1. Introduction

Tests and studies on characterization of rocks have been used to understand the interaction between physical properties, the chemical composition of the rock and the industrial use. The aim is to determine the measurable properties of the rock with special interest in this new industrial application.

Two more interesting aspects of the geometry of space are porosity and the study of the interaction of the rock with supercritical fluid (storage conditions). Therefore, we must consider the status of the rock before and after its contact with fluid, and its behavior, as it is important to determine the new conditions.

New equipment, called

RockTestCO2, has been designed to carry out the study of the interaction of fluid in rocks at high pressure conditions, simulating the process that occurs during the injection of CO

2 in underground geological formations (

Figure 1).

2. Materials and Methods

The first phase consisted on the characterization of technology of fresh rock samples, and in the second phase, will be identical characterization changes after the test. The research began with a petrological study indicates that rock your petrographic analysis, microfractographic, morphological and chemical. Subsequently, we tests of water and mechanical properties parallel. These tests allow us to obtain the value of open porosity of the sample and its degree of saturation, deducted as well as important information geometry its empty spaces (pores and fissures) of great interest in the geological storage of any fluid. The period for the completion of these tests can vary from one to three months, depending on the type of rock. Mechanical tests are faster and they get information that allows determining the elastic constants of tested rocks. New test equipment was necessary to develop the interaction of the rock with fluid.

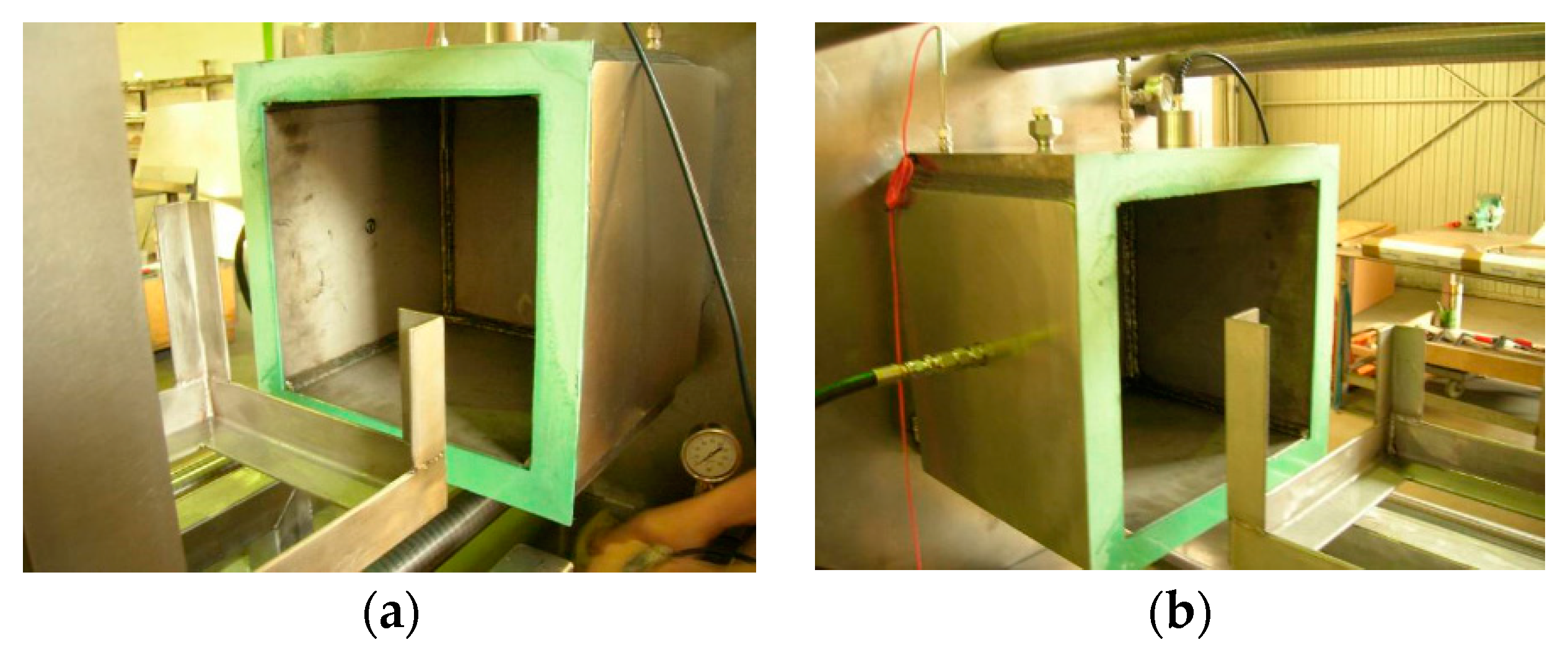

The central part of the equipment consists of AISI 304 stainless steel chamber with internal dimensions of 320 × 320 × 320 mm, 40 mm thick and an approximate weight of 200 kg. A sample rock is introduced with approximate dimensions of 270 × 270 × 270 mm. It also provides two 280 × 280 mm racks of stainless steel AISI 304 for the fixing of prismatic test specimens of 50 mm square and cylindrical samples with a diameter of 54 mm (

Figure 2).

