Abstract

Plant protection unmanned aerial vehicles (UAVs) play a crucial role in agricultural aviation services. In recent years, plant protection UAVs, which improve the accuracy and eco-friendliness of agricultural techniques, have been used to overcome the shortcomings of traditional agricultural operations. First, this paper introduces the development scale, main types, and operation scenarios of China’s plant protection UAVs. Subsequently, the key technologies of plant protection UAVs, such as precision autonomous flight control, pesticide spraying, drift control, and spraying quality measurement technologies, are reviewed. Next, the emergent technologies of plant protection UAVs are studied and analyzed with a focus on better spray effects, calculation models of droplet drift, controllable droplet size atomization technology, droplet drift detection technology, and droplet deposition quality detection technology in the application of plant protection UAVs. Moreover, the technologies of plant protection UAV application are summarized and future research prospects are presented, offering ideas for follow-up research on the key technologies of plant protection UAVs and encouraging agricultural production management to move toward better efficiency, eco-friendliness, and accuracy.

1. Introduction

A plant protection unmanned aerial vehicle (UAV) is a type of operation equipment that integrates pesticide spray equipment on a UAV to spray pesticides on crops. As an integral part of modernization in agricultural equipment, it has been in a stage of rapid development in recent years. Plant protection UAVs are widely used in the prevention and control of diseases, insect pests, and weeds in agriculture and forestry because of their high operational efficiency, wide terrain adaptability, safe applicability, etc. In recent years, different types of UAVs and pesticide control technologies have been developed to achieve dedicated and precise spraying and efficient and intelligent operation. At present, the main application scenarios of plant protection UAVs in modern agriculture are as follows: crop agricultural pesticide spray and fertilization, farmland irrigation, crop sowing, farmland information monitoring, and forest pest monitoring and control.

In the operation process, plant protection UAVs are an underactuated system whose flight stability is easily affected by near-ground environmental factors such as natural wind and electromagnetic interference in the farmland environment. Additionally, their flight stability is dependent on whether information on the farmland and operation conditions can be collected. When applied in complex environments, UAVs fulfill the stricter demand for accurate control by optimizing the software and hardware of the flight control system. In agricultural applications, plant protection drones are required to be not only stable but also, in the application of pesticides, to ensure that precise variable spraying can maximize the utilization rate of agricultural pesticides and reduce environmental pollution simultaneously. Large amounts of farmland in China are threatened by diseases, insect pests, and weeds every year. Traditional methods of spraying are time-consuming, laborious, and inefficient. To overcome these limitations, several studies have been conducted on the spraying technologies of plant protection UAVs. At this stage, the key techniques of plant protection UAV spraying mainly focus on variable-speed spraying, prescription spraying, real-time variable spraying based on target detection, and intelligent spraying. Additionally, it is also necessary to reduce droplet drift, decrease the occurrence of secondary disasters, improve the utilization rate of agricultural pesticides, and evaluate the effect of droplet deposition. The monitoring and prediction of droplet drift deposition is also an area of interest in recent research.

This study summarizes and analyzes the development scale, main types, and operation scenarios of plant protection UAVs in China and summarizes the development status of key technologies for plant protection UAV sprays. By analyzing the emergent technologies of plant protection UAVs, the future development direction of plant protection UAV spraying technology can be determined, with the hope that it can provide a reference for scientific research and for application to scientific research institutions and enterprises in the industry.

Currently, studies on the development status and key technologies of plant protection UAVs in China are scarce. This paper summarizes the current status of development, including the scale, primary operation scenarios, and types of plant protection UAVs in China. It summarizes key technologies such as plant protection UAV precision autonomous flight control, pesticide spraying, drift control, and spraying quality measurement technologies. We examine and analyze emergent technologies such as calculation models of droplet drift, controllable droplet size atomization technology, droplet drift detection technology, and droplet deposition quality detection technology in the application of plant protection UAVs. Moreover, the future development direction of plant protection UAV key technologies is demonstrated to provide a theoretical basis and practical reference for scientific research and for application to scientific research institutions and enterprises in the industry, and to help accelerate the development of China’s plant protection UAV industry.

2. Development and Application of Plant Protection UAVs in China

2.1. Development of Plant Protection UAVs

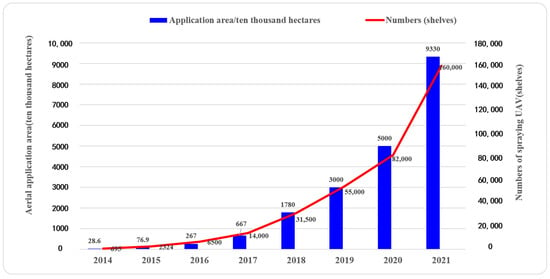

In 2014, multi-rotor-based plant protection drones began to appear in China. Owing to the simple and stable structure and low development costs, multi-rotor plant protection drones have found wide-spread application in China. The number of units increased from more than 4000 in 2016 to 160,000 in 2021, and the operating area increased from 6.67 million hectares in 2017 to 93.3 million hectares in 2021 [1]. According to the statistics of the Civil Aviation Administration of China, there were a total of 832,000 registered UAVs in the whole industry in 2021, including 160,000 plant protection UAVs accounting for 19.2% of all registered UAVs. The overall growth rate of the industry is 80%. In the next 2 to 3 years, China’s plant protection UAV market is expected to maintain a growth rate of more than 50–60%, while plant-protection UAV ownership is expected to reach 250,000 units and the operating area to reach 133 million hectares or more. As is shown in Figure 1, the number and application area of plant protection UAVs in China in recent 8 years have increased dramatically.

Figure 1.

Numbers and application area of plant protection UAVs in China.

2.2. Main Operation Scenes of Plant Protection UAVs

Plant protection UAVs are widely used in agriculture and forestry pest control because of their high efficiency, wide terrain adaptability, and safe application of pesticide separation.

In the prevention and control of agricultural diseases, pests, and weeds, the traditional means of crop disease monitoring is unable to meet the requirements of precision agriculture in current times. The rapid and non-destructive identification and grading of crop diseases and insect pests has always been a focus of agricultural research. At present, the identification and positioning of crop diseases, insect pests, and weeds through UAV multispectral and hyperspectral imaging is the primary way to achieve precise spraying application. Remote sensing monitoring of pests and diseases is required as crop diseases and insect pests cause changes in the cell pigment structure, water and nitrogen content, and external shape of crop leaves, thus causing changes in crop spectral reflectance. For the crop canopy, plant diseases and insect pests can cause changes in crop leaf area index, biomass coverage, etc., and hence, the spectral reflectance of plant diseases and insect pests is significantly different from the spectral reflectance of normal crops in the visible to thermal infrared band. Agricultural pests and diseases affect crops such as: rice, corn, fruit trees, and other bulk economic crops. In terms of weed monitoring, algorithms for weed identification in corn fields have been developed which can reduce herbicide application and improve the accuracy of corn planting management. Extensive studies using plant protection drones for weeding and spraying have been conducted, including the control of weeds in corn, rice, soybeans, and wheat fields.

In forestry pest control, using UAVs to monitor forestry information is an important direction to improve forestry informatization and precision, and it is also a powerful means of forestry pest control. Compared with traditional forestry monitoring methods, UAVs can accurately obtain multi-scale, multi-temporal, and high-resolution imagery data in real time and process and classify the images to precisely identify trees and their pests and diseases. As a crucial branch of machine learning, deep learning has become a popular technology used in image processing in recent years, and it is gradually being applied in forestry pest control to enhance the early detection of forest pests. In recent years, plant protection UAVs have played an especially irreplaceable role in preventing and controlling major forest diseases and pests such as pine wilt nematode disease, Hyphantria cunea, and pine caterpillars. Obtaining the distribution of pests and diseases and achieving fixed-point, timing, and quantitative precision spraying using plant protection UAVs’ remote sensing images can result in the accurate prevention and efficient control of pests and diseases.

