A 3-Degree-of-Freedom MEMS Mirror with Controllable Static and Dynamic Motion for Beam Steering †

Abstract

:1. Introduction

2. Materials and Methods

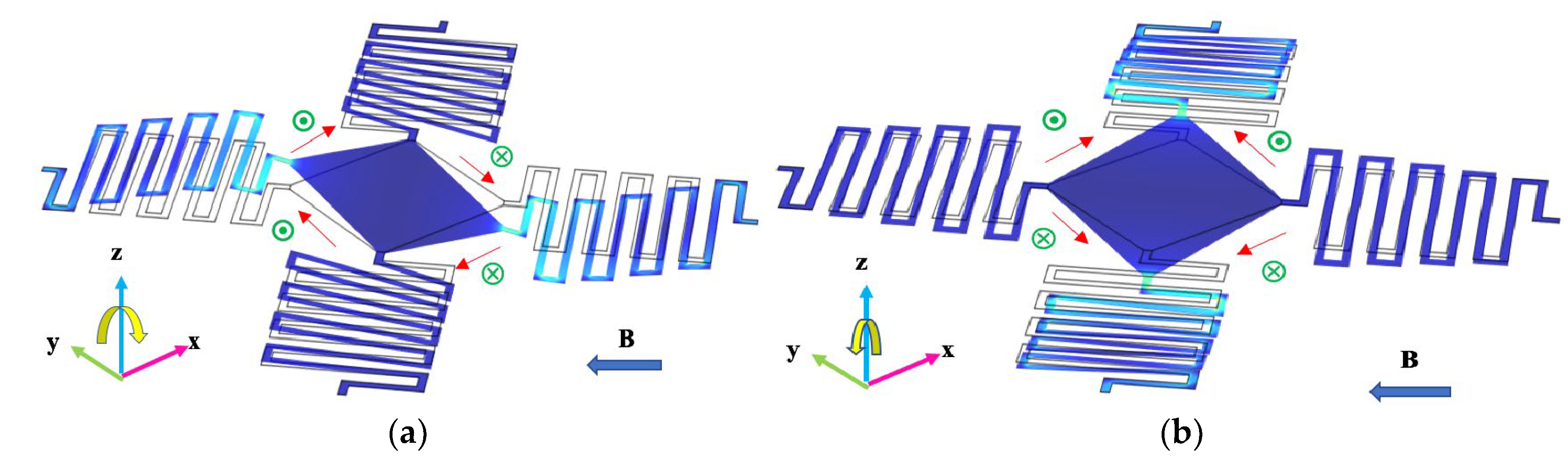

2.1. Design

2.2. Fabrication