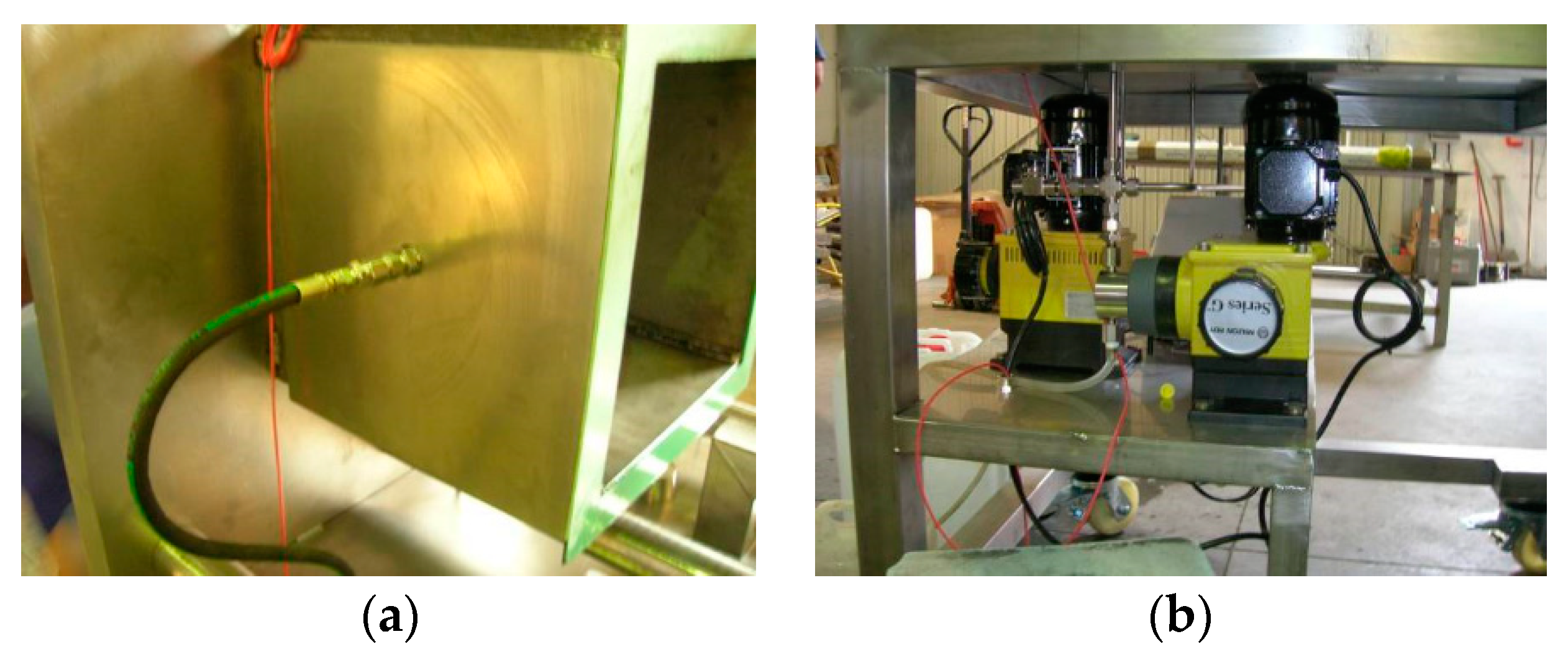

The fluid is introduced into the chamber by a rod directly embedded into a drill that will have been previously done on the rock (

Figure 3a), and it is inserted through the central part. The water enters the bottom of the camera. There are two metering pumps Dosapro mark MILTON ROY© (

Figure 3b), with a flow rate up to 7.5 L/h, a pressure up to 300 bar and a AISI316L stainless steel dispenser. These two pumps are lubricated in oil in a waterproof cap and speed reducers are built into the mechanics.

The closing of this camera is achieved through the action of a hydraulic cylinder, and the end of this cylinder has a tray on which the rock is placed to study, so that the action of hydraulic cylinder allows both entering the rock inside the camera and closing it. As a safety feature, there is a switch that lets you keep closing pressure of the chamber throughout the procedure, preventing accidental opening of the system. It also has a ruptured disk and additional elements for protection and security. A camera 10 is coupled 180 W resistors and two 200 W resistors to heat the interior of it until the desired temperature, using a temperature sensor and a digital controller.

The hydraulic closure is capable of exerting a force of over 95 tons, and it consists of a hydraulic cylinder of 200 × 140 mm and 500 mm in length, a tank with its accessories, filter screens, levels, etc. There is a motor-group with two pumps, and the low pressure gives the flow required for rapid movement and a pressing cylinder for 320 bar, as well as control valves and the associated control.

The entire assembly approximately weighs 1300 kg. This equipment includes a cabinet where both switches activation of different elements by the user, such as electrical control elements and protections necessary to ensure the safety of the people and the equipment according to current regulations (

Figure 4).

Basically, the new test consists of contacting the rock sample with fluid in the natural reservoir conditions of pressure and temperature. The operational parameters of this equipment allow simulating in the laboratory the geological storage of a fluid in the natural conditions of pressure, temperature and salinity.

3. Results

Four samples of rocks (carbonates and sandstones) are used in initial tests. It is necessary to know the physical properties of these rocks in their natural state. For this study performed petrological and petrophysical studies and chemical and morphological analysis. Subsequently, subjected to interaction with a fluid for a variable duration from weeks to months, and finally, it is necessary to re-make all petrophysical tests chemical and morphological analysis to obtain differences by comparison of the physical properties and chemical composition of rocks.

The physical properties are possible to observe the variation in short term tests of several months. Possible variations in chemical composition need more time.

Preliminary results of petrophysical properties confirm those obtained by other laboratories [

1,

2]. It shows a slight increase in effective porosity and a decrease in the mechanical strength.

4. Conclusions

The design and construction of this equipment allows us to investigate known physical and chemical processes that occur between the rocks store/seal and the fluid injected into deep geological storage. Simulation of storing CO2 deep is essential to know the behavior of rocks (store or seal) in its interaction with the CO2. Finally, besides the mathematical modelling, it is necessary to develop a new petrophysical characterization equipment to simulate the pressures and temperatures at which rocks are the target of a geological storage of CO2.