2.3. Types of Plant Protection UAVs

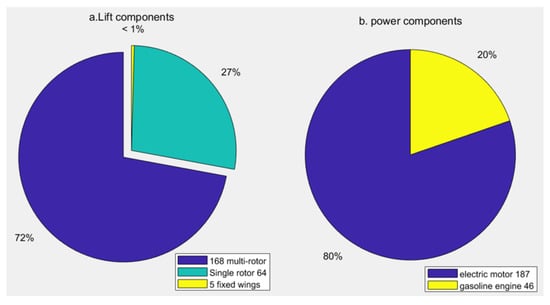

Plant protection UAVs can be divided into various types according to different classification methods. Regarding power, they can be divided into gas-powered, electric, and petrol–electric hybrid plant protection UAVs. Regarding model structure, they can be divided into single-rotor, multi-rotor, and fixed-wing plant protection UAVs. Different rotor types of plant protection UAVs are shown in Figure 2.

Figure 2.

Plant protection UAVs.

Single-rotor plant protection UAVs usually use fuel as their energy source and have the advantages of heavy load, strong downwash airflow, and long endurance time. However, their disadvantages include high complexity of their flight control systems, high maintenance costs, and a large proportion of fuselage weight. Multi-rotor plant protection UAVs have developed rapidly in recent years because of their simple control and high degree of intelligent operation. They account for more than 70% of the plant protection UAV market and generally use a battery as their energy source and a motor as the electric–kinetic energy conversion device. The multi-rotor stability design ensures better flight stability, maneuverability, and energy conversion efficiency. With the continuous development of energy density in batteries, their endurance time has gradually increased from 12 min in 2014 to more than 25–30 min currently, the payload capacity has increased from 12 kg to 50 kg, and the costs of the aircrafts have lowered and are more maintenance-friendly [2]. At present, in order to improve the endurance time of electric multi-rotor UAVs, a small number of petrol–electric hybrid plant protection UAVs have also been developed. These kinds of UAVs convert fuel into electricity constantly and store it in batteries to provide power for multi-rotors. However, owing to the increase in system complexity, these UAVs generally have a higher failure rate and less large-scale applications, and thus, they are only used in particularly demanding application scenarios.

There are approximately 233 types of plant protection UAV types in China [3], including 64 single-rotor types, accounting for approximately 27%; 168 multi-rotor types, accounting for approximately 72%; and 5 fixed-wing types, accounting for approximately 1% of plant protection UAVs (Figure 3a); the gas-powered type accounts for approximately 20% and the battery-powered type accounts for approximately 80% (Figure 3b) [4]. The above data show that the plant protection UAVs in China are mainly battery-powered multi-rotor aircrafts. In the fierce market competition of hundreds of enterprises, DJI Innovation and XAG together occupy nearly 80% of plant protection UAVs in the Chinese market. Since electric multi-rotor UAVs have significant advantages in operation, maintenance, and training, it is expected that plant protection UAVs in China will continue to be dominated by electric multi-rotor UAVs in the next few years.

Figure 3.

Type and proportion of lift and power components in plant protection UAVs.

3. Key Technologies for the Application of Plant Protection UAVs

In the operation of plant protection UAVs, a variety of key techniques are involved, including: the precision autonomous flight control method, precision spraying application technology, droplet drift control technology, and operation quality assessment technology. When a plant protection UAV is working, multiple sensors jointly control its flight altitude height, route, etc. Plant protection UAVs have the ability to operate in complex environments by identifying obstacles and complex terrain using sensors. Each pesticide-spraying method has its own advantages and disadvantages. Selecting the appropriate spraying method under specific conditions can improve agricultural pesticide utilization and control. There is a certain off-target drift in the spraying process of plant protection UAVs, so the study of droplet drift control technology has practical significance. Further optimization of the key techniques for the application of plant protection UAVs can be realized by controlling the quality of operation and evaluating the spraying effect in real time.

3.1. Plant Protection UAV Precision Autonomous Flight Control Technology

3.1.1. Obstacle-Avoidance Control Technology

The farmland operation environment is complex, and UAVs often encounter obstacles such as trees, wires, and buildings during operation. Hence, autonomous identification and real-time avoidance of obstacles are essential for the autonomous flight of plant protection UAVs. A farmland is typically an unstructured environment with various kinds of irregularly distributed obstacles. Therefore, sensors are required to detect and identify obstacles quickly. At present, there are two main problems in the obstacle-avoidance technology of plant protection UAVs: a lack of definition and division of farmland obstacles, and a lack of technical performance indicators in the obstacle-avoidance system, such as response time, obstacle-avoidance speed, etc. A performance comparison of the obstacle-avoidance sensors of different types of navigation is shown in Table 1.

Table 1.

Performance comparison of obstacle-avoidance sensors of different types of navigation.

Based on dual millimeter-wave radar, Sun et al. [5] designed an automatic obstacle-avoidance system for plant protection UAVs. The obstacle-avoidance system was able to detect obstacle parameters effectively. The detection error of the front distance, lateral distance, and width of the obstacle were less than ±115 mm, less than ±195 mm, and less than ±235 mm, respectively. The lateral movement error and forward movement error were less than ±500 mm. Taking a mountain orchard as the research object, Wang et al. [6], designed a flight path control system for plant protection UAVs in mountain orchards by fusing a global navigation satellite system (GNSS) and machine vision. Through field track-control testing in the mountain apple orchard, it was verified that the system achieved high accuracy. Zheng et al. [7] proposed an online rolling optimization method for bidirectional rapidly exploring random trees (RRT) routes based on centroid bias sampling. The entire trajectory dynamics optimization of the planned trajectories was carried out using the minimum snap method and the high- and low-expansion grid probability map method. By simulating different scenarios, it was found that the improved bidirectional RRT algorithm reduces the number of iterations of obstacle-avoidance trajectory re-planning by 23.69% compared with the number of iterations before improvement. The effective obstacle-avoidance trajectory planning time was lesser than 0.33 s, the average obstacle-avoidance trajectory speed was higher than 1.16 m/s, and the obstacle-avoidance trajectory extension rate was less than 20.82%. To reduce the influence of unknown external interference and the uncertainty of internal parameters that always exists in the heading system of small-scale unmanned helicopters, Ding et al. [8] designed a heading controller for unmanned helicopters based on the linear active disturbance-rejection control (LADRC) algorithm. The tracking experiment of the heading angle was carried out using a Trex-600 unmanned helicopter system. The results show that the steady-state tracking error based on LADRC was within ±2.86°. Li et al. [9] proposed a method of autonomous obstacle avoidance in end-to-end plant protection UAVs based on deep learning. They used the binocular vision mounted on the plant protection UAV to collect images in real time while combining the convolutional neural network for information training. This method has the advantages of being systematic, being streamlined, having strong environmental adaptability, and having high system robustness.

In summary, several studies have been conducted on obstacle-avoidance control in UAVs in China. However, most studies use single-transmitting sensors to identify obstacles, do not entail environmental dynamic perception, and lack obstacle-avoidance systems that combine visual and non-visual sensors. Furthermore, the calculation time of the path-search algorithm is extremely long. Additionally, multi-sensor fusion obstacle-avoidance systems are expected to become the mainstream autonomous real-time obstacle-avoidance systems for plant protection UAVs. Real-time active obstacle avoidance will greatly improve the safety, reliability, and intelligence of plant protection UAV operations.

3.1.2. Terrain-Following Control Technology

Terrain-following control technology refers to the real-time control of the height of the fuselage and crop canopy when the plant protection UAV is operating autonomously. When encountering a slope, the sensor needs to identify it in advance and control the pitch angle of the aircraft to keep the relative height of the crop canopy stable. Owing to differences in the crop-canopy density, distribution, and morphology, the detection accuracy of the relative distance between the fuselage and crop canopy is the key factor that will influence the terrain-following control effect.

