Comparing the Performance of the Biathlon Rifles with Wooden and Titanium Frames †

Abstract

1. Introduction

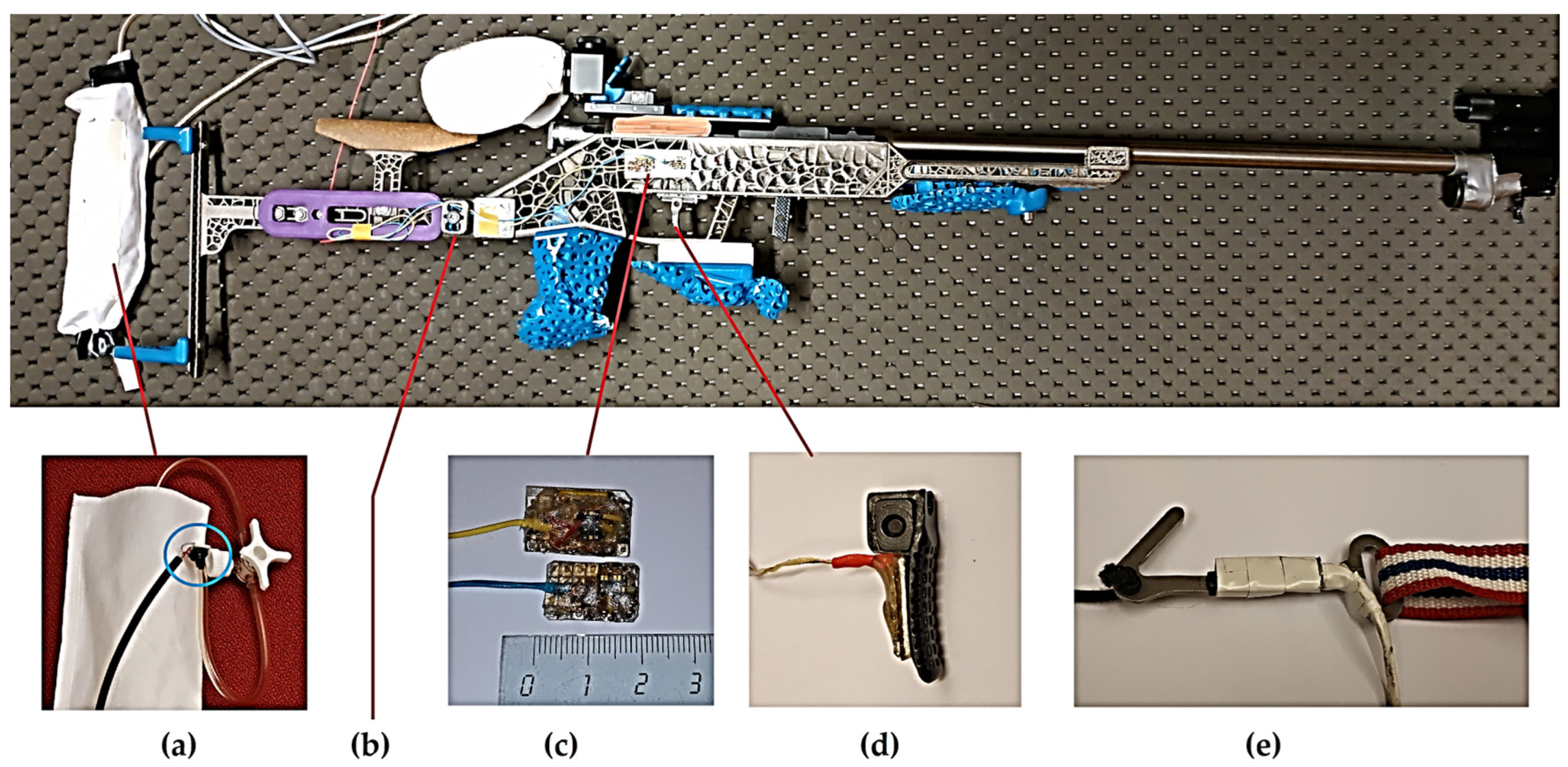

2. Materials and Methods

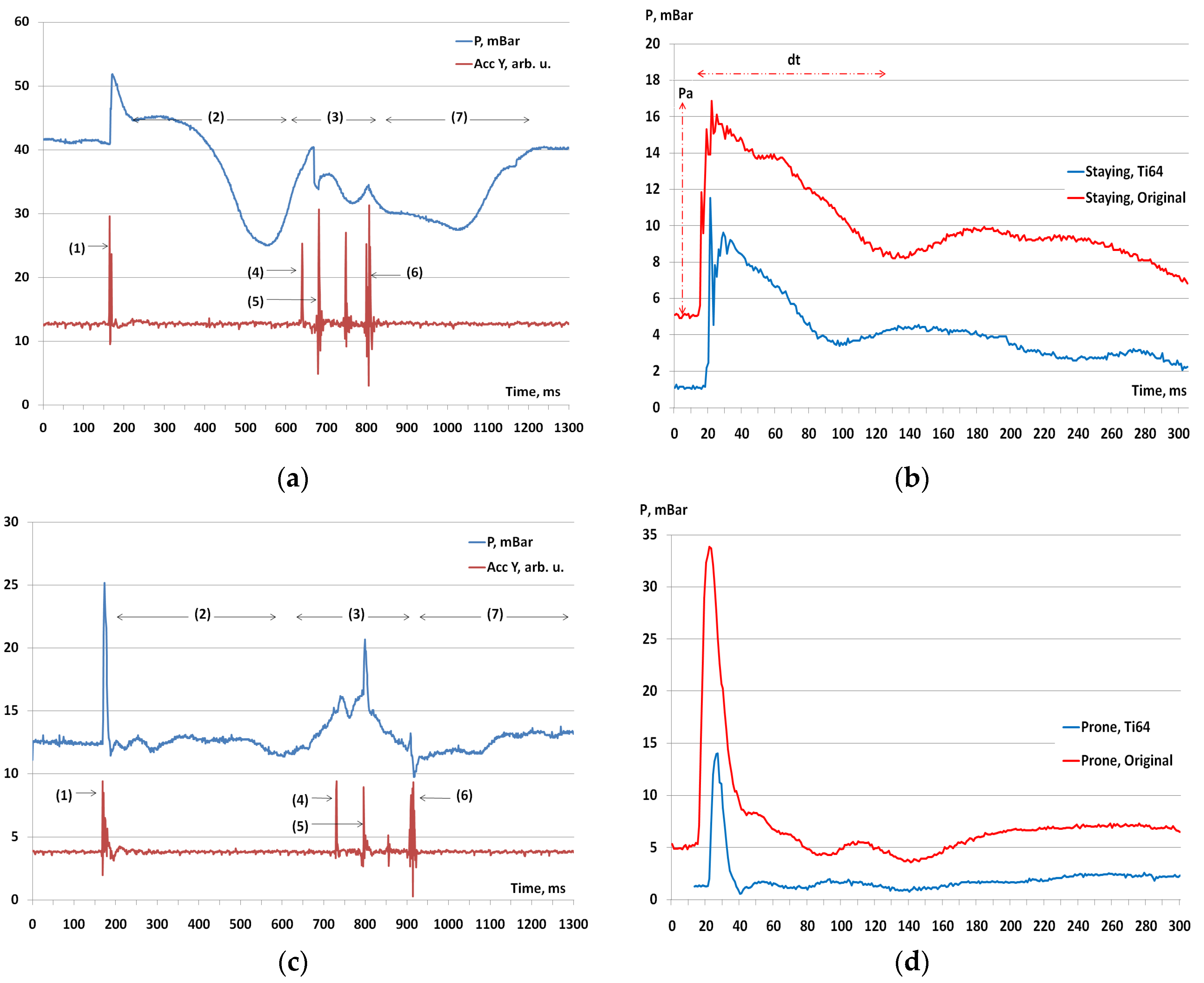

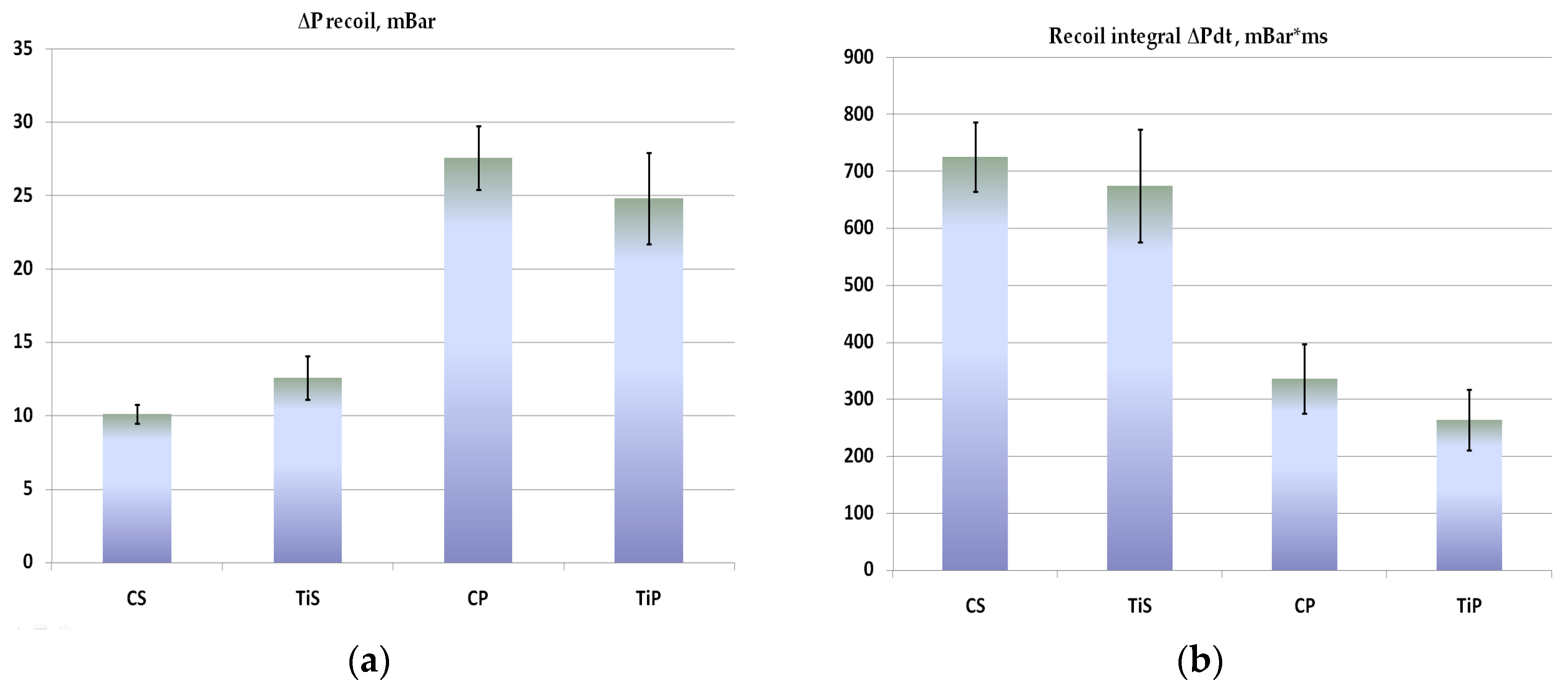

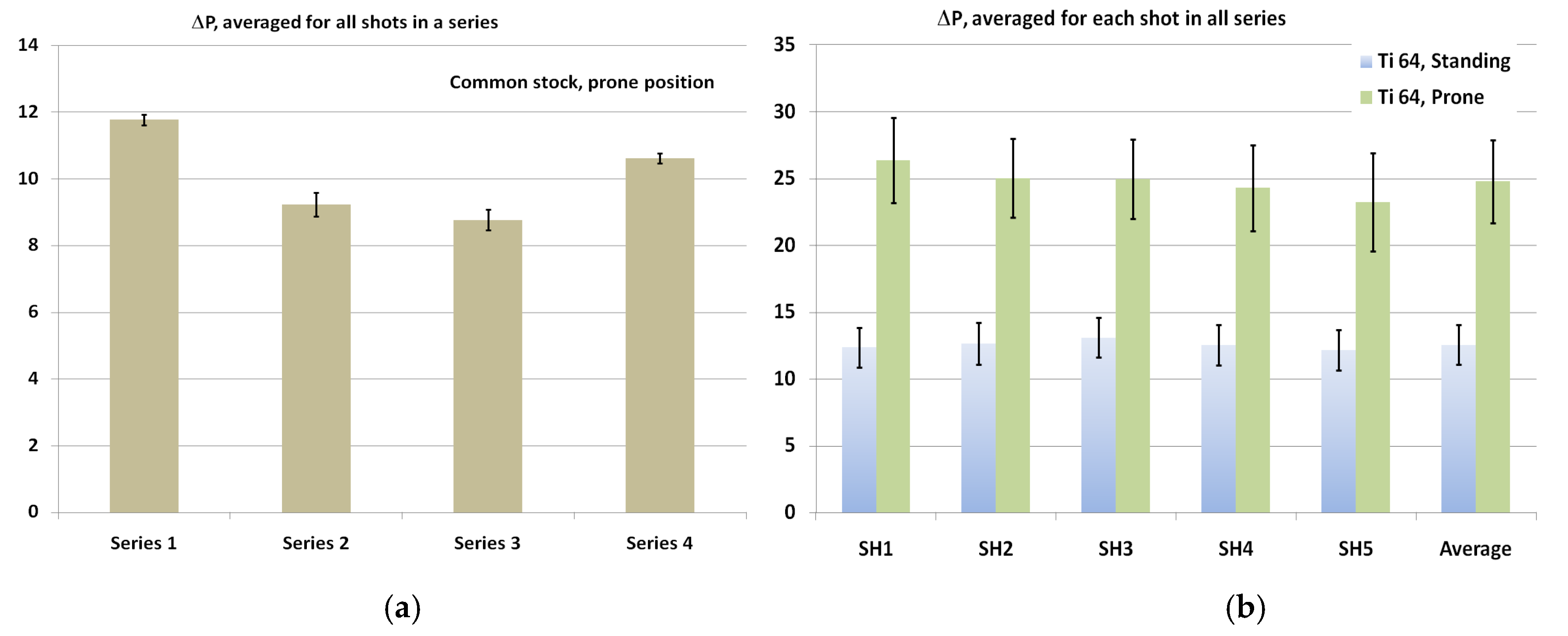

3. Results and Discussion

4. Conclusions

Funding

Conflicts of Interest

References

- Laaksonen, M.S.; Jonsson, M.; Holmberg, H.-C. The Olympic Biathlon—Recent Advances and Perspectives After Pyeongchang. Front. Physiol. 2018, 9, 796. [Google Scholar] [CrossRef] [PubMed]

- Laaksonen, M.S.; Finkenzeller, T.; Holmberg, H.-C.; Sattlecker, G. The influence of physiobiomechanical parameters, technical aspects of shooting, and psychophysiological factors on biathlon performance: A review. J. Sport Heal. Sci. 2018, 7, 394–404. [Google Scholar] [CrossRef] [PubMed]

