Piezoelectric Actuators for In-Liquid Particle Manipulation in Microfluidic Applications †

Abstract

:1. Introduction

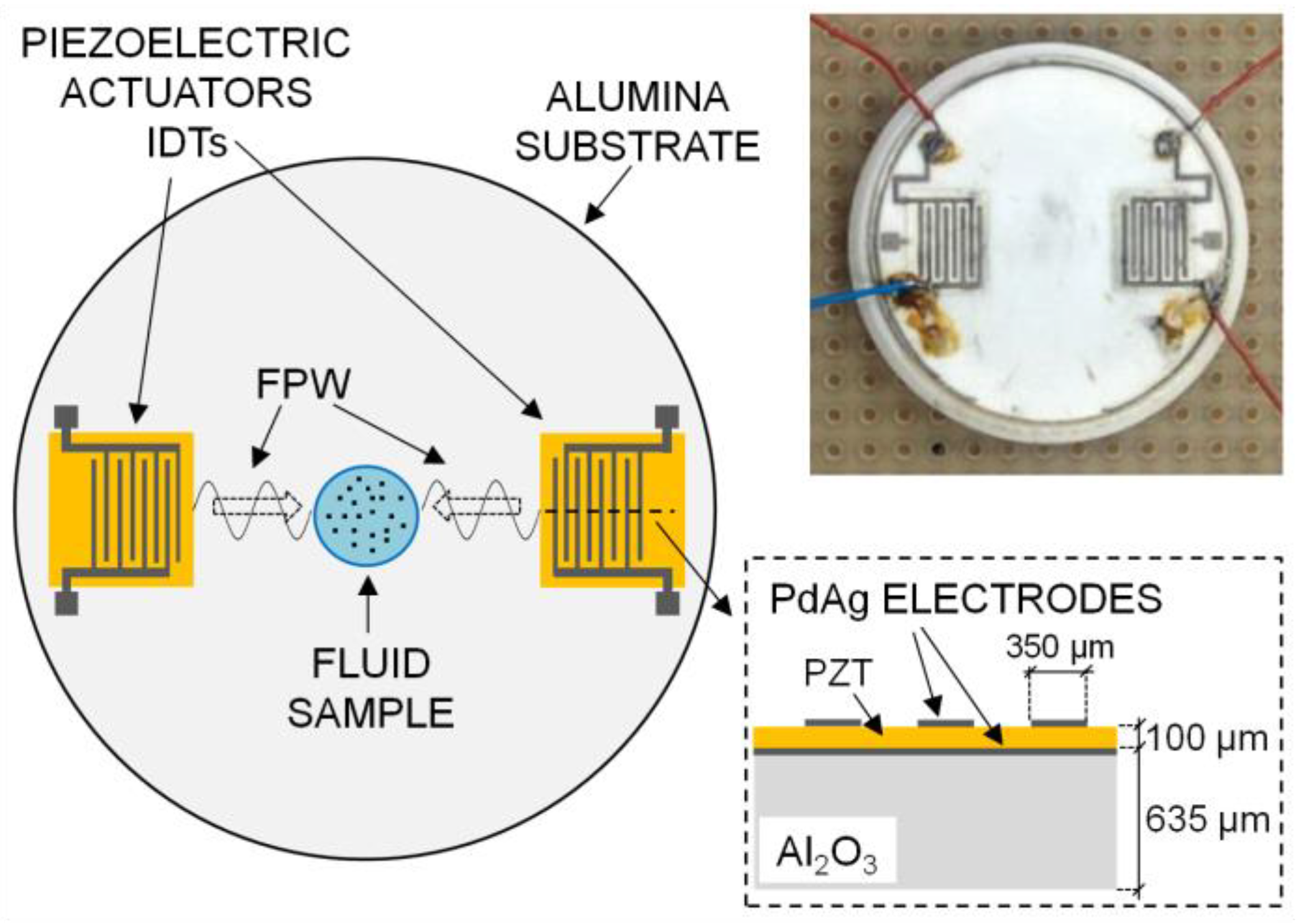

2. Device Description

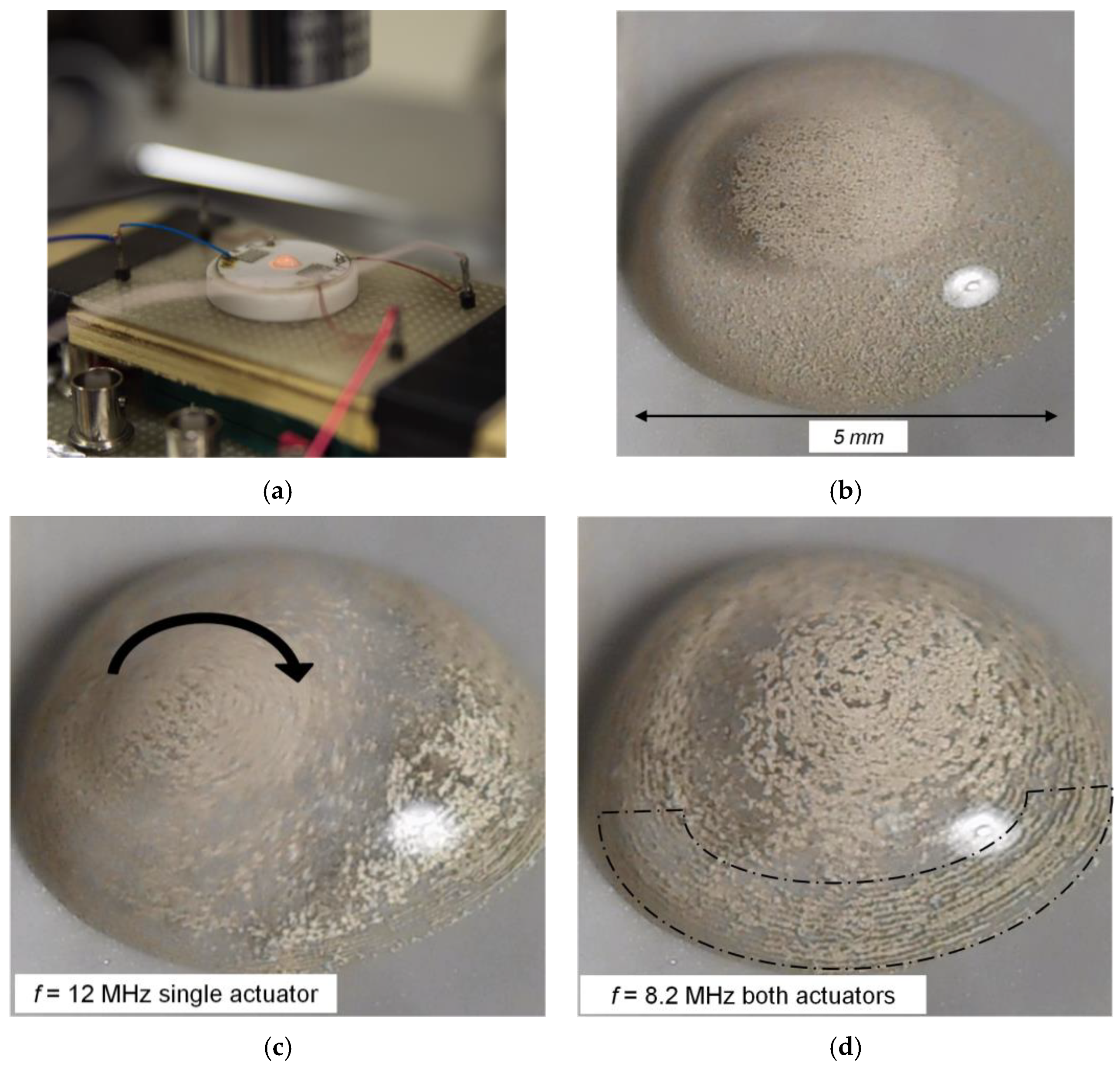

3. Experimental Results

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Fu, Y.Q.; Luo, J.K.; Nguyen, N.T.; Walton, A.J.; Flewitt, A.J.; Zu, X.T.; Li, Y.; McHale, G.; Matthews, A.; Iborra, E.; et al. Advances in piezoelectric thin films for acoustic biosensors, acoustofluidics and lab-on-chip applications. Prog. Mater. Sci. 2017, 89, 31–91. [Google Scholar] [CrossRef]

- Shilton, R.; Tan, M.K.; Yeo, L.Y.; Friend, J.R. Particle concentration and mixing in microdrops driven by focused surface acoustic waves. J. Appl. Phys. 2008, 104, 014910. [Google Scholar] [CrossRef]

- Ding, X.; Lin, S.S.; Kiraly, B.; Yue, H.; Li, S.; Chiang, I.; Shi, J.; Benkovic, S.J.; Huang, T.J. On-chip manipulation of single microparticles, cells, and organisms using surface acoustic waves. PNAS 2012, 109, 11105–11109. [Google Scholar] [CrossRef] [PubMed]

- Orloff, N.D.; Dennis, J.R.; Cecchini, M.; Schonbrun, E.; Rocas, E.; Wang, Y.; Novotny, D.; Simmonds, R.W.; Moreland, J.; Takeuchi, I.; et al. Manipulating particle trajectories with phase-control in surface acoustic wave microfluidics. Biomicrofluidics 2011, 5, 044107. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, V.; Lucklum, R. Overview of Acoustic-Wave Microsensors. In Piezoelectric Transducers and Applications, 2nd ed.; Vives, A.A., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 39–62. [Google Scholar]