With a focus on distribution characteristics and terrain characteristics of the fruit tree canopy in mountain apple orchards, Wang [10] studied a three-dimensional (3D) point-cloud extraction algorithm based on binocular vision images. Subsequently, the multi-point ranging method based on binocular vision was explored, and the UAV flight height imitation control method based on binocular vision was proposed. The ranging and control accuracy of the flight height imitation control algorithm were experimentally verified. The results showed that the average error of the terrain-following control was 0.01 m and the maximum error was 0.15 m when the flight height was 2.5 m. Wu [11] used 3 mm-wave radar sensors to measure the oblique distance between the UAV and the front terrain as well as the relative height with the ground in real time. Based on the slope information obtained, the corresponding height-fusion algorithm was selected and the fuzzy proportion integration differentiation (PID) control algorithm was combined to achieve high-precision terrain-following flight. Wang [12] developed a multi-sensor fusion localization algorithm based on inertial navigation, an optical flow sensor, an ultrasonic sensor, and barometer data by analyzing the mathematical relationship between the position of motion of the multi-rotor and sensors, and establishing the Kalman filter equation based on multi-sensor data Fusion. Subsequently, error data were processed and Chi-square tests were conducted for the sensors. Finally, the position for the multi-rotor to fly near the ground was calculated. Niu [13] achieved real-time control of UAV height using multiple TOF sensors. Using real-time distance measurement of terrain under different viewing angles, UAVs can achieve efficient and complex terrain-following control. At the same time, flight data were collected based on multiple airborne time-of-flight (TOF) sensors and a VICON spatial location system, which provided basic data support for further research on UAV terrain-following control methods based on deep learning.

In summary, the main terrain-following control methods are to combine the sensors and control algorithms such that they control the height difference between the UAV and crop canopy in coordination. At present, improving the robustness and operation accuracy of the multi-sensor fusion algorithm is the main breakthrough point of UAV terrain-following control methods. The focus of subsequent research is setting the slope threshold based on the adaptive algorithm according to geographical conditions and flight height, and accurate control of the relative height distance between the UAV and ground crop canopy in real time.

3.1.3. Navigation Path-Planning Technology

The working path is the basis of the tracking and flying of the machine when UAVs operate autonomously, and determines the quality, efficiency, and total consumption of the machine operation process to a great degree. The basic requirement of path planning in the operation process of plant protection UAVs is to cover all the operation areas at a low cost. By effectively integrating the latitude and longitude information with an electronic map, an optimal operation path- and operation trajectory-planning map can be established with the constraints of the energy, dosage, and turning radius of the UAV, combining the processing of the operation farmland terrain information and operation plot information of the planning algorithm.

At present, research on the operation-path-planning method in agricultural plant protection UAVs focus on the following two aspects: multi-flight operation in a single area and multi-disconnected area operation scheduling. Practically, the operation efficiency of a single plant protection UAV is limited. Kan [14] used multiple plant protection UAVs to plan the co-operative path of multiple plant protection UAVs in different operating areas by improving the particle swarm optimization (PSO) algorithm and optimizing the return order and return point position of each UAV. Wang [15] proposed a 3D path-planning method based on the gravitational search algorithm (GSA) for plant protection UAVs. Due to the addition of height information to the rasterized environment model, the distance calculation of UAVs in the simulation algorithm includes the increase in distance caused by height fluctuation. The established objective function also considers changes in the take-off and landing distance of the UAV caused by the height fluctuation of the terrain between the return and support points, thus enhancing the reliability of the calculation results. In order to cope with more complex environments and plan more efficient paths, an operation-path-planning algorithm with boundary universality was proposed and implemented for rotor-based unmanned aircraft systems to quickly obtain the flight trajectory for fields with all kinds of boundaries, including convex polygons, concave polygons, and even polygons with holes and multiple polygons [16]. Wang et al. [17] proposed a new path-planning approach for plant protection UAVs based on the improved ant colony optimization, which is suitable for multiple 3D spray areas with complex polygonal boundaries and internal obstacles. Aiming to meet the real-time requirements of multi-machine co-operative operation, Cao [18] proposed a task sequence-planning scheme based on the ant colony algorithm. Task sequence optimization using the ant colony algorithm was able to effectively reduce the path cost, and the algorithm running time was less than 1 s. Plant protection UAVs encounter obstacles in spraying operations quite often. To this end, Min [19] proposed an obstacle-avoidance path-planning algorithm based on the genetic algorithm to output the optimal trajectory, and designed a robust backstepping control law to ensure that plant protection UAVs can stably track trajectory instructions. For the obstacle-containing operation area, Xu [20] proposed a UAV route-design algorithm, which is divided into two parts: path-point sampling and path-point sorting. First, the grid method was used to obtain all the valid path points, and these path points were then used to represent the characteristic information of the working area. The hybrid particle swarm optimization algorithm was used to sort the path points, and the arrangement of the path points was used to represent the flight path of the UAV. Xu [21] used the cattle ploughing reciprocation method as the operation mode of the plant protection UAV in a single region. Based on the genetic algorithm, an optimal solution for inter-regional operation sequence planning was achieved that reduced the redundant energy consumption of the plant protection UAV operation.

In summary, several studies have investigated different path-planning algorithms and achieved certain results. However, the existing UAV path-planning algorithms have a slow convergence speed and are not suitable for UAV dynamic path planning. The research on multi-UAV cooperative pesticide application path-planning technology is still in its initial stages, and it is necessary to carry out further research on the path-planning algorithm based on UAV operation ability parameters and the spraying application coverage effect.

3.2. Precision Spraying-Control Technology of Plant Protection UAVs

3.2.1. Speed-Adaptive Variable Spraying-Control Technology

Setting the flight speed of the UAV as the state variable and the amount of pesticide spraying as the control variable, speed-adaptive variable spraying-control technology focuses on using the speed-adaptive feedback variable spraying system to reduce the influence of a change in the UAV speed on the spraying amount, which will improve the uniformity of spraying. The traditional methods of precise variable spraying control are primarily variable pressure, variable concentration, and pulse width modulation (PWM) technology. The pressure-adjustment variable spray method is simple and economic, and thus, it is widely used in variable spray-control systems. However, this technology has nonlinear characteristics and has some limitations such as spray droplet distortion, poor atomization uniformity, and system pressure instability. The variable-concentration variable spray method still has problems such as complex structure, high system cost, and delayed concentration change. These two variable spraying methods are used mainly in ground plant protection machinery and are not used very frequently in plant protection UAVs. PWM variable spray controls the opening and closing time and response rate of the solenoid valve by changing the duty cycle and frequency of the PWM control signal to adjust the flow of the spray. This technology can improve the droplet distortion and system pressure instability and delay problems of variable pressure-control technology very well; moreover, it can ensure the uniformity and wide-range adjustability of pesticide spraying. It is widely used in precision variable spray operation.

To remedy the uneven distribution of droplet deposition caused by the change in UAV flight speed, Guo [22] proposed and studied the method of adjusting the nozzle flow rate, and a model of the relationship between spraying amount and flying speed was established. The system converted the flight speed of UAVs, acquired in real time, into expected flow data and converted the difference between expected flow and real-time flow into a PWM signal to control the input voltage of the diaphragm pump combined with the preset PID algorithm. The experimental results indicated that the control delay of the module was less than 100 ms, and the average control delay was 500 ms when the flow changed continuously. In the field operation test, the uneven application of pesticides was improved to a certain extent, and the uniformity of surface sediment was increased by 30.47%. Based on real-time control of the application amount with the flight speed of the plant protection UAV as the variable, Hu [23] analyzed and studied a set of variable application systems with the controllable application amount based on the flight speed of the plant protection UAV. The UAV speed signal outputted by the flight controller in real time was processed by an external micro-control unit (MCU) to form a PWM signal, and subsequently, the signal was applied to the flow-control system to realize the time-varying application of the UAV speed and volume-control research. The simulation results indicated that the motor speed-control error of the flow-control system was less than 5% under different duty cycle signals. To address the requirements of the plant protection UAV spraying operation, Liu et al. [24] proposed an aerial variable spray-grading-control algorithm and developed a real-time monitoring system suitable for China’s aerial variables by monitoring information, such as operations and other information, in real time and automatically adjusting the spray volume according to the changes in flight parameters. The results of the variable spray test show that the system can accurately regulate the spray volume with a maximum error of 9.26%. Cen et al. [25] used a neural network PID to derive an adaptive variable spray system. It can adjust the spray volume with respect to the flying speed of the UAV. The test data indicated that the average deviation between the actual spray traffic and the target spray volume was 8.43%. Wang et al. [26] designed a spraying-control system based on an advanced RISC machine (ARM) architecture single-chip microcomputer, proposed a control method for spraying flow based on PWM, and used multi-sensor fusion technology to monitor the application parameters in real time. The experimental results indicated that the dynamic variable spraying system was able to achieve the effect of automatic matching between spraying flow and flight speed when the flight speed was 0.8–5.8 m/s. The average deviation between the actual flow and the theoretical flow was 1.9%.

