1. Introduction

Cycling is one of the most practiced physical activities across the world [

1]. Considering the globalization of cycling, major markets for cycling equipment are developing in many hot-weather or tropical locations such as Australia, southern Asia, and the Middle East [

2].

Cyclists are often wearing backpacks, especially during longer events like mountain bike (MTB) and bicycle touring or bike commuting. Weder et al. [

3] emphasized that wearing a backpack during cycling has a significant impact on athletes’ thermoregulation. However, thermoregulation and skin-close microclimate ((MC) temperature and humidity between skin and first clothing layer) is not only an essential aspect for thermal comfort but also for performance [

4], especially in endurance sports such as cycling. Hence, a heat balance represents the major goal for temperature regulation during exercises, especially aiming at avoiding hyperthermia as well as hypothermia [

2].

Weder et al. [

3] and Klauer et al. [

5] experimentally analyzed different backpack systems during cycling in a climate chamber. They concluded that wearing a backpack during cycling affects the MC as well as the interlayer climate ((ILC) temperature and humidity between first clothing layer and midlayer/backpack). Also, corresponding results depended on the tested backpack system. Conventional ventilated backpack systems reduce the temperature (T) and relative humidity (RH) in the MC, as well as in the ILC, compared to full contact backpacks [

3,

5]. Nevertheless, Klauer and Michel [

5] concluded that there is still potential to optimize existing backpack technologies towards better thermal comfort.

Based on these findings [

5], the same research group developed a new ventilated backpack design. This technology utilizes the relative headwind that is generated during cycling for an optimized convective heat transfer between the backpack and the first clothing layer. A computational fluid dynamic modeling approach (CFD) of a cyclist without a backpack visualized that the air flow across the shoulders rejoins behind the neck and head of the rider. Here, the air flow speeds up and follows the back surface with the air stream dropping along the spine region [

6], where the highest temperature and sweat patterns of the torso are located [

7,

8,

9]. A second air flow path that showed potential to improve convective heat transfer is the one curving around the sides of the torso. Based on these findings, it was suggested that the backpack of novel design should catch the high velocity air flow around the shoulders and neck and guide it towards the spine region. A further CFD analysis of a cyclist wearing a backpack with the new rear panel design confirmed the possibility of utilizing the headwind generated during cycling as a driving force for convective heat transfer. The results of the CFD analysis clearly pointed out that new backpack design features change the airstream pattern, introducing stable air flow between the cyclist’s back and the backpack [

6]. However, this CFD study focused only on the air velocity fields and flow patterns as an indication of improved thermal performance and provided no evidence of the concept’s superiority in this area.

Therefore, the main goal of the present study was an experimental investigation of the functionality of the backpack with the new and innovative rear panel design and its comparison to a conventional full contact backpack system. The chosen research approach aimed at testing MC and ILC using recreational cyclists exercising in a climate controlled wind tunnel environment. In addition, the influence of the backpacks on aerodynamic drag and physiological parameters was of interest.

2. Materials and Methods

Seven male subjects (age 34 ± 10 years, body height and weight 1.87 ± 0.05 m and 82.5 ± 7.6 kg) who regularly cycle for exercise participated in the experiments, which were approved by the Regional Ethical Review Board in Umeå, Sweden (Reg. No. 2019/00410). Prior to starting the experiments, the subjects received written information about the study and gave their written consent to participate.

The subjects were cycling on a mountain bike (SC Lite, XXL Europe GmbH, Luzern, Switzerland) with the rear wheel mounted on a “smart trainer” (Flow Smart, Tacx B.V., Wassenaar, The Netherlands), which was placed on a force plate (Kistler 9281EA, Kistler Instrumente AG, Winterthur, Switzerland) in a climatic wind tunnel [

10]. The resistance in the “smart trainer” simulated rolling resistance during pedaling, while the aerodynamic drag (F

D) acting on the cyclist, together with equipment, was registered by the force plate. A power (P) of 130 watts and wind speed of 5.55 m/s were chosen in order to simulate outdoor conditions with a relatively moderate cycling speed. With an expected mechanical efficiency of ~16%–20%, this would give an energy expenditure of ~720 watts (10.3 kCal/min) and an oxygen uptake (

of 2.1 L/min, or 25 mL/kg/min, for a body weight of 82 kg [

11].

