Fabrication of Hybrid Microfluidic System on Transparent Substrates for Electrochemical Applications †

Abstract

:1. Introduction

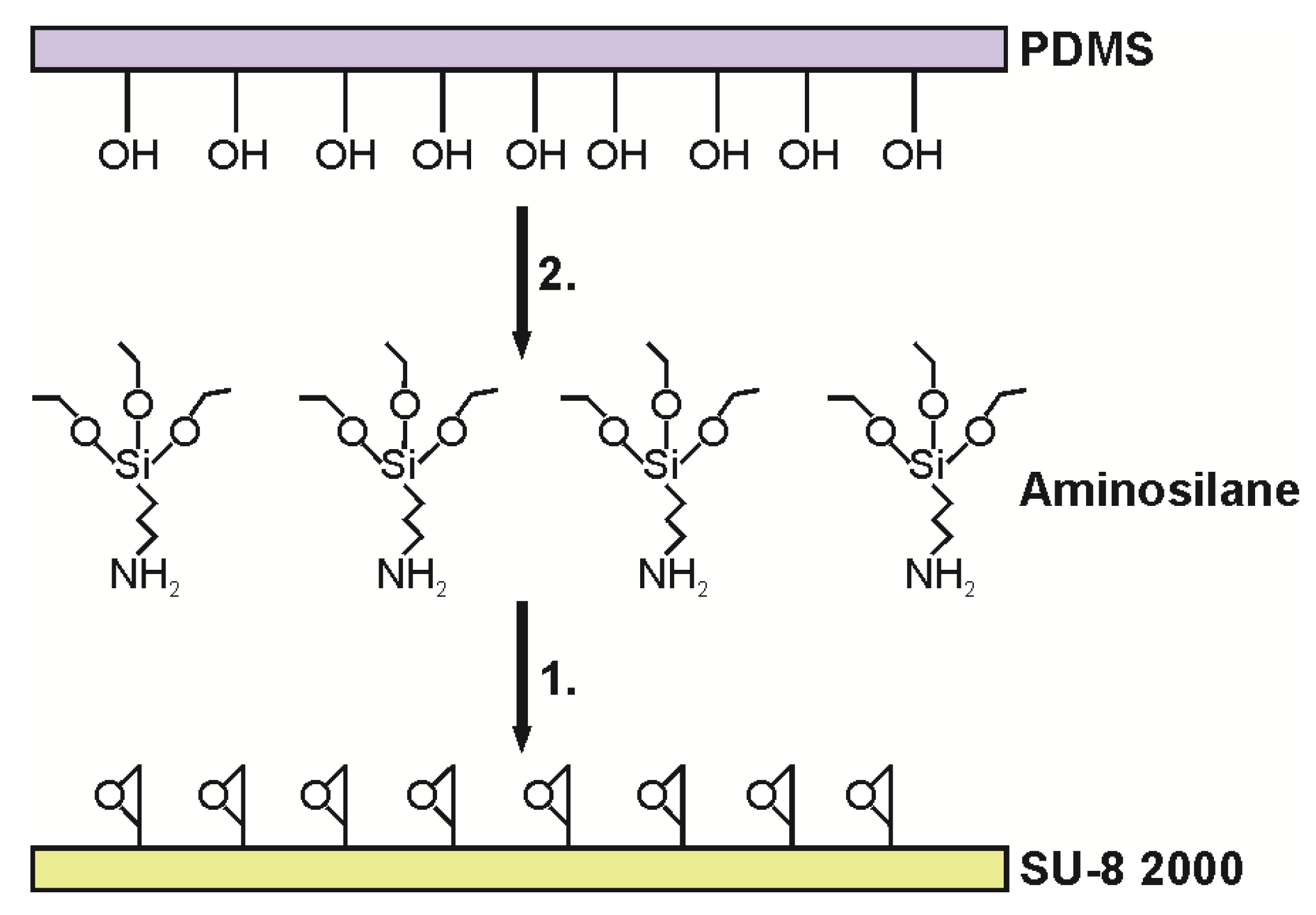

2. Materials and Methods

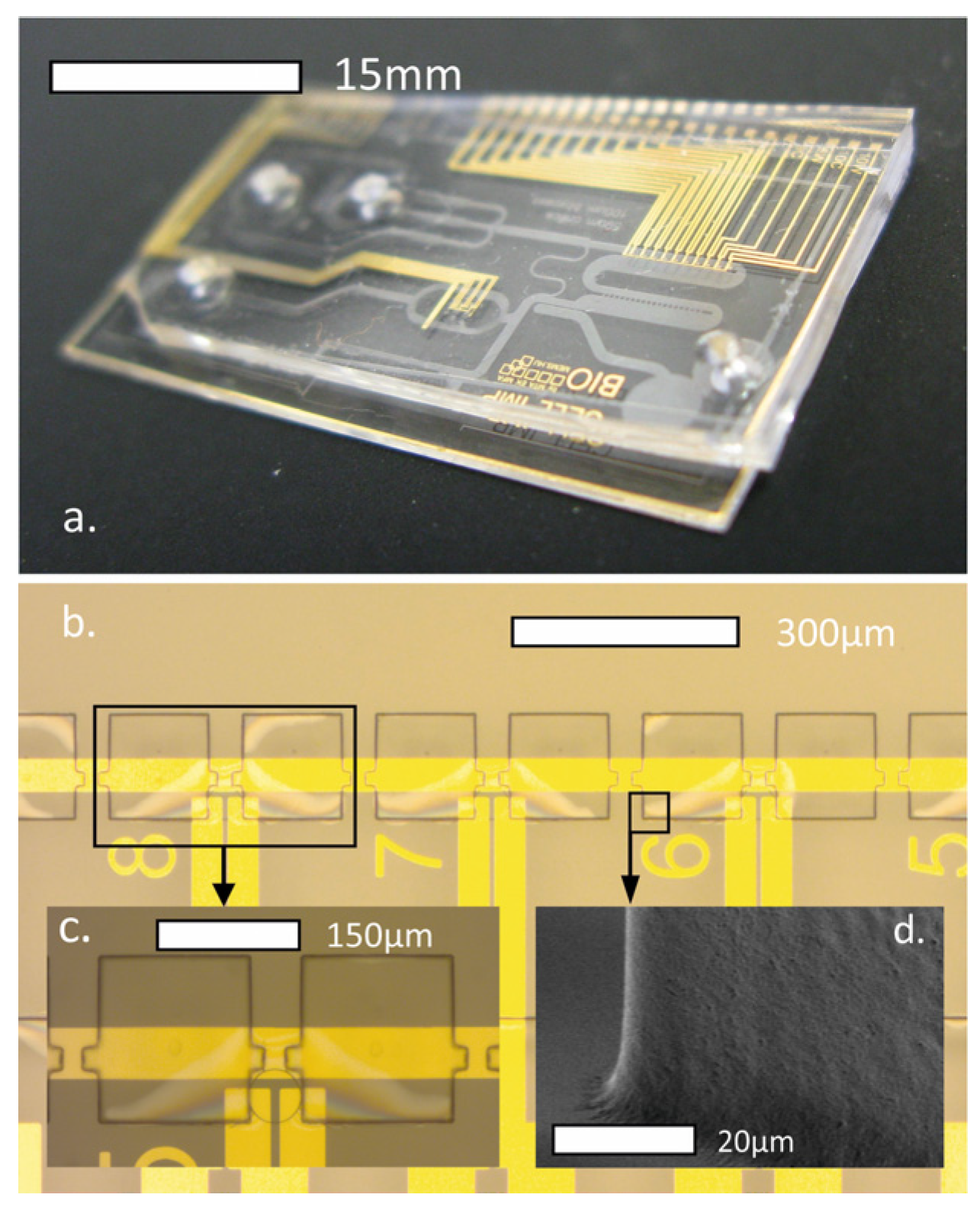

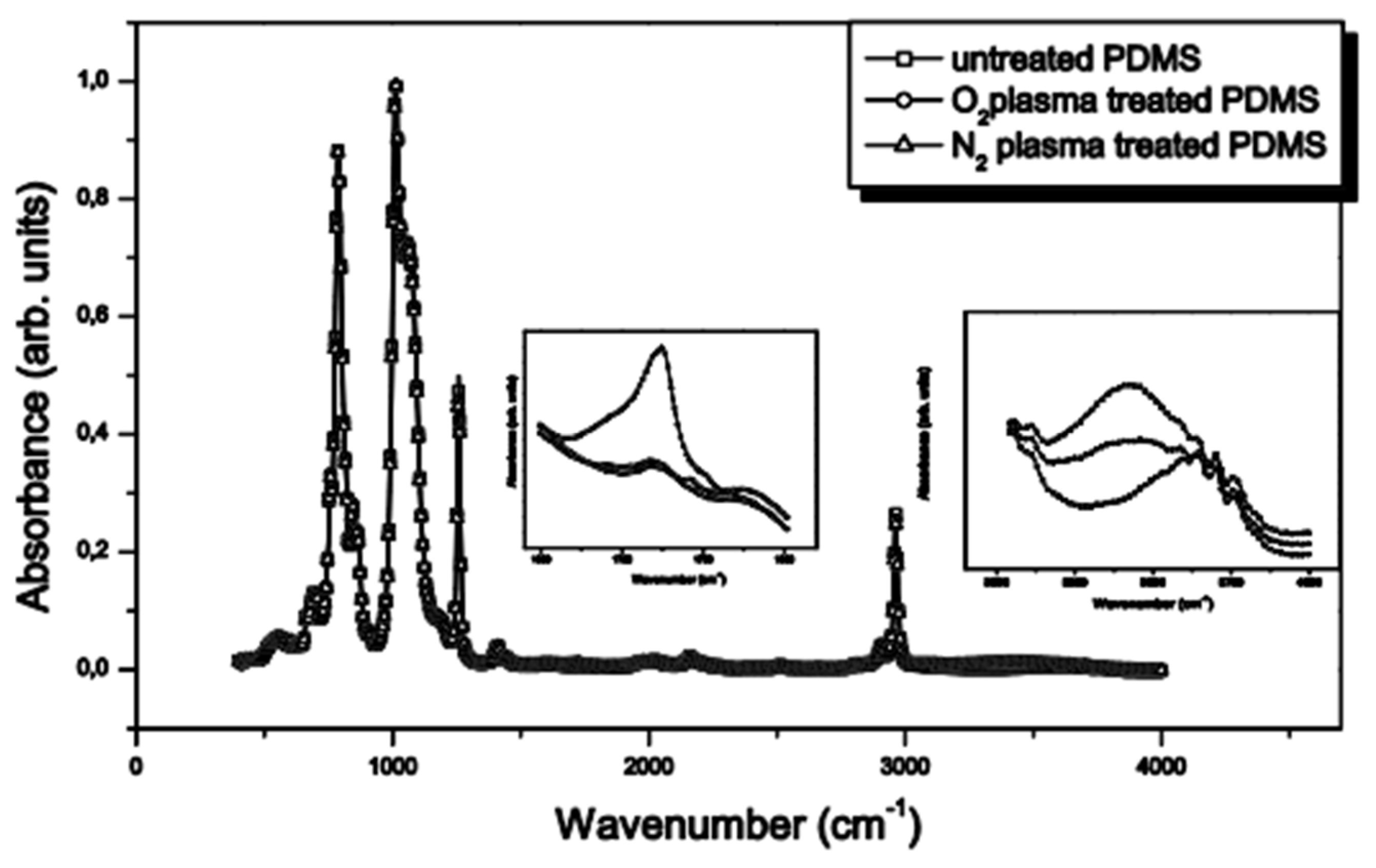

3. Results

4. Conclusions

Acknowledgments

Conflicts of Interest

Reference

- Zhang, Z.; Zhao, P.; Xiao, G.; Watts, B.; Xu, C. Sealing SU-8 microfluidic channels using PDMS. Biomicrofluidics 2011, 5, 046503. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Holczer, E.; Hakkel, O.; Fürjes, P. Fabrication of Hybrid Microfluidic System on Transparent Substrates for Electrochemical Applications. Proceedings 2017, 1, 326. https://doi.org/10.3390/proceedings1040326

Holczer E, Hakkel O, Fürjes P. Fabrication of Hybrid Microfluidic System on Transparent Substrates for Electrochemical Applications. Proceedings. 2017; 1(4):326. https://doi.org/10.3390/proceedings1040326

Chicago/Turabian StyleHolczer, E., O. Hakkel, and P. Fürjes. 2017. "Fabrication of Hybrid Microfluidic System on Transparent Substrates for Electrochemical Applications" Proceedings 1, no. 4: 326. https://doi.org/10.3390/proceedings1040326

APA StyleHolczer, E., Hakkel, O., & Fürjes, P. (2017). Fabrication of Hybrid Microfluidic System on Transparent Substrates for Electrochemical Applications. Proceedings, 1(4), 326. https://doi.org/10.3390/proceedings1040326