1. Introduction

Actually plasmon-based sensors becomes one of the most effective tools in the field of fingerprint detection of hazardous of (bio)significant compounds [

1]. Among the plasmonic approaches the surface plasmon based or surface enhanced Raman scattering sensors chips can be mentioned [

2]. Their utilization allows the detection with unprecedented limit, but real utilization requires the overcoming several practical problems and one of the is the stability. Among the plasmonic methods the gold and silver are the more frequently implemented metals. In turn, their utilization in the case of SERS must be considered from the point of excitation wavelength view. While the gold is more suitable metal for the excitation of SERS response with one of longer wavelength (i.e., far visible wavelength or near infra red), the silver seems to be more appropriate in the case of shorter visible wavelength. The plasmonic structures and substrates are usually based on the gold or silver nanostructures. While the gold is well known because off it chemical inertness, the situation in the case of silvers seems to be rather questionable. It is well known that the silver can undergo simple oxidation or, moreover, morphological changes under the impact of temperature, humidity or various (bio)environment. taking into account the fact, that the plasmon excitation efficiency is a strong function of metals purity, as well as environmental dielectric function, the processes of silver degradation can significantly decrease of silver-based plasmonic sensors. Moreover, the presence of silver oxide interlayer between the metal and targeted analyte can significantly decrease the SERS efficiency, since this analytical method is particularly sensitive to metal-analyte proximity.

Practically, degradation of silver based SERS substrates can take place during the preparation, transport, storage or directly analysis stages of SERS chip utilization. In this work the potential impact of storage and transport on silver substrate efficiency is studied. In particular, the proposed study is focused on two main parameters, which can be varied at the above stages: temperature and humidity. The effect of silver substrates interaction with (bio)environment will be further studied in the next work.

2. Materials and Methods

Silver grating preparation Silver gratings were prepared according to previously published procedure [

3]. First, the thin layer of Su-8 (Microchem) was deposited on the glass substrate by spin-coating method. Then, the excimer laser pattering was applied with the aim to create periodical structure with previously optimized parameters. The thin layer of silver was sputtered on the grating surface with the aim to create structure, able to support surface plasmon-polariton (SPP).

Silver grating treatments The environment stress tests were performed in the climatic test chamber VÖTSCH VC37018.The climatic chamber has a temperature conditioning system, and it provides rapid temperature changing rates in the range of −75 °C to +180 °C. Simultaneously, the relative humidity in the range of 10% to 98 % could be varied also. The temperature and relative humidity of the air in the chamber can be set with high accuracy. High circulating air rates ensure the even distribution of temperature and humidity in the test space. Required environmental conditions could be preprogrammed for different stress test terms. In our environment stress tests, the three model settings were used. In the first setting, the SERS substrates were submitted to the constant temperature 25 °C while the relative humidity was cyclically changed in the range of 20% to 70%. The second setting simulated the different temperature in the range of 10 °C to 50 °C while the relative humidity was set to the high value of 70%. In the last case, the combination of temperature and relative humidity change was used. The change was set in the range of 10 °C to 50 °C and 50% to 70%, respectively. The duration of the one completed cycle was set to 200 min in which the temperature/humidity always remain at a constant value for 60 minutes while the changing slope was set to 1 °C/1% per minute. The separate tests were conducted at a minimum of 150 number of cycles.

Silver grating characterization The X-ray photoelectron spectroscopy (XPS) was performed using an Omicron Nanotechnology Concentrations of elements were calculated in at. % using the manufacturer’s sensitivity factors. For characterization of the sample surface and nanomechanical mapping before and after surface modification, the peak force AFM technique was applied using the Icon (Brucker) microscope. Raman scattering was measured on portable ProRaman-L spectrometer (Laser power 15 mW) Raman spectrometer with 785 nm excitation wavelengths.

3. Results and Discussion

XPS analysis Results of XPS are presented in the

Table 1, which shows the surface concentration of detected elements before and after application of physical teatments.