Three series of tests with the following conditions were performed: (1) without carrying any backpack (WB), (2) carrying a conventional commercial backpack (CB; 16 L, 946 g) belonging to the full contact backpack systems, and (3) carrying a novel backpack having innovative rear panel design (NB; 16 L, 802 g).

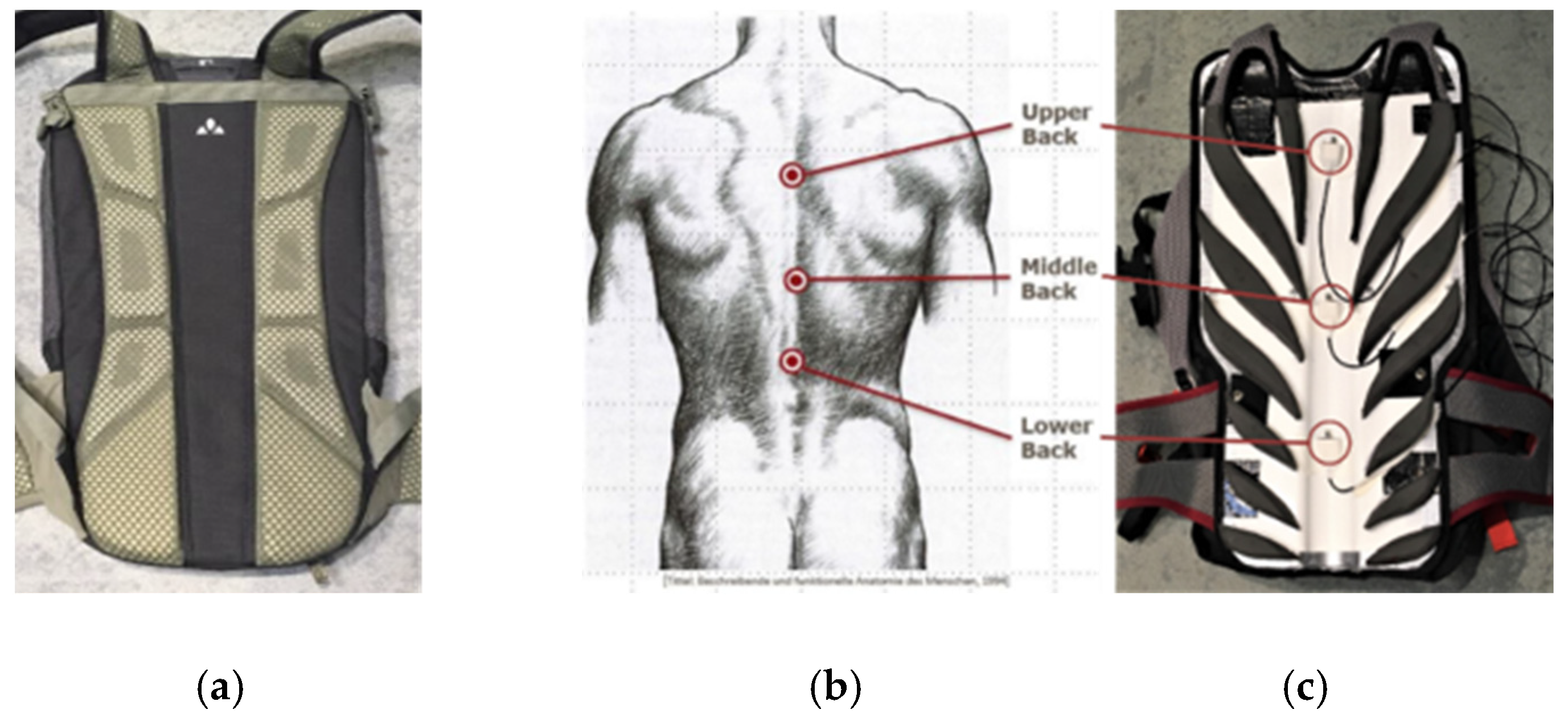

Figure 1a,c show the rear panels of the two backpacks used in the study. The CB (a) rear panel has four supporting pads (10 mm thick) on each side aligned with the user’s spine. The rear panel of the NB (c) has a number of curved spacing elements (18 mm thick) intended to channel the air flow from the top and the sides of the backpack along the back and spine of the cyclist [

8,

9].

