Non-Parametric Shape Optimization of a Football Boot Bottom Plate †

Abstract

:1. Introduction

2. Non-Parametric Optimization

3. Methods

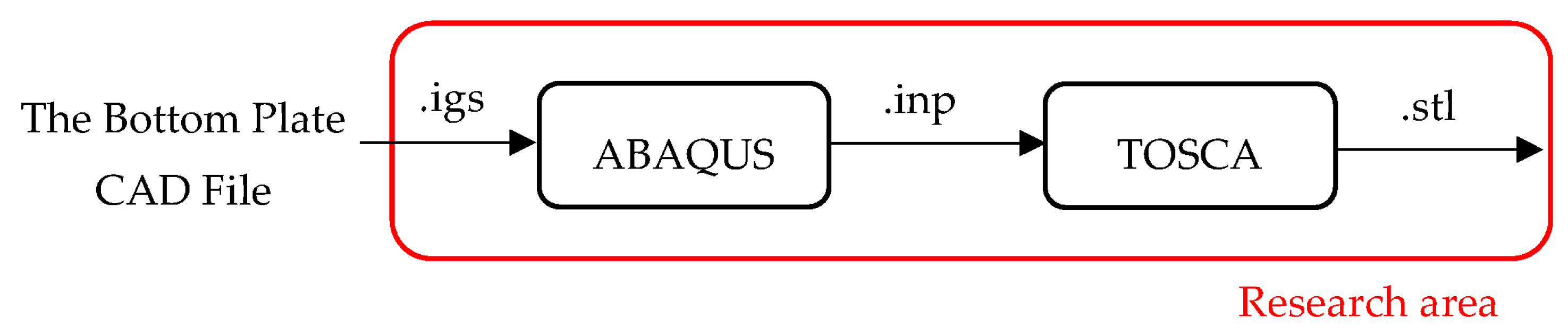

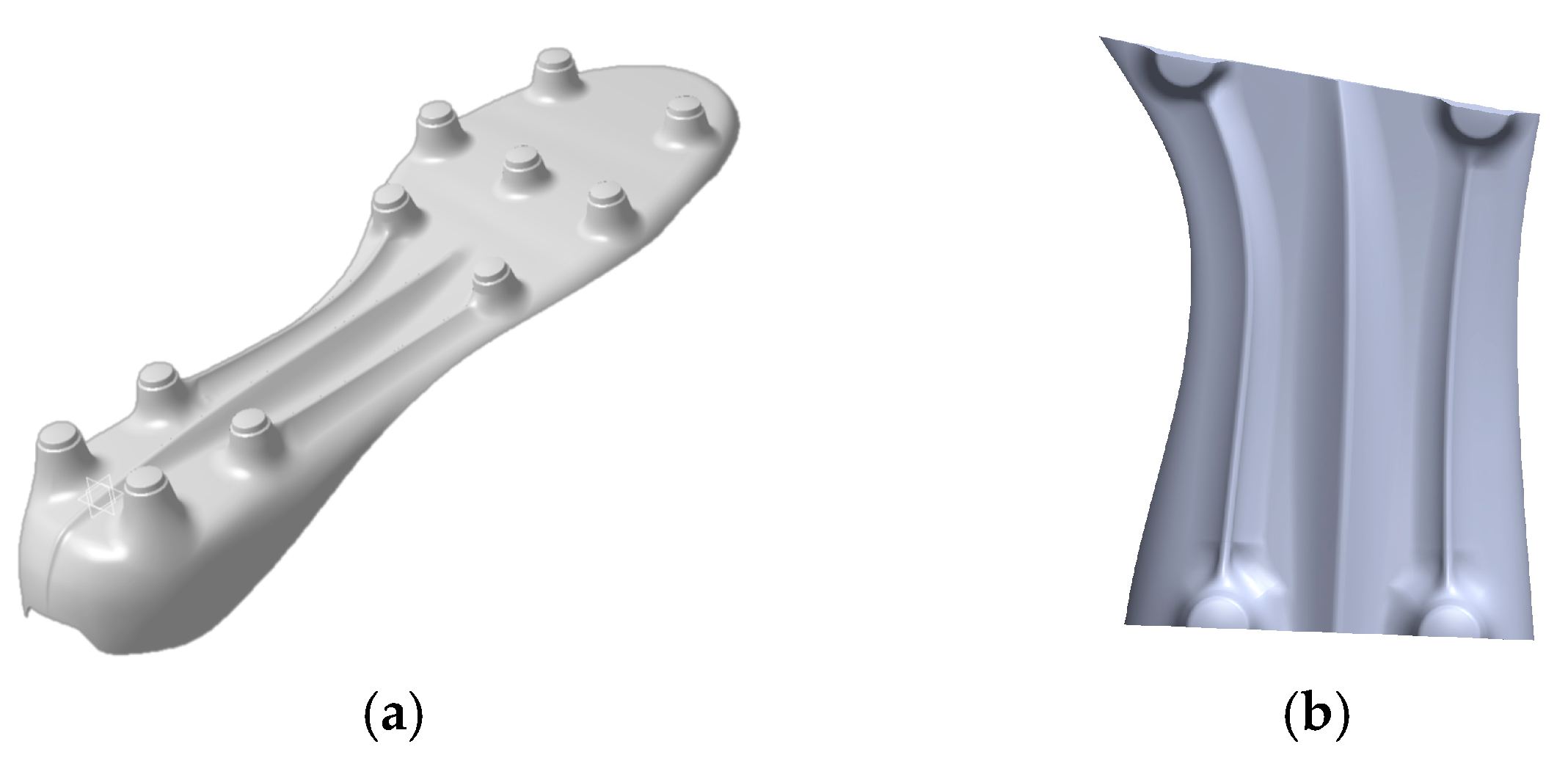

- The full model of the bottom plate CAD file was created (Figure 2a).

- The IGES file (.igs) of the bottom plate midfoot part (Figure 2b) was imported into the Abaqus Part section.

- The mechanical 3-point bending test boundary condition was applied in Abaqus.

- After Abaqus completed the analysis, an input file (.inp) was generated.

- The generated input file (.inp) was imported into Tosca Structure and preprocessed for shape optimization.

