Electromagnetic Sensing for Non-Destructive Real-Time Fruit Ripeness Detection: Case-Study for Automated Strawberry Picking †

Abstract

:1. Introduction

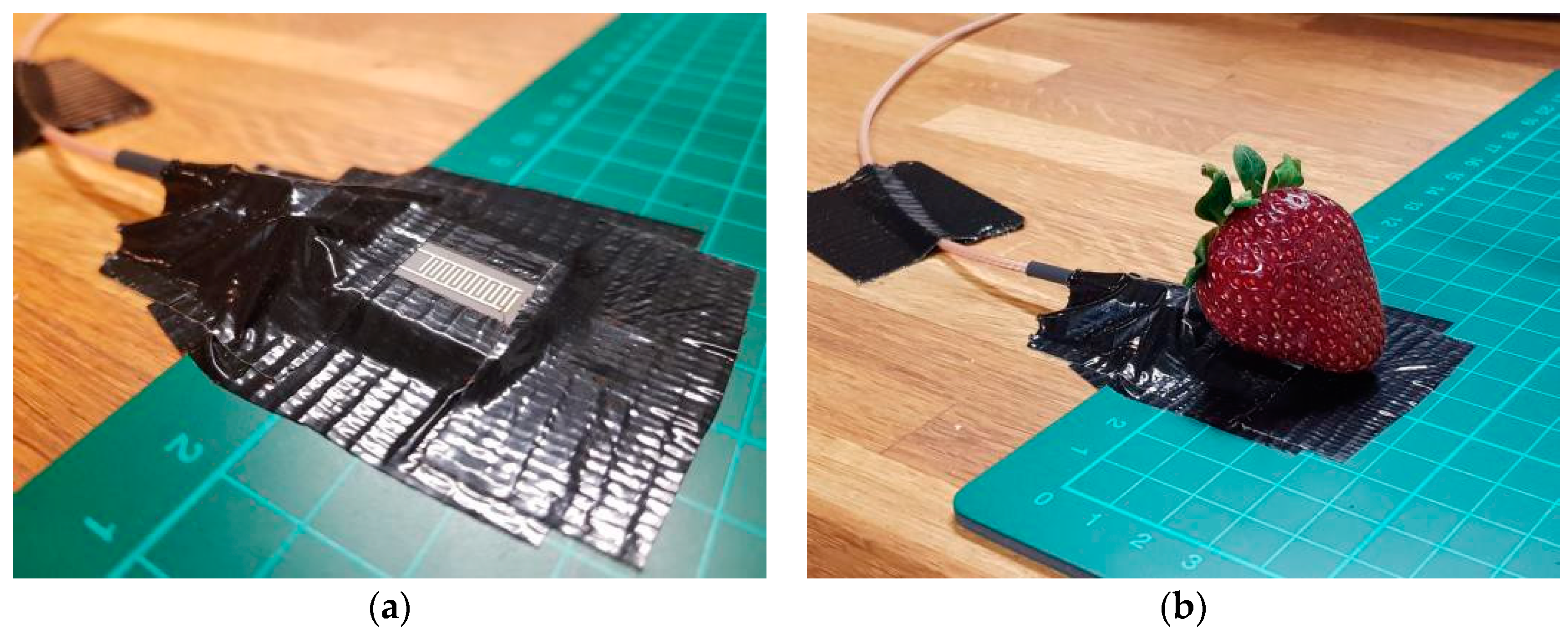

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Grimstad, L.; From, P. The Thorvald II agricultural robotic system. Robotics 2017, 6, 24. [Google Scholar] [CrossRef]

- Nagata, M.; Cui, Y.; Jasper, G. Study on cartesian-type harvesting robot for strawberry. In Proceedings of the 3rd IFAC International Workshop on Bio-Robotics, Information Technology and Intelligent Control for Bioproduction Systems, Sapporo, Japan, 9–10 September 2006; pp. 266–270. [Google Scholar]

- Mason, A.; Korostynska, O.; Louis, J.; Cordova-Lopez, L.E.; Abdullah, B.; Greene, J.; Connell, R.; Hopkins, J. Noninvasive in-situ measurement of blood lactate using microwave sensors. IEEE Trans. Biomed. Eng. 2018, 65, 698–705. [Google Scholar] [CrossRef] [PubMed]

- Korostynska, O.; Mason, A.; Al-Shamma’a, A. Microwave sensors for the non-invasive monitoring of industrial and medical applications. Sens. Rev. 2014, 34, 182–191. [Google Scholar] [CrossRef]

- Meng, Z.; Wu, Z.; Gray, J. Microwave sensor technologies for food evaluation and analysis: Methods, challenges and solutions. Trans. Inst. Meas. Control 2017. [Google Scholar] [CrossRef]

| Grade (G) | Grade Description * | n | Total Grade Weight (g) | Mean Fruit Weight (g) |

|---|---|---|---|---|

| 1 | Green; completely unripened. | 24 | 224 | 9.3 |

| 2 | <50% red; partially ripened, but less than half of surface area of fruit has red colour. | 15 | 226 | 15.1 |

| 3 | >50% red; perhaps almost ripe, but still significant green colouration. | 11 | 149 | 13.5 |

| 4 | Ripe; 100% surface redness. | 14 | 241 | 17.2 |

| 5 | Over-ripe; Deep red colouration, fruit has increased softness. G4 fruits were left at 20 °C for 3 days to develop the over-ripe state. | 14 | 227 | 16.2 |

| Grade | Total Measure-Ments | Total z- Score Rejections | Mean signal Amplitude (dBm) | Standard Deviation |

|---|---|---|---|---|

| 1 | 63 | 3 | −0.664 | 0.422 |

| 2 | 45 | 5 | −1.11 | 0.576 |

| 3 | 33 | 3 | −1.16 | 0.917 |

| 4 | 42 | 3 | −1.17 | 0.866 |

| 5 | 42 | 9 | −1.54 | 0.640 |

| Air ** | 21 | 0 | 0.000443 | 0.0125 |

| Total | 246 | 23 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korostynska, O.; Mason, A.; From, P.J. Electromagnetic Sensing for Non-Destructive Real-Time Fruit Ripeness Detection: Case-Study for Automated Strawberry Picking. Proceedings 2018, 2, 980. https://doi.org/10.3390/proceedings2130980

Korostynska O, Mason A, From PJ. Electromagnetic Sensing for Non-Destructive Real-Time Fruit Ripeness Detection: Case-Study for Automated Strawberry Picking. Proceedings. 2018; 2(13):980. https://doi.org/10.3390/proceedings2130980

Chicago/Turabian StyleKorostynska, Olga, Alex Mason, and Pål Johan From. 2018. "Electromagnetic Sensing for Non-Destructive Real-Time Fruit Ripeness Detection: Case-Study for Automated Strawberry Picking" Proceedings 2, no. 13: 980. https://doi.org/10.3390/proceedings2130980

APA StyleKorostynska, O., Mason, A., & From, P. J. (2018). Electromagnetic Sensing for Non-Destructive Real-Time Fruit Ripeness Detection: Case-Study for Automated Strawberry Picking. Proceedings, 2(13), 980. https://doi.org/10.3390/proceedings2130980