Structural Modifications in Free-Standing InGaN/GaN LEDs after Femtosecond Laser Lift-Off †

Abstract

:1. Introduction

2. Material and Methods

3. Results and Discussion

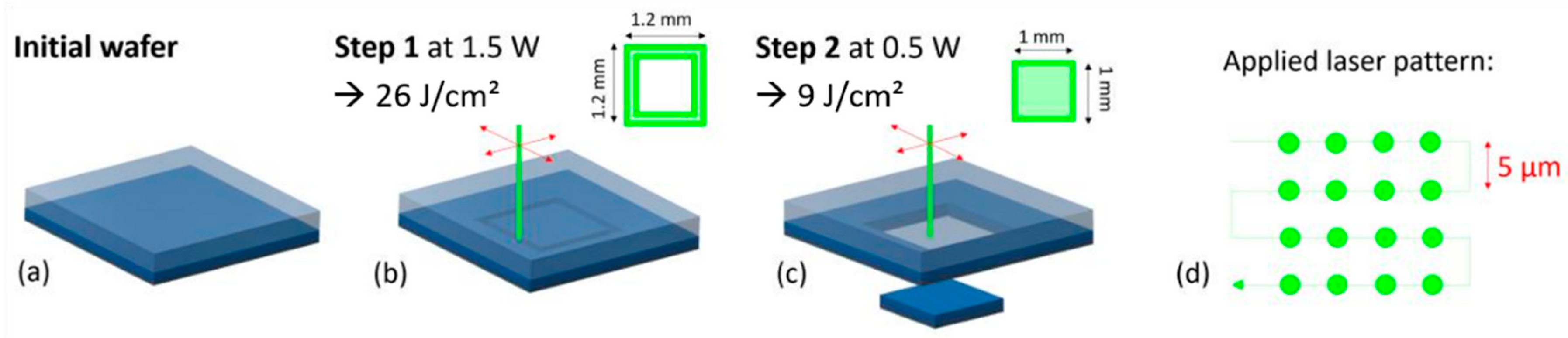

3.1. Creation of Free-Standing GaN LED Chips

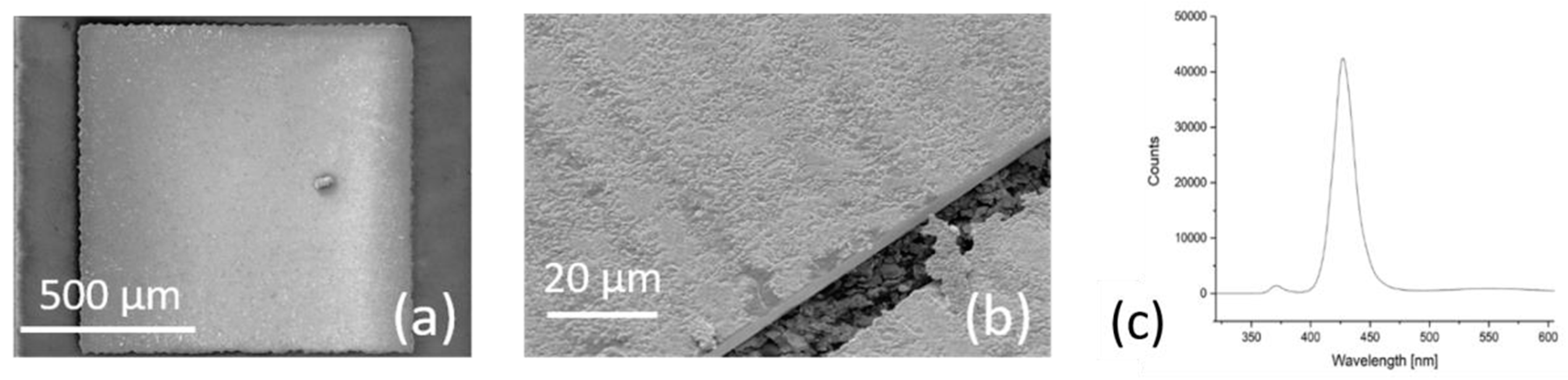

3.2. Laser Induced Damage during Lift-Off

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kim, J.; Kim, J.H.; Cho, S.H.; Whang, K.H. Selective lift-off of GaN light-emitting diode from a sapphire substrate using 266-nm diode-pumped solid-state laser irradiation. Appl. Phys. A Mater. Sci. Process. 2016, 122, 1–6. [Google Scholar] [CrossRef]

- Ueda, T.; Ishida, M.; Yuri, M. Separation of Thin GaN from Sapphire by Laser Lift-Off Technique. Jpn. J. Appl. Phys. 2011, 50, 041001. [Google Scholar] [CrossRef]

- Chu, C.F.; Lai, F.I.; Chu, J.T.; Yu, C.C.; Lin, C.F.; Kuo, H.C.; Wang, S.C. Study of GaN light-emitting diodes fabricated by laser lift-off technique. J. Appl. Phys. 2004, 95, 3916–3922. [Google Scholar] [CrossRef]

- Wang, X.C.; Lim, G.C.; Ng, F.L.; Liu, W.; Chua, S.J. Femtosecond pulsed laser-induced periodic surface structures on GaN/sapphire. Appl. Surf. Sci. 2005, 252, 1492–1497. [Google Scholar] [CrossRef]

- Lu, L.; Gao, Z.Y.; Shen, B.; Xu, F.J.; Huang, S.; Miao, Z.L.; Hao, Y.; Yang, Z.J.; Zhang, G.Y.; Zhang, X.P.; et al. Microstructure and origin of dislocation etch pits in GaN epilayers grown by metal organic chemical vapor deposition. J. Appl. Phys. 2008, 104, 123525. [Google Scholar] [CrossRef]

- Cheng, J.-H.; Wu, Y.S.; Peng, W.C.; Ouyang, H. Effects of Laser Sources on Damage Mechanisms and Reverse-Bias Leakages of Laser Lift-Off GaN-Based LEDs. J. Electrochem. Soc. 2009, 156, H640. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bornemann, S.; Yulianto, N.; Meyer, T.; Gülink, J.; Margenfeld, C.; Seibt, M.; Wasisto, H.S.; Waag, A. Structural Modifications in Free-Standing InGaN/GaN LEDs after Femtosecond Laser Lift-Off. Proceedings 2018, 2, 897. https://doi.org/10.3390/proceedings2130897

Bornemann S, Yulianto N, Meyer T, Gülink J, Margenfeld C, Seibt M, Wasisto HS, Waag A. Structural Modifications in Free-Standing InGaN/GaN LEDs after Femtosecond Laser Lift-Off. Proceedings. 2018; 2(13):897. https://doi.org/10.3390/proceedings2130897

Chicago/Turabian StyleBornemann, Steffen, Nursidik Yulianto, Tobias Meyer, Jan Gülink, Christoph Margenfeld, Michael Seibt, Hutomo Suryo Wasisto, and Andreas Waag. 2018. "Structural Modifications in Free-Standing InGaN/GaN LEDs after Femtosecond Laser Lift-Off" Proceedings 2, no. 13: 897. https://doi.org/10.3390/proceedings2130897

APA StyleBornemann, S., Yulianto, N., Meyer, T., Gülink, J., Margenfeld, C., Seibt, M., Wasisto, H. S., & Waag, A. (2018). Structural Modifications in Free-Standing InGaN/GaN LEDs after Femtosecond Laser Lift-Off. Proceedings, 2(13), 897. https://doi.org/10.3390/proceedings2130897