At present, the research on speed-adaptive variable spraying can improve the spraying effect significantly, but it cannot completely solve the problem of uneven spraying caused by the change in UAV flight speed. Therefore, we should improve the real-time stability of the variable spray system and consider the spraying scheme on the basis of environmental influences such as wind speed, wind direction, and downwash airflow.

3.2.2. Prescription-Based Variable Spraying-Control Technology

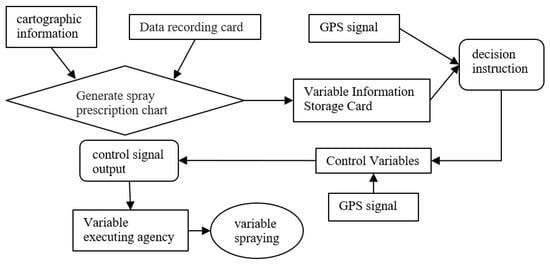

Prescription-based variable spraying-control technology is a control system that guides the variable spraying actuator to complete the variable spraying operation based on differing information on the distribution of farmland pests and weeds. The meaning of prescription application is usually multifaceted, including variable spraying prescription, operation path prescription, spraying target prescription, etc. The workflow of variable spraying system based on prescription diagram is shown in Figure 4.

Figure 4.

Workflow of variable spraying system based on prescription diagram.

Remote sensing UAVs play a vital role in variable spraying technology based on prescription maps. Through a remote sensing UAV equipped with a variety of detection devices, information on diseases, pests and weeds, crop growth, and geography is obtained, and the obtained crop and environmental information is combined to generate a variable spraying prescription decision map. Through analysis of the ground station, the ground plant protection machinery is guided to carry out variable spraying operations, and the plant protection UAV can also process the prescription map in real time for variable spraying operations. This is the primary application scenario of UAVs in prescription variable spraying. Gao et al. [27] developed a real-time interpretation system for variable spraying prescription maps based on ARM architecture. This system can extract parameters such as UAV operating position, speed, and height in real time, and address the prescription map to read the corresponding grid prescription values and send them to the variable spraying system. The test results showed that the variable conversion time of the system was approximately 0.5 s and the variable accuracy was 1 m with room for further optimization. Monitoring the effect of cotton defoliation and ripening is time-consuming and labor intensive. To satisfy the requirements of accurate variable spraying, Qi et al. [28] designed a variable spray device based on network real-time kinematics (RTK). They retrieved the prescription information of UAVs via position matching and implemented the spray decision according to the prescription information. The droplet deposition data in the prescription area were collected through experiments, thus verifying that the device was able to perform variable spray tasks. Yan et al. [29] used UAV remote sensing technology and a vegetation coverage extraction method to monitor cotton fields before and after spraying defoliant. The optimal monitoring method was used to extract information on the cotton vegetation and a variable spraying prescription map was made to guide the second defoliant spraying. The results showed that the application effect was better. Compared with the traditional quantitative application, 7.39% of the pesticide was saved, and the highest proportion of pesticide saved was 14.61%.

At this stage, plant protection UAVs are mainly based on the prescription variable spraying distribution of pests and weeds, and rarely on crop-canopy structure. With the development of pesticide-spraying technology and the diversification of the spraying objects, the prescription application has to take the characteristics of different crops into consideration and optimize the spraying decision model accordingly; moreover research must be conducted on the relationship model between crop-canopy structure morphology, spraying parameters, and the online decision system.

3.2.3. Real-Time Variable Spraying-Control Technology Based on Target Detection

Real-time variable spray based on target detection detects the target and collects its feature information in real time through various advanced-sensor detection technology (infrared, ultrasonic, light detection and ranging (LiDAR), etc.) and satellite positioning technology. The acquired feature information includes the target crop’s position and distribution range, shape contour and volume, internal structure detection, branch and leaf density, and disease, pest, and weed information. By comparing and analyzing the collected data, the spraying parameters are dynamically adjusted in real time to reduce the application of pesticide on non-targets. Research on the application of real-time variable spraying technology based on various types of sensors to identify canopy composite information started later on UAVs.

Due to limitations in the operating environment, it is difficult to apply infrared and ultrasonic sensor technologies to plant protection UAV operations and there is need for further exploration if they are to be applied in plant protection UAVs. Compared with the ultrasonic sensing measurement method, LiDAR has the advantages of high measurement accuracy and data processing speed. In [30], the leaf shape, volume, and area density of the target crop were extracted by analyzing point cloud information. Machine-vision target-detection technology uses a binocular digital camera to obtain canopy images. The canopy 3D image and structure (height, volume, LAI, etc.) parameters were obtained by obtaining the canopy volume and other parameter information through an image-processing algorithm, and the measurement error was approximately 10%. The obtained feature information was processed by the algorithm and used in the automatic target system of the plant protection UAV to achieve the effect of precise target spraying. Wang et al. [31] proposed a vision-based adaptive variable-rate spraying system. By identifying the blank area of the paddy field, the flow of the spraying system was accurately controlled to reduce the unnecessary waste of pesticides.

Compared with the traditional continuous spraying method, the real-time variable spraying-control technology based on target detection can improve the utilization rate of pesticides and operation efficiency, and reduce environmental pollution. At present, the variable spraying technology of ground-to-target spraying devices is relatively mature. The application of plant protection UAVs is limited by droplet drift control, the long-distance accurate detection technology of the target, and the low-delay-control technology of pesticide spraying.

3.3. Droplet Drift-Control Technology

During the process of pesticide spraying, approximately 20–30% of the small pesticide droplets are carried by the wind and drift to non-target areas, which is the main cause for pesticide loss and low pesticide utilization rates. Many factors influence plant protection UAV spraying and have an impact on the drift of pesticide, such as the physical and chemical properties of the pesticide being sprayed, spraying system parameters (nozzle type, spray pressure, nozzle installation angle), meteorological parameters, flight parameters, rotor wind field, etc. Several researchers have studied pesticide droplet drift in plant protection UAV spraying and have made a lot of progress. At present, the main research directions include adding anti-drift adjuvant [32], using anti-drift nozzles, effectively preventing drift and increasing the penetration of the droplet by increasing the downwash airflow field of the UAV, and reasonably controlling the flight parameters of the plant protection UAV. The principles, advantages, and disadvantages of each technology are shown in Table 2.

Table 2.

Comparison of droplet drift-control technology.

Yao et al. [33] compared the effective range and flow field distribution of an AS350B3e helicopter in four different flight-speed ranges and observed the changes in droplet drift after adding aerial adjuvant. They found that under the same operating conditions, droplet drift was reduced by 33.94% with aerial adjuvant. The addition of aerial adjuvant was able to reduce droplet drift by 33.94%. Wang et al. [34] compared and analyzed the effects of different types and concentrations of adjuvant on the drift potential index (DIX) and volume median diameter (VMD) of different nozzles using a controllable wind tunnel environment and a Spraytec droplet size analyzer. Subsequently, the droplet drift distribution characteristics of the fuel-powered single-rotor plant protection UAV under the conditions of precise operating parameters (speed and height) were studied, and the test results were correlated with crosswind speed, flight height, and flight speed. Correlation analysis and regression analysis can set the operation buffer zone to reduce the harm caused by droplet drift [35]. Wang et al. [36] conducted a wheat field spray test on four typical domestic plant protection UAVs by changing the flight parameters of UAVs and replacing pesticides with tartrazine tracer aqueous solution. The relationship between the flight parameters and droplet deposition of different types of plant protection UAVs was obtained. Revealing the influence of wind field under a UAV rotor on droplet drift deposition, Chen et al. [37] preliminarily confirmed that the wind field under the wing of the multi-rotor UAV affected the distribution of droplet deposition in a rice canopy through an aerial spraying test. The results showed that the smaller the horizontal wind speed below the rotor, the stronger the vertical wind speed, and the smaller the droplet drift. This provides an idea for reducing the drift deposition of aerial spray droplets. Zhang et al. [38] studied the atomization performance of a pulse-width-modulation variable-rate nozzle and droplet deposition characteristics in a wind tunnel environment. The test results showed that the PWM duty cycle increased, the droplet deposition evaluation index (DEIX) value decreased, and the droplet drift rate increased. Environmental wind speed and nozzle height also had an impact on droplet deposition drift. Chen et al. [39] proposed a method to adjust the spray angle and spray pressure of plant protection UAVs to reduce the drift of spray droplets. The results show that, compared with that of a system that cannot adjust the injection angle and pressure, the droplet drift distance of an adjustable system was reduced by 33.7%.

