1. Introduction

Bioplastics offer great potential to achieve global bioeconomic goals such as using secondary local biomass for polymerization instead of fossil raw materials and the associated negative impacts on the environment [

1]. However, bioplastics are significantly more susceptible to oxidative decomposition processes [

2]. Conventional additives, which can contain extremely critical substances, are currently primarily used to stabilize bioplastics [

3]. For this reason, antioxidative stabilizers from biogenic by-products represent a more environmentally friendly solution to produce fully bio-based plastics for technical applications.

One promising opportunity is offered by the large volumes of coffee by-products that are generated from coffee cultivation, care and harvesting, processing on the coffee farms, as well as roasting, and further processing of the coffee beans. These coffee by-products contain functional phytonutrients, e.g., antioxidants that currently often go unused and, if properly processed, are suitable for secondary food applications or material use [

4]. Besides vitamins, they contain many polyphenolic secondary plant compounds. The type and concentrations of antioxidants depend on several parameters. So far, the influences on the antioxidant properties have been proven by the following:

The type of coffee by-product [

5];

The variety and its peel color [

6];

The conditions in which the coffee plants are grown, including soil quality, altitude, climate, and cultivation practices [

7];

Drying and storage of the coffee and coffee by-products [

8].

Less information on the influence on the antioxidative properties of coffee by-products and bioplastic composites is available for:

The homogeneity of the coffee by-product and contaminants;

Temperature during by-product and biocomposite processing;

The grinding method and the particle size;

The mass fraction of the coffee by-product in the biopolymer;

Containing carbohydrates and potential caramelization or Maillard reactions,

The compounding and extrusion conditions.

Figure 1 shows the composition of a coffee cherry (COC) from a naturally processed coffee Arabica. Depending on the picking technique, available machines, filters, and manual selections, portions of parchment (PMT), green coffee beans (GCB) or coffee defects (COD), and coffee wood (COW) may be present during the pulping of COC, usually as small twigs.

The production of quality coffee involves several process steps. Depending on the type of preparation (dry, natural pulped, semi-washed, or fully washed), pure coffee by-products or heterogeneous blended by-products are produced. After picking, the by-products are exposed to different conditions depending on the processing method, ranging from UV radiation during air drying to mechanical, thermal, and bacterial stress during machine processing. For the use of coffee by-products as antioxidant stabilizers in bioplastics, gentle grinding into flour with small primary particle sizes is crucial.

Table 1 shows the chronological order of processing steps from by-product harvesting to conversion into bioplastic. In order to utilize the natural antioxidants in the biopolymer, it is critical that they are not thermally, oxidatively, or hydrolytically degraded or polymerized into macroradicals throughout the processing chain. Temperature (directly via heating or indirectly via shear friction) and time of exposure have the highest influence on antioxidant degradation during processing and storage [

8,

9].

