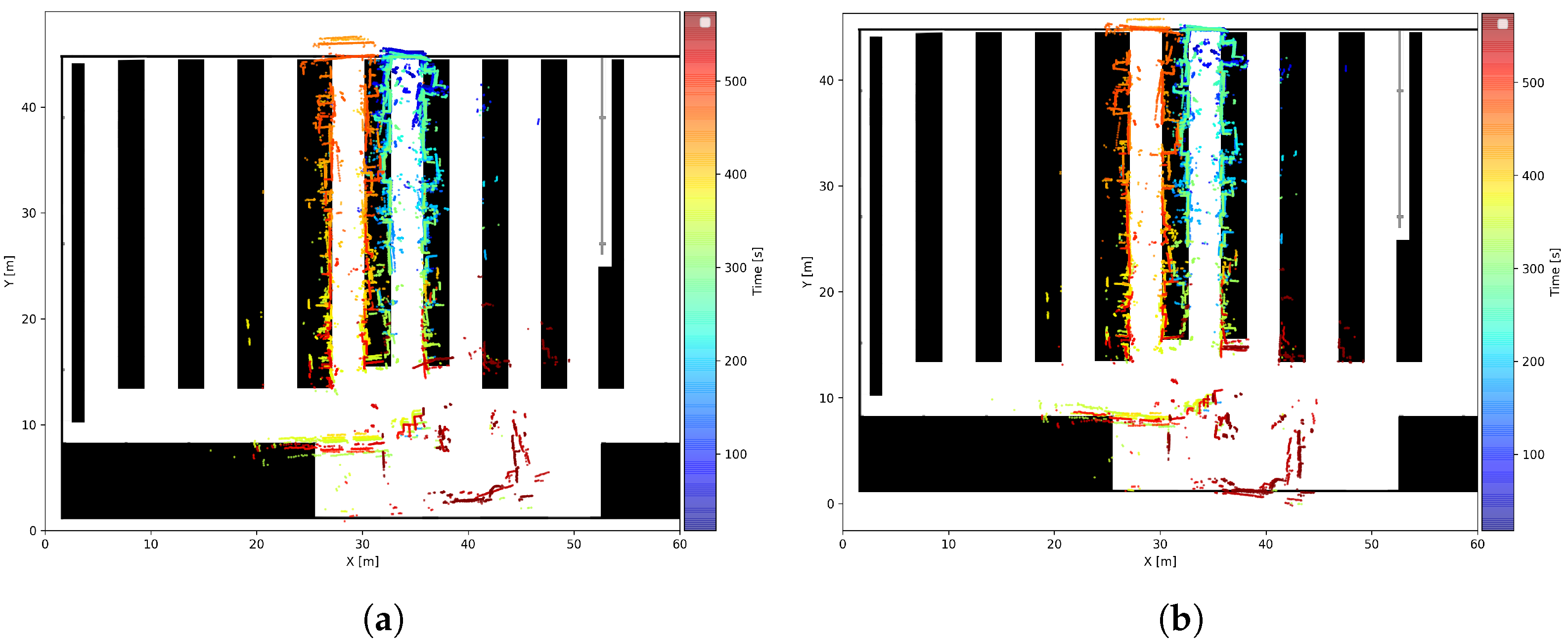

4.1.2. Experiments at Warehouse

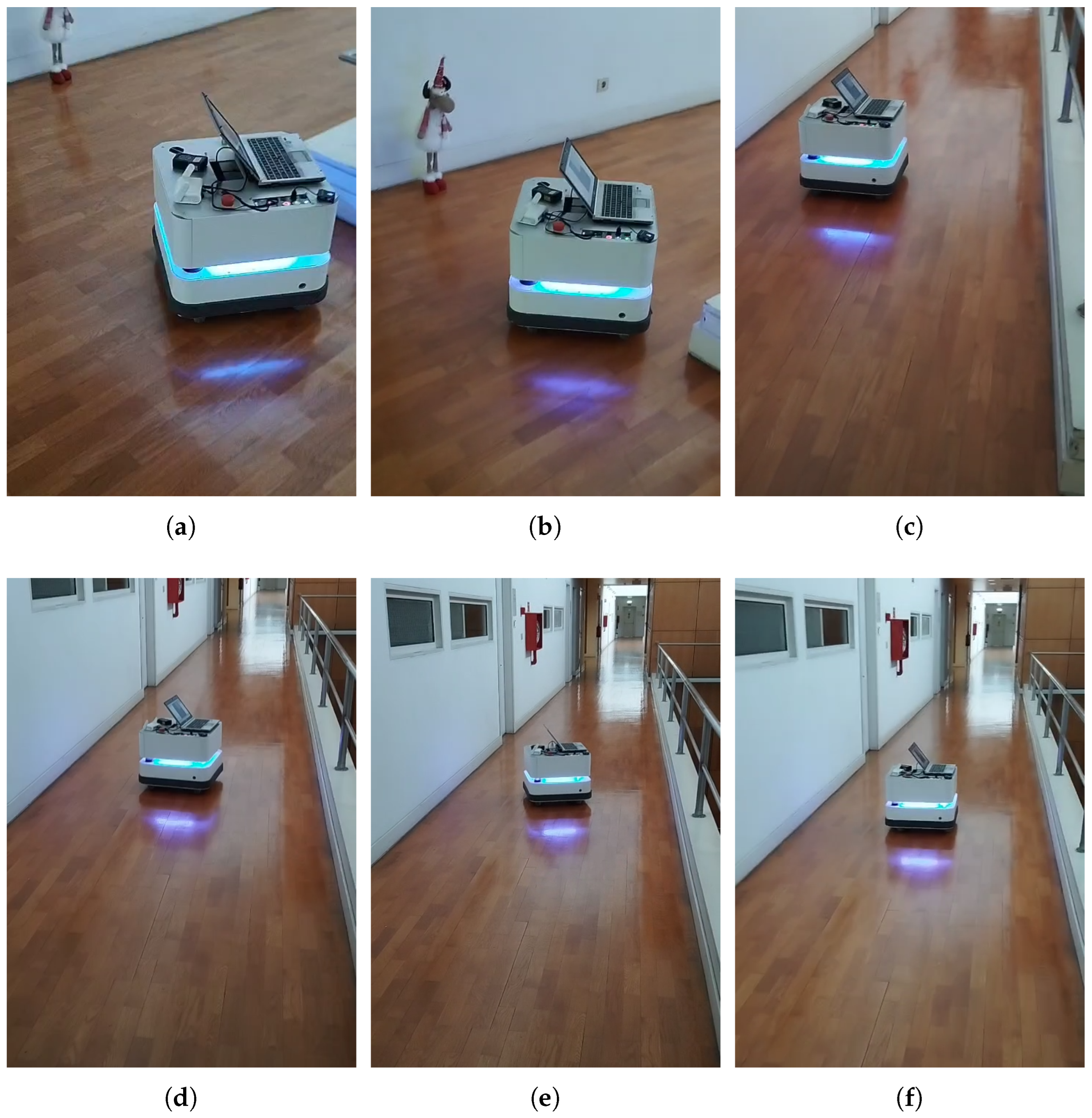

4.2. UAV Experiments

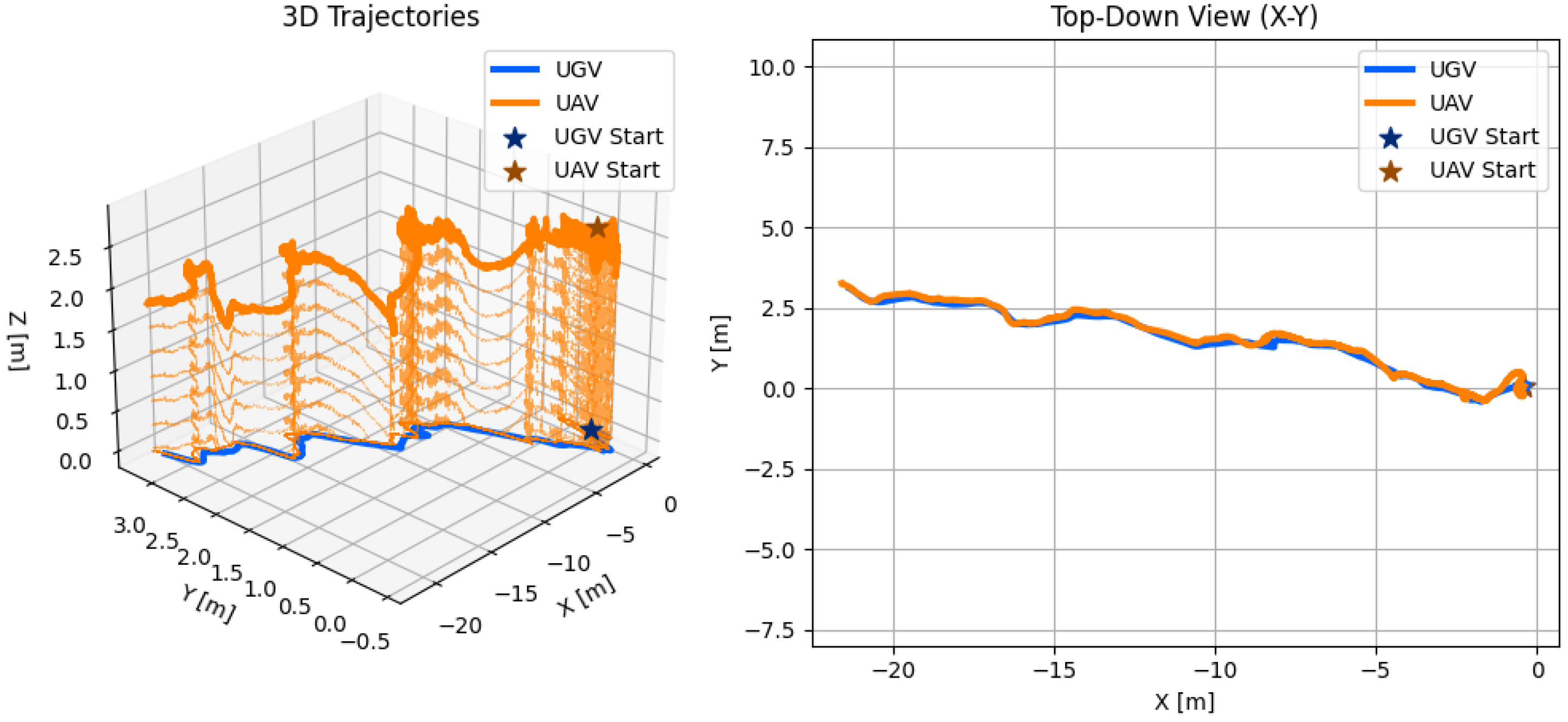

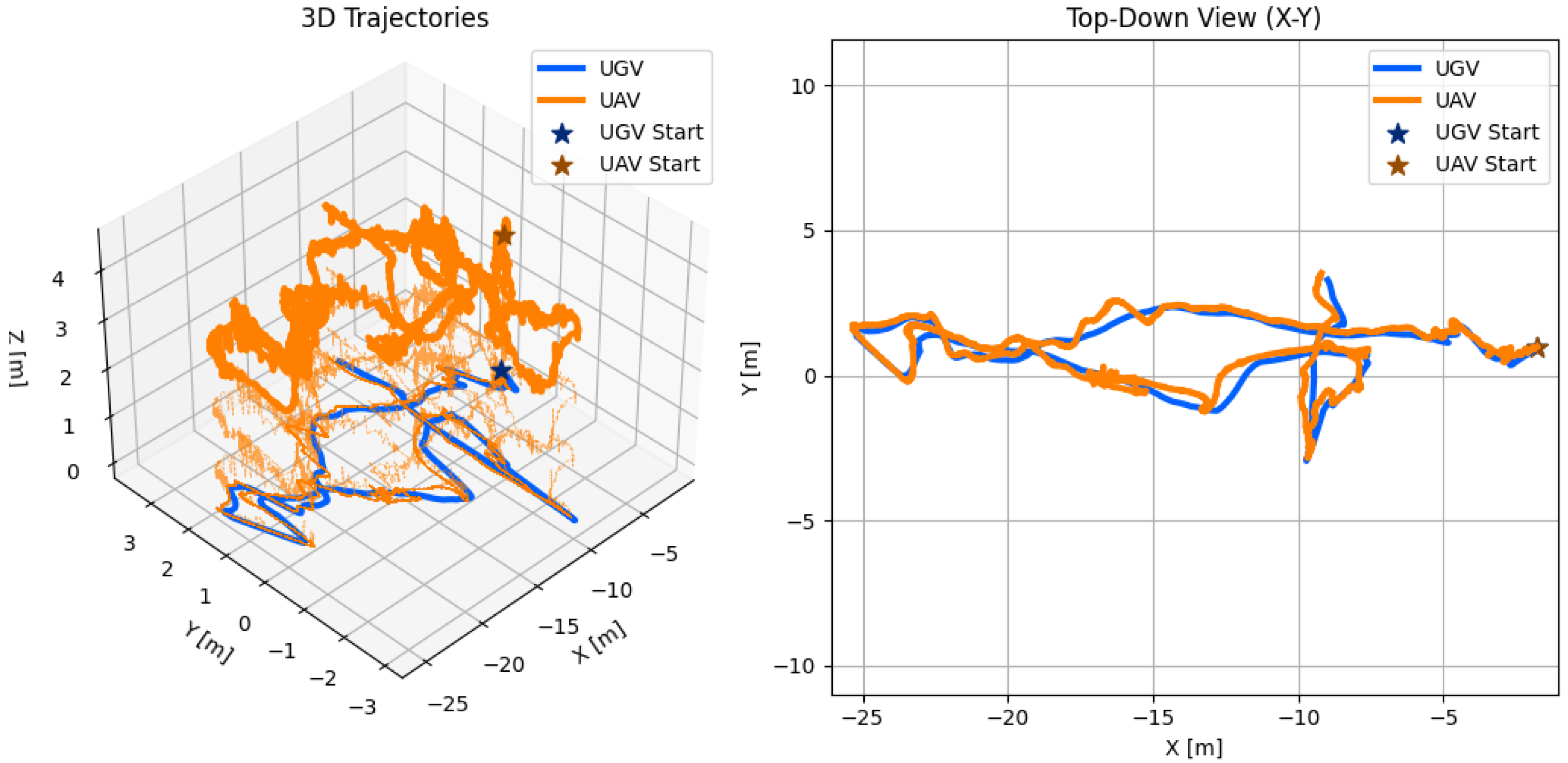

4.2.1. Follow Mode

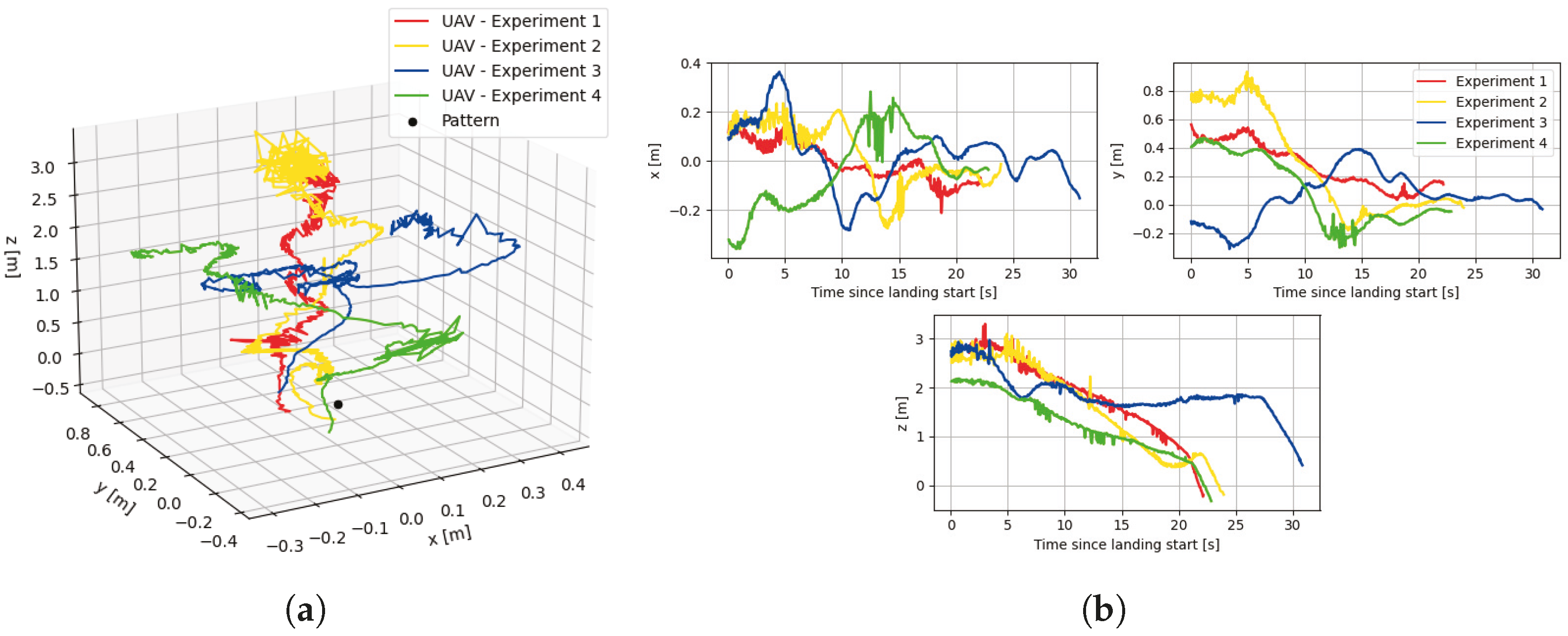

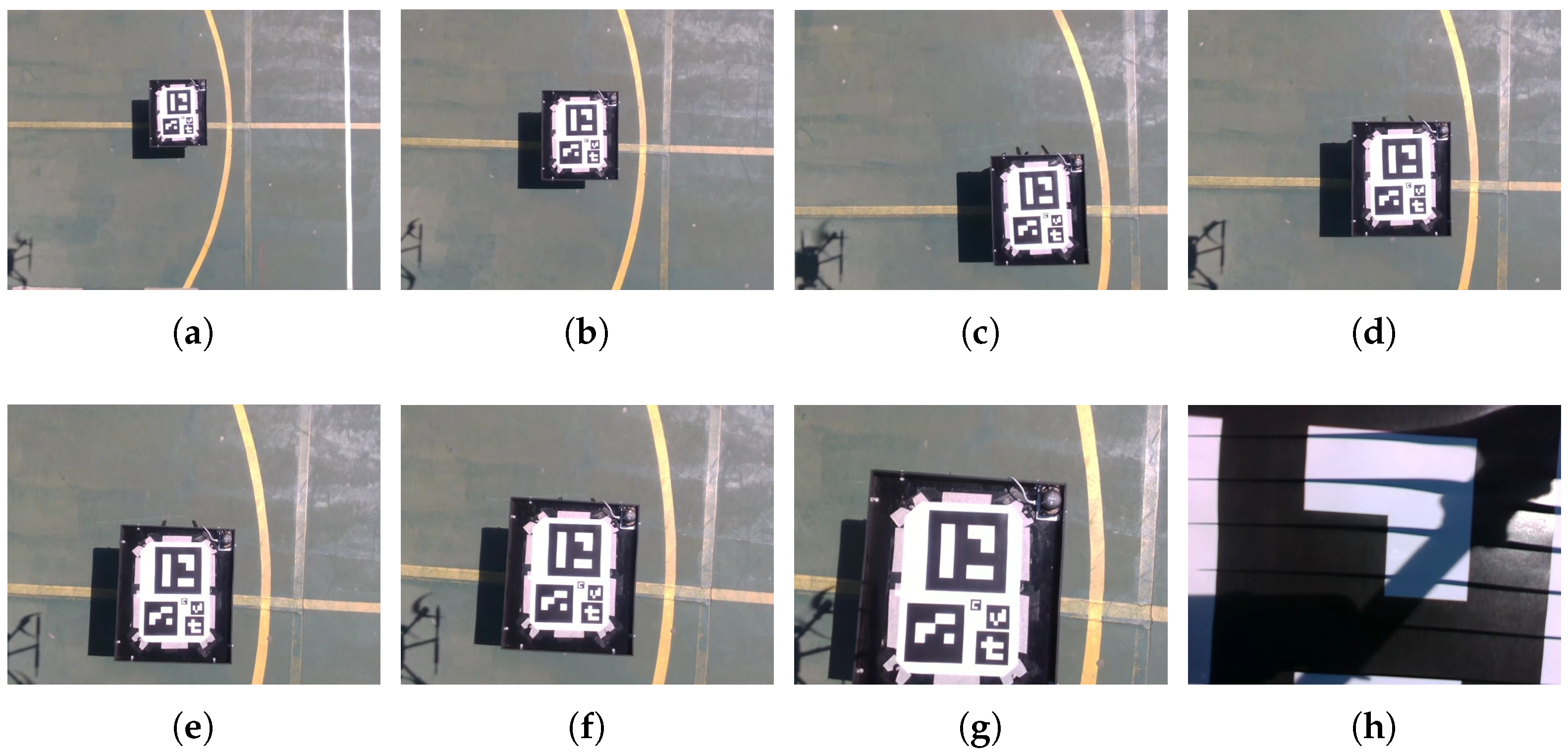

4.2.2. Landing Mode

