Study of Elongation and Temperature Effects on Nanocomposite Based on Elastic Fiber †

Abstract

:1. Introduction

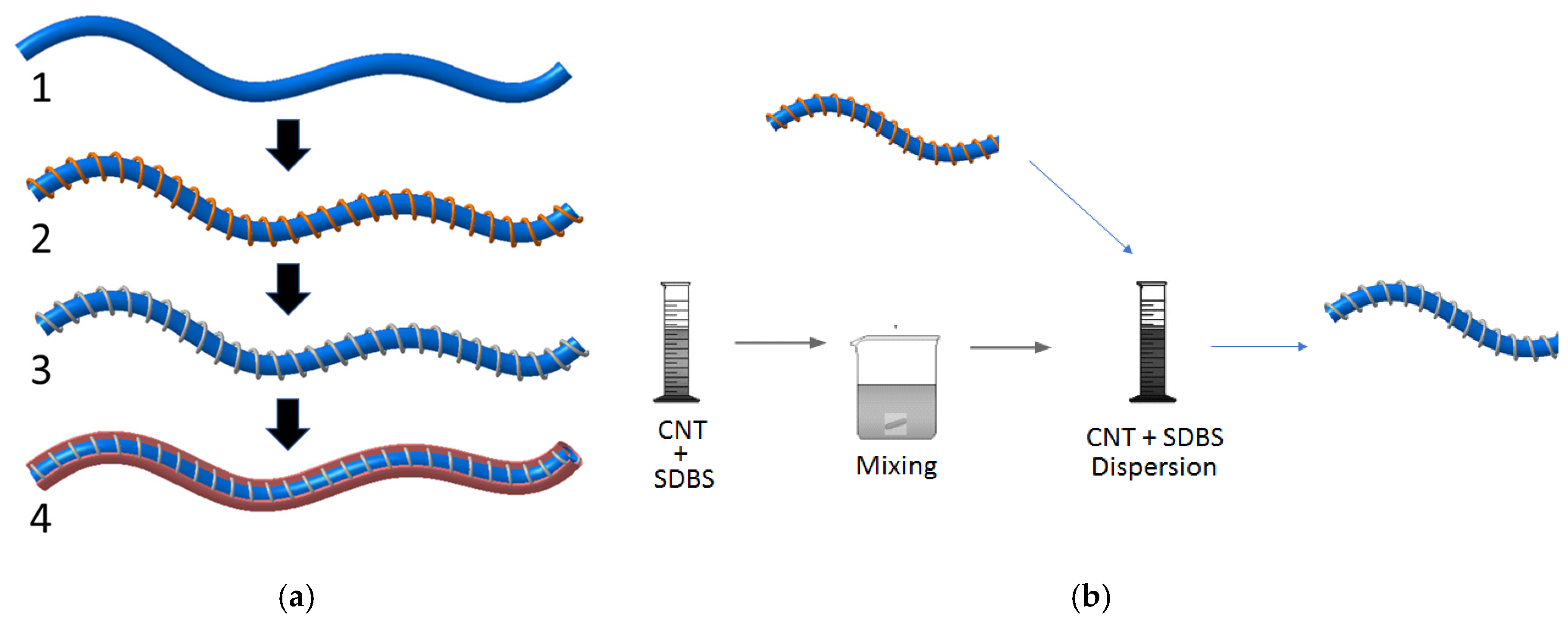

2. Materials and Methods

3. Results

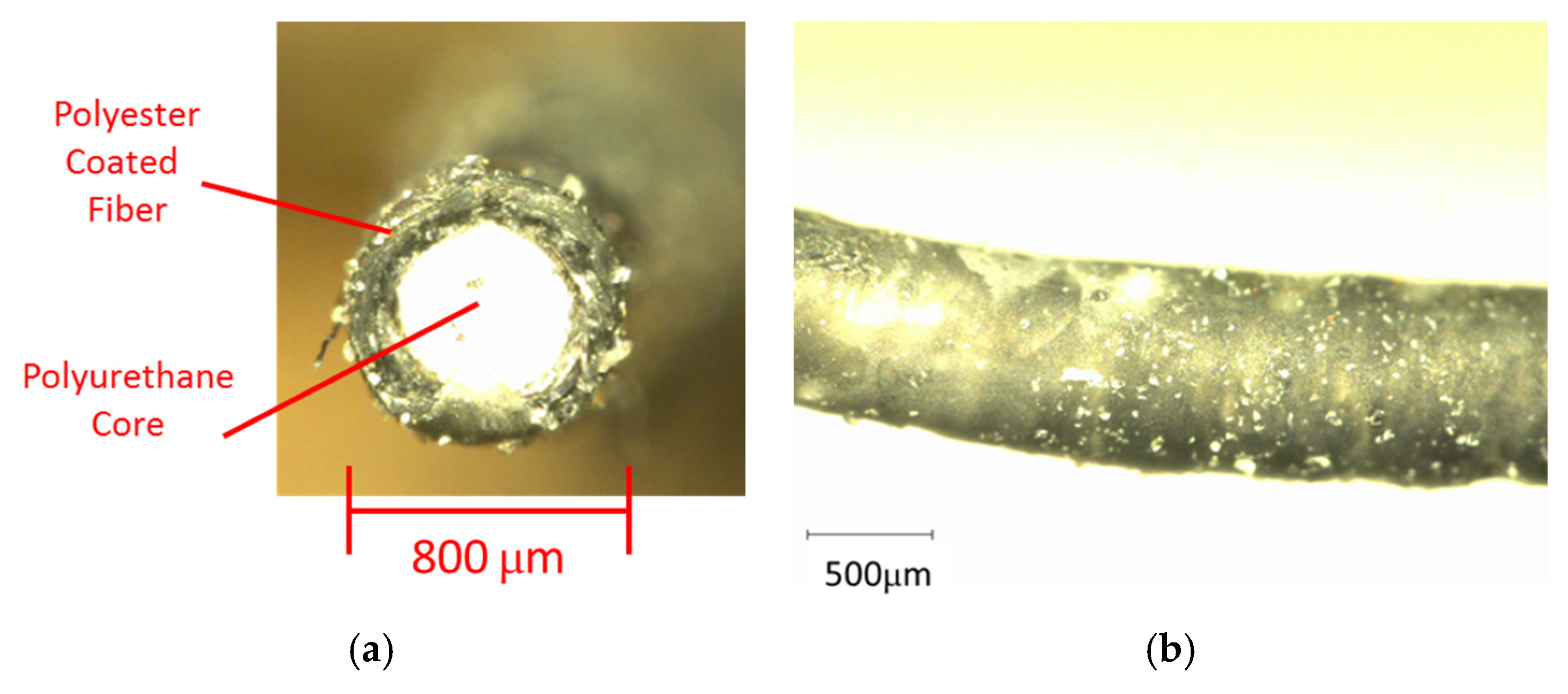

3.1. Microscopical Characterization

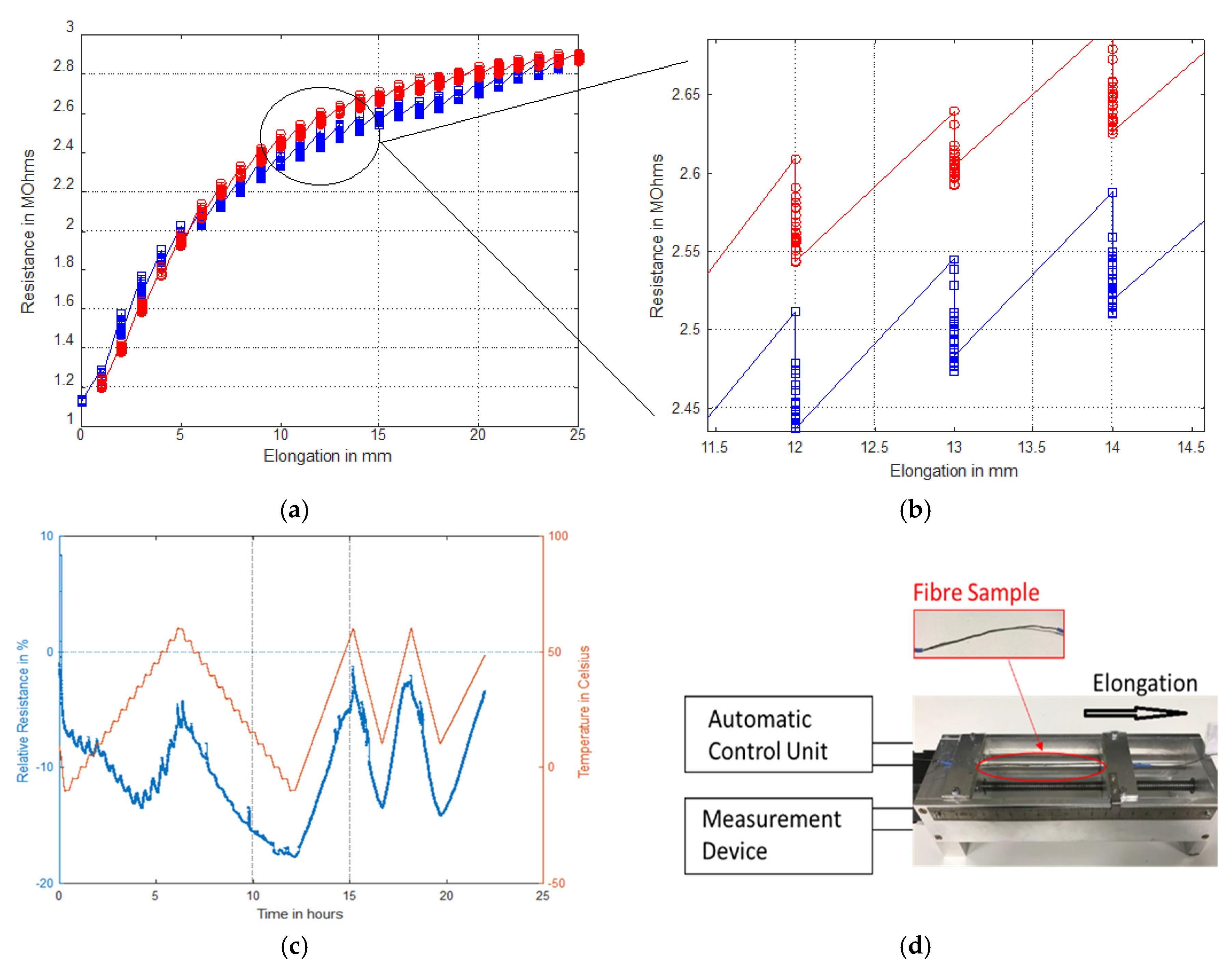

3.2. Electrical Characterization

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Sun, J.; Huang, Y.; Fu, C.; Wang, Z.; Huang, Y.; Zhu, M.; Zhi, C.; Hu, H. High-performance stretchable yarn supercapacitor based on PPy@CNTs@urethane elastic fiber core spun yarn. Nano Energy 2016, 27, 230–237. [Google Scholar] [CrossRef]

