Fabrication of a CMOS-based Imaging Chip with Monolithically Integrated RGB and NIR Filters †

Abstract

:1. Introduction

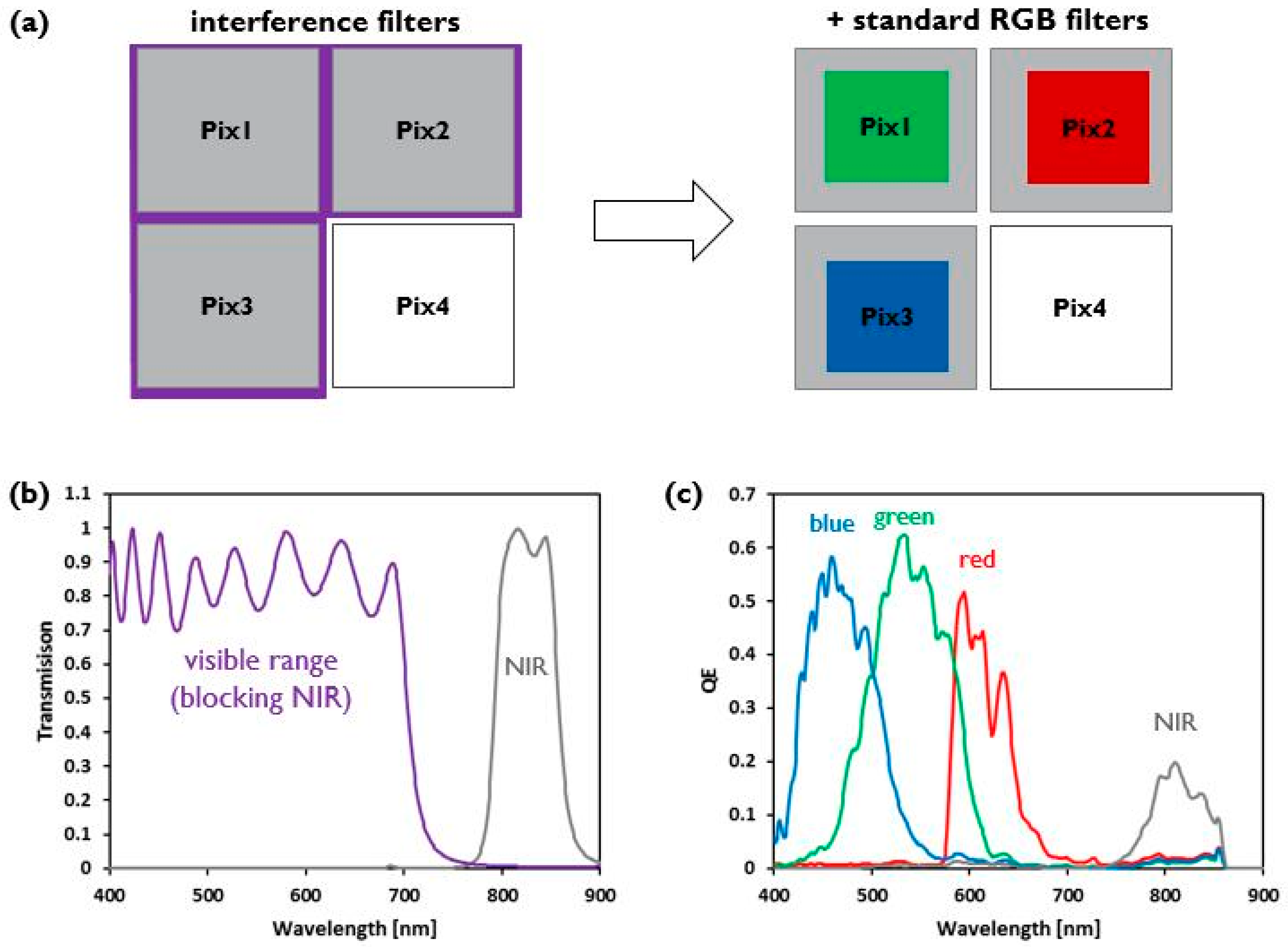

2. Combining NIR Block, Narrowband NIR, and RGB Filters

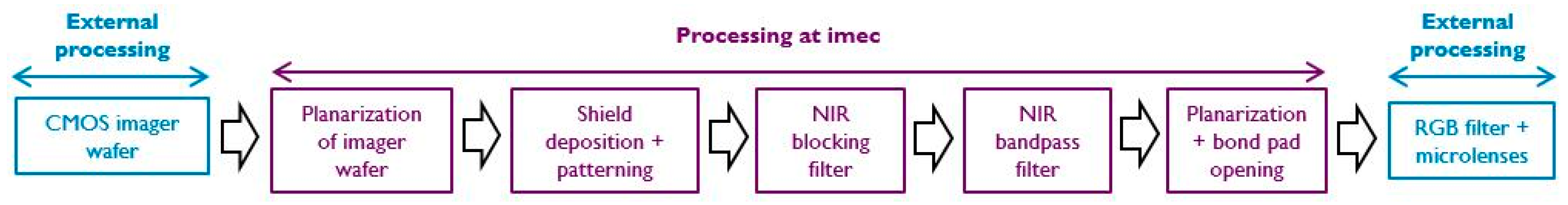

3. Overview of the Process Flow

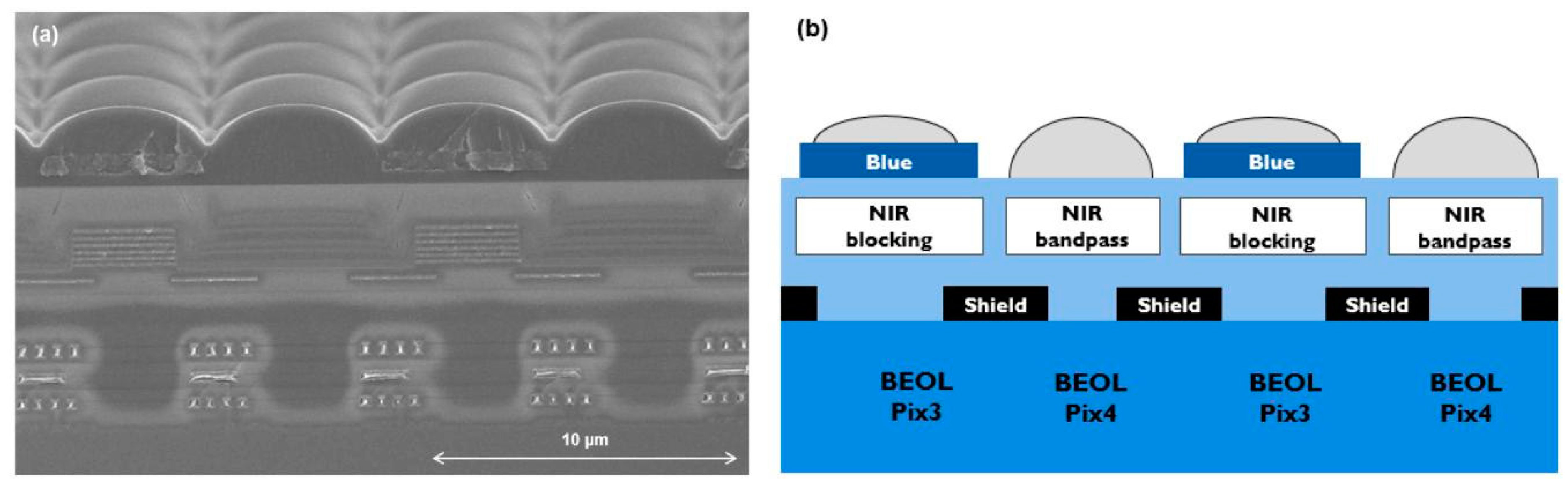

4. Filters

5. Shield

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Zhang, X.; Sim, T.; Miao, X. Enhancing photographs with Near InfraRed images. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Anchorage, AK, USA, 23–28 June 2008. [Google Scholar] [CrossRef]

- Geelen, B.; Spooren, N.; Tack, K.; Lambrechts, A.; Jayapala, M. System-level analysis and design for RGB-NIR CMOS camera. Proc. SPIE 2017, 10110. [Google Scholar] [CrossRef]

- Chen, Z.; Wang, X.; Liang, R. RGB-NIR multispectral camera. Opt. Express 2014, 22, 4985–4994. [Google Scholar] [CrossRef] [PubMed]

- Teranaka, H.; Monno, Y.; Tanaka, M.; Okutomi, M. Single-Sensor RGB and NIR Image Acquisition: Toward Optimal Performance by Taking Account of CFA Pattern, Demosaicking, and Color Correction. Electron. Imaging 2016. [CrossRef]

