A Disposable Inkjet-Printed Humidity and Temperature Sensor Fabricated on Paper †

Abstract

:1. Introduction

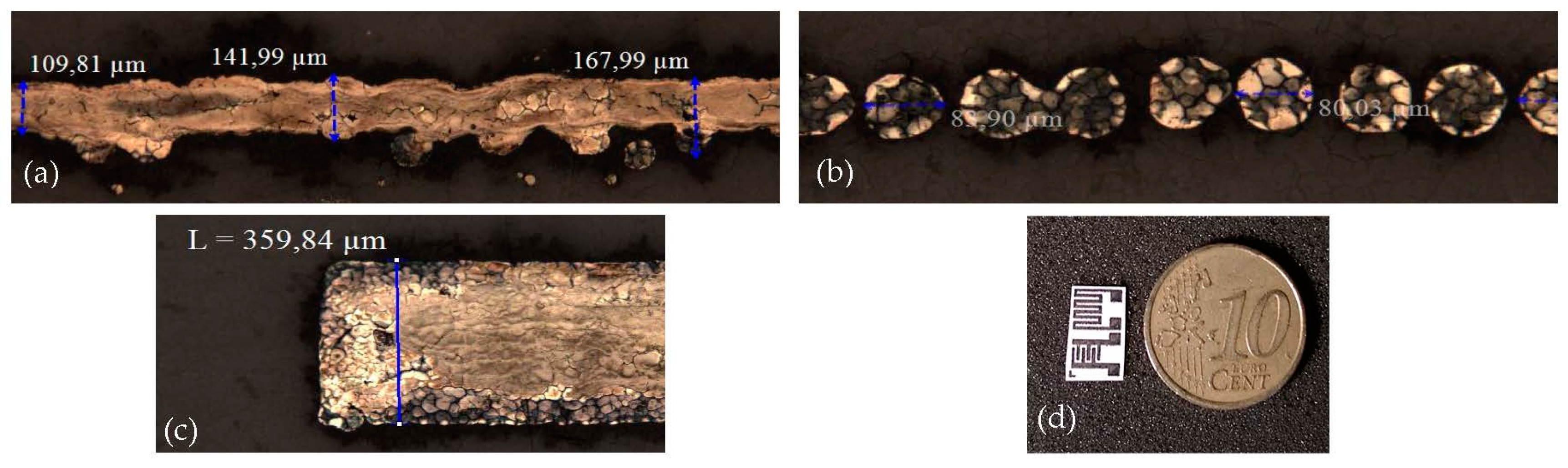

2. Materials and Methods

2.1. Inkjet Printing

2.2. Measurement Protocols

3. Results & Discussion

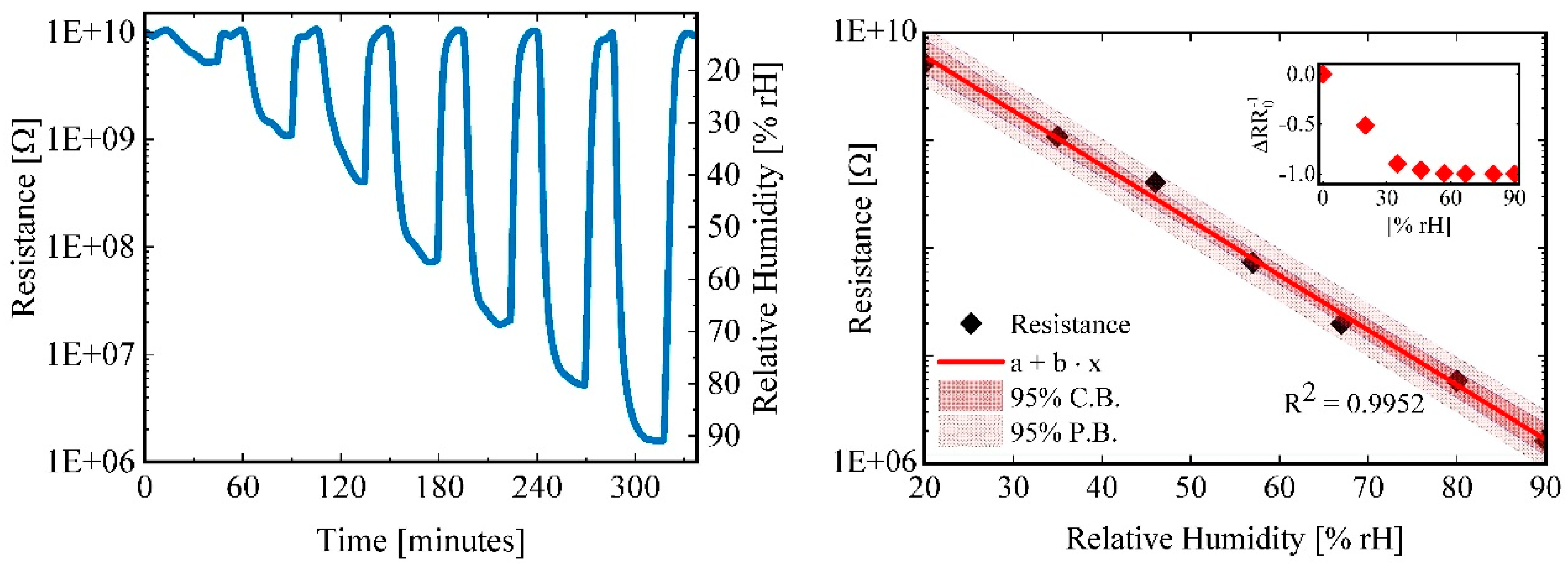

3.1. Humidity Measurements

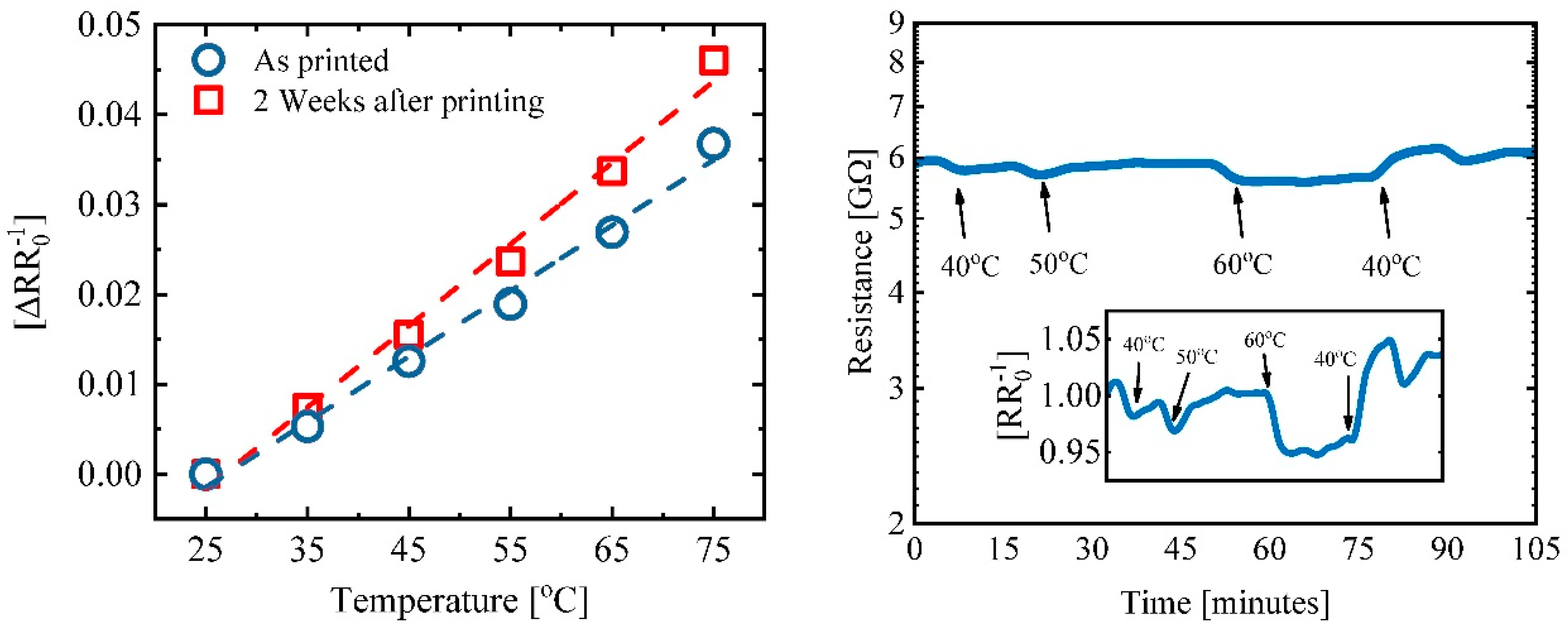

3.2. Temperature Measurements

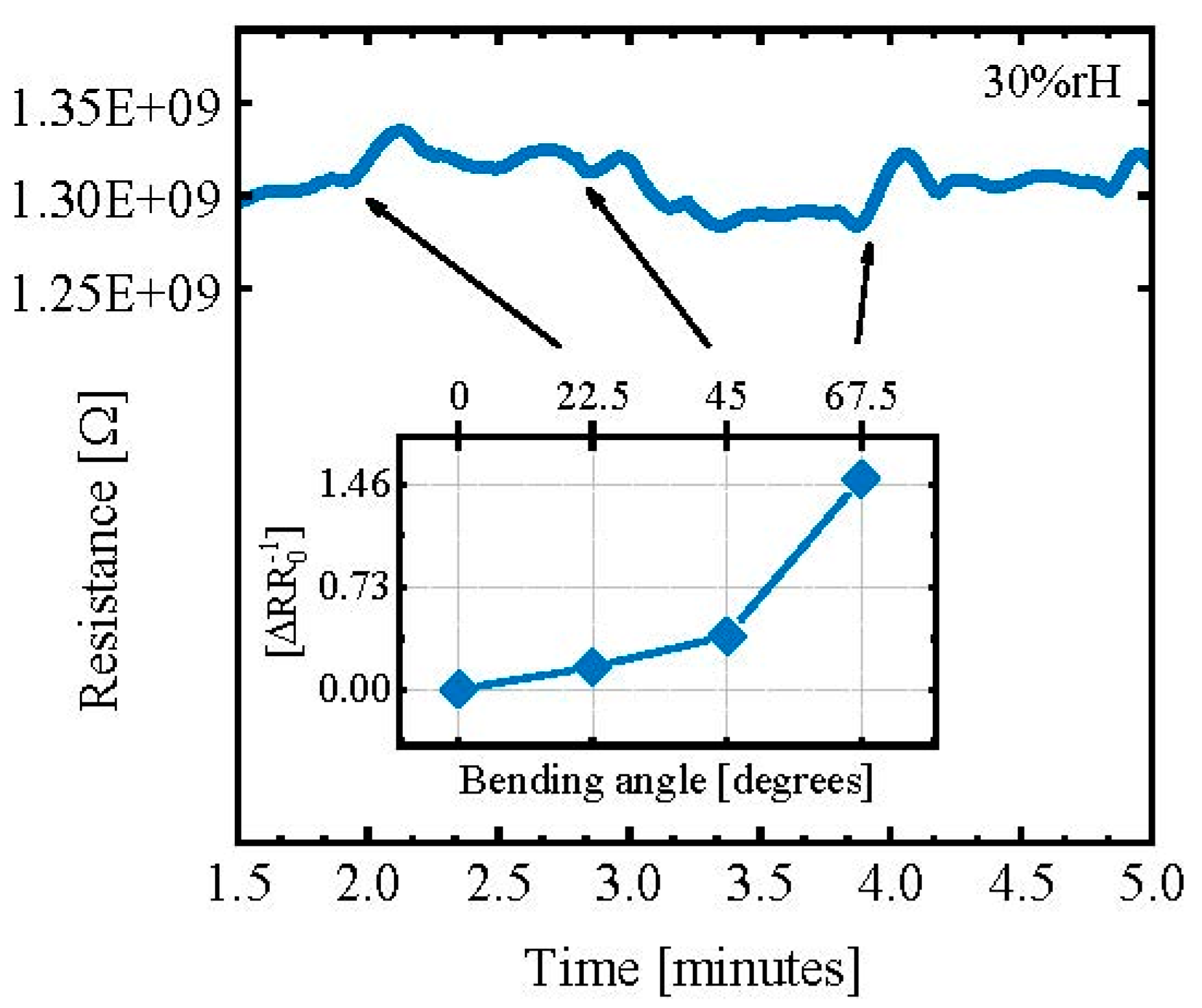

3.3. Bending Effects on Sensor Resistance

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Gaspar, C.; Olkkonen, J.; Passoja, S.; Smolander, M. Paper as Active Layer in Inkjet-Printed Capacitive Humidity Sensors. Sensors 2017, 17, 1464. [Google Scholar] [CrossRef] [PubMed]

