Hermetic Cavities Using Gold Wafer Level Thermocompression Bonding †

Abstract

:1. Introduction

2. Experimental

2.1. Process Flow Description

2.2. Equipment and Bonding Parameters

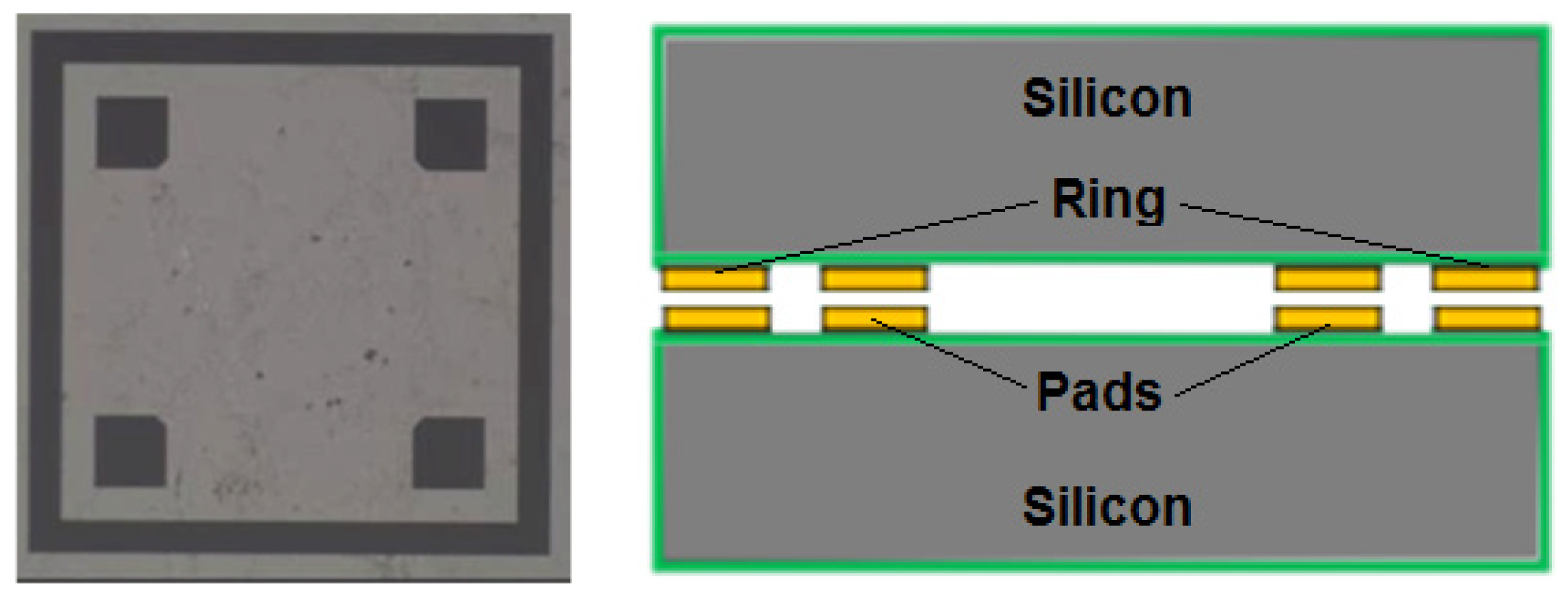

2.3. Tests Structures

3. Results

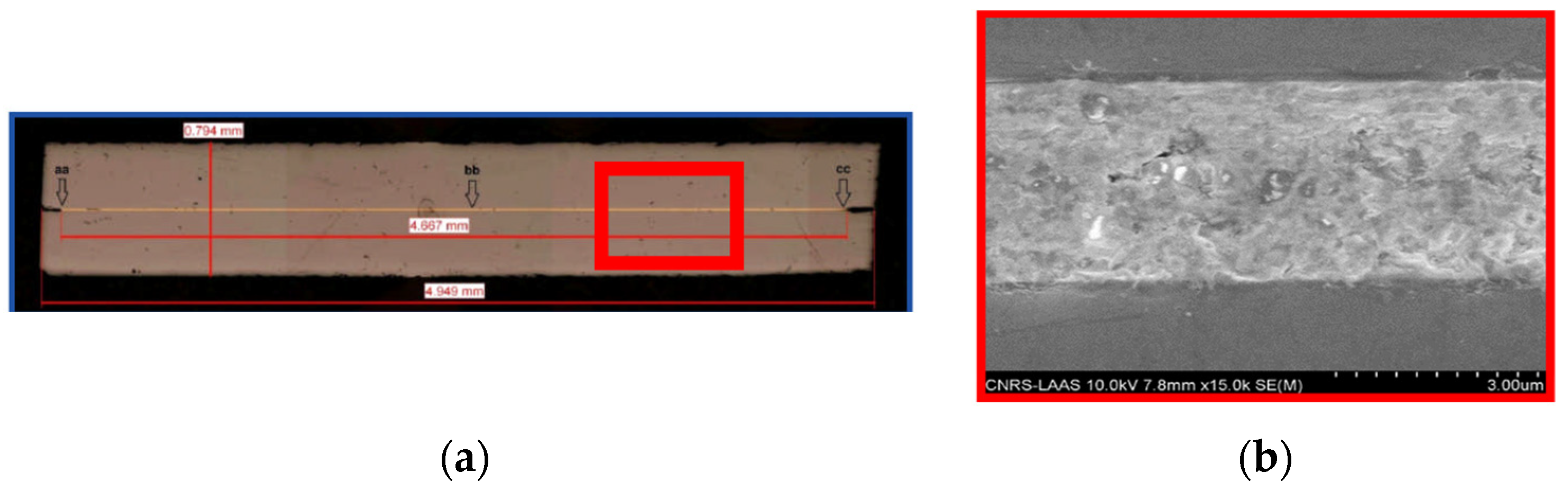

3.1. Gold Interface

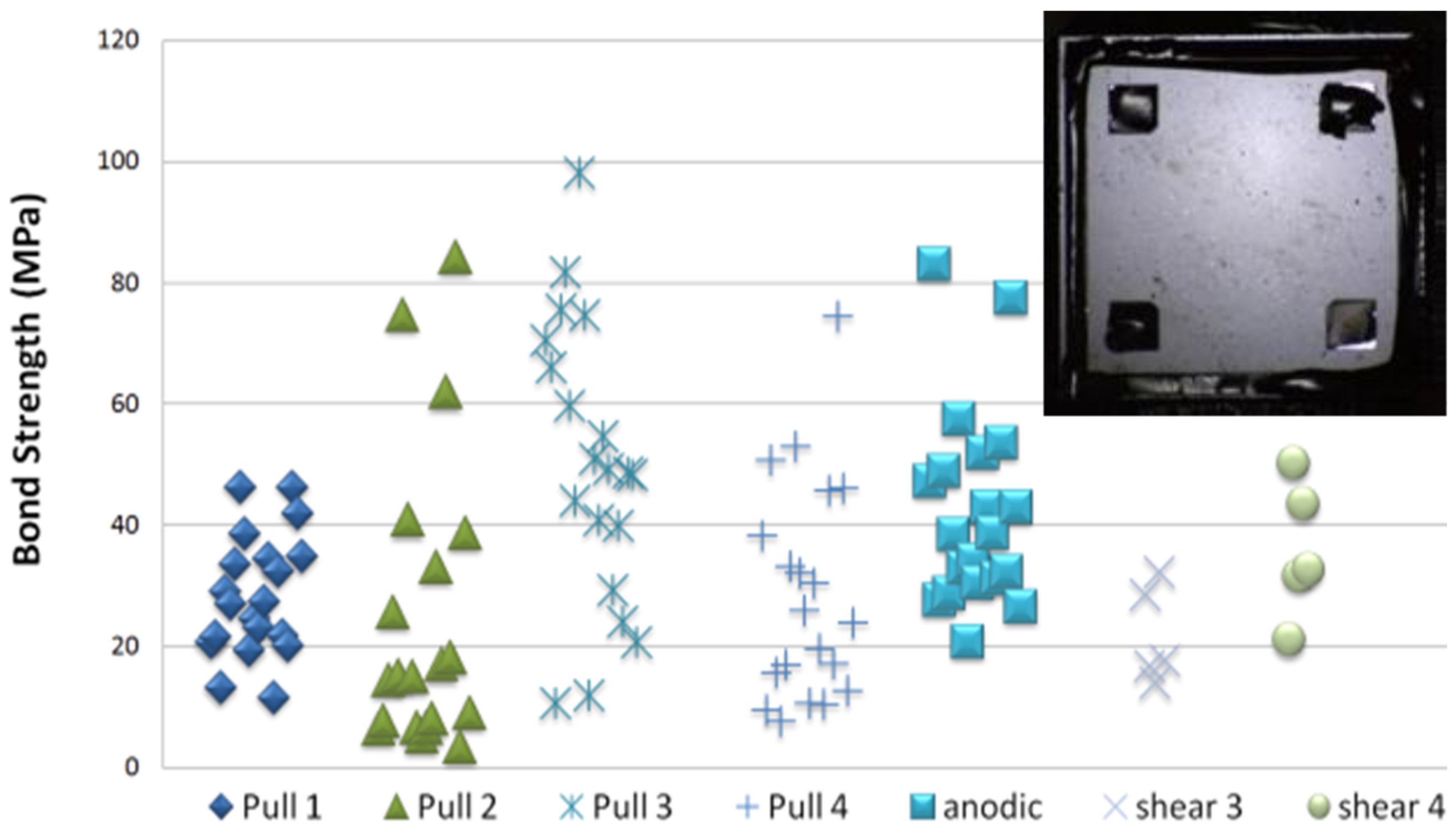

3.2. Bond Strength

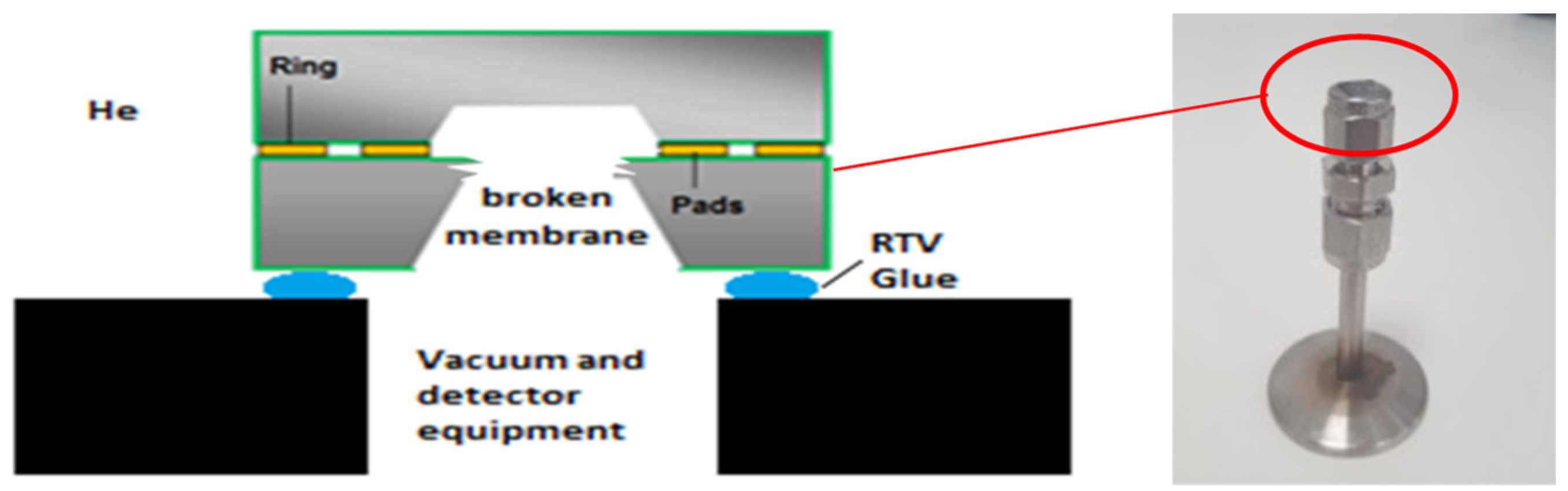

3.3. Hermeticity

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Malik, N.; Tofteberg, H.R.; Poppe, E.; Finstad, T.G.; Schjølberg-Henriksenb, K. Environmental Stress Testing of Wafer-Level Au-Au Thermocompression Bonds Realized at Low Temperature: Strength and Hermeticity. ECS J. Solid State Sci. Technol. 2015, 4, P236–P241. [Google Scholar] [CrossRef]

- Tsau, C.H.; Spearing, S.M.; Schmidt, M.A. Low temperature wafer-level bonding for hermetic packaging of 3D microsystems. Micromech. Microeng. 2011, 21, 075006. [Google Scholar]