As is evident from the

Table 1, the surface of as deposited silver grating consists dominantly from pure silver. Additional presence of oxygen and carbon related XPS peaks can be attributed to the some samples contamination, which occurs, probably, during the deposition procedure. Further temperature treatment of silver grating does not lead to significant changes of elements concentration. Some increase of oxygen concentration was observed under the temperature influence and can be expected previously, due to gradual metal oxidation. More significant changes were observed in the case of silver grating exposed to the cyclic humidity changes. In this case apparent decrease of silver concentration with simultaneous increasing of oxygen concentration was observed. Created oxide layer is more pronounced and can affects the plasmonic properties of structure more strongly. Observed changes were founded to be even more significant on the case, where the humidity treatment was combined with temperature variation. Measured oxygen concentration increased several time and reach the value of 36 percent, indicating the formation of apparent oxide layer.

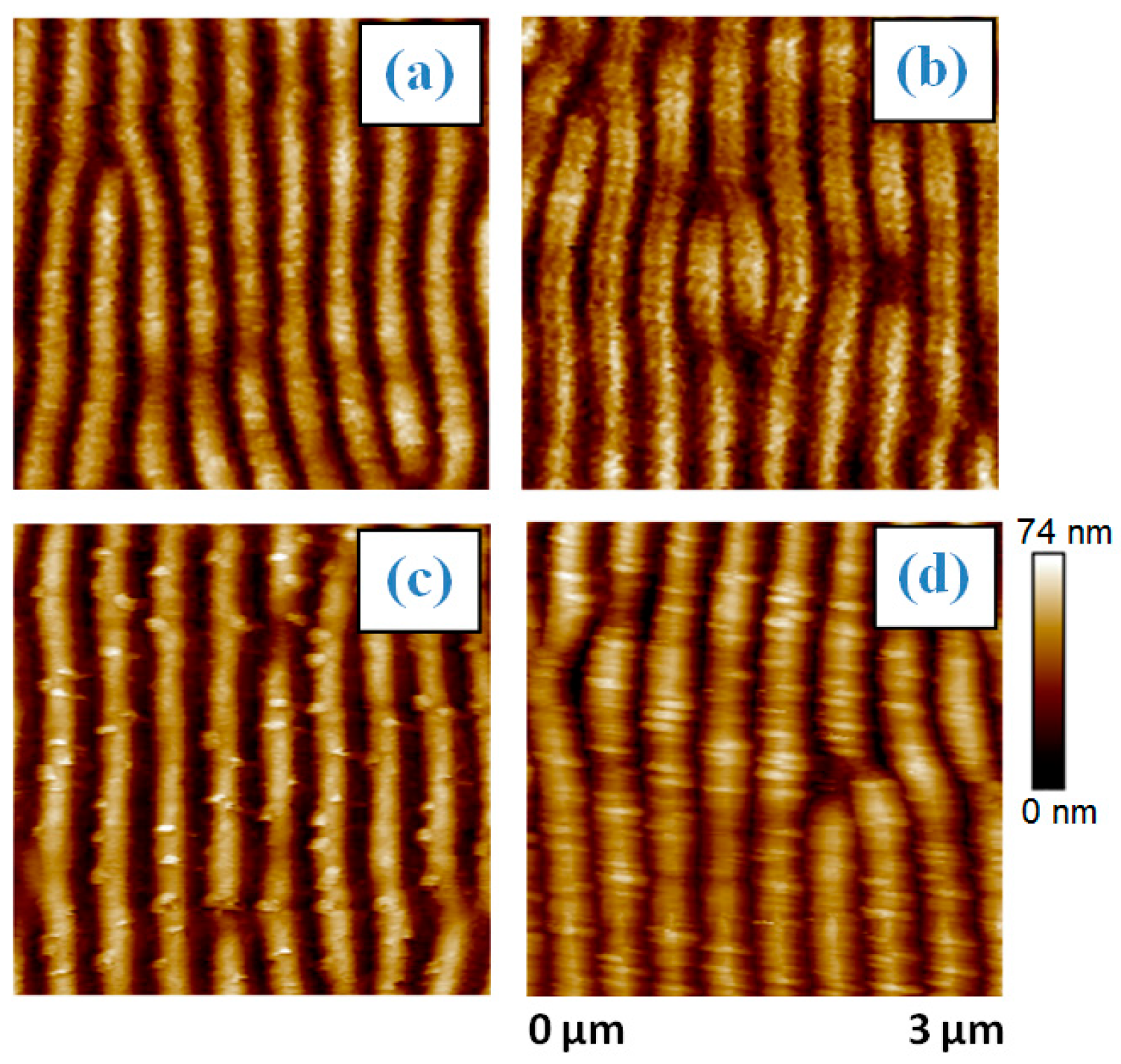

AFM analysis It is well known, that the efficiency of plasmon excitation (and, in turn, SERS enhancement) is a strong function of the plasmonic structures shape and mutual arrangement. Deviation from this ideal situation can cause the decrease of plasmonic substrate efficiency. in our case the grating parameters as well as the thickness of silver were also optimal for more effective SPP excitation. On the other hand, it is well known, that the silver layer can undergo significant morphological changes under the external treatments. Such changes usually results in the disruption of silver layer homogeneity, formation of cluster-like structures and so on. To examine the potential impact of temperature variation, humidity variation as well as their combination the AFM measurements were performed. Results of surface morphology check are presented in the

Figure 1.

As is evident from

Figure 1a the surface of pristine silver grating represents the periodical structure with smaller features, characteristic for sputtered method of metal deposition. Further application of temperature treatment (

Figure 1b) affects the surface morphology—metal features becomes more pronounced. However, conservation of silver layer integrity can be expected in this case. More pronounced changes are evident in the case of silver layer exposed to periodical humidity changes (

Figure 1c). In this case formation of cluster on the silver surface is evident and can be described in terms of metal oxidation. Further and more pronounced disruption of silver layer structure was observed in the case of combined treatment (

Figure 1d). In this case the structure deviate significantly from pristine. So, in the case of all applied treatments changes of silver layer morphology were observed, but they were more significant in under the humidity or temperature/humidity expositions.