- Dankoco, M.D.; Tesfay, G.Y.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing process on flexible substrate. Mater. Sci. Eng. B 2016, 205, 1–5. [Google Scholar] [CrossRef]

- Barmpakos, D.; Segkos, A.; Tsamis, C.; Kaltsas, G. A disposable flexible humidity sensor directly printed on paper for medical applications. J. Phys. Conf. Ser. 2017, 931, 012003. [Google Scholar] [CrossRef]

- Kawahara, Y.; Hodges, S.; Cook, B.S.; Zhang, C.; Abowd, G. Instant inkjet circuits: lab-based inkjet printing to support rapid prototyping of UbiComp devices. In Proceedings of the 2013 ACM international joint conference on Pervasive and ubiquitous computing, Zurich, Switzerland, 8–12 September 2013. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barmpakos, D.; Segkos, A.; Tsamis, C.; Kaltsas, G. A Disposable Inkjet-Printed Humidity and Temperature Sensor Fabricated on Paper. Proceedings 2018, 2, 977. https://doi.org/10.3390/proceedings2130977

Barmpakos D, Segkos A, Tsamis C, Kaltsas G. A Disposable Inkjet-Printed Humidity and Temperature Sensor Fabricated on Paper. Proceedings. 2018; 2(13):977. https://doi.org/10.3390/proceedings2130977

Chicago/Turabian StyleBarmpakos, Dimitris, Apostolos Segkos, Christos Tsamis, and Grigoris Kaltsas. 2018. "A Disposable Inkjet-Printed Humidity and Temperature Sensor Fabricated on Paper" Proceedings 2, no. 13: 977. https://doi.org/10.3390/proceedings2130977

APA StyleBarmpakos, D., Segkos, A., Tsamis, C., & Kaltsas, G. (2018). A Disposable Inkjet-Printed Humidity and Temperature Sensor Fabricated on Paper. Proceedings, 2(13), 977. https://doi.org/10.3390/proceedings2130977