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kembro, J.; Norrman, A. The transformation from manual to smart warehousing: An exploratory study with Swedish retailers. Int. J. Logist. Manag. 2022, 33, 107–135. [Google Scholar] [CrossRef]

- Gago, R.M.; Pereira, M.Y.A.; Pereira, G.A.S. An aerial robotic system for inventory of stockpile warehouses. Eng. Rep. 2021, 3, e12396. [Google Scholar] [CrossRef]

- Kalinov, I.; Safronov, E.; Agishev, R.; Kurenkov, M.; Tsetserukou, D. High-Precision UAV Localization System for Landing on a Mobile Collaborative Robot Based on an IR Marker Pattern Recognition. In Proceedings of the 2019 IEEE 89th Vehicular Technology Conference (VTC2019-Spring), Kuala Lumpur, Malaysia, 28 April–1 May 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Harik, E.H.C.; Guérin, F.; Guinand, F.; Brethé, J.F.; Pelvillain, H. Towards An Autonomous Warehouse Inventory Scheme. In Proceedings of the 2016 IEEE Symposium Series on Computational Intelligence (SSCI), Athens, Greece, 6–9 December 2016; pp. 1–8. [Google Scholar] [CrossRef]

- Dhaliwal, A. The rise of automation and robotics in warehouse management. In Transforming Management Using Artificial Intelligence Techniques; CRC Press: Boca Raton, FL, USA, 2020; pp. 63–72. [Google Scholar]

- de Koster, R. Automated and Robotic Warehouses: Developments and Research Opportunities. Logist. Transp. 2018, 38, 33–40. [Google Scholar] [CrossRef]

- Custodio, L.; Machado, R. Flexible automated warehouse: A literature review and an innovative framework. Int. J. Adv. Manuf. Technol. 2020, 106, 533–558. [Google Scholar] [CrossRef]

- Inventory Drone—EYESEE. Available online: https://www.eyesee-drone.com/inventory-drone/ (accessed on 22 April 2025).