- Jost, K.; Durkin, D.P.; Haverhals, L.M.; Brown, E.K.; Langenstein, M.; de Long, H.C.; Trulove, P.C.; Gogotsi, Y.; Dion, G. Natural Fiber Welded Electrode Yarns for Knittable Textile Supercapacitors. Adv. Energy Mater. 2015, 5, 1401286. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres, R.; Jalasutram, A.; Benchirouf, A.; Müller, C.; Kanoun, O. Study of Elongation and Temperature Effects on Nanocomposite Based on Elastic Fiber. Proceedings 2017, 1, 389. https://doi.org/10.3390/proceedings1040389

Torres R, Jalasutram A, Benchirouf A, Müller C, Kanoun O. Study of Elongation and Temperature Effects on Nanocomposite Based on Elastic Fiber. Proceedings. 2017; 1(4):389. https://doi.org/10.3390/proceedings1040389

Chicago/Turabian StyleTorres, Renato, Adytia Jalasutram, Abderrahmane Benchirouf, Christian Müller, and Olfa Kanoun. 2017. "Study of Elongation and Temperature Effects on Nanocomposite Based on Elastic Fiber" Proceedings 1, no. 4: 389. https://doi.org/10.3390/proceedings1040389

APA StyleTorres, R., Jalasutram, A., Benchirouf, A., Müller, C., & Kanoun, O. (2017). Study of Elongation and Temperature Effects on Nanocomposite Based on Elastic Fiber. Proceedings, 1(4), 389. https://doi.org/10.3390/proceedings1040389