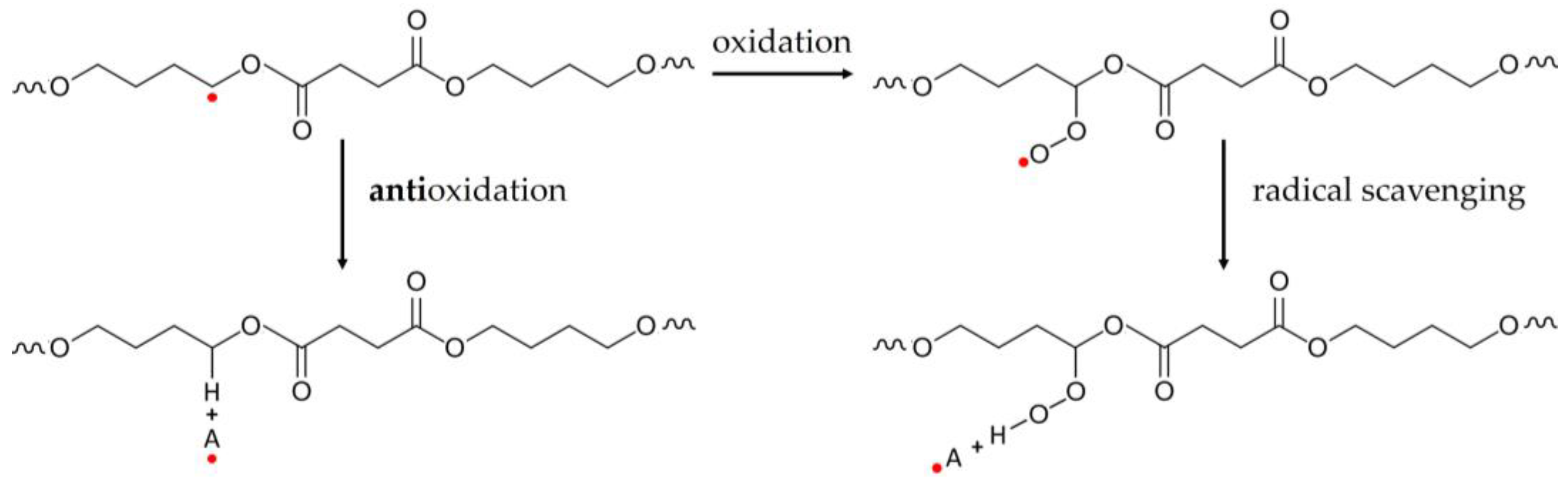

Bioplastics offer great potential to be produced from local renewable biomass streams and used for technical applications without abrasive microplastics having a harmful impact on the environment. However, unstabilized, most bioplastics are subject to multiple degradation processes, which can lead to premature mechanical failure of a bioplastic. Most radical-inducing reactions are based on a hydrogen abstraction from the methyl group next to the ester group, e.g., for bio-based poly(butylene succinate) (BioPBS), a promising substitute for conventional polyolefines. Adding natural antioxidants, the main reactions to stabilize a BioPBS are the following (

Figure 2):

Figure 2.

Schematic thermo-oxidative reaction of PBS and the mechanism of coffee antioxidant action preventing oxidation (

left) or eliminating oxidized triggers by radical scavenging (

right). The red dot represents free radicals [

11].

Figure 2.

Schematic thermo-oxidative reaction of PBS and the mechanism of coffee antioxidant action preventing oxidation (

left) or eliminating oxidized triggers by radical scavenging (

right). The red dot represents free radicals [

11].

2. Materials and Methods

The investigated unstabilized bio-based poly(butylene succinate) grade BioPBS™ FZ71PM (PTT MCC Bi-ochem Co., Ltd., Bangkok, Thailand) was synthesized fermentatively from bio-based succinic acid and 1,4-butanediol and used for injection molding applications. The poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) grade Enmat Y1000 (TianAn Biologic Materials Co., Ltd., Ningbo City, China) is an unstabilized high crystalline biopolymer, which was produced by bacteria via a fermentation process.

The coffee by-products were kindly provided by the Coffee Consulate (Mannheim, Germany).

Table 2 shows the individual coffee by-products studied, whose origin is mainly in the two coffee plantations in Fazendas Dutra, Brazil (20°18′49.7″ S 42°07′33.9″ W) and Badra Estate, India (13°21′07.0″ N 75°28′31.8″ E). Details about species and variety, year and process of harvesting, and the type and mass fraction of composition are listed.

The micronization of the coffee by-products was performed using a TurboRotor® milldryer from Mahltechnik Görgens GmbH (Dormagen, Germany), a hybrid method to grind and dry thermal-sensitive biomass. The rotor speed was 113 rpm with an air throughput of 1600 kg/h. The intake air/exit temperature (°C) were (COC-CAS = 136/80, COC-SLN = 128/80, COC-PAL = 164/80, and COC-PDCN = 176/81, for both PMT = 136/99 and SSK-MIX = 65/70 °C). The PBS was compounded with 5 wt.-% coffee by-products on a composer 450 miniaturized single-screw extruder (MSE) with a mixing screw (3D Evo B.V., NL). The PHBV was processed with 5 wt.-% COC on a co-rotating twin-screw extruder (TSE) type LTE20-44 (Labtech Engineering Co., Ltd., Thailand). The coffee by-product powders had residual moistures (% r.H.) of (COC-CAS = 4.93, COC-SLN = 2.44, COC-PAL = 2.54, COC-PDCN = 1.52, PMT-SLN = 3.59, PMT-PDD = 3.62, and SSK-MIX = 2.95). The temperature profile of the MSE = 150–180–190–180 °C for the BioPBS compounds with all coffee by-products and the TSE = 140–145–150–155–160–165 °C for the PHBV compounds with 5 wt.-% COC-SLN.