Wang et al. [40] designed a PWM variable spraying system for micro-UAVs and used a wind tunnel with controllable multi-wind speed to test the droplet deposition law of variable spraying for a hovering UAV via the phosphor test method. The test results indicated that the wind speed significantly affected droplet deposition. The droplets with a particle size of 101.74 μm were more likely to drift, the deposition peak area was concentrated beyond 4 m from the nozzle, and the drift deposition was much lower than the droplets with particle sizes of 164.00 μm and 228.16 μm. Chai [41] designed a quadratic residual compensation atomization model of electricity, which was able to realize variable particle size control in aerial spraying.

In summary, to remedy droplet drift deposition, several studies have investigated the influence of various factors on drift deposition and proposed targeted control methods, but there is a lack of overall consideration of multiple factors. The integration of related technologies can achieve a better drift reduction effect. Research on a real-time monitoring systems for droplet drift can quickly reduce unnecessary drift loss and pesticide pollution.

3.4. Spraying Quality Measurement Technology

When the plant protection UAV is spraying, spraying system parameters, meteorological parameters, flight parameters, and other factors cause problems including droplet drift, uneven deposition distribution, and low utilization of pesticides [42,43]. To measure the quality of UAV spray, the main evaluation indicators include droplet deposition amount, droplet deposition density, droplet deposition uniformity and penetration, and droplet drift rate. Measuring the amount of droplet deposition on plant leaves is an important indicator that can enable direct evaluation of the utilization rate of pesticide spray for plants. Spray effect detection technology mainly includes digital image analysis, a measurement method for droplet collector eluent based on a fluorescence spectrometer, spectral analysis, and fluorescence excitation technology.

For real-time deposition effect evaluation, Zhang et al. [44] designed a real-time monitoring system for the ground deposition of aerial spraying droplets based on variable permittivity capacitors and sensor network technology. The measurement results indicated that compared with the water-sensitive paper image analysis method, the droplet ground deposition distribution curve obtained via the two methods fit well, with an r-squared value of 0.9146, while the measurement accuracy of the droplet deposition amount was not ideal. The system can be applied to the detection of droplet deposition trends and deposition characteristics. For rapid and continuous measurement of the droplet deposition characteristic parameters of UAV spraying, an aerial spraying droplet deposition characteristic detection system based on spectral analysis and fluorescence excitation technology was developed. The spectral characteristic curve of the medium was obtained by continuously collecting droplets, and the droplet deposition characteristic parameter detection model was established [45]. Li et al. [46] designed a spray quality testing system for UAVs based on waterborne acrylic resin and digital image-processing technology. The system was able to detect three droplet parameters (droplet size, deposition density, and coverage) in real time, so as to analyze the UAV spray quality. Guo [47] optimized and improved an image-processing algorithm for droplets on water-sensitive test paper; the dynamic threshold algorithm was used to mitigate the influence of uneven image brightness on droplet region extraction. The circular-segmentation judgment method based on circularity was used for the detection of droplet deposition performance parameters as the adhesive droplet area is not easily segmented or over-segmented. Sun [48] developed a droplet deposition measurement system based on the principle of conductivity by conducting a correlation test of the conductivity of sampling liquid and determining the droplet deposition amount. The test showed that they had a good correlation under the condition of a dilute solution, and the square of the correlation coefficient reached 0.99.

At present, droplet deposition-sensing and -detection technology is in the nascent stages of development. To elaborate, the physical characteristics of different pesticides affect the measurement accuracy of sensors greatly, which inhibits them from being employed for the detection of droplet deposition in large-scale spray scenarios. Facing a wide variety of crop canopies and changing spray-working environments, large-scale field spray deposition-detection technology has problems including inconvenient layout and a large amount of data.

4. State of Current Research on Plant Protection UAVs

At present, plant protection UAVs are developing rapidly, the upstream and downstream industrial chains are gradually improving, and the operation scenarios are constantly being enriched. However, in the process of aerial spraying, the effect of droplet deposition will be affected by environmental factors, resulting in deposition area offset, and such offsets are difficult to predict. To reduce the impact of off-target droplet drift and achieve the expected spraying effect, several studies have been conducted by researchers in China. At present, the emerging technologies in China to remedy pesticide drift mainly include computational modeling simulation and prediction technology for droplet drift, controllable particle size atomization technology and equipment, accurate detection technology and systems for droplet drift, and rapid detection technology and instruments for droplet deposition in the field.

4.1. Computational Modeling Simulation and Prediction Technology for Droplet Drift

The principle of spray drift calculation modeling is to predict the droplet drift deposition area according to the current environmental wind field and operation parameters, and thus, adjust the operation parameters in real time to avoid spraying non-targets. At present, the main models used in plant protection UAV application research include: the inviscid model, the computational fluid dynamics model (including the finite volume method and finite difference method models), and the lattice Boltzmann model [49]. Comparison of advantages and disadvantages of numerical models for plant protection UAV spraying is shown in Table 3.

Table 3.

Advantages and disadvantages of numerical models for plant protection UAV spraying.

There are few studies on droplet drift based on the inviscid model. To explore the influence of the wing tip vortex of a single-rotor plant protection UAV on droplet deposition, Wen et al. [50] used computational fluid dynamics (CFD) to simulate the distribution of the wing tip vortex of a single-rotor plant protection UAV with different flight parameters. The test results showed that the drift of droplets behind the UAV will be greater when the flight speed exceeds 5 m/s. Zhang et al. [51] established a three-dimensional CFD model of the downwash airflow of a six-rotor plant protection UAV by comparing and analyzing the differences in the velocity space variation of the downwash airflow of the rotor in the presence and absence of fruit trees under the UAV. Liang et al. [52] studied droplet drift under different spray heights and spray pressures by generating different constant stress airflow fields in a closed test field. A bimodal distribution mathematical model based on a normal-distribution probability density function was established. The relationship between deposition range and deposition amount was systematically expressed, and the influence of each level factor on each parameter in bimodal distribution was analyzed. The results indicated that the multi-peak distribution better described the droplet deposition distribution (R2 ≥ 0.99) in the presence of a stress airflow field. With an increase in the number of peaks, the fitting degree of the model increased, and with an increase in crosswind speed, the fitting degree decreased. Zhang et al. [53] proposed a more convenient CFD simulation method than the traditional detection method to analyze droplet drift in the application of an N-3 unmanned helicopter. However, the simulation results were quite different from the experimental results. A possible reason may be the difference between the experimental and simulation conditions, and the decomposition of the fluorescent agent under strong sunlight could affect the experimental results, which need to be further optimized. Tang et al. [54] used computational fluid dynamics methods to investigate the downwash flow field of an agricultural helicopter (AF-25B; Copterworks) and the resulting movement characteristics of spray droplets. They proposed a method to predict the drift and deposition of aviation spray under complex conditions. Yang et al. [55] established a downwash airflow model containing six-rotor plant protection UAVs based on CFD simulation technology. They simulated and analyzed the droplet movement characteristics of centrifugal rotating nozzle spray in a downwash airflow field. Ni et al. [56] combined CFD simulation analysis and wind tunnel test methods to investigate the droplet drift law and build a relationship model between droplet drift distance and drift amount, which provided a reference for the prediction of droplet drift.

Based on analysis of the current literature, the general actual spraying operation needs quick calculation, and the research on droplet drift is based mainly on the inviscid model. Studies involving flow detail analysis and spray optimization are increasingly using the lattice Boltzmann method; for the studies on complex meteorological conditions, basic flow structure, and two-phase flow, the computational fluid dynamics model is still the best choice. A lot of calculation cycles are required to calculate the complex downwash airflow of a plant protection UAV; the calculation cycle can be reduced effectively and the practicability of the system can be improved by optimizing the adaptive grid and parallel algorithm.