- Corvus Robotics—Warehouse Inventory Drones. Available online: https://www.corvus-robotics.com/ (accessed on 23 April 2025).

- Infinium Scan. Available online: https://infiniumrobotics.com/infinium-scan/ (accessed on 22 April 2025).

- Inventory with Drones—Doks.inventairy. Available online: https://doks-solution.com/doks-inventairy-drohne-inventur-lager-indoor/ (accessed on 22 April 2025).

- Dexory. Available online: https://www.dexory.com/ (accessed on 7 April 2025).

- DroneScan. Available online: https://www.dronescan.co/ (accessed on 23 April 2025).

- Guinand, F.; Guérin, F.; Petitprez, E. UAV-UGV Multi-robot System for Warehouse Inventory: Scheduling Issues. In Proceedings of the Computational Collective Intelligence, Rhodes, Greece, 29 September–1 October 2021; Nguyen, N.T., Iliadis, L., Maglogiannis, I., Trawiński, B., Eds.; Springer: Cham, Switzerland, 2021; pp. 241–254. [Google Scholar]

- Zhong, Y.; Wang, Z.; Yalamanchili, A.V.; Yadav, A.; Srivatsa, B.R.; Saripalli, S.; Bukkapatnam, S.T. Image-based flight control of unmanned aerial vehicles (UAVs) for material handling in custom manufacturing. J. Manuf. Syst. 2020, 56, 615–621. [Google Scholar] [CrossRef]

- Kwon, W.; Park, J.H.; Lee, M.; Her, J.; Kim, S.H.; Seo, J.W. Robust Autonomous Navigation of Unmanned Aerial Vehicles (UAVs) for Warehouses’ Inventory Application. IEEE Robot. Autom. Lett. 2020, 5, 243–249. [Google Scholar] [CrossRef]

- Qiu, Z.; Lin, D.; Lv, J.; Sun, Z.; Zheng, Z. A Closed Stockyard UAV Intelligent Inventory System. J. Phys. Conf. Ser. 2023, 2513, 012010. [Google Scholar] [CrossRef]

- Moura, A.; Antunes, J.; Dias, A.; Martins, A.; Almeida, J. Graph-SLAM Approach for Indoor UAV Localization in Warehouse Logistics Applications. In Proceedings of the 2021 IEEE International Conference on Autonomous Robot Systems and Competitions (ICARSC), Feira, Portugal, 28–29 April 2021; pp. 4–11. [Google Scholar] [CrossRef]

- Beul, M.; Droeschel, D.; Nieuwenhuisen, M.; Quenzel, J.; Houben, S.; Behnke, S. Fast Autonomous Flight in Warehouses for Inventory Applications. IEEE Robot. Autom. Lett. 2018, 3, 3121–3128. [Google Scholar] [CrossRef]

- Lewis, J.; Lima, P.U.; Basiri, M. Collaborative 3D Scene Reconstruction in Large Outdoor Environments Using a Fleet of Mobile Ground Robots. Sensors 2023, 23, 375. [Google Scholar] [CrossRef]

- Kalinov, I.; Petrovsky, A.; Ilin, V.; Pristanskiy, E.; Kurenkov, M.; Ramzhaev, V.; Idrisov, I.; Tsetserukou, D. WareVision: CNN Barcode Detection-Based UAV Trajectory Optimization for Autonomous Warehouse Stocktaking. IEEE Robot. Autom. Lett. 2020, 5, 6647–6653. [Google Scholar] [CrossRef]

- IDMind. IDMind—Living Robotics. Available online: https://www.idmind.pt/ (accessed on 3 May 2025).

- Carpenter, J.R.; D’Souza, C.N. Navigation Filter Best Practices; Technical Report; NASA, Langley Research Center: Hampton, VA, USA, 2018.