The microscopic analysis of native and milldried coffee by-products was performed with a digital microscope VHX 950F (KEYENCE DEUTSCHLAND GmbH, Neu-Isenburg, Germany). Particle size and distribution were performed with a CILAS particle size analyzer 1090 (Cilas S.A., Orleans, France), a laser diffraction granulometer at ambient temperature. The color change via thermal treatment of the powders was performed with a Kofler Heizbank

® (Wagner & Munz GmbH, München, Germany) with heating zones from 50 to 260 °C. The antioxidative properties of the coffee by-products were analyzed by FC assays according to Singleton et al. [

12] and ABTS assays according to the procedure of Re et al. [

13]. The antioxidative properties of the PBS and PHBV compounds were analyzed using the Dynamic Oxidation Induction Temperature (OIT) analysis according to DIN EN ISO 11357-6 with the onset and offset method with the DSC 214 Polyma (NETZSCH-Gerätebau GmbH, Selb, Germany). The OIT is the temperature at which a material begins to undergo significant thermo-oxidative degradation in the presence of an oxidizing atmosphere.

3. Results and Discussion

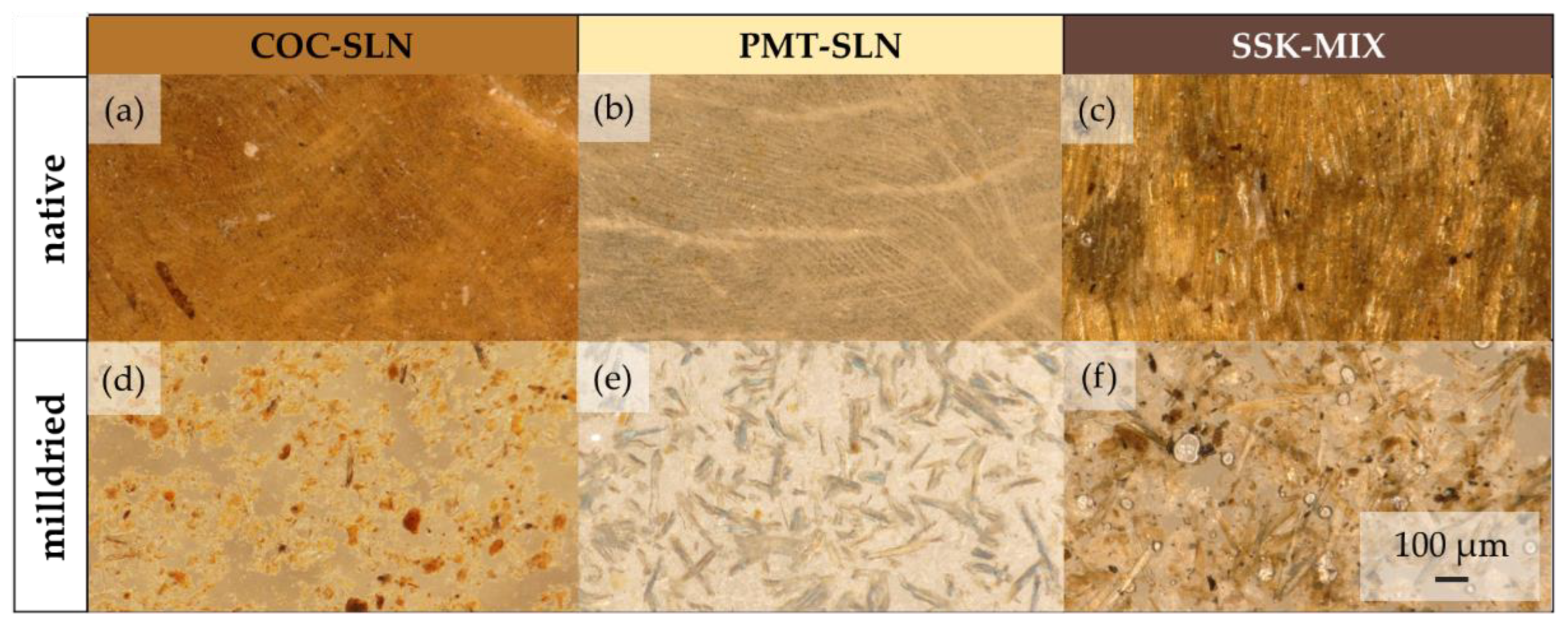

Microscopic images of the native and mill-dried by-products of COC, PMT, and SSK are shown in

Figure 3.