Each subject was tested at the same time of day on three consecutive days and the order of test conditions was randomized for all subjects. The ambient air temperature (T), relative humidity (RH) and density (ρ) were 18.1 ± 0.8 °C, 13.6% ± 2.7% and 1.14 ± 0.01 kg/m3 during the experiments and were not significantly (p > 0.05) different between the three test conditions. During the tests, all subjects wore the same type of short and thin cycling pants (Vaude Men’s Advanced Pants III, 78% polyamide and 22% elastane), together with a short sleeved cycling shirt (Vaude Men’s Mossano Tricot IV, 100% polyester).

The test protocol duration was 45 min (min), where the first 5 and last 10 min were resting periods when the subjects were sitting on the bike without pedaling and headwind. The cycling was carried out for 30 min between the two resting periods. Due to the relatively moderate workload, there was no need for any warm-up period. The heights of the handlebars and saddle were individually adjusted and were the same for all three test conditions for each subject. The upper body was slightly forward-tilted and supported against the handlebars with relatively straight arms.

The dependent variables were T and RH, measured in MC and ILC, heart rate (HR),

, and F

D. HR was recorded using a transmitter with electrodes mounted around the subjects chest and a receiver on the wrist (Fenix 5X, Garmin International Inc., Olathe, AR, USA).

was measured using an automated metabolic system (Moxus Modular Metabolic System, AEI Technologies, Texas, USA). T and RH were measured with T/RH combined sensors and stored with a mobile data logger (60 Hz, SHT25, Sensiron, MSR147WD, MSR Electronics GmbH, Seuzach, Switzerland). Three sensors were placed on the two backpacks (ILC) at high, medium and low positions (

Figure 1a,c). Three sensors were also placed along the spine (MC) at the corresponding positions for the backpacks (

Figure 1b). Additionally, one sensor was placed in the MC on the chest in the lower part of the sternum. Thus, in total, four T/RH sensors for test WB and seven sensors for test conditions CB and NB were used. The P and cadence (C) and all dependent variables were compiled as mean for the measured values during 60 s every fifth min throughout the protocol. Recording for T and RH values started from the first min of the protocol, while HR and

values were starting on fifth min of the overall test. Recording of P, C and F

D values started at the 10th min and ended at 35th min of the tests.

Statistics

The statistical analyses were carried out using SPSS for Windows statistical software release 24.0 (SPSS Inc., Chicago, IL, USA). The test condition variance and time interval variance of P, C, T, RH, HR, and FD where analyzed using two-way ANOVA with repeated measures. The variance of the wind tunnel ambient T, RH and ρ between the three test conditions was analyzed using one-way ANOVA with repeated measures. The Bonferroni post hoc test was used to discern any significant differences found with ANOVA and for adjustments of α for multiple comparisons (p < 0.05). The results are reported as mean value ± standard deviation (SD).