4.2. Controllable Droplet Size Atomization Technology and Equipment

The parameters of droplet deposition distribution are all evaluated based on droplet size. Droplet size directly affects the application effect and the pesticide utilization rate while using plant protection UAVs. Therefore, some researchers have designed different types of controllable droplet size nozzles to control droplet size.

At present, the spraying technologies for controlling droplet size include: electric rotating cage spraying, electrostatic spraying, pressure nozzle spraying, electric centrifugal nozzle spraying, etc. Pressure nozzle spraying technology is a conventional atomization method; its advantages include low cost, long life, and strong penetrating ability. Combined with the actual operation test results, a centrifugal atomization nozzle controlled by a motor facilitates narrow droplet size distribution and a wide atomization range, which has obvious advantages over the pressure nozzle and hydraulic atomization nozzle [57]. A centrifugal spraying system has more advantages in large-load machines and fruit tree operation as it can provide a large flow, fine droplets, and adaptive powder operation (the proportion of powder in fruit tree operation is higher, and protective fungicides are used more). In small- and medium-sized load types, flow requirements are not high, and low cost and long-lasting pressure nozzle spray technology still has its own advantages. The change in droplet size resulting from a centrifugal nozzle is mostly determined by the structure and rotation speed of the centrifugal nozzle. Guo [22] proposed and developed a droplet size-control module based on a centrifugal nozzle, and established a mathematical model between flow rate, nozzle speed, and droplet size through laboratory tests. The test results indicated that the greater the speed of the centrifugal nozzle, the smaller the droplet size, and the greater the nozzle flow, the larger the droplet size. After the variable spraying system was turned on, the volume diameter of the droplet size was closer to the set optimal value of 250 μm, and the average volume diameter of the closest droplet size was 245.97 μm. Zhao et al. [58] carried out a quadratic regression orthogonal test on the atomization test platform with an Aerial-E electric rotating cage atomizer as the control object, and established a droplet size model. The results of the conducted experiments showed that the model had high prediction accuracy and was able to achieve fine control of droplet size variables during aerial spraying operations.

In summary, in studies of controllable droplet size atomization spray devices, the performance of the centrifugal nozzle is usually better than hydraulic nozzle atomization. Some researchers have developed a droplet size-control module based on centrifugal nozzles and established a droplet size model. However, the currently developed controllable droplet size atomization devices cannot achieve real-time control of droplet size based on different pesticide liquid parameters. The next step would be to conduct further research on nozzle structure design to improve pesticide utilization.

4.3. Precise Detection Technology and Systems for Droplet Drift

The operating environments of plant protection UAVs are complex. The types of surrounding crops are different and the operating area is often close to water sources and residential areas; hence, it is necessary and urgent to reduce the harm of pesticide drift pollution. Droplet drift detection technology is an emergent technique toward this end. The main droplet drift detection technologies are the rapid measurement of droplet drift based on laser photography, the three-dimensional spatial distribution test method of spray fields based on LiDAR detection technology, and the application of drift deposition monitoring systems for plant protection UAVs.

Wang [59] applied laser imaging technology to the quantitative analysis of spray drift in wind tunnels, combined with computer image batch processing technology, and the characteristic layers and parameters in the image were extracted and fitted with the actual measurement results of spray drift. A regression equation was used to establish the calculation method based on image parameters. Finally, an evaluation method for the rapid measurement of spray drift in wind tunnels, based on laser photography, was established. However, this method is limited to wind tunnels and requires external ambient light; hence, this method is difficult to employ for measurement processes except in outdoor fields. In a subsequent study, a method for all-round 3D testing of droplet deposition and drift in plant protection UAVs was proposed. This method comprehensively analyzed ground deposition, vertical deposition, ground drift, and air drift, and obtained the 3D distribution of spray droplets sprayed by plant protection UAVs [60]. Traditional droplet drift measurement technology cannot obtain the 3D spatial distribution of pesticide-spraying in real time; the accuracy of measurements is insufficient and there are environmental and human influencing factors. The sampling materials are usually arranged during measurement, and the measurement efficiency is too low. Using LiDAR detection technology, the 3D spatial distribution results of the number of droplets in a spray field were obtained in real time and all at once. The detection results indicated that the method was highly reliable and efficient for operation. Li et al. [61] proposed a test method to determine the 3D spatial distribution of spray volume based on LiDAR technology. Using a sixteen-line LiDAR sensor, 3D spatial detection was carried out for the spray fields of seven different types of nozzles under laboratory conditions. Additionally, a neural network was used to fit the detection results with the measured spray results to verify the accuracy of the method. It provided ways of realizing the rapid measurement of pesticide droplet drift caused by the wingtip vortex of a plant protection UAV. Zhang et al. [62] designed and developed a monitoring system for spray deposition and drift in plant protection UAVs. The system realized real-time monitoring of the deposition distribution and drift range in plant protection UAV pesticide application, and automatically defined the boundary of the deposition offset area and the potential risk area, prompting the operator to take necessary measures in time to reduce the risk of droplet drift. Wang et al. [63] proposed a test method for pesticide droplet drift while using plant protection UAVs in orchards based on a simulated orchard test bench and designed and manufactured a simulated vineyard test bench and an air drift-collection device.

In summary, the current 3D spatial distribution methods based on LiDAR detection spray volume are tested primarily for single-nozzle spray in the laboratory, but detection in outdoor multiple nozzles needs to be studied further. Additionally, the prediction model of deposition drift needs to be further optimized to realize the comprehensive prediction of pesticide deposition area, drift risk area, and crop-canopy deposition.

4.4. Rapid Detection Technology and Instruments for Droplet Deposition in the Field

At present, there are many detection techniques for detecting droplet deposition quality and each of them has its own characteristics. The main methods for droplet deposition quality detection include: liquid metering, image processing, optics, electromagnetism, etc. A comparison of each droplet deposition quality detection technology is shown in Table 4.

Table 4.

Comparison of droplet deposition quality detection techniques.

Among all the methods, the water-sensitive paper method is widely used for the quality detection of liquid pesticides in plant protection UAVs, which detects droplet characteristics by performing image analysis of the water-sensitive paper. In some studies, fluorescence excitation techniques have also been used to measure deposition, the principle of which is similar to the fluorescence particle tracing method and which has a higher sensitivity. However, owing to the particularity of fluorescent substances, the test results are easily affected by light and other environmental factors. To study the distribution of droplet deposition sprayed by plant protection UAVs on cotton, Hu et al. [64] used Allura Red aqueous solution as a tracer to measure the pesticide spray distribution. The parameters of the droplets were tested using droplet test cards and analyzed using the image-processing software DepositScan. However, the water-sensitive paper method usually needs to be arranged in a specific position in advance. The operation is not very convenient, the data processing steps are cumbersome, and the amount of droplet deposition cannot be displayed in real time during actual operation. In future research, the amount of droplet deposition can be quickly analyzed using water-sensitive paper.

Liu et al. [65] designed an online droplet image-collection and -analysis device based on the principle of structural light transmission and visual detection. This device detected the amount of positive and negative droplet depositions. Zhang et al. [66] used infrared thermal imaging and UAV to test the canopy temperature of crops before and after spraying, and the deposition effect of spraying on the rice canopy was reflected by the temperature change rate. For the rapid acquisition of droplet deposition on the ground after spraying, Wu et al. [67] designed an inter-digital droplet deposition acquisition system based on the principle of standing wave rate, which can achieve real-time detection of droplet deposition in a greenhouse. Experiments show that the maximum measurement error of the droplet deposition-detection system does not exceed 7.95%. Some researchers have changed their research ideas from a macro perspective, and used deep learning technologies to develop droplet deposition-detection technology. Lu et al. [68] proposed an improved SPP-Net-Inception-v4 model to overcome low classification accuracy, the requirement of a large number of network model parameters, and the slow operation speed of traditional crop-canopy pesticide deposition classification models. By overcoming the bottleneck in feature description and using a spatial pyramid pooling network (SPP-Net), the classification model realized the extraction and fusion of the performance characteristics of spraying deposition in citrus canopy thermal infrared images. The accuracy of the model was 95.07%, and it converged optimally on the validation set.

In summary, the water-sensitive paper method has its own drawbacks and does not have the ability to quickly detect droplet deposition. Therefore, the development of rapid detection sensors and detection systems for droplet deposition is a research prospect at this stage, but the current droplet deposition-sensing and -detection technologies are still in the nascent stages of development. Therefore, it is imperative to develop a new online detection system for the real-time detection of droplet deposition in large-scale spray scenarios to improve detection accuracy and provide convenient field tests to detect droplet deposition characteristics.