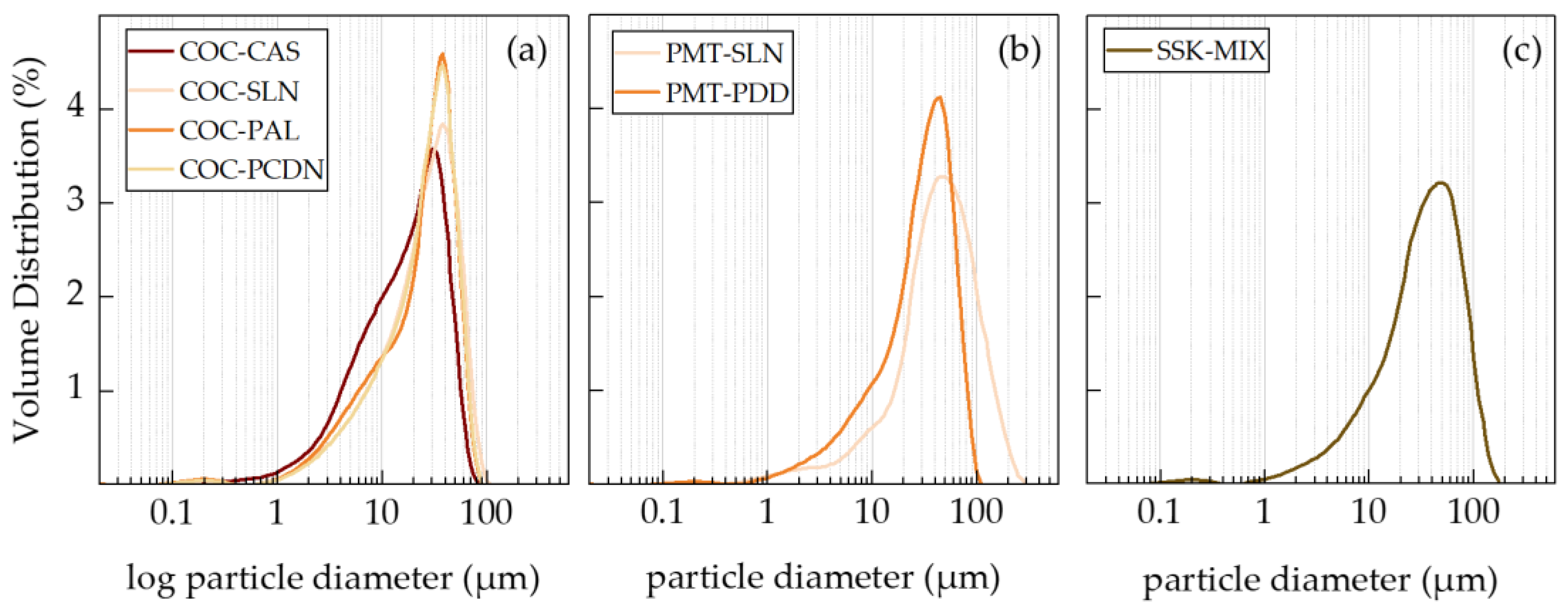

The lignocellulosic structure consists mainly of (α-)cellulose, hemicellulose, and lignin. PMTs are supposed to have the highest insoluble dietary fiber content of appr. 90% compared to concentrations of appr. 60% for SSK and lower amounts for COC [

14]. In addition to the fiber content, the most important factors are the fiber dimensions after milling and the polyphenols bound in the fibers. It could be shown that higher fiber sizes (fiber length >> 100 µm) can have a negative impact on the mechanical and fracture mechanical properties at higher filling rates in BioPBS composite [

11]. In

Figure 3d–f it can be seen that PMT has the fibers with the highest diameter, SSK has comparatively long and thin fibers, and the COC has almost no fiber structure. This is also evident from the particle size distribution results (

Figure 4). All COCs show comparable particle sizes with a d

97 < 100 µm. For the two PMTs, the PMT-SLN shows a broader distribution and larger particle sizes overall. The SSK also shows a small proportion of particles or fibers with sizes above 100 µm. The size of the particles and thus the total surface area has a great influence on the binding of the ground by-products to the bioplastic matrix, the distribution and thus the mechanical properties of the biocomposites. Furthermore, the by-product geometry and size influence the release of antioxidants [

11].