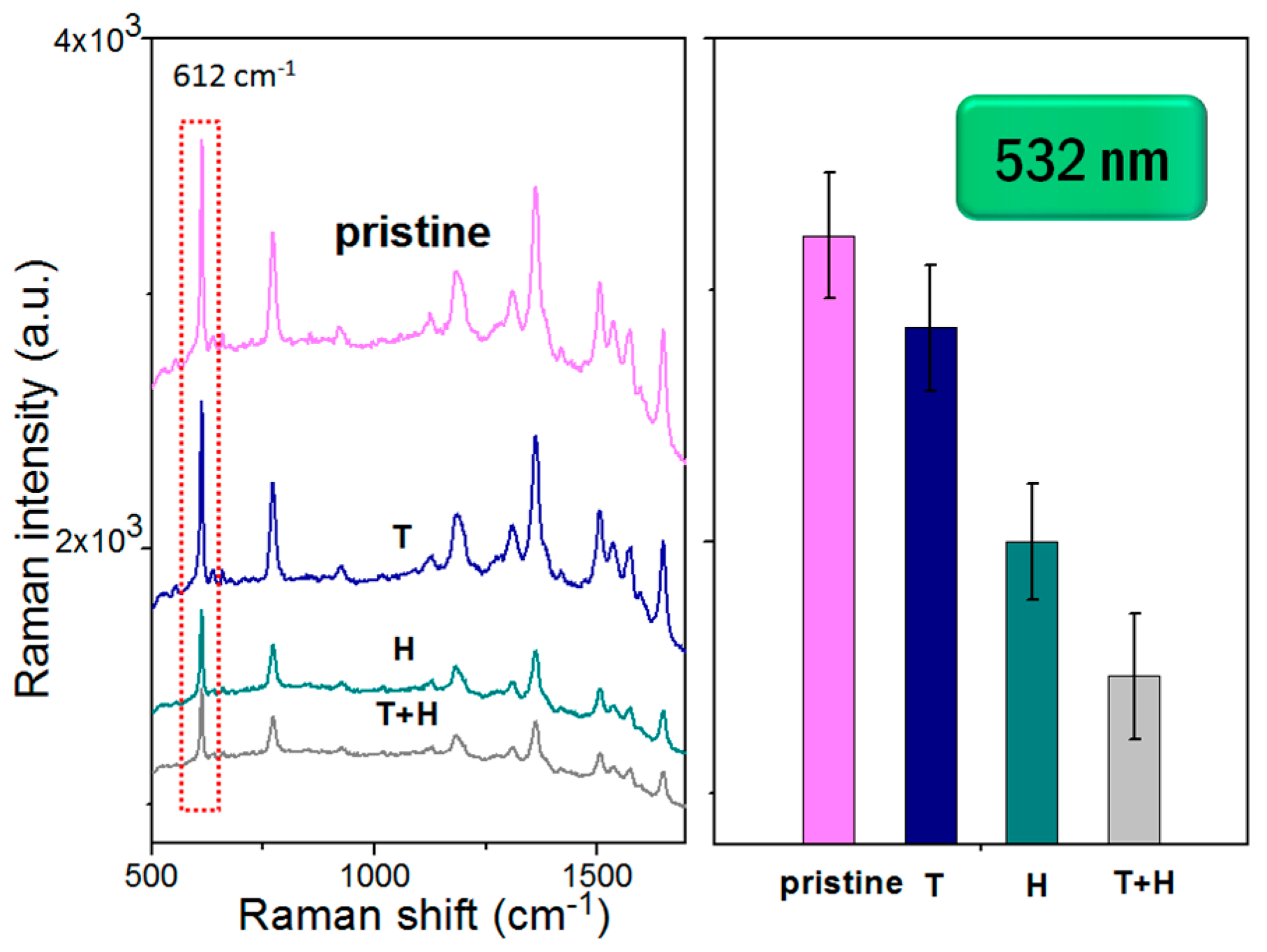

SERS analysis Last, but not least the SERS measurements were performed on the pristine and treated silver gratings. It must be also noted, that the prepared silver gratings were chosen as a substrate for SERS sensor fabrication due to homogeneous response and strong signal enhancement, as was described before [

3]. So, the evaluation of SRRS results were performed from the point of absolute SERS signal intensity and the homogeneity of SRS signal.

From the measure results of Raman signal from further deposited R6G molecules (

Figure 2) the pristine samples show the perfect SERS enhancement as well as Raman convergence. Temperature treatment slightly decrease the value of SERS intensity, but almost not affect the Raman homogeneity. Application of periodical humidity changes leads to more significant SERS decrease. Finally, and as can be expected, the combination of humidity and temperature simultaneous variation leads to the most pronounced SERS decrease and significant deviation of SERS signal along the active sample surface.

4. Conclusions

In this work the effect of physical treatment of silver grating on their plasmonic properties (SERS) was studied. In particular, three kind of samples aging were applied: periodical variation of temperature, humidity, and their combination. Silver surface chemistry (potential oxidation) was studied by the XPS method and more pronounced changes were observed, when the humidity treatments were applied. Surface morphology of pristine and treated samples were evaluated using the AFM technique and pronounced impact of all applied kinds of aging was observed. Finally, the intensity of samples SERS efficiency was estimate using the SERS approach. The more significant worse of silver plasmonic properties (i.e., decrease of absolute value of SERS enhancement and increase of SERS signal deviation) was observed in the case of simultaneous exposition and temperature and humidity periodical variation.