The First Frequency-Modulated (FM) Pitch Gyroscope †

Abstract

:1. Introduction

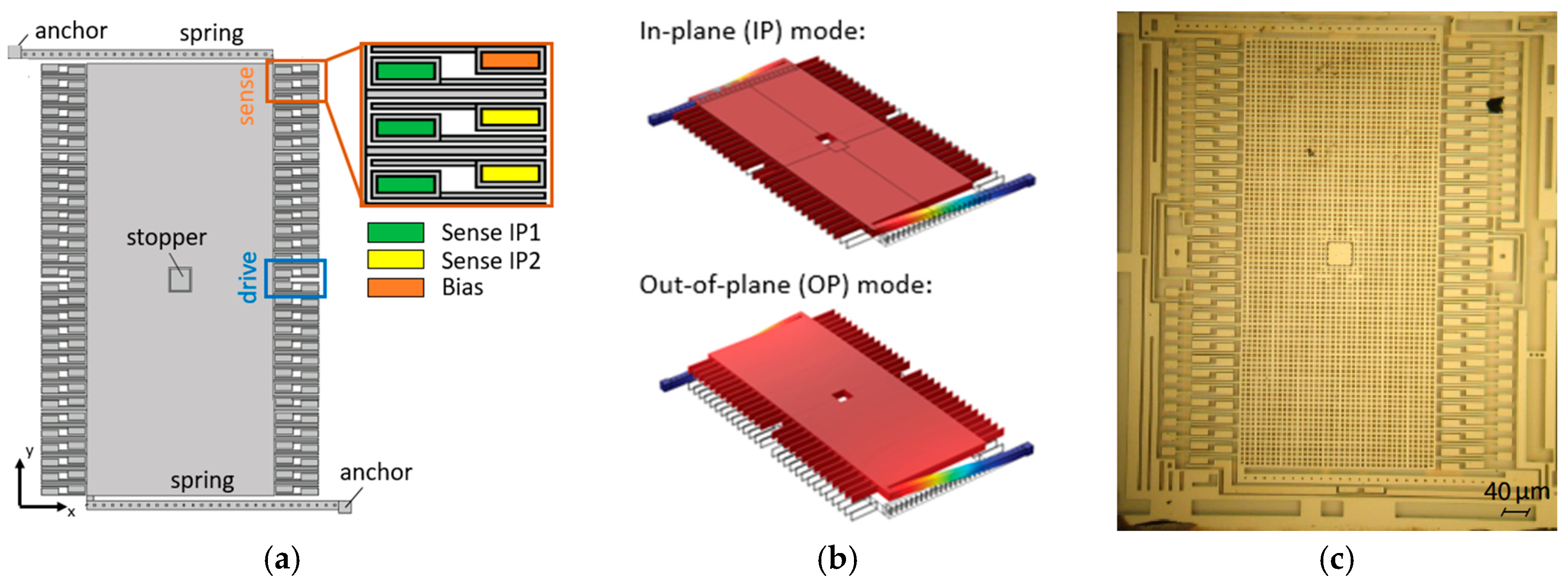

2. Working Principle and Mechanical Design

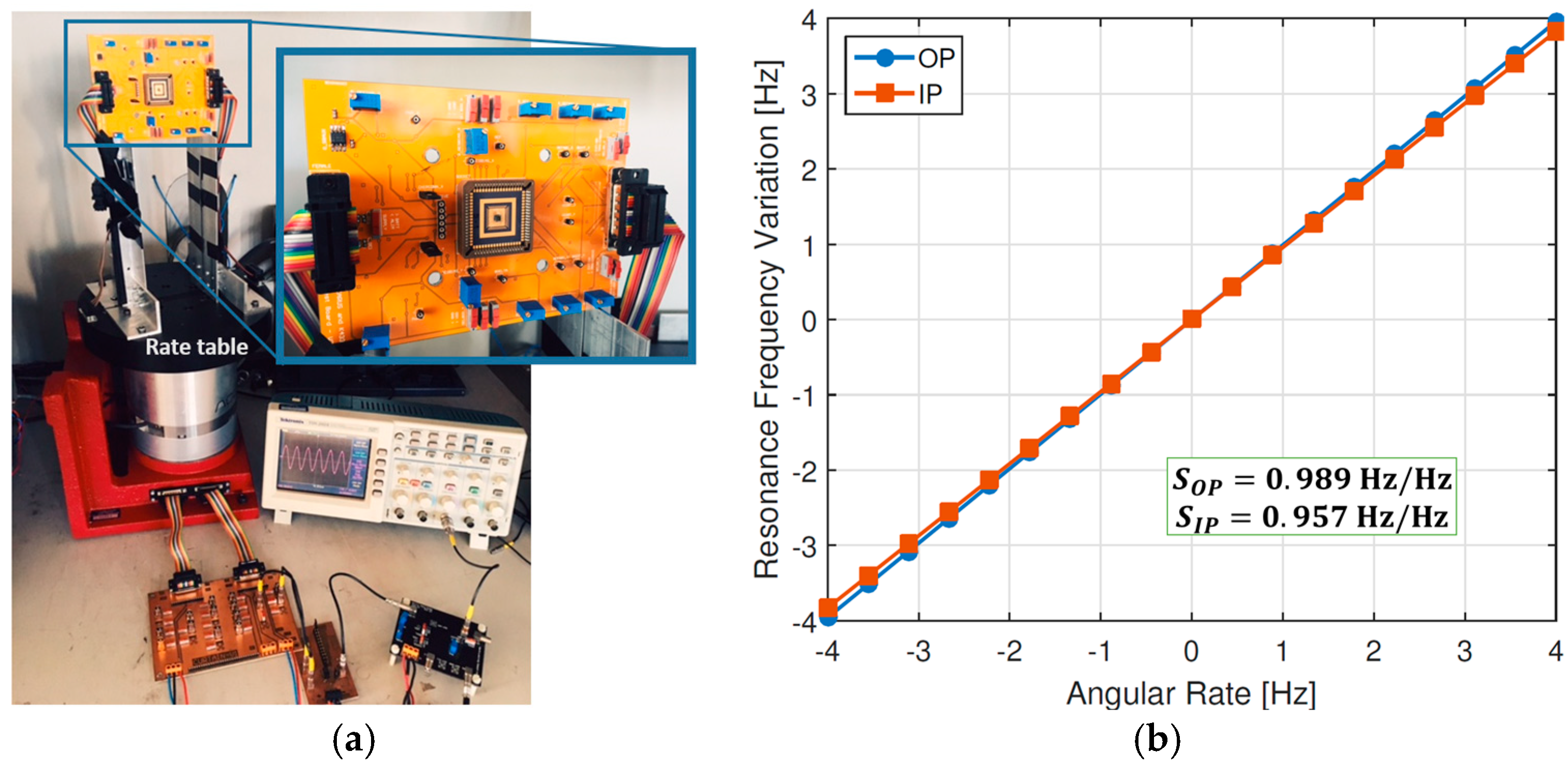

3. Experimental Measurements

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Kline, M.H.; Yeh, Y.-C.; Eminoglu, B.; Najar, H.; Daneman, H.; Horsley, D.A.; Boser, B.E. Quadrature FM gyroscope. In Proceedings of the 2013 IEEE 26th International Conference on Micro Electro Mechanical Systems (MEMS), Taipei, Taiwan, 20–24 January 2013; pp. 604–608. [Google Scholar]

- Minotti, P.; Mussi, G.; Dellea, S.; Bonfanti, A.; Lacaita, A.L.; Langfelder, G.; Zega, V.; Comi, C.; Facchinetti, S.; Tocchio, A. A 160 µA, 8 mdps/Hz1/2 frequency modulated MEMS yaw gyroscope. In Proceedings of the 2017 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL), Kauai, HI, USA, 28–30 March 2017; pp. 1–4. [Google Scholar]

- Izyumin, I.I.; Kline, M.H.; Yeh, Y.C.; Eminoglu, B.; Ahn, C.H.; Hong, V.A.; Yang, Y.; Ng, E.J.; Kenny, T.W.; Boser, B.E. A 7 ppm, 6 deg/hr frequency-output MEMS gyroscope. In Proceedings of the 2015 IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 33–36. [Google Scholar]

- Frangi, A.; Fedeli, P.; Laghi, G.; Langfelder, G.; Gattere, G. Near vacuum gas damping in MEMS: Numerical modeling and experimental validation. J. Microelectromech. Syst. 2016, 25, 890–899. [Google Scholar] [CrossRef]

