Making Nutritious Gluten-Free Foods from Quinoa Seeds and Its Flours †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Gravimetric Measures

3. Results and Discussion

3.1. Physical Properties

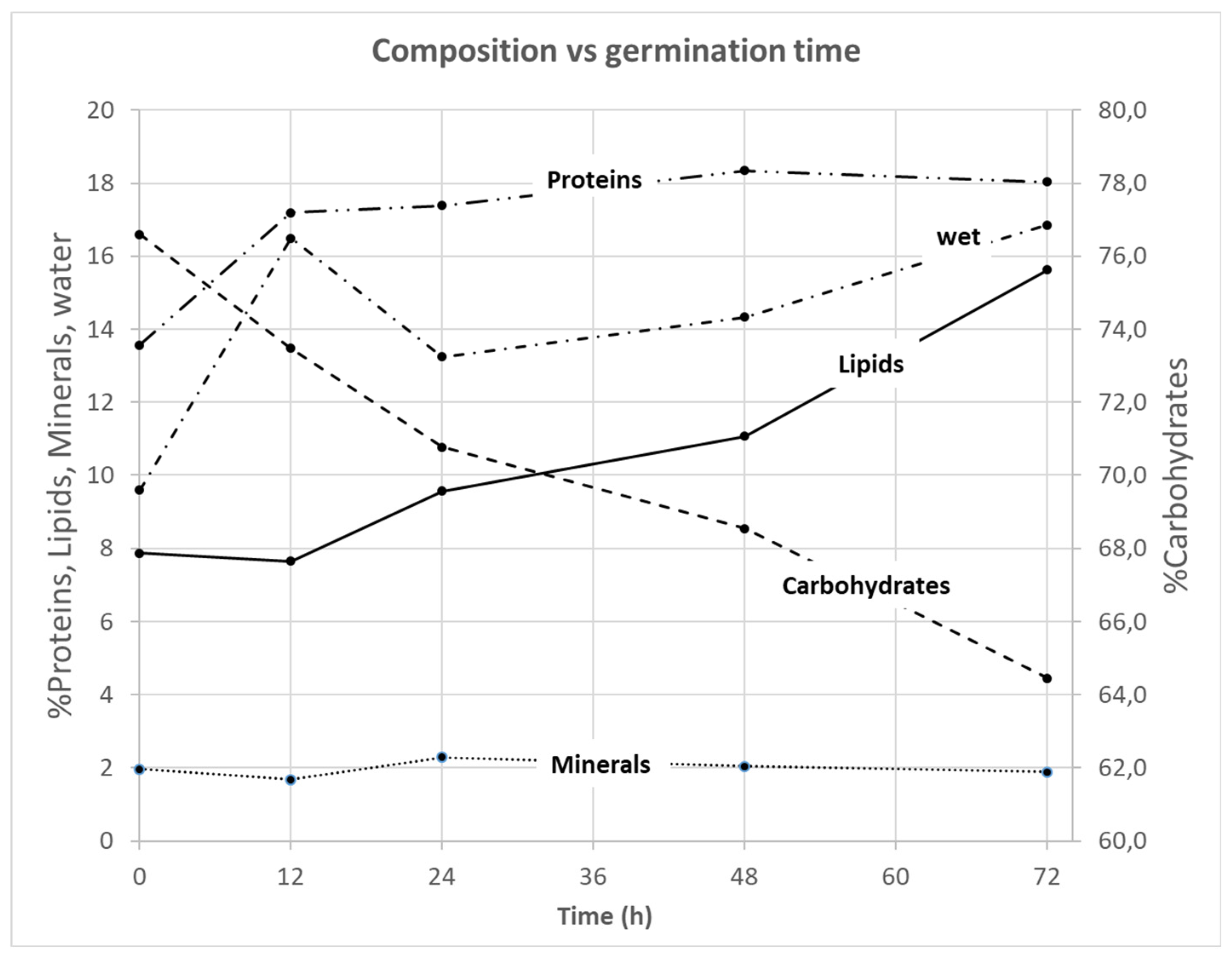

3.2. Chemical Properties

3.3. Products Development

4. Conclusions

Funding

Acknowledgments

References

- Czaja-Bulsa, G. Non coeliac gluten sensitivity—A new disease with gluten intolerance. Clin. Nutr. 2015, 34, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Vidueiros, S.M.; Curti, R.N.; Dyner, L.M.; Binaghi, M.J.; Peterson, G.; Bertero, H.D.; Pallaro, A.N. Diversity and interrelationships in nutritional traits in cultivated quinoa (Chenopodium quinoa Willd.) from Northwest Argentina. J. Cereal Sci. 2015, 62, 87–93. [Google Scholar] [CrossRef]