- Ihalainen, S.; Laaksonen, M.S.; Kuitunen, S.; Leppävuori, A.; Mikkola, J.; Lindinger, S.J.; Linnamo, V. Technical determinants of biathlon standing shooting performance before and after race simulation. Scand. J. Med. Sci. Sports 2018, 28, 1700–1707. [Google Scholar] [CrossRef] [PubMed]

- Björklund, G. Shooting efficiency for winners of World Cup and World Championship races in men’s and women’s biathlon: where is the cut-off? Int. J. Perform. Anal. Sport 2018, 18, 1–9. [Google Scholar] [CrossRef]

- Laaksonen, M.S.; Ainegren, M.; Lisspers, J. Evidence of Improved Shooting Precision in Biathlon After 10 Weeks of Combined Relaxation and Specific Shooting Training. Cogn. Behav. Ther. 2011, 40, 237–250. [Google Scholar] [CrossRef] [PubMed]

- Lonzi, B.; Martarelli, M.; Santolini, C.; Scalise, L. Measurement of firing impulse force in rifles. In Proceedings of the International Conference on Noise and Vibration Engineering, Leuven, Belgium, 15–17 September 2014; pp. 2065–2075. [Google Scholar]

- Koptyug, A.; Ainegren, M. Experimental Measurement of Rifle Dynamics During the Range Shooting of Biathlon Weapons. Procedia Eng. 2015, 112, 349–354. [Google Scholar] [CrossRef][Green Version]

- Hao, L.; Raymont, D.; Yan, C.; Hussein, A.; Young, P. Design and additive manufacturing of cellular lattice structures. In Proceedings of the Innovative Developments in Virtual and Physical Prototyping, Leiria, Portugal, 28 September–1 October 2011; pp. 249–254. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koptyug, A.; Bäckström, M.; Olsson, V. Comparing the Performance of the Biathlon Rifles with Wooden and Titanium Frames. Proceedings 2020, 49, 62. https://doi.org/10.3390/proceedings2020049062

Koptyug A, Bäckström M, Olsson V. Comparing the Performance of the Biathlon Rifles with Wooden and Titanium Frames. Proceedings. 2020; 49(1):62. https://doi.org/10.3390/proceedings2020049062

Chicago/Turabian StyleKoptyug, Andrey, Mikael Bäckström, and Victor Olsson. 2020. "Comparing the Performance of the Biathlon Rifles with Wooden and Titanium Frames" Proceedings 49, no. 1: 62. https://doi.org/10.3390/proceedings2020049062

APA StyleKoptyug, A., Bäckström, M., & Olsson, V. (2020). Comparing the Performance of the Biathlon Rifles with Wooden and Titanium Frames. Proceedings, 49(1), 62. https://doi.org/10.3390/proceedings2020049062