Development and Evaluation of Tri-Axial Fiber Bragg Grating Force Sensor for Catheter †

Abstract

:1. Introduction

2. Materials and Methods

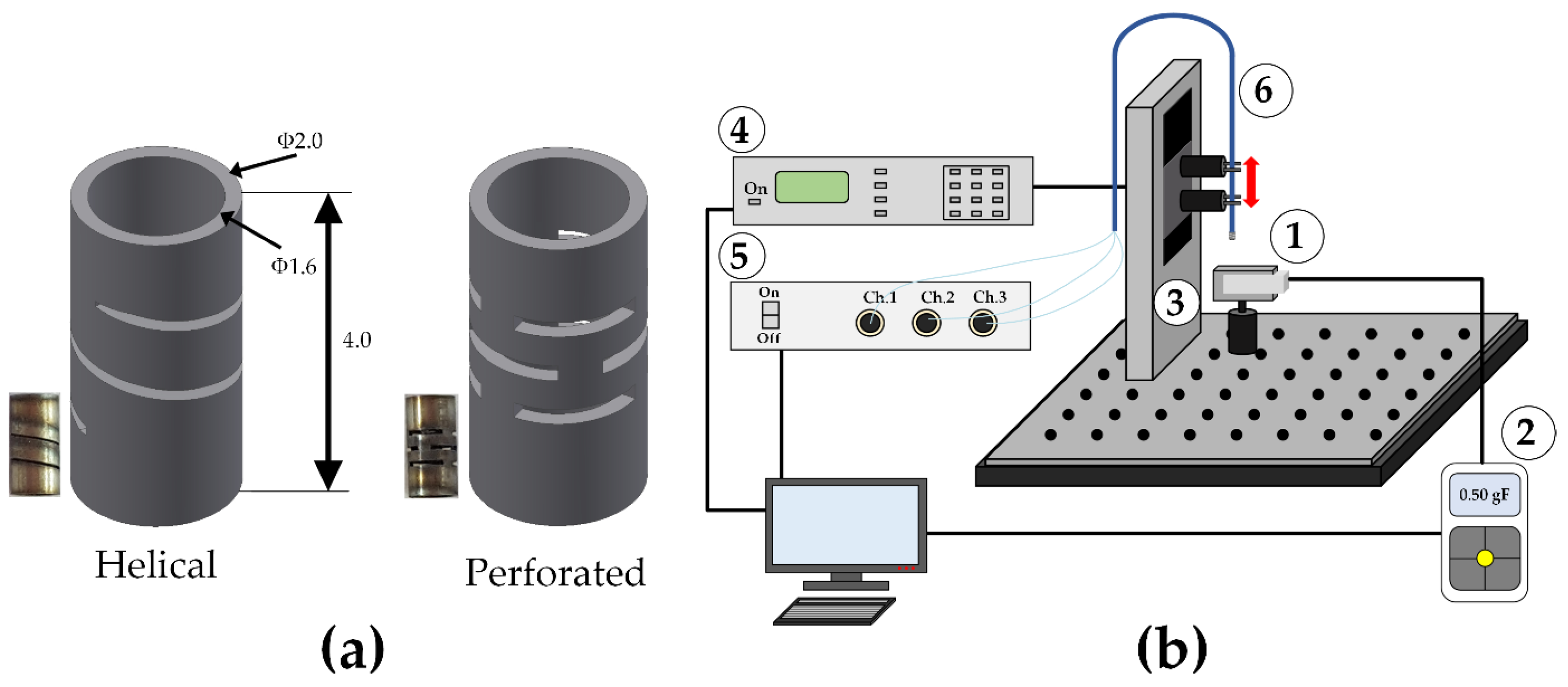

2.1. Flexure Structure Design and FBG Sensor Fabrication

2.2. Force Measurement Setup

3. Results and Discussion

3.1. Operating Principle of FBG Sensor

3.2. Flexure Stress Distribution and Sensitivity

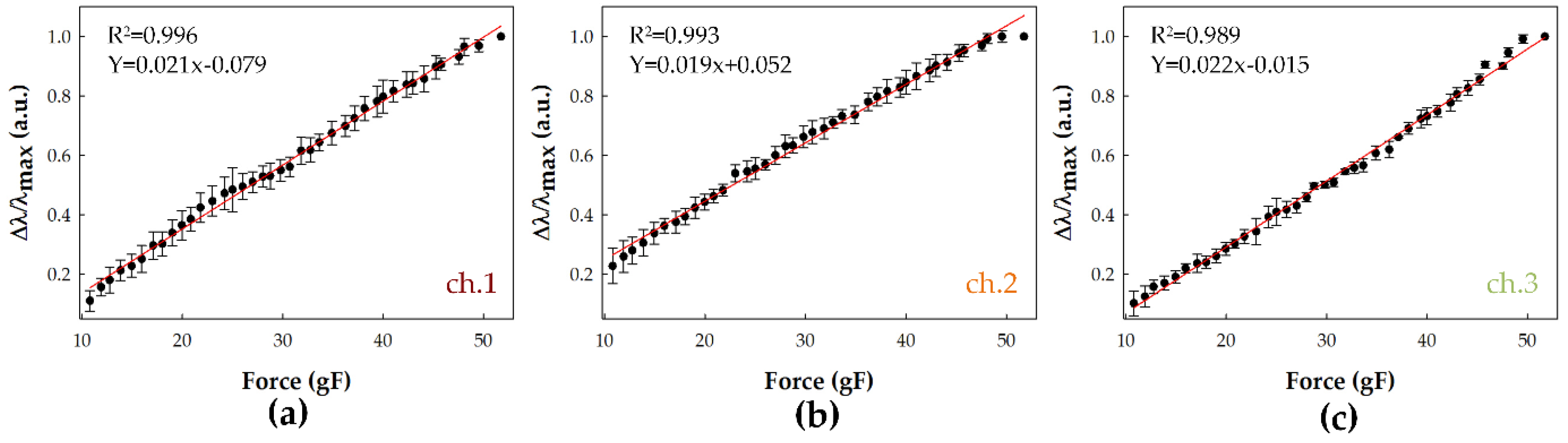

3.3. FBG Force Sensor Response

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Polygerinos, P.; Puangmali, P.; Schaeffter, T.; Razavi, R.; Seneviratne, L.D.; Althoefer, K. Novel Miniature MRI-Compatible Fiber-Optic Force Sensor for Cardiac Catheterization Procedures. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation (ICRA), Anchorage, AK, USA, 3–7 May 2010. [Google Scholar]

- Torres, B.; Payá-Zaforteza, I.; Calderón, P.A.; Adam, J.M. Analysis of the strain transfer in a new FBG sensor for structural health monitoring. Eng. Struct. 2011, 33, 539–548. [Google Scholar] [CrossRef]

- Kulkarni, A.; Na, J.; Kim, Y.; Kim, T. The plastic optical fiber cantilever beam as a force sensor. Microw. Opt. Technol. Lett. 2009, 51, 1020–1023. [Google Scholar] [CrossRef]

- Xu, L.; Ge, J.; Fok, M.P. Temperature-insensitive fiber-optic contact force sensor for steerable catheters. IEEE Sens. J. 2016, 16, 4771–4775. [Google Scholar] [CrossRef]

- Kersey, A.D.; Davis, M.A.; Patrick, H.J.; LeBlanc, M.; Koo, K.P.; Askins, C.G.; Putnam, M.A.; Friebele, E.J. Fiber grating sensors. J. Lightwave Technol. 1997, 15, 1442–1463. [Google Scholar] [CrossRef]