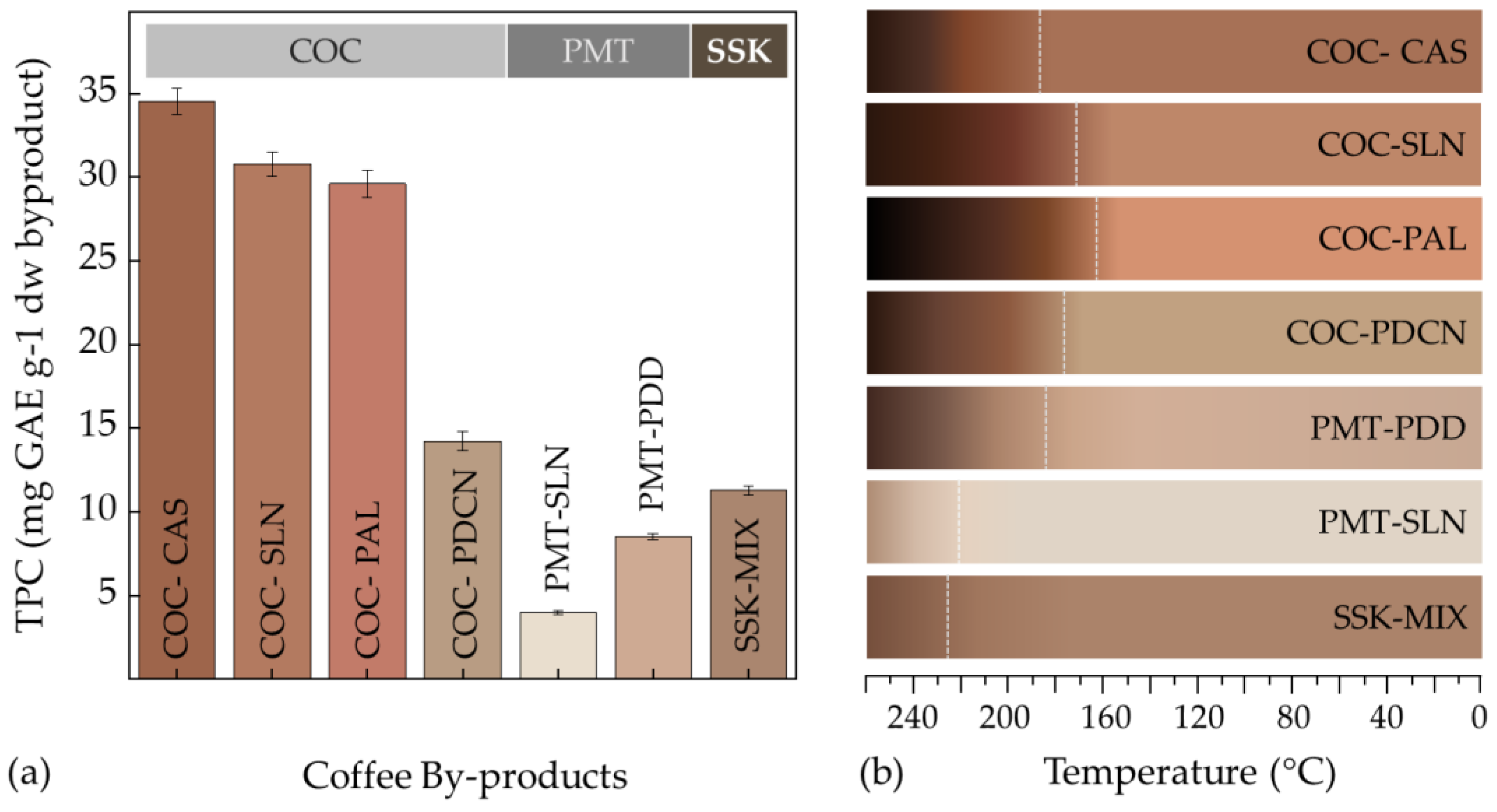

Figure 5a shows the total polyphenol contents of the ground coffee by-products. All four COCs show the highest concentrations of total polyphenols.

