Design, Fabrication and Optimization of a Silicon MEMS Natural Gas Sensor †

Abstract

:1. Introduction

2. Design and Simulation

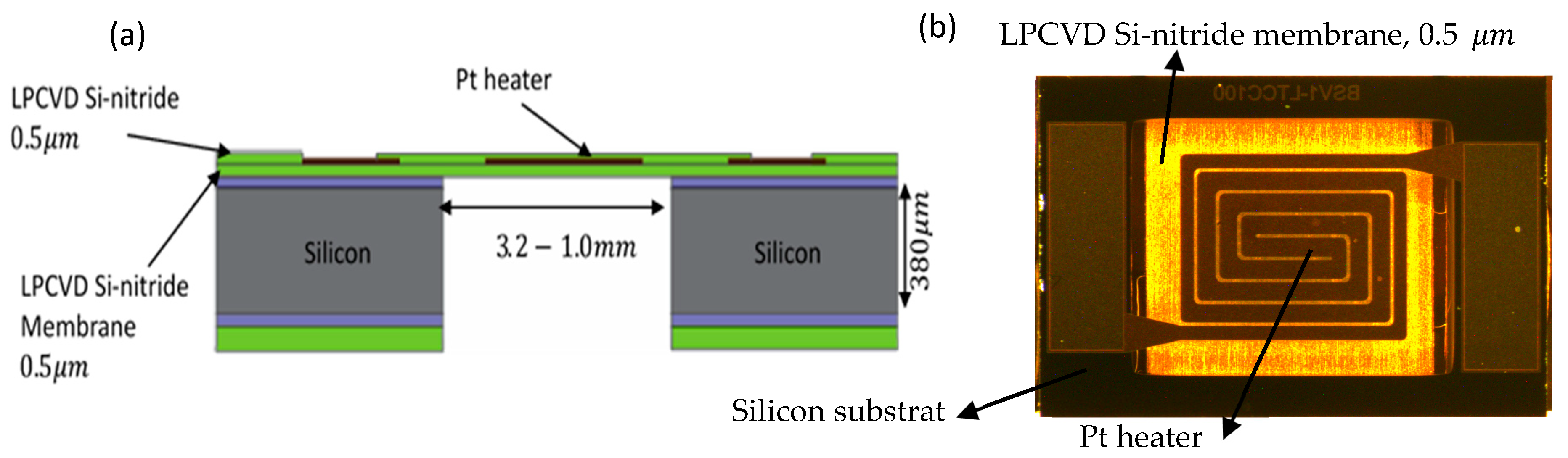

2.1. Design of MEMS Hotplate

2.2. Finite Element Modeling of the Sensor

2.3. Fabrication of MEMS Hotplate

2.4. Characterization of MEMS Hotplate

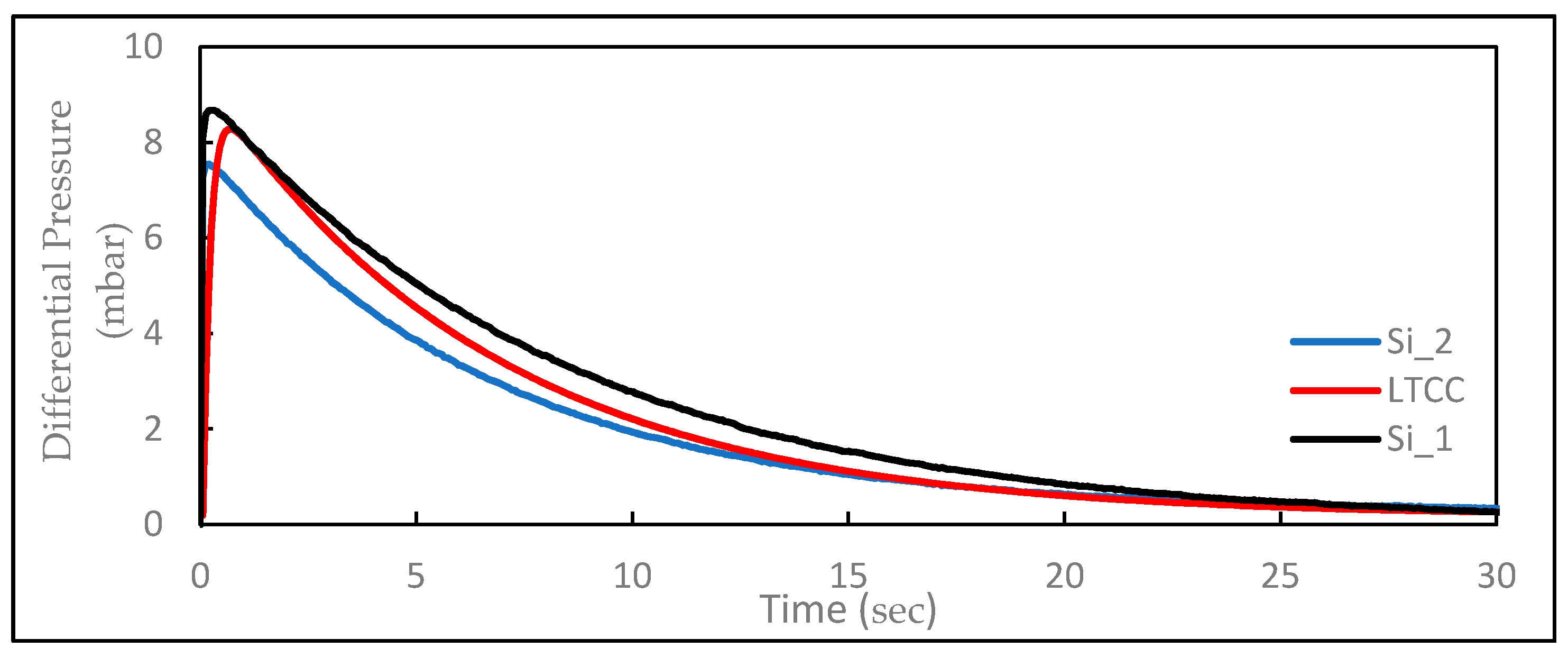

3. Experimental Study and Analysis

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Slim, B.; Levinsky, H.; Knijp, J. Retrofit Wobbe Control System for Industrial Gasburners. In Proceedings of the International Gas Union Research Conference 2017, Rio de Janeiro, Brazil, 24–27 October 2016. [Google Scholar]

- Pickenaecker, K.; Wawrzinek, K.; Trimis, D. Optimization of burners by air-ratio-controlled combustion based on wobbe number measurement. In Proceedings of the European Conference on Small Burner and Heating Technology, Stuttgart, Germany, 16–17 March 2000; pp. 231–240. [Google Scholar]

- Slater, C.; Farine, G. Gas Sensor. European Patent Application EP 2 993 472 A1, 3 September 2016. [Google Scholar]

| Device | Substrate Size (mm2) | Membrane Size (mm2) | Substrate Thickness (μm) | Resistance (Ω) |

|---|---|---|---|---|

| Si_1 | 5.2 × 3.55 | 3.2 × 2.55 | 380 | 150 |

| Si_2 | 3.0 × 3.0 | 2.0 × 2.0 | 380 | 150 |

| Si_3 | 1.5 × 1.5 | 1.0 × 1.0 | 380 | 190 |

| LTCC | 5.2 × 3.55 | 3.2 × 2.55 | 220 | 30 |