- Rao, Y.-J.; Webb, D.J.; Jackson, D.A.; Zhang, L.; Bennion, I. Optical in-fiber Bragg grating sensor systems for medical applications. J. Biomed. Opt. 1998, 3, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Chung, K.M.; Liu, Z.; Lu, C.; Tam, H.Y. Highly sensitive compact force sensor based on microfiber Bragg grating. IEEE Photonics Technol. Lett. 2012, 24, 700–702. [Google Scholar] [CrossRef]

- Thiagalingam, A.; D’Avila, A.; Foley, L.; Guerrero, J.L.; Lambert, H.; Leo, G.; Ruskin, J.N.; Reddy, V.Y. Importance of Catheter Contact Force during Irrigated Radiofrequency Ablation: Evaluation in a Porcine Ex Vivo Model Using a Force-Sensing Catheter. J. Cardiovasc. Electrophysiol. 2010, 21, 806–811. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, D.; Kim, H.-U.; Kulkarni, A.; Kim, T. Development and Evaluation of Tri-Axial Fiber Bragg Grating Force Sensor for Catheter. Proceedings 2017, 1, 549. https://doi.org/10.3390/proceedings1040549

Shin D, Kim H-U, Kulkarni A, Kim T. Development and Evaluation of Tri-Axial Fiber Bragg Grating Force Sensor for Catheter. Proceedings. 2017; 1(4):549. https://doi.org/10.3390/proceedings1040549

Chicago/Turabian StyleShin, Dongjoo, Hyeong-U Kim, Atul Kulkarni, and Taesung Kim. 2017. "Development and Evaluation of Tri-Axial Fiber Bragg Grating Force Sensor for Catheter" Proceedings 1, no. 4: 549. https://doi.org/10.3390/proceedings1040549

APA StyleShin, D., Kim, H.-U., Kulkarni, A., & Kim, T. (2017). Development and Evaluation of Tri-Axial Fiber Bragg Grating Force Sensor for Catheter. Proceedings, 1(4), 549. https://doi.org/10.3390/proceedings1040549