3. Results

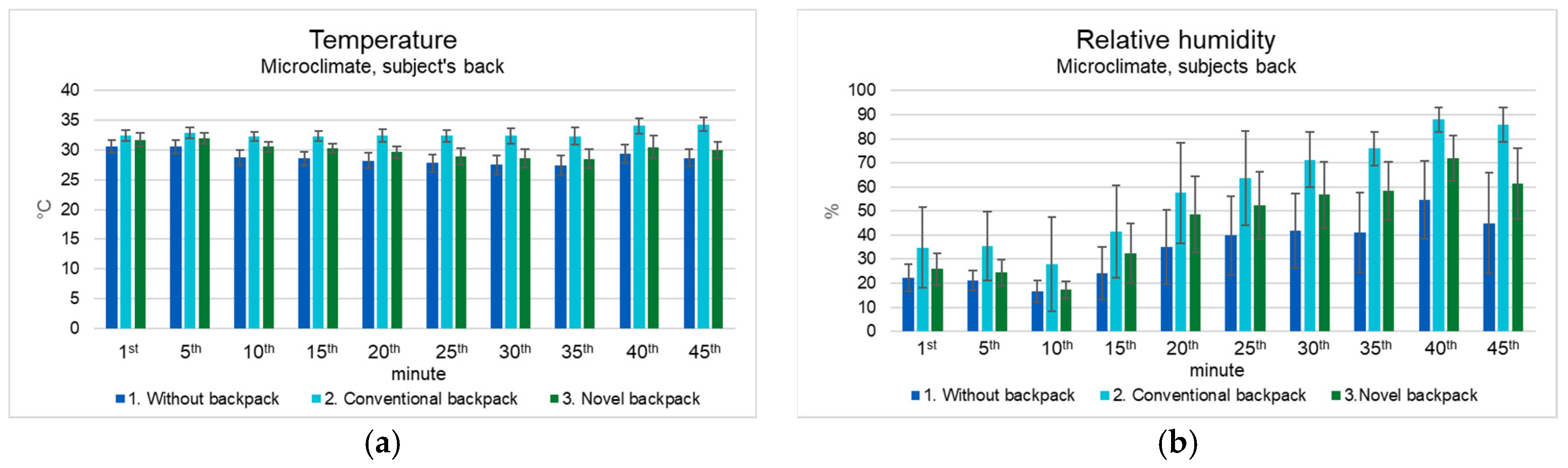

Results of averaged values of the three T/RH sensors positioned in the MC along the spine are presented in

Figure 2a,b. The statistical analyses showed significant (

p < 0.05) differences in T between all three test conditions (WB, CB and NB). A significant difference was also found in RH for CB vs. WB and NB, while there was no difference in RH between WB and NB. Further, there were significant differences in T between different time intervals in the protocol. This occurred for the 1st and 5th min vs. 10th and 15th min and for the 25th, 30th and 35th min vs. 40th and 45th min. Furthermore, significant differences were found in RH for the 1st vs. 10th, 35th, 40th and 45th min; for the 5th, 10th and 15th min vs. 30th, 35th, 40th and 45th min; for the 25th vs. 20th and 30th min and, finally, between the 35th and 40th min.

