Investigation of Application-Specific Thin Film Sensor Systems with Wireless Data Transmission System †

Abstract

:1. Introduction

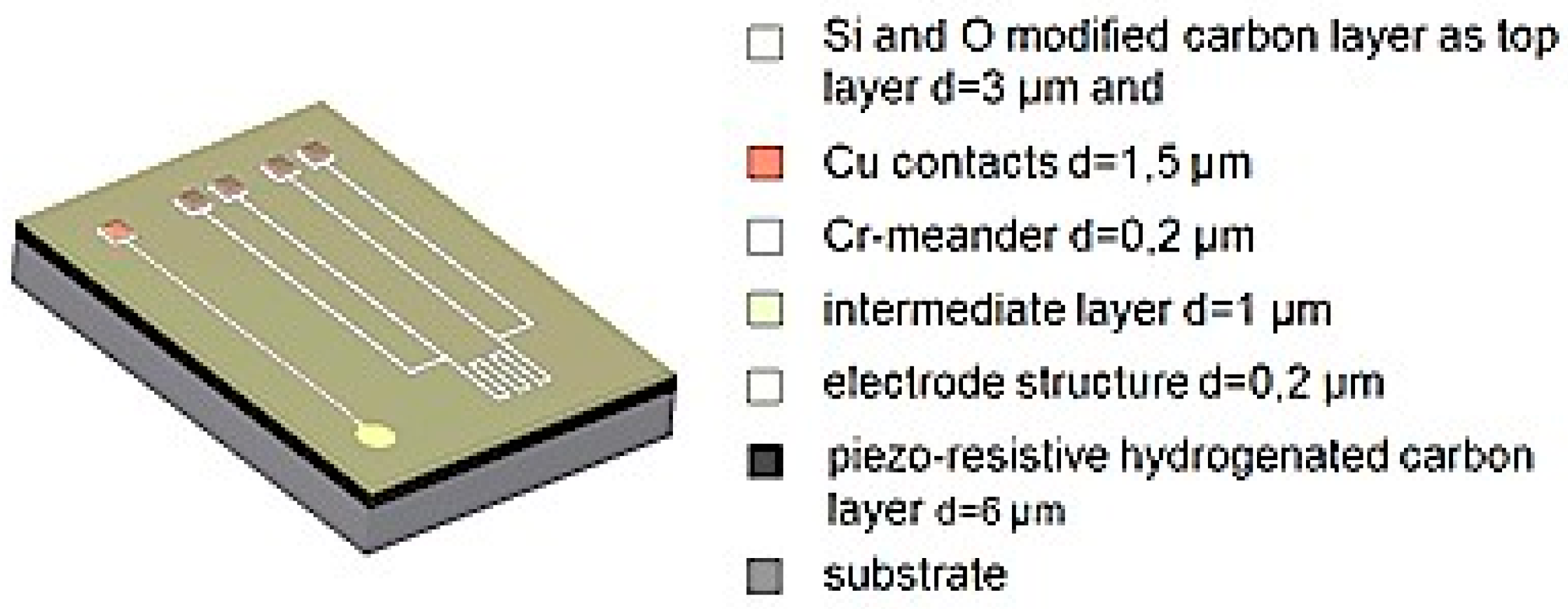

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Biehl, S.; Rumposch, C.; Paetsch, N.; Bräuer, G.; Weise, D.; Scholz, P.; Landgrebe, D. Multifunctional thin film sensor system as monitoring system in production. Microsyst. Technol. 2016, 22, 1757–1765. [Google Scholar] [CrossRef]

- Meškinis, Š.; Gudaitis, R.; Vasiliauskas, A.; Čiegis, A.; Šlapikas, K.; Tamulevičius, T.; Andrulevičius, M.; Tamulevičius, S. Piezoresistive properties of diamond like carbon films containing copper. Diamond Relat. Mater. 2015, 60, 20–25. [Google Scholar] [CrossRef]

- Biehl, S. Entwicklung von Dünnschichtsensoren auf Basis piezoresistiver Kohlenwasserstoffschichten. Dissertation, Fraunhofer IST, Braunschweig, Germany, 2011. [Google Scholar]

- Hesse, S.; Schnell, G. Sensoren für die Prozess- und Fabrikautomation; Springer Fachmedien: Wiesbaden, Germany, 2014; ISBN 978-3-658-05866-1. [Google Scholar]

- Robertson, J. Improving the properties of diamond-like carbon. Diamond Relat. Mater. 2003, 12, 79–84. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyer-Kornblum, E.; Biehl, S.; Paetsch, N.; Bräuer, G. Investigation of Application-Specific Thin Film Sensor Systems with Wireless Data Transmission System. Proceedings 2018, 2, 919. https://doi.org/10.3390/proceedings2130919

Meyer-Kornblum E, Biehl S, Paetsch N, Bräuer G. Investigation of Application-Specific Thin Film Sensor Systems with Wireless Data Transmission System. Proceedings. 2018; 2(13):919. https://doi.org/10.3390/proceedings2130919

Chicago/Turabian StyleMeyer-Kornblum, Eike, Saskia Biehl, Nancy Paetsch, and Günter Bräuer. 2018. "Investigation of Application-Specific Thin Film Sensor Systems with Wireless Data Transmission System" Proceedings 2, no. 13: 919. https://doi.org/10.3390/proceedings2130919

APA StyleMeyer-Kornblum, E., Biehl, S., Paetsch, N., & Bräuer, G. (2018). Investigation of Application-Specific Thin Film Sensor Systems with Wireless Data Transmission System. Proceedings, 2(13), 919. https://doi.org/10.3390/proceedings2130919