| Device | Applied Power (mW) | Calculated Viscosity (* 10−5 Pa·s) |

|---|---|---|

| Si_1 | 80 | 1.89 |

| Si_2 | 45 | 1.85 |

| Si_3 | 22.5 | 1.87 |

| LTCC | 400 | 1.88 |

| Device | Applied Power (mW) | Calculated Viscosity Methane(Pa·s) | Calculated Viscosity Nitrogen (Pa·s) |

|---|---|---|---|

| Si_1 | 40 | 1.09 ×10−5 | 1.75 |

| Si_2 | 50 | 1.10 ×10−5 | 1.65 |

| LTCC | 150 | 1.10 ×10−5 | 1.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaker, M.; Sundfør, E.; Farine, G.; Slater, C.; Farine, P.-A.; Briand, D. Design, Fabrication and Optimization of a Silicon MEMS Natural Gas Sensor. Proceedings 2017, 1, 470. https://doi.org/10.3390/proceedings1040470

Shaker M, Sundfør E, Farine G, Slater C, Farine P-A, Briand D. Design, Fabrication and Optimization of a Silicon MEMS Natural Gas Sensor. Proceedings. 2017; 1(4):470. https://doi.org/10.3390/proceedings1040470

Chicago/Turabian StyleShaker, Marjan, Erik Sundfør, Gaël Farine, Conor Slater, Pierre-André Farine, and Danick Briand. 2017. "Design, Fabrication and Optimization of a Silicon MEMS Natural Gas Sensor" Proceedings 1, no. 4: 470. https://doi.org/10.3390/proceedings1040470

APA StyleShaker, M., Sundfør, E., Farine, G., Slater, C., Farine, P.-A., & Briand, D. (2017). Design, Fabrication and Optimization of a Silicon MEMS Natural Gas Sensor. Proceedings, 1(4), 470. https://doi.org/10.3390/proceedings1040470