- Kohlbrecher, S.; von Stryk, O.; Meyer, J.; Klingauf, U. A flexible and scalable SLAM system with full 3D motion estimation. In Proceedings of the 2011 IEEE International Symposium on Safety, Security, and Rescue Robotics, Kyoto, Japan, 1–5 November 2011; pp. 155–160. [Google Scholar] [CrossRef]

- Pomerleau, F.; Colas, F.; Ferland, F.; Michaud, F. Relative Motion Threshold for Rejection in ICP Registration. In Field and Service Robotics; Howard, A., Iagnemma, K., Kelly, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2009; Volume 62, pp. 229–238. [Google Scholar] [CrossRef]

- Morales, J.; Castelo, I.; Serra, R.; Lima, P.U.; Basiri, M. Vision-Based Autonomous Following of a Moving Platform and Landing for an Unmanned Aerial Vehicle. Sensors 2023, 23, 829. [Google Scholar] [CrossRef] [PubMed]

- AWS Robotics. AWS RoboMaker Small Warehouse World—GitHub Repository. Available online: https://github.com/aws-robotics/aws-robomaker-small-warehouse-world (accessed on 4 May 2025).

- Thrun, S.; Fox, D.; Burgard, W.; Dellaert, F. Robust Monte Carlo localization for mobile robots. Artif. Intell. 2001, 128, 99–141. [Google Scholar] [CrossRef]

- Konolige, K.; Grisetti, G.; Kümmerle, R.; Burgard, W.; Limketkai, B.; Vincent, R. Efficient Sparse Pose Adjustment for 2D mapping. In Proceedings of the 2010 IEEE/RSJ International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; pp. 22–29. [Google Scholar] [CrossRef]

- Grisetti, G.; Stachniss, C.; Burgard, W. Improved Techniques for Grid Mapping With Rao-Blackwellized Particle Filters. IEEE Trans. Robot. 2007, 23, 34–46. [Google Scholar] [CrossRef]

- Ferreira, D.; Basiri, M. Dynamic Target Tracking and Following with UAVs Using Multi-Target Information: Leveraging YOLOv8 and MOT Algorithms. Drones 2024, 8, 488. [Google Scholar] [CrossRef]

| ID | x [cm] | y [cm] | Size [cm] |

|---|---|---|---|

| 10 | −3.9 | −3.5 | 2.5 |

| 55 | −6.3 | −8.6 | 5.4 |

| 168 | −13.4 | −7.3 | 7.5 |

| 227 | −10.4 | 5.6 | 13.1 |

| 946 | 8.2 | 1.2 | 18.4 |

| [m/s] | [m/s 2] | |||

|---|---|---|---|---|

| x | 0.40 | 0.40 | 0.15 | 0.0001 |

| y | 0.40 | 0.40 | 0.15 | 0.0001 |

| z | 0.35 | 0.17 | 0.40 | 0.01 |

| 0.15 | 0.25 | 0.50 | 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaffilla, R.; Alvito, P.; Basiri, M. Collaborative Infrastructure-Free Aerial–Ground Robotic System for Warehouse Inventory Data Capture. Drones 2025, 9, 792. https://doi.org/10.3390/drones9110792

Chaffilla R, Alvito P, Basiri M. Collaborative Infrastructure-Free Aerial–Ground Robotic System for Warehouse Inventory Data Capture. Drones. 2025; 9(11):792. https://doi.org/10.3390/drones9110792

Chicago/Turabian StyleChaffilla, Rafaela, Paulo Alvito, and Meysam Basiri. 2025. "Collaborative Infrastructure-Free Aerial–Ground Robotic System for Warehouse Inventory Data Capture" Drones 9, no. 11: 792. https://doi.org/10.3390/drones9110792

APA StyleChaffilla, R., Alvito, P., & Basiri, M. (2025). Collaborative Infrastructure-Free Aerial–Ground Robotic System for Warehouse Inventory Data Capture. Drones, 9(11), 792. https://doi.org/10.3390/drones9110792