- Renzetti, S.; Rosell, C.M. Role of enzymes in improving the functionality of proteins in non-wheat dough systems. J. Cereal Sci. 2016, 67, 35–45. [Google Scholar] [CrossRef]

- Ahmad, S.; Ahmad, M.; Rashid, H.; Ahmad, I. In fl uence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Technol. 2016, 51, 49–57. [Google Scholar] [CrossRef]

- Cervilla, N.; Mufari, J.; Calandri, E.; Guzmán, C. Propiedades Físicas de Semillas y Análisis proximal de harinas de Chenopodium Quinoa Willd Cosechadas en Distintos Años y Provenientes de la Provincia de Salta. II Jorn. Investig. Ing. NEA Países Limítrofes 2013, 7, 14–15. [Google Scholar]

- Cervilla, N.; Romina, J.; Calandri, E.; Guzman, C. Determinación del contenido de aminoácidos en harinas de quinoa de origen argentino. Evaluación de su calidad proteica. Actual. Nutr. 2012, 13, 107–113. Available online: http://www.revistasan.org.ar/pdf_files/trabajos/vol_13/num_2/RSAN_13_2_107.pdf (accessed on 13 May 2017).

- Mufari, J.; Miranda-Villa, P.; Bergesse, A.; Cervilla, N.; Calandri, E. Physico-chemical analysis and protein fraction compositions of different quinoa cultivars. Acta Alim. 2018, 47, 462–469. [Google Scholar] [CrossRef]

- Miranda-Villa, P.P.; Mufari, J.R.; Bergesse, A.E.; Calandri, E.L. Effects of Whole and Malted Quinoa Flour Addition on Gluten-Free Muffins Quality. J. Food Sci. 2018, 84, 147–153. [Google Scholar] [CrossRef] [PubMed]

- Mufari, J.R.; Gorostegui, H.A.; Miranda-Villa, P.P.; Bergesse, A.E.; Calandri, E.L. Oxidative Stability and Characterization of Quinoa Oil Extracted from Wholemeal and Germ Flours. J. Am. Oil Chem. Soc. 2020, 97, 57–66. [Google Scholar] [CrossRef]

- García Luna, P.P.; López Gallardo, G. Evaluación de la absorción y metabolismo intestinal. Nutr. Hosp. 2007, 22, 5–13. [Google Scholar] [PubMed]

- Tapia, M. Cultivos Andinos Sub-Explotados y su Aporte a la Alimentación. 2000. Available online: http://www.fao.org/tempref/GI/Reserved/FTP_FaoRlc/old/prior/segalim/prodalim/prodveg/cdrom/contenido/libro10/home10.htm (accessed on 24 March 2020).

- Mota, C.; Santos, M.; Mauro, R.; Samman, N.; Matos, A.S.; Torres, D.; Castanheira, I. Protein content and amino acids profile of pseudocereals. Food Chem. 2016, 193, 55–61. [Google Scholar] [CrossRef] [PubMed]

- Miranda Villa, P.M. Efecto de la Adición de Harina de Quinoa y Lupino Dulce Sobre la Calidad Tecnológica de Panes Libres de Gluten. Ph.D. Thesis, FCEFyN–UNC, Córdoba, Argentina, 2019. [Google Scholar]

- Naqash, F.; Gani, A.; Gani, A.; Masoodi, F.A. Gluten-free baking: Combating the challenges—A review. Trends Food Sci. Technol. 2017, 66, 98–107. [Google Scholar] [CrossRef]