The COC or coffee pulp COP, the outermost layer of the coffee fruit, is said to contain high levels of anthocyanins, tannins, and other highly reactive polyphenols that resist UV irradiation and predators. The COC-CAS showed the highest level of polyphenols. COC-Palhina consists of appr. 30 wt.-% GCB or COD. GCBs are supposed to contain the highest amount of phenolic compounds, which might be a reason for the high TPC of COC-PAL. Surprisingly, the COC-PDCN has only about half as much total polyphenols compared to the other COCs. One possible explanation could be that about a quarter of the composition of the COC-PDCN consists of PMT. The PMTs have the lowest TPC in the overall comparison. This, in turn, can be attributed to the fact that the polyphenols in the dietary fiber of the PMTs are not released during extraction for the assays [

15]. SSK, on the other hand, have a considerable amount of polyphenols, even if they have already undergone thermal treatment by roasting. These findings are also consistent with the results of the radical scavenging properties or antioxidative activity AA

ABTS in

Table 3.

Figure 5b shows the influence of increasing temperatures on the optical brown discoloration of the by-products. COC and coffee husks (COH, resulting from dry processing) with the earliest discoloration point also have high levels of various monosaccharides [

16]. Reduced sugars and amino acids can initiate Maillard reactions and thus a brown discoloration. The PMT-PDD also consists of about 40 wt% COC and shows more discoloration than the corresponding pure PMT-SLN.