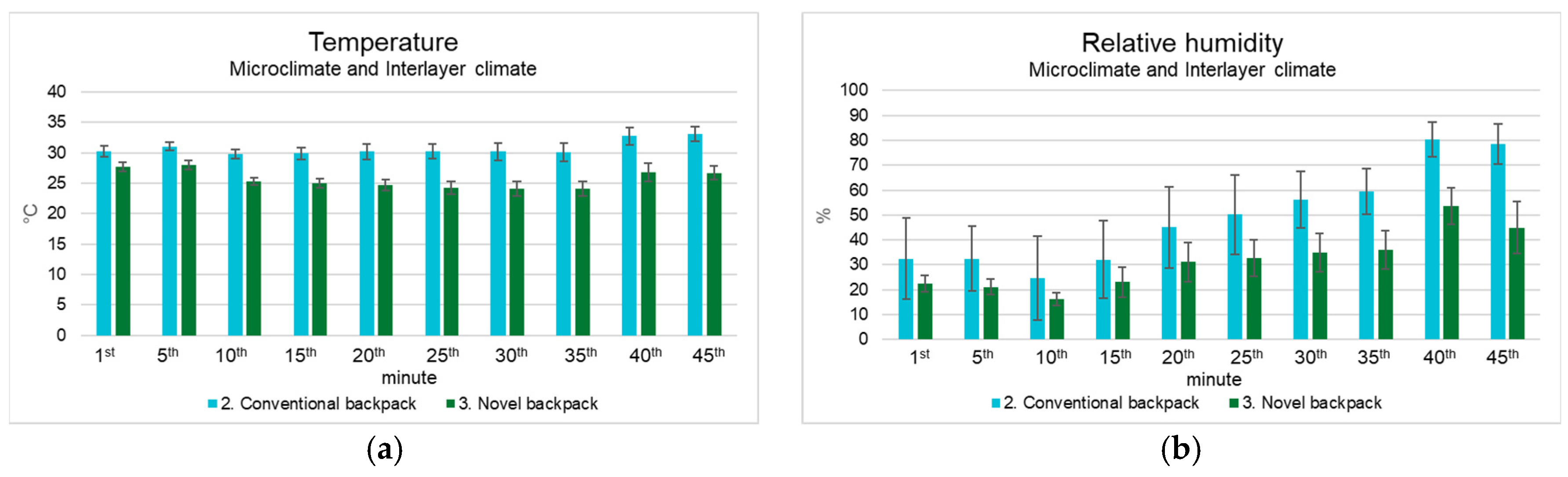

A mean of the values of all seven sensors, placed in the MC and ILC, for the two test conditions using different backpacks are presented in

Figure 3. A significant difference was found in both T and RH between CB and NB. A significant difference was also found for the mean of the ILC sensors separately (results not shown here). Also, significant differences were found in T between different time intervals. This occurred for the 1st min vs. 10th, 15th and 25th min; for the 5th min differences were added vs. 20th and 30th min; for the 40th vs. 25th, 30th and 35th min and, finally, for the 45th min vs. the 10th, 15th, 20th, 25th, 30th and 35th min. As regards RH, significant differences were found for the 1st and 5th min vs. 35th, 40th and 45th min; for the 10th min difference was added vs. the 30th min and for the 15th min also vs. 25th min. Finally, significant differences in RH were also found for the 40th and 45th min vs. all other time intervals.

The results for HR,

, P, C and F

D are presented in

Table 1. There were no significant (

p > 0.05) differences between the three test conditions in HR,

, P, C and F

D. Similarly, there were no differences in P and C between different time intervals during cycling. However, there were significant differences in HR and

between the cycling and resting periods, but not within these periods. Finally, there was a small but significant difference in the recorded F

D values for the final time interval vs. the three initial ones, but it was probably due to electrical drift in the force plate.

4. Discussion

With regard to the mean value of the three sensors placed in the MC on the subjects back, there was a statistically significant difference in T between all three test conditions. Not surprisingly, average T was lowest without carrying a backpack and lower when wearing the backpack with novel design compared to wearing a backpack of conventional design, see

Figure 2a. Further, even when it comes to RH, wearing a backpack of conventional design resulted in the highest values, see

Figure 2b. However, there was no statistical difference between the other two test conditions, only a trend to lower RH values for the test without using any backpack. Furthermore, in the paired comparison of mean values for all sensors placed in the MC and ILC, both T and RH were significantly lower for the test using the backpack with innovative rear panel design, see

Figure 3a,b. These findings go hand in hand with the results in Weder et al. [

3] and Klauer et al. [

5].

Regarding the comparison between different time intervals in the protocol, the statistical difference meant a slight decrease in T towards the middle of the protocol, which was systematic for all three test conditions, see

Figure 2a. This was followed by a slight increase in T as the protocol went from cycling to resting on the bike. The results for T shown in

Figure 3a followed the same pattern, though less evident for the test using the conventional backpack. Further, RH also showed a slight decrease initially, where the protocol went from rest to cycling with headwind. This was followed by a gradual increase during the remaining part of the protocol, where the increase was somewhat greater for the test condition using the conventional backpack, see

Figure 2b and

Figure 3b. In general, it seems that RH is much more sensitive with reference to the headwind and over time compared to T. Moreover, the measurements also show that there is a certain delay before the sweating starts as a result of the increased energy expenditure and body temperature.

One thing that may have affected the results is that the test conditions already showed different T and RH values in the 1st min. This was because the subjects carried the backpacks for a few minutes before the measurements started, which apparently affected both T and RH in MC and ILC.

The established differences between the test conditions occurred without any differences in HR,

, P, C and F

D. HR and

was ~120 b/min and 24 mL/kg/min, which is approximately 60%–65% of the subjects’ predicted maximal values at their age [

11]. Interestingly, there was no difference in F

D with and without the use of a backpack. This was also the case between the two tests with different backpacks, even though the differences in T and RH values indicated a presence of air flow between the novel backpack rear panel and the cyclist’s back. Most probably, this was due to the difficulty of detecting small differences in aerodynamic drag over the overall F

D from the cyclist, bicycle and “smart trainer”.