- Mäkinen, O.E.; Hager, A.S.; Arendt, E.K. Localisation and development of proteolytic activities in quinoa (Chenopodium quinoa) seeds during germination and early seedling growth. J. Cereal Sci. 2014, 60, 484–489. [Google Scholar] [CrossRef]

| Code b | 1000 Seeds Weight | True Density | Bulk Density | d1 | d2 | e | Equivalent Diameter | Ash | Lipids | Carbohyd | Poteins |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (g) | (g/mL) | (g/mL) | (mm) | (mm) | (mm) | (mm) | |||||

| CENTRAL REGION SEEDS | |||||||||||

| PCh | 2.47 ± 0.01 b | 1.01629272 | 0.554 ± 0.04 d | 1.88 ± 0.15 a | 1.91 ± 0.17 a | 1.12 ± 0.17 a | 1.59 ± 0.15 a | 3.51 ± 0.21 c | 6.54 ± 0.04 c | 72.33 ± 0.51 | 17.18 ± 0.25 a |

| P1Rc | 2.13 ± 0.01 a | 0.98586377 | 0.730 ± 0.01 a | 1.74 ± 0.11 c | 1.81 ± 0.12 b | 1.00 ± 0.10 c | 1.47 ± 0.10 b | 4.31 ± 0.22 a | 6.43 ± 0.04 c | 70.46 ± 0.42 | 18.25 ± 0.14 a |

| P2Rc | 2.70 ± 0.02 a | 1.21518085 | 0.619 ± 0.01 c | 1.90 ± 0.11 a | 1.93 ± 0.13 a | 1.14 ± 0.15 a | 1.61 ± 0.12 a | 3.39 ± 0.04 c | 6.49 ± 0.04 c | 72.02 ± 0.58 | 17.64 ± 0.45 a |

| FCh | 2.44 ± 0.01 b | 1.07205692 | 0.687 ± 0.01 b | 1.76 ± 0.17 c | 1.83 ± 0.15 b | 1.06 ± 0.14 b | 1.51 ± 0.14 b | 4.02 ± 0.10 b | 6.16 ± 0.17 d | 73.68 ± 0.52 | 15.68 ± 0.17 b |

| F1Rc | 2.16 ± 0.01 c | 1.23720517 | 0.589 ± 0.02 d | 1.80 ± 0.13 b | 1.84 ± 0.14 b | 1.00 ± 0.18 c | 1.42 ± 0.13 b | 4.43 ± 0.16 a | 6.92 ± 0.17 b | 70.28 ± 1.95 | 17.61 ± 1.49 a |

| F2Rc | 2.20 ± 0.01 c | 1.06173958 | 0.744 ± 0.01 a | 1.74 ± 0.13 c | 1.78 ± 0.11 b | 1.01 ± 0.11 c | 1.46 ± 0.10 b | 3.89 ± 0.03 b | 8.19 ± 0.05 a | 70.50 ± 0.29 | 16.95 ± 0.18 a |

| BCh | 2.29 ± 0.01 c | 0.98119775 | 0.577 ± 0.02 d | 1.70 ± 0.12 c | 1.78b ± 0.15 b | 0.97 ± 0.15 c | 1.43 ± 0.13 c | 3.56 ± 0.15 c | 7.05 ± 0.01 b | 71.44 ± 0.61 | 17.41 ± 0.28 a |

| B1Rc | 2.14 ± 0.01 c | 1.21661019 | 0.729 ± 0.01 a | 1.72 ± 0.18 c | 1.77 ± 0.12 b | 0.98 ± 0.10 c | 1.44 ± 0.11 c | 3.97 ± 0.04 b | 7.27 ± 0.00 b | 71.40 ± 0.18 | 16.87 ± 0.13 a |

| B2Rc | 2.05 ± 0.01 c | 1.21884051 | 0.715 ± 0.01 a | 1.70 ± 0.11 c | 1.75 ± 0.14 b | 0.96 ± 0.11 c | 1.42 ± 0.11 c | 4.14 ± 0.07 b | 5.83 ± 0.24 e | 72.30 ± 1.23 | 18.25 ± 0.14 a |

| NORTHERN SEEDS c | |||||||||||

| 2007 | 3.2 ± 0.1 b | 1.19 ± 0.10 a | 0.69 ± 0.01 d | 2.08 ± 0.10 a | 2.12 ± 0.13 a | 1.00 ± 0.10 a | 1.64 ± 0.10 a | 2.65 ± 0.58 b | 9.03 ± 0.44 b | 71.79 ± 1.57 | 16.53 ± 0.55 b |

| 2008 | 3.0 ± 0.2 a | 1.24 ± 0.11 a | 0.72 ± 0.01 c | 2.09 ± 0.10 a | 2.12 ± 0.14 a | 1.02 ± 0.10 a | 1.66 ± 0.10 a | 3.25 ± 0.10 b | 9.06 ± 0.20 b | 70.61 ± 0.73 | 17.08 ± 0.43 b |