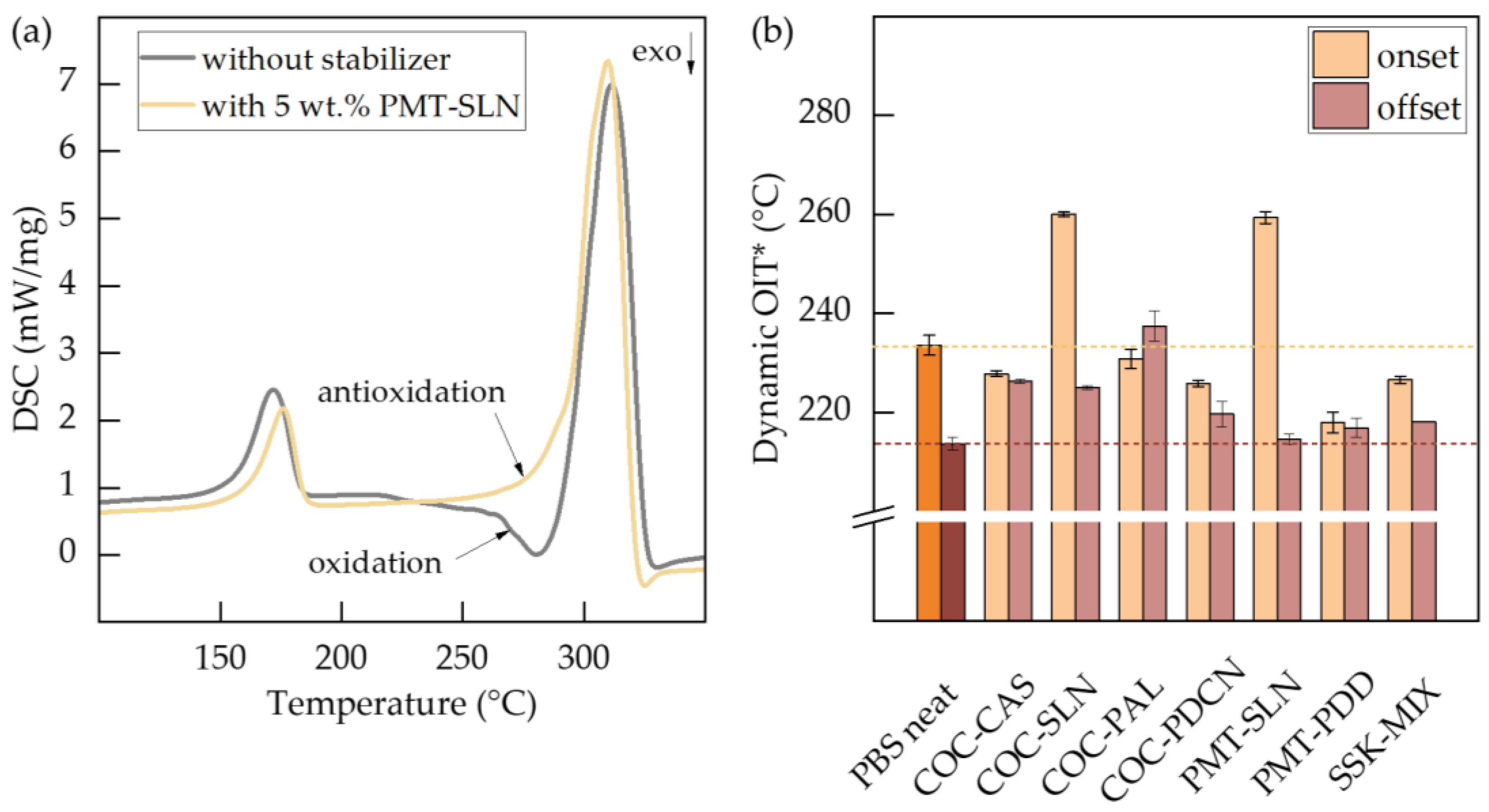

The results of the stabilizing antioxidative properties of PHBV and PBS compounds can be seen in

Figure 6. The onset OIT temperatures of the progressive oxidation were determined tangentially from the maxima of the first deviation. First radical reactions can be indicated with the offset method. PHBV without any stabilizer showed a significant exothermic reaction from appr. 220 °C on due oxidation (

Figure 6a). Adding 5 wt.-% of COC-SLN completely prevented that exothermic reaction and successfully stabilized the PBHV against oxidation.

COC-SLN also showed the best stabilizing effect for the PBS compound. The highest radical scavenging reactions were reached by the COC-PAL, which might be traced back to the polyphenols from the GCB. The lower onset might be related to transformation processes due to Maillard reactions. The PMT-SLN can convince with high OIT values despite the lowest TPC values. It can be assumed that the polyphenols bound in the cell walls of the PMT are only released at an elevated melt temperature and have an antioxidant effect in accordance with the findings of Benitez et al. [

17].

4. Conclusions

Along the coffee production chain, a large amount of coffee by-products is generated, whose functional ingredients hold great potential for antioxidant stabilization of biopolyesters such as BioPBS and PHBV. Fully washed PMT is more homogenous generated than pulped-natural PMT. Naturally produced coffee can generate COC with a heterogeneous composition and different amounts of accompanying by-products. The small amount of dietary fiber compared to PMT and SSK result in small particle sizes that can be readily incorporated into bioplastics. The higher proportions of monosaccharides, in turn, can lead to Maillard reactions during extrusion at higher temperatures, which can complicate processing and result in brown discoloration. The coffee by-products studied were able to achieve thermo-oxidative effects in both PHBV and PBS, with the COC-SLN containing a proportion of GCB and the pure PMT-SLN with a high fiber content achieving the best results.

Funding

The research was funded by Bundesministerium für Ernährung und Land-wirtschaft (BMEL, the Federal Ministry of Food and Agriculture of Germany) and FNR (Agency for Renewable Resources), grant number: 2219NR348.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The author is thankful to S. Schwarz from Coffee Consulate and the associated coffee farmers for providing the coffee by-products and information and Team EISBiR for their support during the experiments.

Conflicts of Interest

The author declares no conflict of interest.