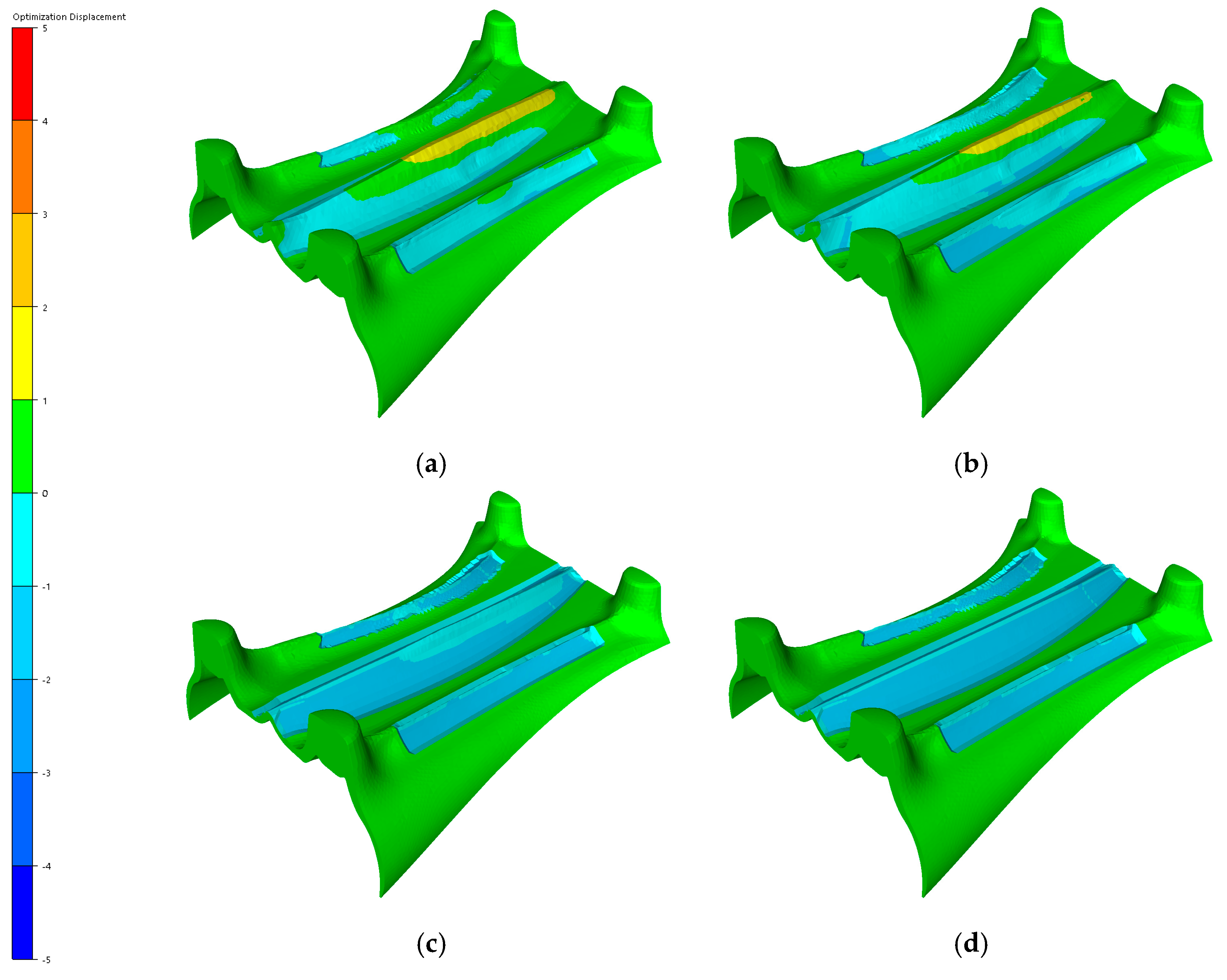

- Four different bending stiffnesses were targeted.

- The optimum shape of the bottom plate was saved to a .stl file.