- Ferrari, V.; Marioli, D.; Taroni, A. Theory, modeling and characterization of PZT-on-alumina resonant piezo-layers as acoustic-wave mass sensors. Sens. Actuators A 2000, 92, 182–190. [Google Scholar] [CrossRef]

- Royer, D.; Dieulesaint, E. Elastic Waves in Solids I: Free and Guided Propagation; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

| Frequency | λ(A0) | λ(S0) |

|---|---|---|

| f1 = 6.7 MHz | 0.74 mm | 1.16 mm |

| f2 = 8.2 MHz | 0.6 mm | 0.77 mm |

| f3 = 12 MHz | 0.44 mm | 0.45 mm |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demori, M.; Baù, M.; Dalola, S.; Ferrari, M.; Ferrari, V. Piezoelectric Actuators for In-Liquid Particle Manipulation in Microfluidic Applications. Proceedings 2017, 1, 392. https://doi.org/10.3390/proceedings1040392

Demori M, Baù M, Dalola S, Ferrari M, Ferrari V. Piezoelectric Actuators for In-Liquid Particle Manipulation in Microfluidic Applications. Proceedings. 2017; 1(4):392. https://doi.org/10.3390/proceedings1040392

Chicago/Turabian StyleDemori, Marco, Marco Baù, Simone Dalola, Marco Ferrari, and Vittorio Ferrari. 2017. "Piezoelectric Actuators for In-Liquid Particle Manipulation in Microfluidic Applications" Proceedings 1, no. 4: 392. https://doi.org/10.3390/proceedings1040392

APA StyleDemori, M., Baù, M., Dalola, S., Ferrari, M., & Ferrari, V. (2017). Piezoelectric Actuators for In-Liquid Particle Manipulation in Microfluidic Applications. Proceedings, 1(4), 392. https://doi.org/10.3390/proceedings1040392