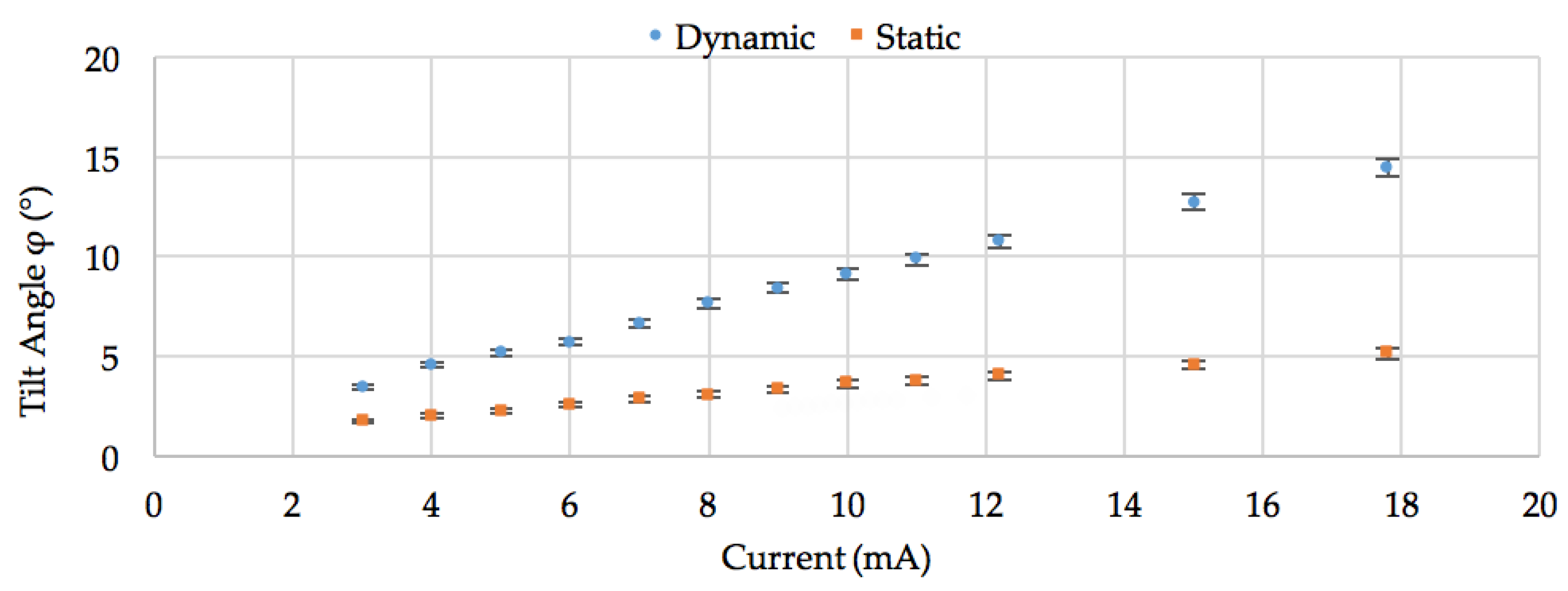

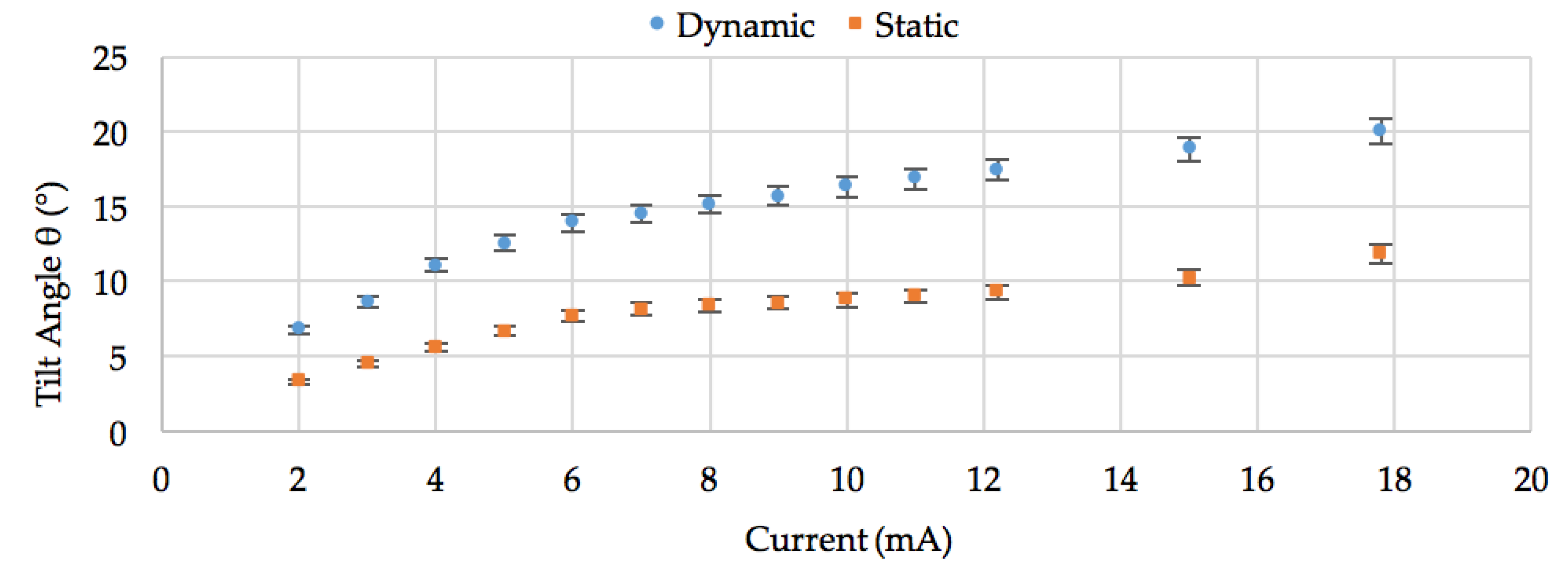

3. Results and Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ma, J. Advanced MEMS-based technologies and displays. Displays 2015, 37, 2–10. [Google Scholar] [CrossRef]

