Characterization of a Micro-Opto-Mechanical Transducer for the Electric Field Strength †

Abstract

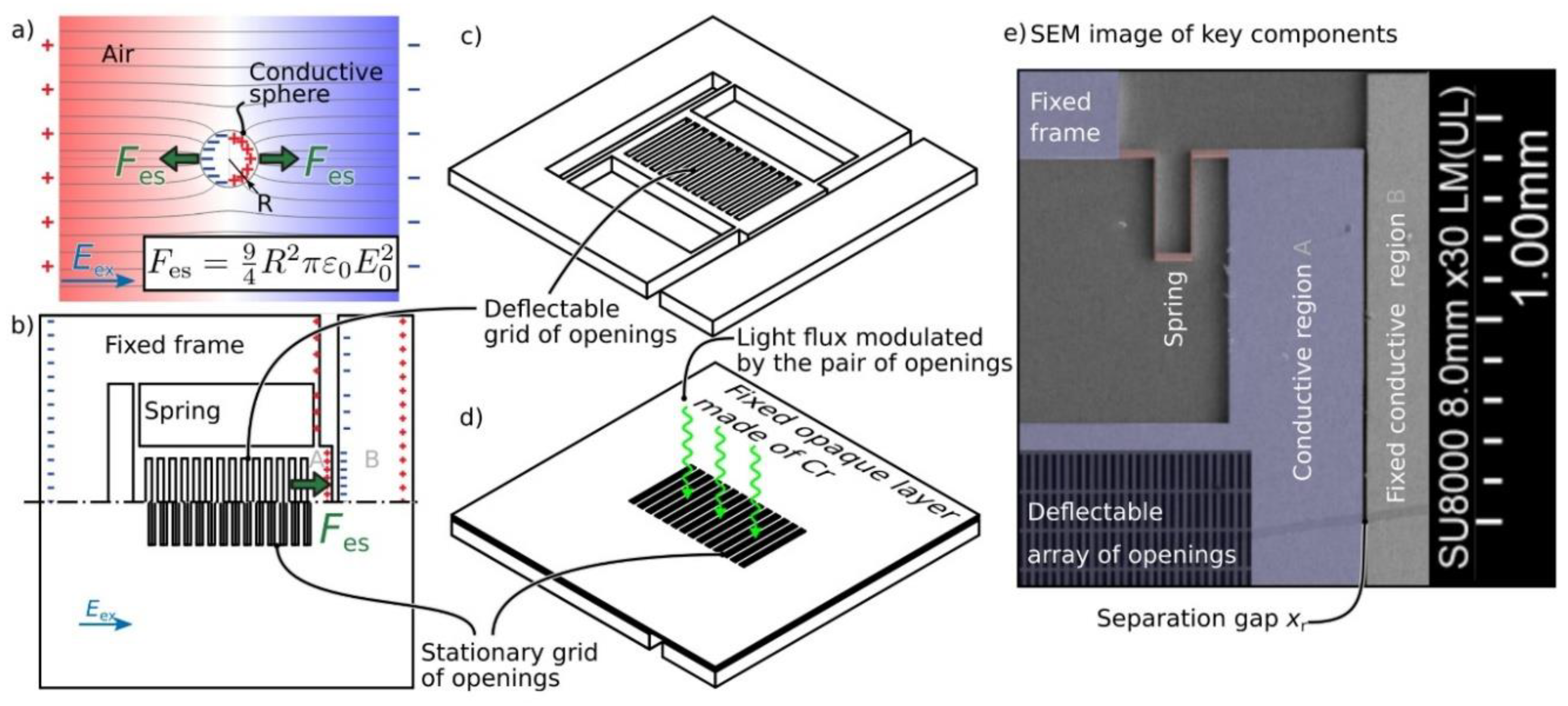

:1. Introduction

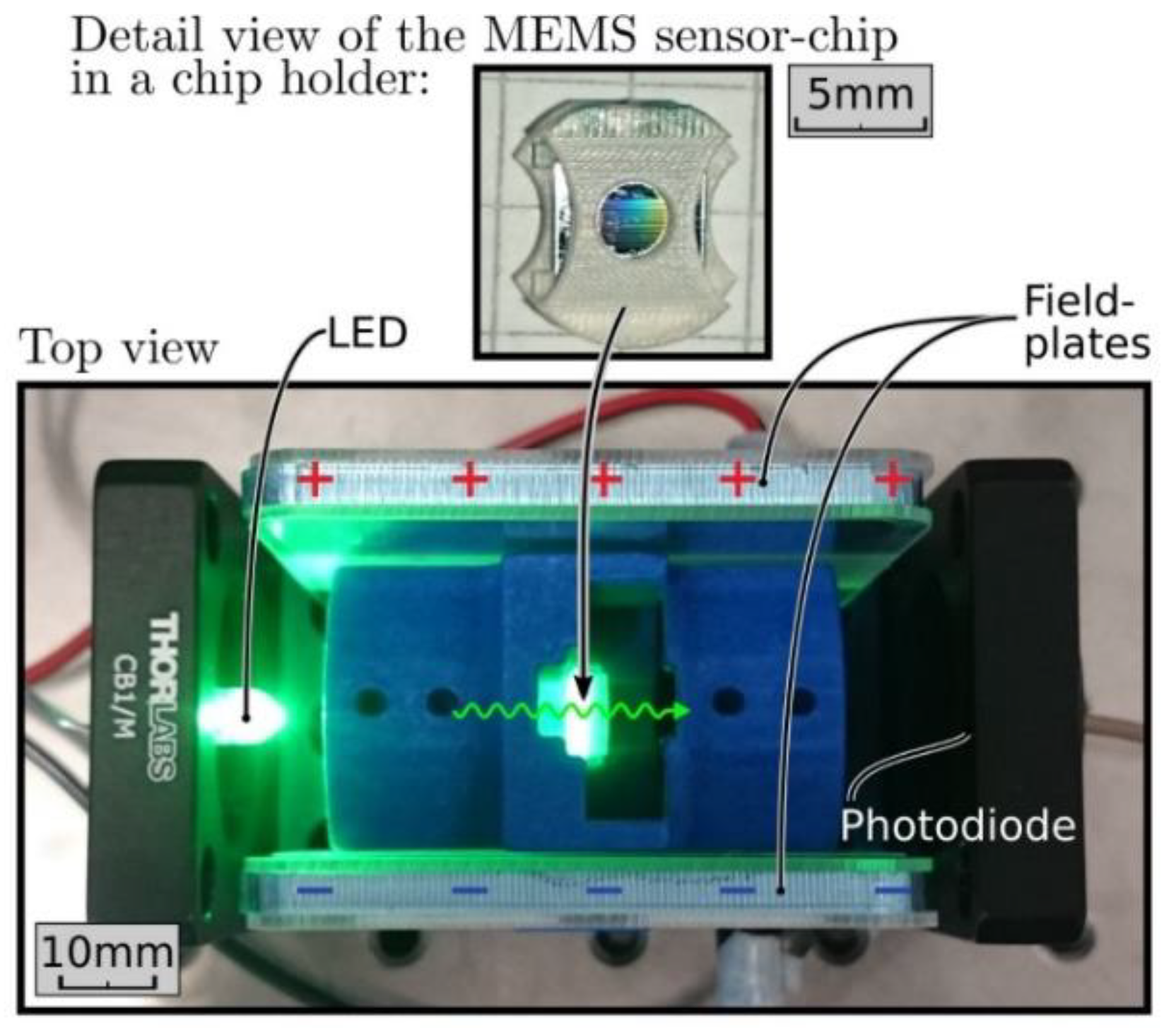

2. Measurement Set-Up

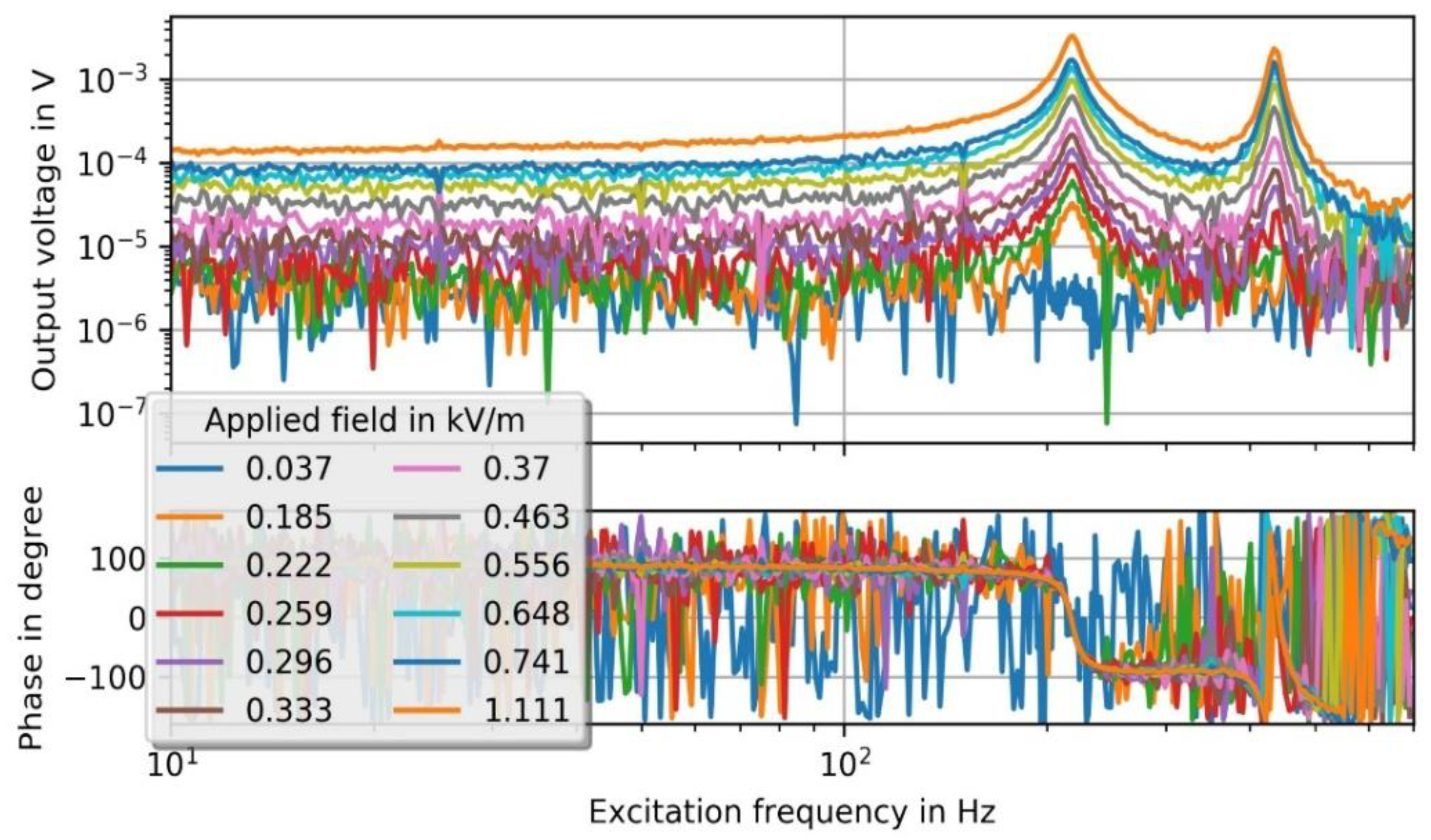

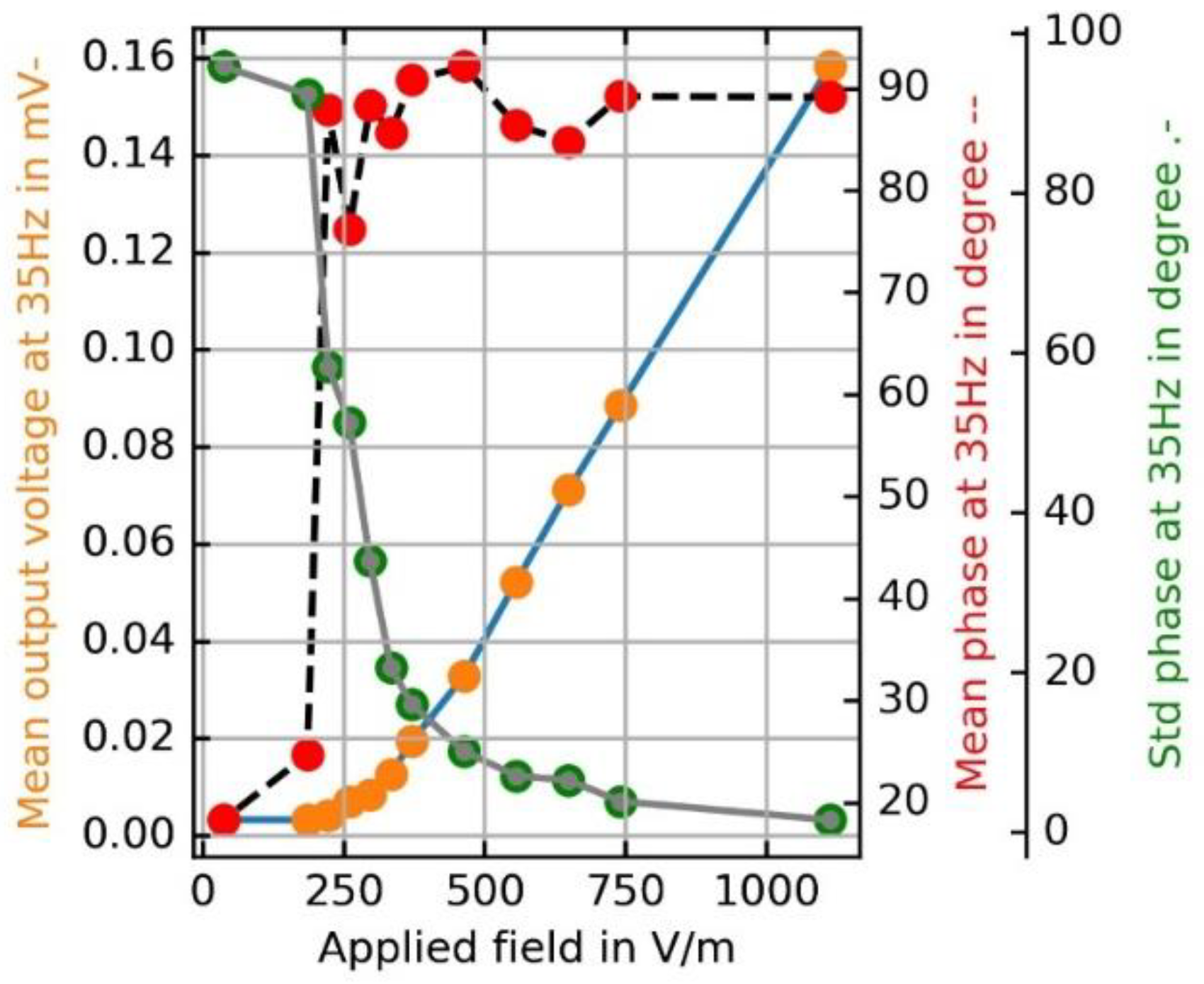

3. Results

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- DIRECTIVE 2013/35/EU. Of the European Parliament and of the Council, 26 June 2013, on the minimum health and safety requirements regarding the exposure of workers to the risks arising from physical agents. Off. J. Eur. Union 2013, 179, 1. [Google Scholar]