References

- Andhalkar, V.V.; Ahorsu, R.; de María, P.D.; Winterburn, J.; Medina, F.; Constantí, M. Valorization of Lignocellulose by Producing Polyhydroxyalkanoates under Circular Bioeconomy Premises: Facts and Challenges. ACS Sustain. Chem. Eng. 2022, 50, 16459–16475. [Google Scholar] [CrossRef]

- Hallstein, J.; Gomoll, A.; Lieske, A.; Büsse, T.; Balko, J.; Brüll, R.; Malz, F.; Metzsch-Zilligen, E.; Pfaendner, R.; Zehm, D. Unraveling the cause for the unusual processing behavior of commercial partially bio-based poly(butylene succinates) and their stabilization. J. Appl. Polym. Sci. 2021, 138, 50669. [Google Scholar] [CrossRef]

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066. [Google Scholar] [CrossRef] [PubMed]

- Klingel, T.; Kremer, J.I.; Gottstein, V.; de Rezende, T.R.; Schwarz, S.; Lachenmeier, D.W. A Review of Coffee By-Products Including Leaf, Flower, Cherry, Husk, Silver Skin, and Spent Grounds as Novel Foods within the European Union. Foods 2020, 9, 665. [Google Scholar] [CrossRef]

- Hejna, A. Potential applications of by-products from the coffee industry in polymer technology—Current state and perspectives. Waste Manag. 2021, 121, 296–330. [Google Scholar] [CrossRef] [PubMed]

- Esquivel, P.; Viñas, M.; Steingass, C.B.; Gruschwitz, M.; Guevara, E.; Carle, R.; Schweiggert, R.M.; Jiménez, V.M. Coffee (Coffea arabica L.) by-Products as a Source of Carotenoids and Phenolic Compounds—Evaluation of Varieties with Different Peel Color. Front. Sustain. Food Syst. 2020, 4, 590597. [Google Scholar] [CrossRef]

- Pereira, P.V.; Silveira, D.L.; Schwan, R.F.; Silva, S.A.; Coelho, J.M.; Bernardes, P.C. Effect of altitude and terrain aspect on the chemical composition of Coffea canephora cherries and sensory characteristics of the beverage. J. Sci. Food Agric. 2021, 101, 2570–2575. [Google Scholar] [CrossRef]

- Esparza, I.; Cimminelli, M.J.; Moler, J.A.; Jiménez-Moreno, N.; Ancín-Azpilicueta, C. Stability of Phenolic Compounds in Grape Stem Extracts. Antioxidants 2020, 9, 720. [Google Scholar] [CrossRef] [PubMed]

- Volf, I.; Ignat, I.; Neamtu, M.; Popa, V.I. Thermal stability, antioxidant activity, and photo-oxidation of natural polyphenols. Chem. Pap. 2014, 68, 122–129. [Google Scholar] [CrossRef]

- Brito, J.; Hlushko, H.; Abbott, A.; Aliakseyeu, A.; Hlushko, R.; Sukhishvili, S.A. Integrating Antioxidant Functionality into Polymer Materials: Fundamentals, Strategies, and Applications. ACS Appl. Mater. Interfaces 2021, 35, 41372–41395. [Google Scholar] [CrossRef] [PubMed]

- Rennert, M.; Hiller, B.T. Influence of Coffee Variety and Processing on the Properties of Parchments as Functional Bioadditives for Biobased Poly(butylene succinate) Composites. Polymers 2023, 15, 2985. [Google Scholar] [CrossRef] [PubMed]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 9–10, 1231–1237. [Google Scholar] [CrossRef]

- Iriondo-DeHond, A.; Aparicio García, N.; Fernandez-Gomez, B.; Guisantes-Batan, E.; Velázquez Escobar, F.; Blanch, G.P.; Velázquez Escobar, M.I.; Sanchez-Fortun, S.; del Castillo, M.D. Validation of coffee by-products as novel food ingredients. Innov. Food Sci. Emerg. Technol. 2019, 6, 194–204. [Google Scholar] [CrossRef]

- Esquivel, P.; Jiménez, V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012, 2, 488–495. [Google Scholar] [CrossRef]

- Cangussu, L.B.; Melo, J.C.; Franca, A.S.; Oliveira, L.S. Chemical Characterization of Coffee Husks, a By-Product of Coffea arabica Production. Foods 2021, 10, 3125. [Google Scholar] [CrossRef]

- Benítez, V.; Rebollo-Hernanz, M.; Aguilera, Y.; Bejerano, S.; Cañas, S.; Martín-Cabrejas, M.A. Extruded coffee parchment shows enhanced antioxidant, hypoglycaemic, and hypolipidemic properties by releasing phenolic compounds from the fibre matrix. Food Funct. 2021, 3, 1097–1110. [Google Scholar] [CrossRef] [PubMed]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).