- Tocchio, A.; Falorni, L.; Comi, C.; Zega, V. Frequency Modulation MEMS Triaxial Gyroscope. Deposited Patent No. 102016000106928, 24 October 2016. [Google Scholar] [CrossRef]

| IP Mode | OP Mode | |

|---|---|---|

| Natural frequency | 24,157 Hz | 26,250 Hz |

| Angular Gain | 0.9753 | 0.9759 |

| Quality factor (see [4]) | 1800 | 900 |

| Modal Mass | 14 nKg | 13 nKg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zega, V.; Minotti, P.; Mussi, G.; Tocchio, A.; Falorni, L.; Facchinetti, S.; Bonfanti, A.; Lacaita, A.L.; Comi, C.; Langfelder, G.; et al. The First Frequency-Modulated (FM) Pitch Gyroscope. Proceedings 2017, 1, 393. https://doi.org/10.3390/proceedings1040393

Zega V, Minotti P, Mussi G, Tocchio A, Falorni L, Facchinetti S, Bonfanti A, Lacaita AL, Comi C, Langfelder G, et al. The First Frequency-Modulated (FM) Pitch Gyroscope. Proceedings. 2017; 1(4):393. https://doi.org/10.3390/proceedings1040393

Chicago/Turabian StyleZega, Valentina, Paolo Minotti, Giorgio Mussi, Alessandro Tocchio, Luca Falorni, Stefano Facchinetti, Andrea Bonfanti, Andrea L. Lacaita, Claudia Comi, Giacomo Langfelder, and et al. 2017. "The First Frequency-Modulated (FM) Pitch Gyroscope" Proceedings 1, no. 4: 393. https://doi.org/10.3390/proceedings1040393

APA StyleZega, V., Minotti, P., Mussi, G., Tocchio, A., Falorni, L., Facchinetti, S., Bonfanti, A., Lacaita, A. L., Comi, C., Langfelder, G., & Corigliano, A. (2017). The First Frequency-Modulated (FM) Pitch Gyroscope. Proceedings, 1(4), 393. https://doi.org/10.3390/proceedings1040393