Thermoelastic Stress Analysis and Dissipated Energy Evaluation Using Infrared-Optical Synchronous Measurement †

Abstract

:1. Introduction

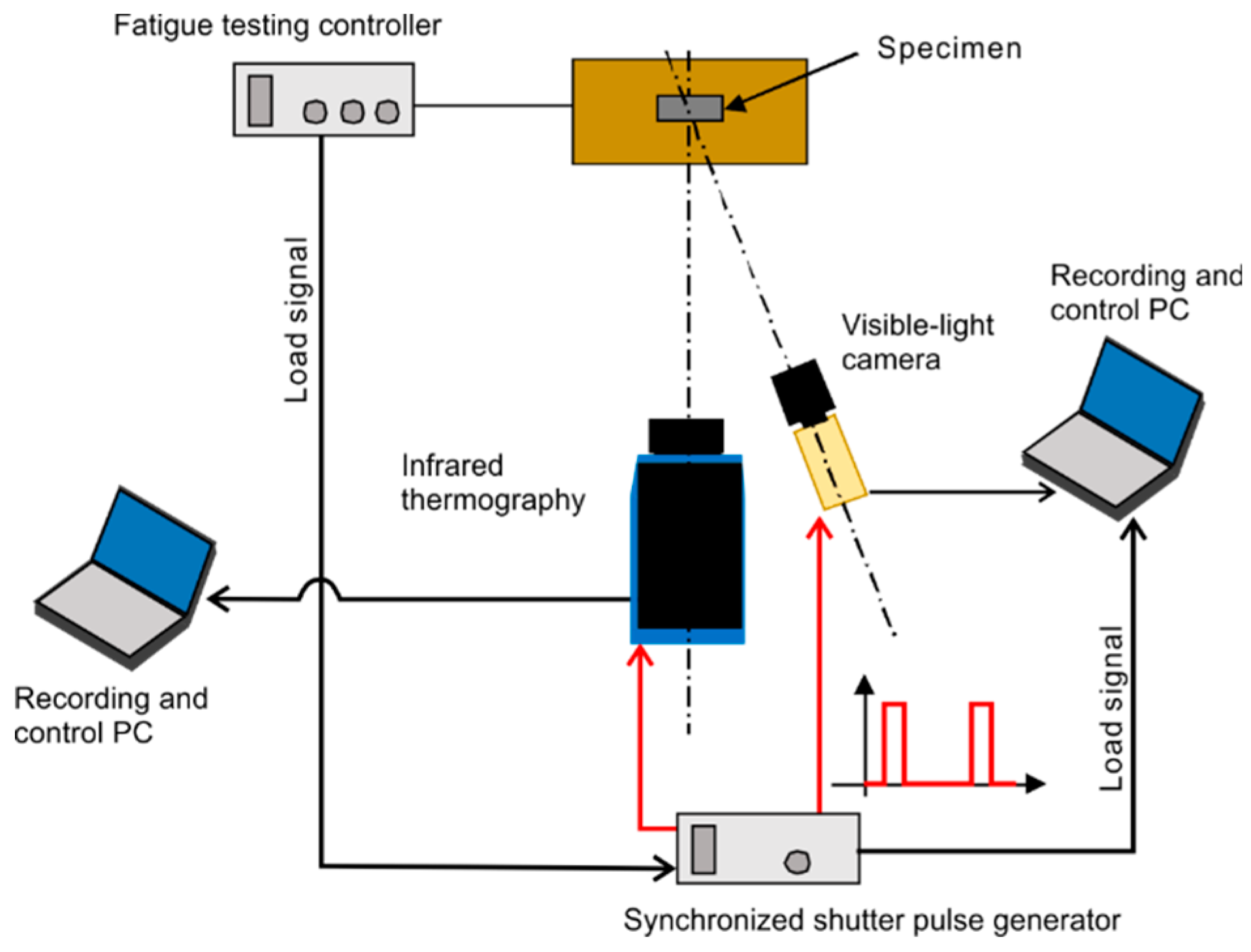

2. Thermoelastic Effect and False Temperature Change

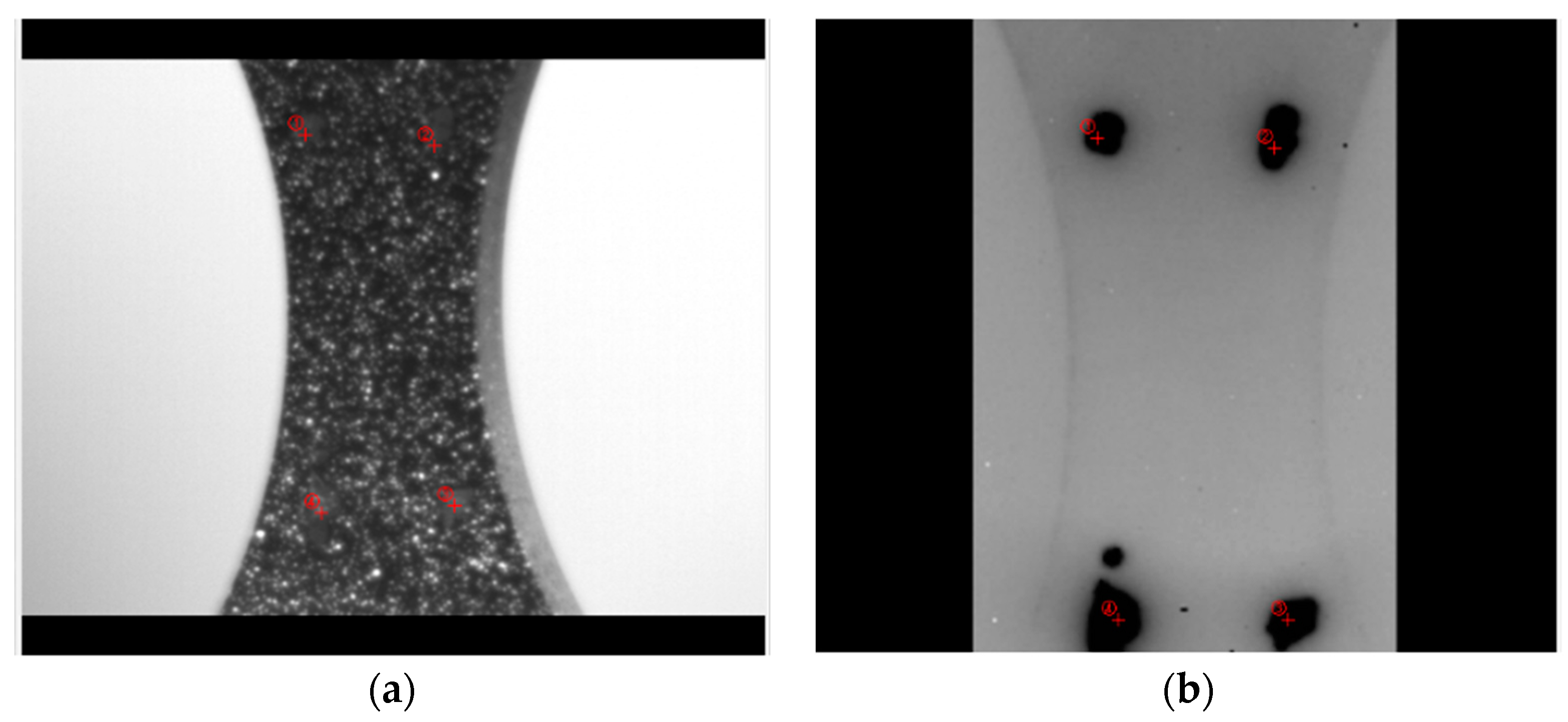

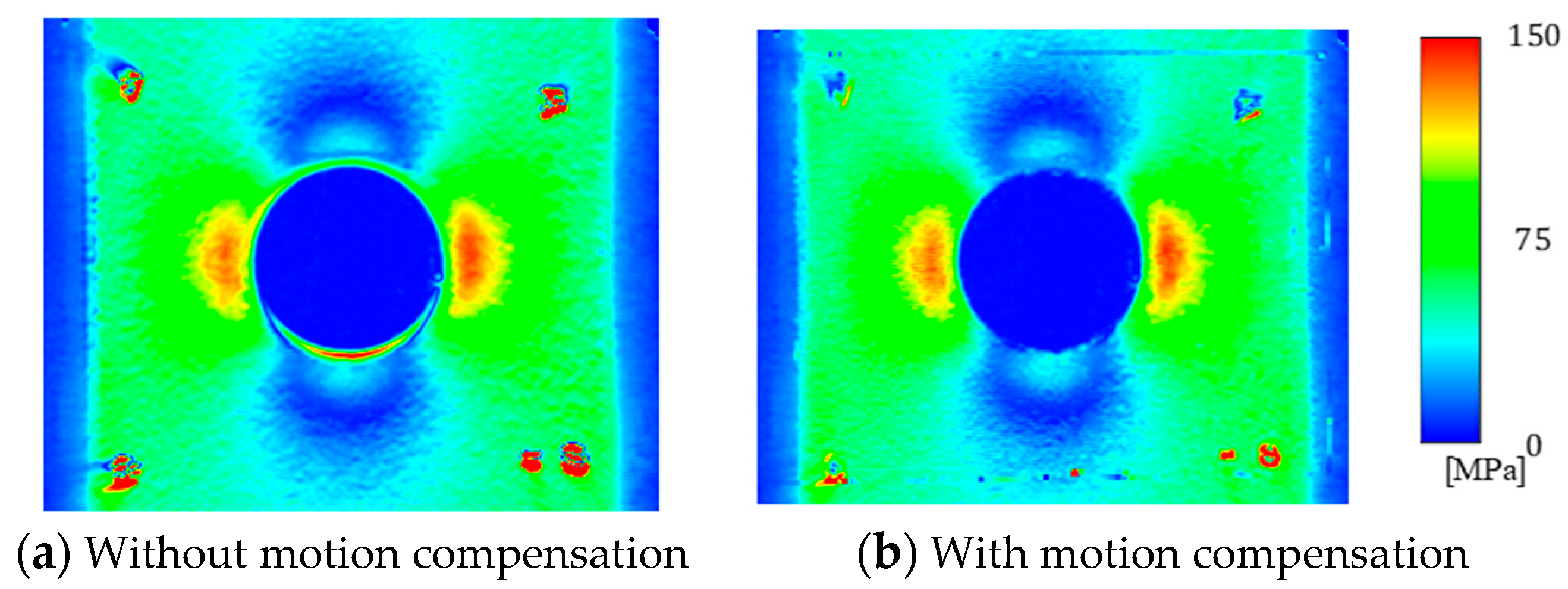

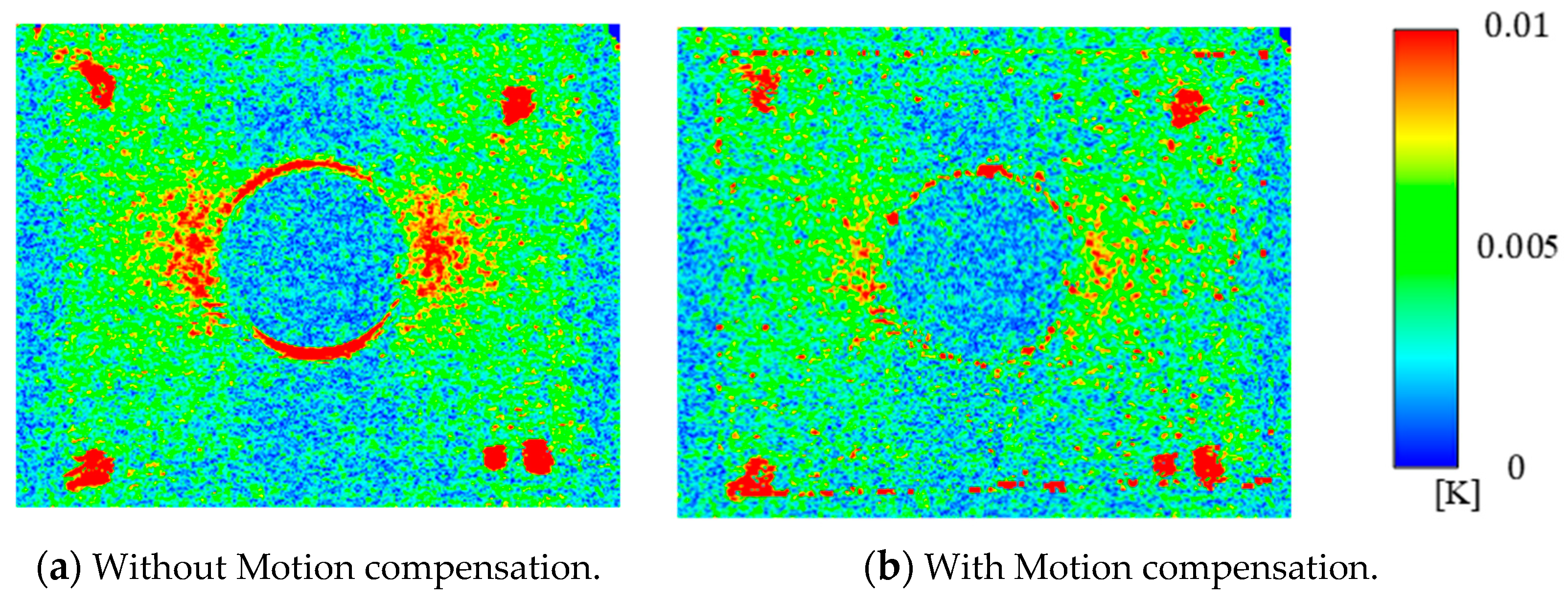

3. Motion Compensation System with the Infrared-Optical Synchronous Measurement

4. Experiment Results

5. Conclusions

References

- Sakagami, T. Remote nondestructive evaluation technique using infrared thermography for fatigue cracks in steel bridges. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 755–779. [Google Scholar] [CrossRef]

- Sakagami, T.; Kubo, S.; Tamura, E.; Nishimura, T. Identification of plastic-zone based on double frequency lock-in thermographic temperature measurement. In Proceedings of the ICF11, Turin, Italy, 1 October 2005. [Google Scholar]