5. Summary and Future Scope

Spraying pesticides using plant protection UAVs greatly improves their operation efficiency. However, they are limited by crop canopy structure and terrain. With the in-depth study of plant protection UAV flight control technology, pesticide-spraying technology, pesticide drift control technology, operation detection technology, and current emergent technologies, existing farmland farming will become more efficient, resource-saving, and environmentally friendly. Plant protection UAVs have developed rapidly owing to good spraying effects, high efficiency, strong applicability, and ease of operation. The flexibility of the drones is suitable for the fragmented croplands of China. Additionally, they are less restricted by geographical conditions. At the same time, the technology also provides potential solutions to the problems of population aging and the decline in the number of farmers; hence, it is a promising prospect for agriculture.

The essence of future UAV development is data-driven aerial mobile agents in a network environment which integrate intelligent perception, intelligent cognition, and intelligent action. The production of more intelligent operation modes will enable the production of more intelligent and precise plant protection UAVs. Given the rapid development of sensors, a high-precision spray-control system that integrates vision, distance, and environmental sensors will be designed to achieve accurate target spraying, reduce the challenges of poor-control effects, and solve the challenges of low pesticide utilization rate and secondary disasters caused by the drifting of the pesticides. Additionally, the operation time can be determined, and it can be operated independently based on crop growth stage and pest information. A fully autonomous intelligent prevention and control network can be established, and joint prevention and control operations can be carried out in advance based on a wide range of pest data. At present, the load capacity of plant protection UAVs is mostly at the level of forty kilograms. In order to cope with the operation demand of larger areas, plant protection UAVs need to develop the ability to carry a larger load. The operation scenarios of plant protection UAVs are constantly advancing, and their applications are also expanding. The operation forms of UAV seeding, fertilization, and transportation have begun to take shape. The continuous upgrading of the key technologies of plant protection UAVs has profound impacts on the development of modern precision agriculture.

Author Contributions

Conceptualization, R.Z.; methodology, R.Z. and P.H.; investigation, P.H.; resources, R.Z. and L.C.; writing—original draft preparation, P.H.; writing—review and editing, P.H., R.Z. and J.Y.; supervision, R.Z.; project administration, R.Z.; funding acquisition, R.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was partly funded by National Natural Science Foundation of China (32071907) and the Outstanding Scientist Cultivation Project of the Beijing Academy of Agriculture and Forestry Sciences (JKZX202205).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ma, Y.; Xu, Y.; Sun, L.; Chen, Z.; Feng, J.; Wu, X. Development Status and Prospect of Aviation Plant Protection in China. Agrochemicals 2022, 61, 469–477. (In Chinese) [Google Scholar] [CrossRef]

- Sun, L.; Chen, B.; Zhao, J.; Wang, Q.; Wang, J.; Song, Y.; Chen, Z.; Han, H.; Wang, F.; Fu, J. Application and Prospect of UAV Application Technology in Agricultural Production. Jiangsu Agric. Sci. 2022, 50, 31–42. (In Chinese) [Google Scholar] [CrossRef]

- Lan, Y.; Chen, S.; Deng, J.; Zhou, Z.; Ouyang, F. Development Situation and Problem Analysis of Plant protection Unmanned Aerial Vehicle in China. J. South China Agric. Univ. 2019, 40, 217–225. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, Z.; Ming, R.; Zang, Y.; He, X.; Luo, X.; Lan, Y. Development Status and Countermeasures of Agricultural Aviation in China. Trans. Chin. Soc. Agric. Eng. 2017, 33, 1–13, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Sun, K.; Wu, K.; Wang, Y.; Shao, Z. Research on Obstacle Avoidance System of Plant Protection UAV Based on Millimeter Wave Radar. Transducer Microsyst. Technol. 2020, 39, 73–76. [Google Scholar] [CrossRef]

- Wang, D.; Fan, Y.; Xue, J.; Yuan, D.; Shen, K.; Zhang, H. Flight Path Control of UAV in Mountain Orchards Based on Fusion of GNSS and Machine Vision. Trans. Chin. Soc. Agric. Mach. 2019, 50, 20–28, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zheng, Z.; Yang, S.; Zheng, Y.; Liu, X.; Chen, J.; Su, D. Obstacle Avoidance Path Planning Algorithm for Multi-Rotor UAVs. Trans. Chin. Soc. Agric. Eng. 2020, 36, 59–69, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Ding, L.; Ma, R.; Shan, W.; Wu, H. Linear Active Disturbance Rejection Control for Yaw Channel of Small-Scale Unmanned Helicopter. Trans. Chin. Soc. Agric. Mach. 2017, 48, 22–27, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, J.; Bai, Y.; Pei, X.; Wu, H. Research on Autonomous Obstacle Avoidance of Agricultural UAV Based on Deep Learning. Trans. Chin. Soc. J. Agric. Mech. Res. 2021, 43, 1–7, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, D. Research on Key Technologies of Adaptive Navigation for Plant Protection UAV in Mountainous Orchards. Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2019. [Google Scholar]

- Wu, K.; Sun, X.; Zhang, J.; Chen, F. Terrain Following Method of Plant Protection UAV Based on Height Fusion. Trans. Chin. Soc. Agric. Mach. 2018, 49, 17–23, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, Z.; Yang, M.; Wang, X. Multi-Rotor UAV Near-Ground Positioning Algorithm Based on Multi-Sensor Fusion. J. Chengdu Univ. Inf. Sci. Technol. 2018, 33, 261–267. (In Chinese) [Google Scholar] [CrossRef]

- Niu, Y. Design of Multi-Sensor Fusion Terrain Following System for Small UAV; Shenzhen University: Shenzhen, China, 2017. [Google Scholar]

- Kan, P.; Jiang, Z.; Liu, Y.; Wang, Z. Cooperative Path Planning of Multi Plant Protection UAV. Acta Aeronaut. Astronaut. Sinna 2020, 41, 260–270. (In Chinese) [Google Scholar] [CrossRef]

- Wang, Y.; Chen, H.; Li, J. 3D Path Planning Approach Based on Gravitational Search Algorithm for Sprayer UAV. Trans. Chin. Soc. Agric. Mach. 2018, 49, 28–33, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Huang, X.; Zhang, L.; TANG, L.; Tang, C.; Li, X.; He, X. Path Planning for Autonomous Operation of Drone in Fields with Complex Boundaries. Trans. Chin. Soc. Agric. Mach. 2020, 51, 34–42, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, Y.; Wang, W.; Xu, F.; Wang, J.; Chen, H. Path Planning Approach Based on Improved Ant Colony Optimization for Sprayer UAV. Trans. Chin. Soc. Agric. Mach. 2020, 51, 103–112, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Cao, R.; Li, S.; Ji, Y.; Xu, H.; Zhang, M. Multi-Machine Cooperation Task Planning Based on Ant Colony Algorithm. Trans. Chin. Soc. Agric. Mach. 2019, 50, 34–39, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Min, J.; Jiang, M. Method of Trajectory Optimization and Control for Plant Protection UAV in Spraying Operation. J. Agric. Mech. Res. 2022, 44, 28–33. (In Chinese) [Google Scholar] [CrossRef]

- Xu, L.; Yang, Z.; Huang, Z.; Ding, W. Route Planning Method for Plant Protection Unmanned Aerial Vehicles Combined with Hybrid Particle Swarm Optimization. J. Chin. Comput. Syst. 2020, 41, 1826–1832. (In Chinese) [Google Scholar] [CrossRef]

- Xu, B.; Chen, L.; Tan, Y.; Xu, M. Path Planning Based on Minimum Energy Consumption for Plant Protection UAVs in Sorties. Trans. Chin. Soc. Agric. Mach. 2015, 46, 36–42, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Guo, Y. Research and Experiment on Variable Rate Spraying System of UAV with Adaptive Speed. Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2019. [Google Scholar]

- Hu, H. Study on the Dosage Control System of Plant Protection UAV. Ph.D. Thesis, Shihezi University, Shihezi, China, 2019. [Google Scholar]