- Kainz, A.; Steiner, H.; Schalko, J.; Jachimowicz, A.; Kohl, F.; Stifter, M.; Beigelbeck, R.; Keplinger, F.; Hortschitz, W. Distortion-free measurement of electric field strength with a MEMS sensor. Nat. Electron. 2018, 1, 68–73. [Google Scholar] [CrossRef]

- Hortschitz, W.; Steiner, H.; Stifter, M.; Kohl, F.; Kahr, M.; Kainz, A.; Raffelsberge, T.; Keplinger, F. Novel high resolution MOEMS inclination sensor. In Proceedings of the IEEE Sensors, Valencia, Spain, 2–5 November 2014; pp. 1889–1892. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hortschitz, W.; Kainz, A.; Steiner, H.; Kovacs, G.; Stifter, M.; Kahr, M.; Schalko, J.; Keplinger, F. Characterization of a Micro-Opto-Mechanical Transducer for the Electric Field Strength. Proceedings 2018, 2, 855. https://doi.org/10.3390/proceedings2130855

Hortschitz W, Kainz A, Steiner H, Kovacs G, Stifter M, Kahr M, Schalko J, Keplinger F. Characterization of a Micro-Opto-Mechanical Transducer for the Electric Field Strength. Proceedings. 2018; 2(13):855. https://doi.org/10.3390/proceedings2130855

Chicago/Turabian StyleHortschitz, Wilfried, Andreas Kainz, Harald Steiner, Gabor Kovacs, Michael Stifter, Matthias Kahr, Johannes Schalko, and Franz Keplinger. 2018. "Characterization of a Micro-Opto-Mechanical Transducer for the Electric Field Strength" Proceedings 2, no. 13: 855. https://doi.org/10.3390/proceedings2130855

APA StyleHortschitz, W., Kainz, A., Steiner, H., Kovacs, G., Stifter, M., Kahr, M., Schalko, J., & Keplinger, F. (2018). Characterization of a Micro-Opto-Mechanical Transducer for the Electric Field Strength. Proceedings, 2(13), 855. https://doi.org/10.3390/proceedings2130855