- Brémond, P.; Potet, P. Lock-in thermography: A tool to analyze and locate thermomechanical mechanisms in materials and structures. Aerosp./Def. Sens. Simul. Controls 2001, 4360, 560–567. [Google Scholar]

- Luong, M. Infrared thermographic scanning of fatigue in metals. Nucl. Eng. Des. 1995, 158, 363–376. [Google Scholar] [CrossRef]

- La Rosa, G. Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components. Int. J. Fatigue 2000, 22, 65–73. [Google Scholar] [CrossRef]

- Krapez, J.-C.; Pacou, D. Thermography detection of damage initiation during fatigue tests. Proc. SPIE 2002, 4710, 435–449. [Google Scholar]

- Hayabusa, K.; Inaba, K.; Ikeda, H.; Kishimoto, K. Estimation of fatigue limits from temperature data measured by IR thermography. Exp. Mech. 2017, 57, 185–194. [Google Scholar] [CrossRef]

- Shiozawa, D.; Inagawa, T.; Washio, T.; Sakagami, T. Accuracy improvement in dissipated energy measurement by using phase information. Meas. Sci. Technol. 2017, 28, 44004. [Google Scholar] [CrossRef]

- Sakagami, T.; Yamaguchi, N.; Kubo, S.; Nishimura, T. A new full-field motion compensation technique for infrared stress measurement using digital image correlation. J. Strain Anal. Eng. Des. 2008, 43, 539–549. [Google Scholar] [CrossRef]

- Chen, D.; Sun, S.; Dulieu-Barton, J.; Li, Q.; Wang, W. Crack growth analysis in welded and non-welded T-joints based on lock-in digital image correlation and thermoelastic stress analysis. Int. J. Fatigue 2018, 110, 172–185. [Google Scholar] [CrossRef]

- Wang, W.; Fruehmann, R.K.; Dulieu-Barton, J.M. Application of Digital Image Correlation to Address Complex Motions in Thermoelastic Stress Analysis. Strain 2015, 51, 405–418. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shiozawa, D.; Uchida, Y.; Kobayashi, K.; Hori, M.; Sakagami, T.; Kubo, S. Thermoelastic Stress Analysis and Dissipated Energy Evaluation Using Infrared-Optical Synchronous Measurement. Proceedings 2019, 27, 50. https://doi.org/10.3390/proceedings2019027050

Shiozawa D, Uchida Y, Kobayashi K, Hori M, Sakagami T, Kubo S. Thermoelastic Stress Analysis and Dissipated Energy Evaluation Using Infrared-Optical Synchronous Measurement. Proceedings. 2019; 27(1):50. https://doi.org/10.3390/proceedings2019027050

Chicago/Turabian StyleShiozawa, Daiki, Yuji Uchida, Kazuki Kobayashi, Mitsuhiro Hori, Takahide Sakagami, and Shiro Kubo. 2019. "Thermoelastic Stress Analysis and Dissipated Energy Evaluation Using Infrared-Optical Synchronous Measurement" Proceedings 27, no. 1: 50. https://doi.org/10.3390/proceedings2019027050

APA StyleShiozawa, D., Uchida, Y., Kobayashi, K., Hori, M., Sakagami, T., & Kubo, S. (2019). Thermoelastic Stress Analysis and Dissipated Energy Evaluation Using Infrared-Optical Synchronous Measurement. Proceedings, 27(1), 50. https://doi.org/10.3390/proceedings2019027050