3.1. FEA Pre-Processing

3.2. Calculation of Bending Stiffness

3.3. Non-Parametric Shape Optimization Pre-Processing

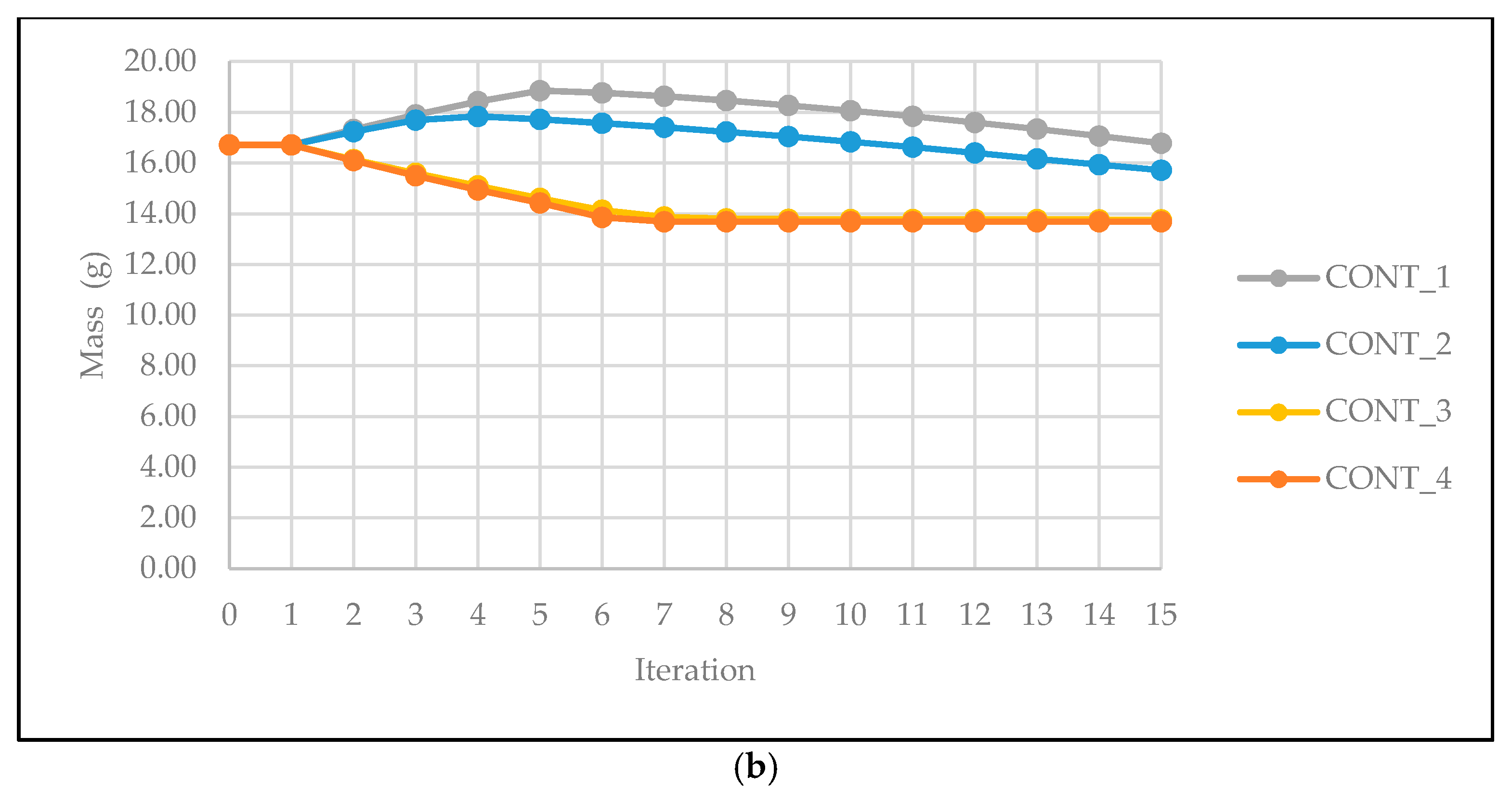