- Liu, Y.; Ru, Y.; Chen, Q.; Chen, X.; Liu, B. Design and Test of Real-time Monitoring System for UAV Variable Spray. Trans. Chin. Soc. Agric. Mach. 2020, 51, 91–99, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Cen, Z.; Yue, X.; Wang, L.; Ling, K.; Chen, Z.; Lu, Y. Design and test of self-adaptive variable spray system of UAV based on neural network PID. Trans. Chin. Soc. J. South China Agric. Univ. 2019, 40, 100–108, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, D.; Zhang, J.; Li, W.; Xiong, B.; Zhang, S.; Zhang, W. Design and Test of Dynamic Variable Spraying System of Plant Protection UAV. Trans. Chin. Soc. Agric. Mach. 2017, 48, 86–93, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Gao, R.; Shan, J.; Yang, Z.; Wen, S.; Lan, Y.; Zhang, Q.; Wang, Y. Design and Experiment of Real-Time Interpretation System for Plant Protection UAV Variable Spray Prescription Map. J. Jilin Univ. Eng. Ed. 2020, 50, 361–374. (In Chinese) [Google Scholar] [CrossRef]

- Qi, H.; Zhou, J.; Li, C.; Chen, P.; Liang, Y.; Huang, G.; Zou, J. Feasibility of Variable Rate Spraying of Centrifugal UAV Using Network RTK. Trans. Chin. Soc. Agric. Mach. 2021, 37, 81–89, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Yan, C.; Li, W.; Lan, Y.; Hu, C.; Lu, L.; Zhao, J. Study on Cotton Defoliation Effect Monitoring and Formulation Map Generation Based on Multi-Spectral Remote Sensing of UAV. J. Nanjing Agric. Univ. 2022, 45, 799–808. (In Chinese) [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, C.; Xu, L.; Ru, Y.; Zheng, J.; Li, Q. Research Progress of Tree Precision Application Technology. J. For. Eng. 2022, 7, 12–22. (In Chinese) [Google Scholar] [CrossRef]

- Wang, L.; Lan, Y.; Yue, X.; Ling, K.; Cen, Z.; Cheng, Z.; Liu, Y.; Wang, J. Vision-Based Adaptive Variable Rate Spraying Approach for Unmanned Aerial Vehicles. Int. J. Agric. Biol. Eng. 2019, 12, 18–26. [Google Scholar] [CrossRef]

- Zhang, R.; Zhang, Z.; Xu, G.; Chen, L.; Hewitt, A. Effect of Spray Adjuvant Types and Concentration on Nozzle Atomization. Trans. Chin. Soc. Agric. Eng. 2018, 34, 36–43, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Yao, W.; Lan, Y.; Wang, J.; Wen, S.; Wang, G.; Chen, S. Droplet Drift Characteristics of Aerial Spraying of AS350B3e Helicopter. Trans. Chin. Soc. Agric. Eng. 2017, 33, 75–83, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, X.; He, X.; Song, J.; Herbst, A. Effect of Adjuvant Types and Concentration on Spray Drift Potential of Different Nozzles. Trans. Chin. Soc. Agric. Eng. 2015, 31, 49–55, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, X.; He, X.; Wang, C.; Wang, Z.; Li, L.; Wang, S.; Bonds, A.; Herbst, A.; Wang, Z. Spray Drift Characteristics of Fuel Powered Single-Rotor UAV for Plant Protection. Trans. Chin. Soc. Agric. Eng. 2017, 33, 117–123, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wang, C.; Song, J.; He, X.; Wang, Z.; Wang, S.; Meng, Y. Effect of Flight Parameters on Distribution Characteristics of Pesticide Spraying Droplets Deposition of Plant-Protection Unmanned Aerial Vehicle. Trans. Chin. Soc. Agric. Eng. 2017, 33, 109–116, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Chen, S.; Lan, Y.; Bradley, K.; Li, J.; Liu, A.; Mao, Y. Effect of Wind Field Below Rotor on Distribution of Aerial Spraying Droplet Deposition by Using Multi-Rotor UAV. Trans. Chin. Soc. Agric. Mach. 2017, 48, 105–113, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, R.; Li, L.; Fu, W.; Chen, L.; Yi, T.; Tang, Q.; Hewitt, A. Spraying Atomization Performance by Pulse Width Modulated Variable and Droplet Deposition Characteristics in Wind Tunnel. Trans. Chin. Soc. Agric. Eng. 2019, 35, 42–51, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Chen, Y.; Hou, C.; Tang, Y.; Zhuang, J.; Lin, J.; Luo, S. An effective spray drift reducing method for a plant-protection unmanned aerial vehicle. Int. J. Agric. Biol. Eng. 2019, 12, 14–20. [Google Scholar] [CrossRef]

- Wang, L.; Lan, Y.; Hoffmann, W.; Fritz, B.; Chen, D.; Wang, S. Design of Variable Spraying System and Influencing Factors on Droplets Deposition of Small UAV. Trans. Chin. Soc. Agric. Mach. 2016, 47, 15–22, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Chai, S. Design and Development of Airborne Atomization System for Aviation Precision Spraying. Master’s Thesis, Northwest A&F University, Xianyang, China, 2020. [Google Scholar]

- Li, J.; Lan, Y.; Shi, Y. Research Progress on Airflow Characteristics and Field Pesticide Application System of Rotary-Wing UAV. Trans. Chin. Soc. Agric. Eng. 2018, 34, 104–118, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Yang, Z.; Ge, L.; Qi, L.; Chen, Y.; Wu, Y. Influence of UAV Rotor Down-Wash Airflow on Spray Width. Trans. Chin. Soc. Agric. Mach. 2018, 49, 116–122, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, R.; Chen, L.; Lan, Y.; Xu, G.; Kan, J.; Zhang, D. Development of a Deposit Sensing System for Aerial Spraying Application. Trans. Chin. Soc. Agric. Mach. 2014, 45, 123–127, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, R.; Wen, Y.; Yi, T.; Chen, L.; Xu, G. Development and Application of Aerial Spray Droplets Deposition Performance Measurement System Based on Spectral Analysis Technology. Trans. Chin. Soc. Agric. Eng. 2017, 33, 80–87, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, M.; Li, X.; Yang, W.; Hao, Z. Design and Experiment of UAV Spray Quality Detection System. Trans. Chin. Soc. Agric. Mach. 2021, 52, 36–42, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Guo, N.; Liu, S.; Xu, H.; Tian, S.; Li, T. Improvement on Image Detection Algorithm of Droplets Deposition Characteristics. Trans. Chin. Soc. Agric. Eng. 2018, 34, 176–182, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Sun, C. Design and Application of Measurement System for Droplet Quantity Based on Solution Conductivity Principle. Ph.D. Thesis, Northwest A&F University, Xianyang, China, 2017. [Google Scholar]

- Tang, Q.; Zhang, R.; Chen, L.; Li, L.; Xu, G. Research Progress of Key Technologies and Verification Methods of Numerical Modeling for Plant Protection Unmanned Aerial Vehicle Application. Smart Agric. 2021, 3, 1–21, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wen, S.; Han, J.; Lan, Y.; Yin, X.; Lu, Y. Influence of Wing Tip Vortex on Drift of Single Rotor Plant Protection Unmanned Aerial Vehicle. Trans. Chin. Soc. Agric. Mach. 2018, 49, 127–137, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, H.; Qi, L.; Wu, Y.; Liu, W.; Cheng, Z.; Musiu, E. Spatiotemporal Distribution of Down-Wash Airflow for Multi-Rotor Plant Protection UAV Based on Porous Model. Trans. Chin. Soc. Agric. Mach. 2019, 50, 112–122, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Liang, Z.; Fan, G.; Wang, G.; Ding, H.; Zhang, X. Distribution Model of Wind-Stressed Droplet Deposition Based on Bimodal Distribution. Trans. Chin. Soc. Agric. Mach. 2020, 51, 28–37, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhang, S.; Xue, X.; Qin, W.; Sun, Z.; Ding, S.; Zhou, L. Simulation and Experimental Verification of Aerial Spraying Drift on N-3 Unmanned Spraying Helicopter. Trans. Chin. Soc. Agric. Eng. 2015, 31, 87–93, (In Chinese with English Abstract). [Google Scholar] [CrossRef]