- Aguirre, A.D.; Herz, P.R.; Chen, Y.; Fujimoto, J.G.; Piyawattanametha, W.; Fan, L.; Wu, M.C. Two-axis MEMS Scanning Catheter for Ultrahigh Resolution Three-dimensional and En Face Imaging. Opt. Express 2007, 15, 2445–2453. [Google Scholar] [CrossRef] [PubMed]

- Hokari, R.; Hane, K. Micro-mirror laser scanner combined with a varifocal mirror. Microsyst. Technol. 2012, 18, 475–480. [Google Scholar] [CrossRef]

- Hung, C.-L.A.; Lai, Y.-H.H.; Lin, T.W.; Fu, S.G.; Lu, S.-C.M. An electrostatically driven 2D micro-scanning mirror with capacitive sensing for projection display. Sens. Actuators A-Phys. 2015, 222, 122–129. [Google Scholar] [CrossRef]

- Morrison, J.; Imboden, M.; Little, D.C.T.; Bishop, D.J. Electrothermally actuated tip-tilt-piston micromirror with integrated varifocal capability. Opt. Express 2015, 23, 9555–9566. [Google Scholar] [CrossRef]

- Yalcinkaya, A.D.; Urey, H.; Brown, D.; Montague, T.; Sprague, R. Two-axis electromagnetic microscanner for high resolution displays. J. Microelectromech. Syst. 2006, 15, 786–794. [Google Scholar] [CrossRef]

- Baran, U.; Brown, D.; Holmstrom, S.; Balma, D.; Davis, W.O.; Muralt, P.; Urey, H. Resonant PZT MEMS scanner for high-resolution displays. J. Microelectromech. Syst. 2012, 21, 1303–1310. [Google Scholar] [CrossRef]

- Wei, Z.; Li, P.; Zhang, X.; Wang, Y.; Hu, F. InGaN/GaN micro mirror with electrostatic comb drive actuation integrated on a patterned silicon-on-insulator wafer. Opt. Express 2018, 26, 7672–7682. [Google Scholar] [CrossRef]

- Makishi, W.; Kawai, Y.; Esashi, M. Magnetic torque driving 2D micro scanner with a non-resonant large scan angle. In Proceedings of the TRANSDUCERS 2009—2009 International Solid-State Sensors, Actuators and Microsystems Conference, Denver, CO, USA, 21–25 June 2009; pp. 904–907. [Google Scholar] [CrossRef]

- Afsharipour, E.; Park, B.; Shafai, C. Large Tilt Angle Lorentz Force Actuated Micro-Mirror with 3 DOF for Optical Applications. Proc. Eurosensors 2017, 1, 351. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Afsharipour, E.; Park, B.; Soltanzadeh, R.; Shafai, C. A 3-Degree-of-Freedom MEMS Mirror with Controllable Static and Dynamic Motion for Beam Steering. Proceedings 2018, 2, 938. https://doi.org/10.3390/proceedings2130938

Afsharipour E, Park B, Soltanzadeh R, Shafai C. A 3-Degree-of-Freedom MEMS Mirror with Controllable Static and Dynamic Motion for Beam Steering. Proceedings. 2018; 2(13):938. https://doi.org/10.3390/proceedings2130938

Chicago/Turabian StyleAfsharipour, Elnaz, Byoungyoul Park, Ramin Soltanzadeh, and Cyrus Shafai. 2018. "A 3-Degree-of-Freedom MEMS Mirror with Controllable Static and Dynamic Motion for Beam Steering" Proceedings 2, no. 13: 938. https://doi.org/10.3390/proceedings2130938

APA StyleAfsharipour, E., Park, B., Soltanzadeh, R., & Shafai, C. (2018). A 3-Degree-of-Freedom MEMS Mirror with Controllable Static and Dynamic Motion for Beam Steering. Proceedings, 2(13), 938. https://doi.org/10.3390/proceedings2130938