| 2009 | 4.7 ± 0.1 d | 1.15 ± 0.04 a | 0.68 ± 0.01 b | 2.47 ± 0.11 c | 2.41 ± 0.14 b | 1.38 ± 0.12 c | 2.01 ± 0.08 c | 3.04 ± 0.06 a | 8.8 ± 0.41 b | 74.41 ± 1.03 | 13.75 ± 0.56 a |

| 2010 | 3.4 ± 0.1 c | 1.28 ± 0.03 a | 0.66 ± 0.02 a | 2.12 ± 0.10 a | 2.22 ± 0.12 a | 1.11 ± 0.07 b | 1.73 ± 0.07 b | 3.00 ± 0.08 a | 6.05 ± 0.50 a | 76.81 ± 0.97 | 14.14 ± 0.39 a |

| 2011 | 3.5 ± 0.1 c | 1.26 ± 0.01 a | 0.66 ± 0.01 a | 2.20 ± 0.09 b | 2.19 ± 0.0 a | 1.15 ± 0.11 b | 1.77 ± 0.08 b | 3.22 ± 0.10 b | 6.52 ± 0.35 a | 73.5 ± 0.78 | 16.76 ± 0.33 b |

| Amino Acid | 2007 | 2008 | 2009 | 2010 | 2011 | Quinoa a | Wheat a | Rice a | Oats a | Corn a | Barley a | Milk a |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| aspartic acid | 1.07 ± 0.00 | 0.69 ± 0.04 | 1.09 ± 0.06 | 0.84 ± 0.04 | 1.14 ± 0.07 | 0.88 | 0.49 | 0.81 | 1.06 | 0.60 | 0.67 | 0.26 |

| glutamic acid | 1.87 ± 0.00 | 1.81 ± 0.04 | 1.90 ± 0.1 | 1.47 ± 0.04 | 2.24 ± 0.07 | 1.43 | 4.17 | 1.62 | 2.92 | 1.80 | 2.77 | 0.76 |

| serine | 0.39 ± 0.00 | 0.15 ± 0.00 | 0.55 ± 0.03 | 0.11 ± 0.03 | 0.57 ± 0.24 | 0.44 | 0.56 | 0.43 | 0.66 | 0.47 | 0.48 | 0.20 |

| histidine | 0.40 ± 0.00 | 0.29 ± 0.01 | 0.40 ± 0.02 | 0.90 ± 0.03 | 0.79 ± 0.53 | 0.29 | 0.25 | 0.2 | 0.29 | 0.26 | 0.25 | 0.09 |

| glycine | 0.69 ± 0.00 | 0.50 ± 0.01 | 0.78 ± 0.04 | 0.66 ± 0.02 | 0.59 ± 0.26 | 0.62 | 0.42 | 0.39 | 0.66 | 0.35 | 0.45 | 0.07 |

| threonine | 0.43 ± 0.00 | 0.19 ± 0.00 | 0.43 ± 0.02 | 0.35 ± 0.02 | 0.61 ± 0.27 | 0.42 | 0.32 | 0.31 | 0.46 | 0.34 | 0.39 | 0.15 |

| arginine | 1.04 ± 0.00 | 0.87 ± 0.00 | 1.15 ± 0.08 | 0.89 ± 0.04 | 1.34 ± 0.07 | 0.84 | 0.42 | 0.65 | 0.88 | 0.40 | 0.56 | 0.11 |

| alanine | 0.58 ± 0.00 | 0.65 ± 0.01 | 0.58 ± 0.03 | 0.48 ± 0.01 | 0.54 ± 0.44 | 0.56 | 0.37 | 0.47 | 0.63 | 0.72 | 0.46 | 0.12 |

| proline | 0.77 ± 0.00 | 0.55 ± 0.02 | 0.35 ± 0.06 | 0.09 ± 0.03 | 1.48 ± 0.06 | 0.37 | 1.39 | 0.37 | 0.72 | 0.85 | 1.28 | 0.31 |

| tyrosine | 0.34 ± 0.01 | 0.07 ± 0.01 | 0.32 ± 0.02 | 0.28 ± 0.01 | 0.26 ± 0.01 | 0.34 | 0.28 | 0.28 | 0.46 | 0.36 | 0.37 | 0.16 |

| valine | 0.62 ± 0.01 | 0.12 ± 0.01 | 0.71 ± 0.08 | 0.56 ± 0.07 | 0.50 ± 0.01 | 0.54 | 0.49 | 0.43 | 0.71 | 0.46 | 0.59 | 0.20 |