- Tack, K.; Geelen, B.; Vereecke, B. HSI with Variable Fill Factor Per Spectral Band. EP Patent application No. EP3339821A1, 27 June 2018. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vereecke, B.; Besien, E.V.; Tezcan, D.S.; Spooren, N.; Tack, N.; Lambrechts, A. Fabrication of a CMOS-based Imaging Chip with Monolithically Integrated RGB and NIR Filters. Proceedings 2018, 2, 751. https://doi.org/10.3390/proceedings2130751

Vereecke B, Besien EV, Tezcan DS, Spooren N, Tack N, Lambrechts A. Fabrication of a CMOS-based Imaging Chip with Monolithically Integrated RGB and NIR Filters. Proceedings. 2018; 2(13):751. https://doi.org/10.3390/proceedings2130751

Chicago/Turabian StyleVereecke, Bart, Els Van Besien, Deniz Sabuncuoglu Tezcan, Nick Spooren, Nicolaas Tack, and Andy Lambrechts. 2018. "Fabrication of a CMOS-based Imaging Chip with Monolithically Integrated RGB and NIR Filters" Proceedings 2, no. 13: 751. https://doi.org/10.3390/proceedings2130751

APA StyleVereecke, B., Besien, E. V., Tezcan, D. S., Spooren, N., Tack, N., & Lambrechts, A. (2018). Fabrication of a CMOS-based Imaging Chip with Monolithically Integrated RGB and NIR Filters. Proceedings, 2(13), 751. https://doi.org/10.3390/proceedings2130751