- Tsau, C.H.; Spearing, S.M.; Schmidt, M.A. Characterization of wafer-level thermocompression bonds. J. Microelectromech. Syst. 2004, 13, 6. [Google Scholar] [CrossRef]

- Taklo, M.M.V.; Storas, P.; Schjølberg-Henriksen, K.; Hasting, H.K.; Jakobsen, H. Strong, high-yield and low-temperature thermocompression silicon wafer-level bonding with gold. J. Micromech. Microeng. 2004, 14, 884. [Google Scholar] [CrossRef]

- Ishida, H. Low Temperature Hermetic Seal Bonding for Wafer Level MEMS Packaging Using Submicron Gold Particles with Stencil Printing Patterning, Braunschweig; ProceedingsWaferBond15. 2015.

- Kebabi, B.; Malek, C.K.; Ladan, F.R. Stress and microstructure relationships in gold thin films. Vacuum 1990, 41, 1353–1355. [Google Scholar] [CrossRef]

| Cell Number | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| ΔR/R (ppm) | 248 | 568 | 333 | 3770 | 2370 | 1070 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Charlot, S.; Pons, P.; Dilhan, M.; Vallet, I.; Brida, S. Hermetic Cavities Using Gold Wafer Level Thermocompression Bonding. Proceedings 2017, 1, 607. https://doi.org/10.3390/proceedings1040607

Charlot S, Pons P, Dilhan M, Vallet I, Brida S. Hermetic Cavities Using Gold Wafer Level Thermocompression Bonding. Proceedings. 2017; 1(4):607. https://doi.org/10.3390/proceedings1040607

Chicago/Turabian StyleCharlot, Samuel, Patrick Pons, Monique Dilhan, Isabelle Vallet, and Sebastiano Brida. 2017. "Hermetic Cavities Using Gold Wafer Level Thermocompression Bonding" Proceedings 1, no. 4: 607. https://doi.org/10.3390/proceedings1040607

APA StyleCharlot, S., Pons, P., Dilhan, M., Vallet, I., & Brida, S. (2017). Hermetic Cavities Using Gold Wafer Level Thermocompression Bonding. Proceedings, 1(4), 607. https://doi.org/10.3390/proceedings1040607