| methionine | 1.26 ± 0.01 | 0.78 ± 0.03 | 0.13 ± 0.01 | 0.11 ± 0.03 | 1.51 ± 0.34 | 0.24 | 0.17 | 0.18 | 0.23 | 0.18 | 0.20 | 0.09 |

| cysteine | 0.27 ± 0.01 | 1.64 ± 0.08 | 0.06 ± 0.00 | 0.04 ± 0.00 | 0.69 ± 0.01 | --- | 0.30 | 0.08 | 0.37 | 0.15 | 0.27 | 0.03 |

| isoleucine | 0.53 ± 0.01 | 0.44 ± 0.01 | 0.53 ± 0.03 | 0.43 ± 0.01 | 0.64 ± 0.01 | 0.43 | 0.44 | 0.30 | 0.53 | 0.35 | 0.42 | 0.16 |

| leucine | 0.86 ± 0.01 | 0.66 ± 0.02 | 0.88 ± 0.05 | 0.71 ± 0.02 | 1.01 ± 0.02 | 0.72 | 0.84 | 0.65 | 1.01 | 1.19 | 0.78 | 0.33 |

| phenylalanine | 0.52 ± 0.01 | 0.31 ± 0.01 | 0.52 ± 0.03 | 0.43 ± 0.01 | 0.58 ± 0.02 | 0.49 | 0.58 | 0.41 | 0.70 | 0.46 | 0.60 | 0.19 |

| lysine | 0.63 ± 0.00 | 0.49 ± 0.01 | 0.60 ± 0.03 | 0.60 ± 0.02 | 0.78 ± 0.01 | 0.67 | 0.25 | 0.30 | 0.52 | 0.25 | 0.41 | 0.27 |

| Amino Acids | Year 2010 | Year 2009 | ||||

|---|---|---|---|---|---|---|

| Pre-School Chillaren | School Children | Adults | Pre-School Children | School Children | Adults | |

| 2–5 Years Old | 10–12 Years Old | 2–5 Years Old | 0–12 Years Old | |||

| Histidine | 400 | 400 | 475 | 136.8 | 136.8 | 162.5 |

| Isoleucine | 128.6 | 128.6 | 276.9 | 125 | 110.7 | 269.2 |

| Leucine | 90.9 | 136.4 | 315.8 | 87.9 | 131.8 | 305.3 |

| Lysine | 86.9 | 114.5 | 315 | 69 | 90.9 | 250 |

| Methionine ± Cysteine b | 50.8 | 57.7 | 74.7 | 59.2 | 67.3 | 87.1 |

| Phenylalanine ± Tyrosine | 95.4 | 273.2 | 316.3 | 88.9 | 254.5 | 294.7 |

| Threonine | 86.2 | 104.6 | 325.6 | 82.4 | 100 | 311.1 |

| Tryptophan | s/d | s/d | s/d | 427.3 | 522.2 | 940 |

| Valine | 134 | 187.6 | 360.8 | 217.1 | 304 | 584.6 |

| Chemical Scoring | 50.8 | 57.7 | 74.7 | 67.3 | 59.2 | 87.1 |

| PDCAAS c | 40.6 | 46.2 | 59.8 | 47.4 | 53.8 | 69.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villa, P.M.; Cervilla, N.; Mufari, R.; Bergesse, A.; Calandri, E. Making Nutritious Gluten-Free Foods from Quinoa Seeds and Its Flours. Proceedings 2020, 53, 5. https://doi.org/10.3390/proceedings2020053005

Villa PM, Cervilla N, Mufari R, Bergesse A, Calandri E. Making Nutritious Gluten-Free Foods from Quinoa Seeds and Its Flours. Proceedings. 2020; 53(1):5. https://doi.org/10.3390/proceedings2020053005

Chicago/Turabian StyleVilla, Patricia Miranda, Natalia Cervilla, Romina Mufari, Antonella Bergesse, and Edgardo Calandri. 2020. "Making Nutritious Gluten-Free Foods from Quinoa Seeds and Its Flours" Proceedings 53, no. 1: 5. https://doi.org/10.3390/proceedings2020053005

APA StyleVilla, P. M., Cervilla, N., Mufari, R., Bergesse, A., & Calandri, E. (2020). Making Nutritious Gluten-Free Foods from Quinoa Seeds and Its Flours. Proceedings, 53(1), 5. https://doi.org/10.3390/proceedings2020053005