- The optimization objective was set to minimize the mass of the bottom plate.

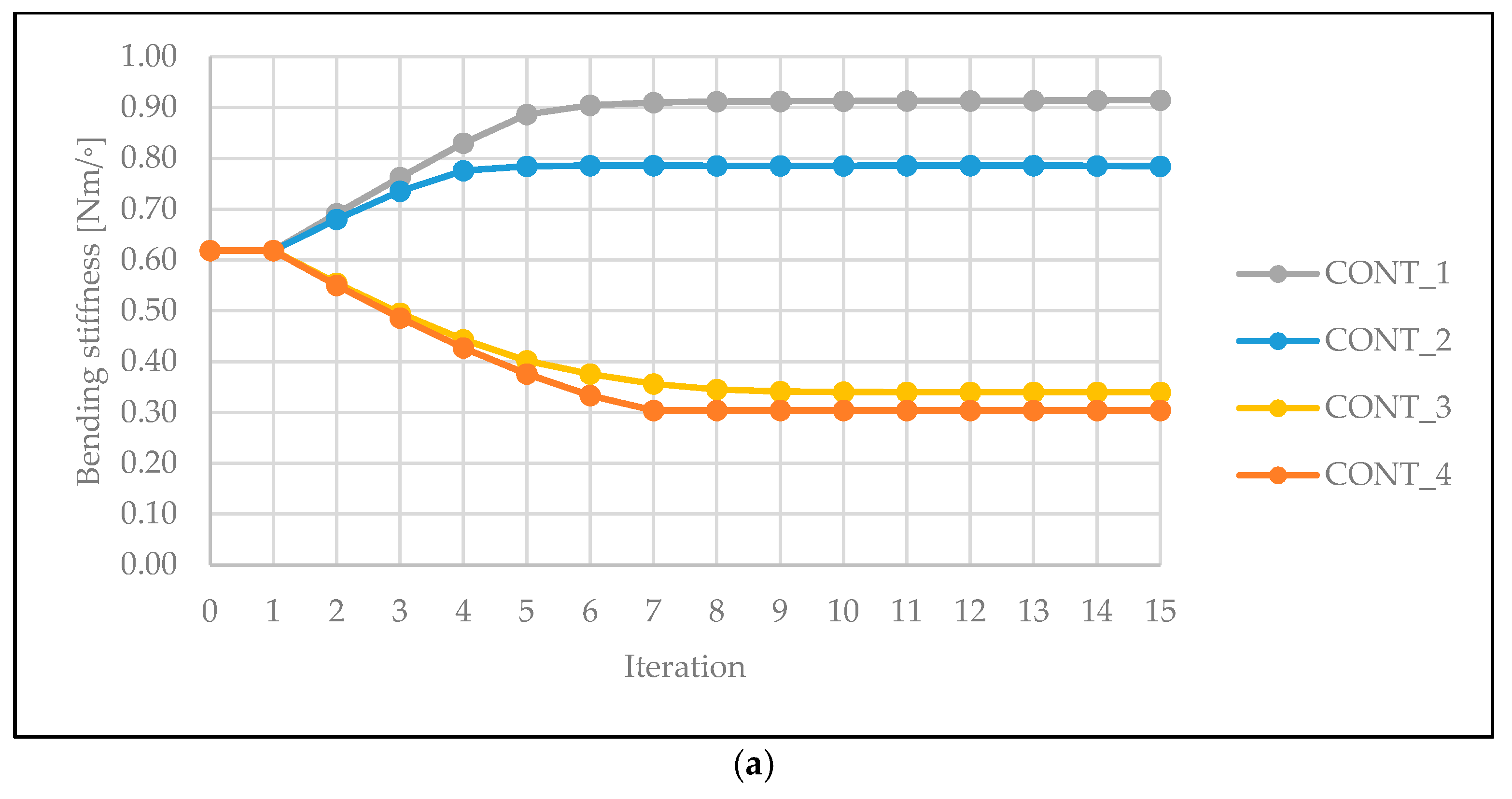

- Four different inequality constraints (CONT_#) were set as follows:

- CONT_1

- : 145% ≤ the target bending stiffness ≤ 155% of the initial bending stiffness

- CONT_2

- : 125% ≤ the target bending stiffness ≤ 135% of the initial bending stiffness

- CONT_3

- : 55% ≤ the target bending stiffness ≤ 65% of the initial bending stiffness

- CONT_4

- : 45% ≤ the target bending stiffness ≤ 55% of the initial bending stiffness

4. Results and Discussion

5. Conclusions

Conflicts of Interest

References

- Hennig, E.; Sterzing, T. The influence of soccer shoe design on playing performance: a series of biomechanical studies. Footwear Sci. 2010, 2, 3–11. [Google Scholar] [CrossRef]

- Fraser, S.; Harland, A.R.; Smith, P.; Lucas, T. A Study of Football Footwear Bending Stiffness. Procedia Eng. 2014, 72, 315–320. [Google Scholar] [CrossRef]

- Stefanyshyn, D.; Fusco, C. Athletics: Increased shoe bending stiffness increases sprint performance. Sport. Biomech. 2004, 3, 55–66. [Google Scholar] [CrossRef] [PubMed]

- Wannop, J.; Schrier, N.; Worobets, J.; Stefanyshyn, D. Influence of forefoot bending stiffness on American football performance. Footwear Sci. 2015, 7, S141–S142. [Google Scholar] [CrossRef]

- Schröder, H. Shape Optimization of Football Boot Outsoles: Engineering Midfoot and Forefoot Bending Stiffness. Master’s Thesis, Otto-von-Guericke-Universität Magdeburg, Magdeburg, Germany, 18 December 2018. [Google Scholar]

- Meske, R.; Sauter, J.; Schnack, E. Nonparametric gradient-less shape optimization for real-world applications. Struct. Multidiscip. Optim. 2005, 30, 201–218. [Google Scholar] [CrossRef]

- ABAQUS. Dassault Systèmes, 2018. Available online: https://www.3ds.com/products-services/simulia/products/abaqus/ (accessed on 25 May 2020).

- TOSCA. Dassault Systèmes, 2019. Available online: https://www.3ds.com/products-services/simulia/products/tosca/ (accessed on 25 May 2020).

- Hahn, Y.; Cofer, J.I. Study of Parametric and Non-Parametric Optimization of a Rotor-Bearing System. Aircraft Engine Fans Blowers 2014. [Google Scholar] [CrossRef]

- Chen, J.; Shapiro, V.; Suresh, K.; Tsukanov, I. Parametric and Topological Control in Shape Optimization. In Proceedings of the 32nd Design Automation Conference, Parts A and B, Philadelphia, USA, 10–13 September 2006; pp. 575–586. [Google Scholar] [CrossRef]

- Böhm, M.; Clausen, P.M. Non-Parametric Shape Optimization in Industrial Context. In Inverse Problems, Control and Shape Optimization; Palaiseau, France, 2012; pp. 7–8. Available online: http://www.cmap.polytechnique.fr/picof/Symposia/8b7b891f.pdf.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-R.; Harland, A.; Roberts, J. Non-Parametric Shape Optimization of a Football Boot Bottom Plate. Proceedings 2020, 49, 152. https://doi.org/10.3390/proceedings2020049152

Lee J-R, Harland A, Roberts J. Non-Parametric Shape Optimization of a Football Boot Bottom Plate. Proceedings. 2020; 49(1):152. https://doi.org/10.3390/proceedings2020049152

Chicago/Turabian StyleLee, Jeong-Ro, Andy Harland, and Jonathan Roberts. 2020. "Non-Parametric Shape Optimization of a Football Boot Bottom Plate" Proceedings 49, no. 1: 152. https://doi.org/10.3390/proceedings2020049152

APA StyleLee, J.-R., Harland, A., & Roberts, J. (2020). Non-Parametric Shape Optimization of a Football Boot Bottom Plate. Proceedings, 49(1), 152. https://doi.org/10.3390/proceedings2020049152