1. Introduction

It is required for upcoming aging society to realize next generation robots such as assistant robots for housework, business work and nursing. The robots will coexist with parsons and assist them. Tactile sensors make the robots to detect contacts with parsons and things, and to grasp and hold them gently and safely. If tactile sensors detect human-like thermal sensing, they are useful for material estimation. The robots are enable to estimate materials of things, such as metals, glasses, clothes and human bodies by contact. And the robots will be able to feel health of patients. Beside an infrared thermo-camera, the tactile sensors detect temperatures of behind objects contiguously. The tactile sensors should cover whole the hands, arms and body of the robots for them to work well.

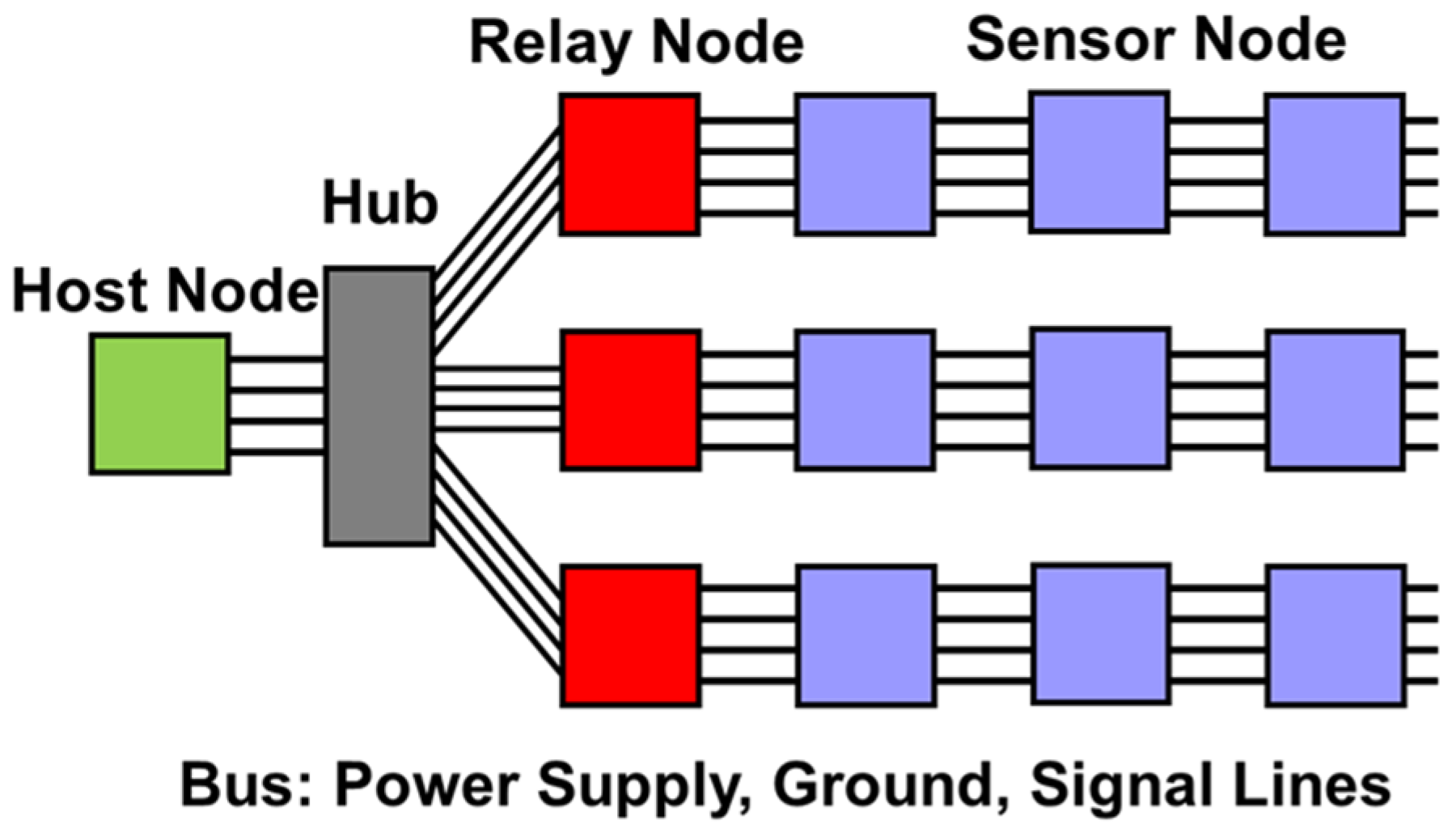

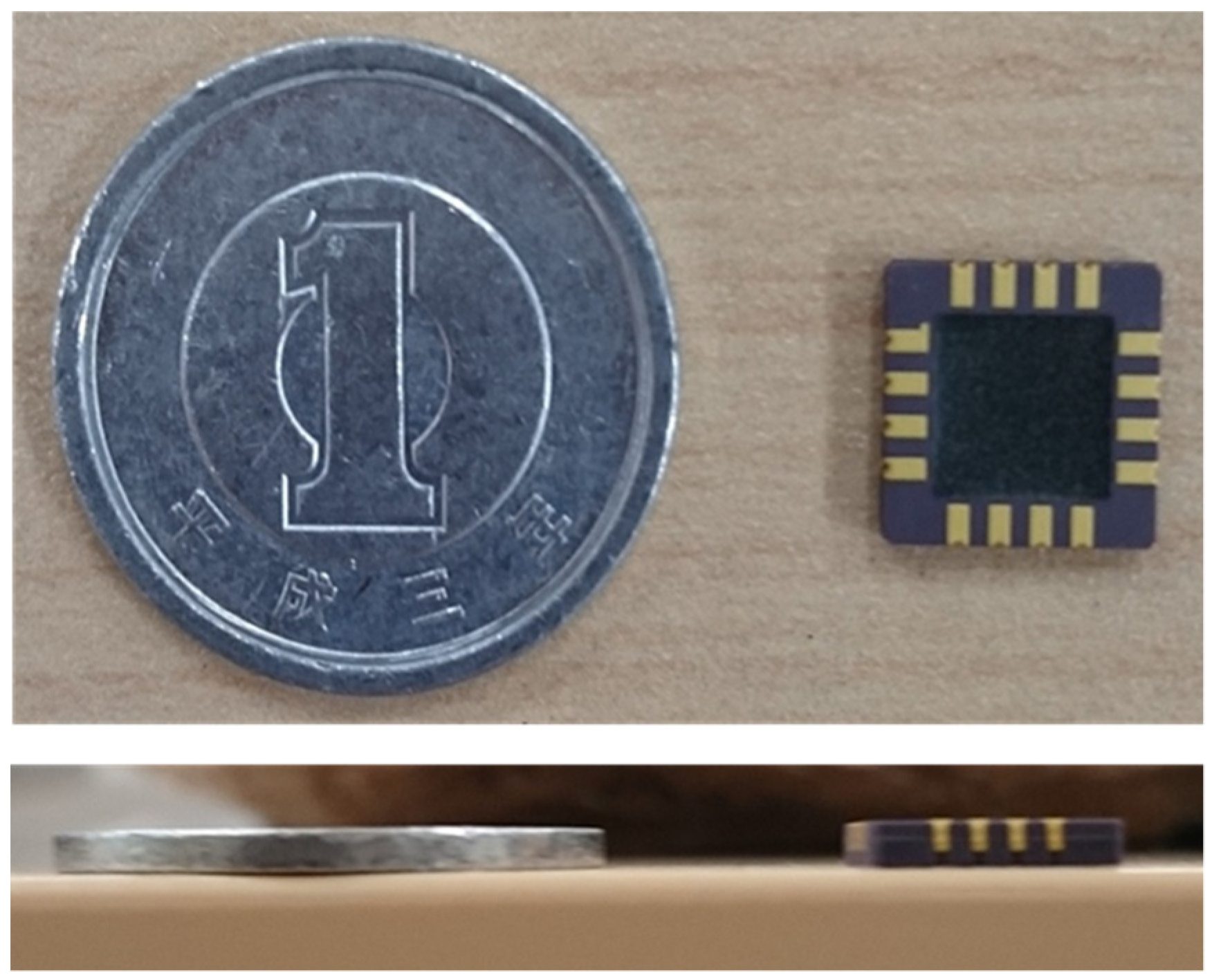

A special nerve-net LSI chip has advantages in reducing number of wiring and simultaneous measurement with various sensors [

1,

2] (

Figure 1 and

Figure 2). The LSI chip was packaged in ceramics for good thermal conductivity and durability (

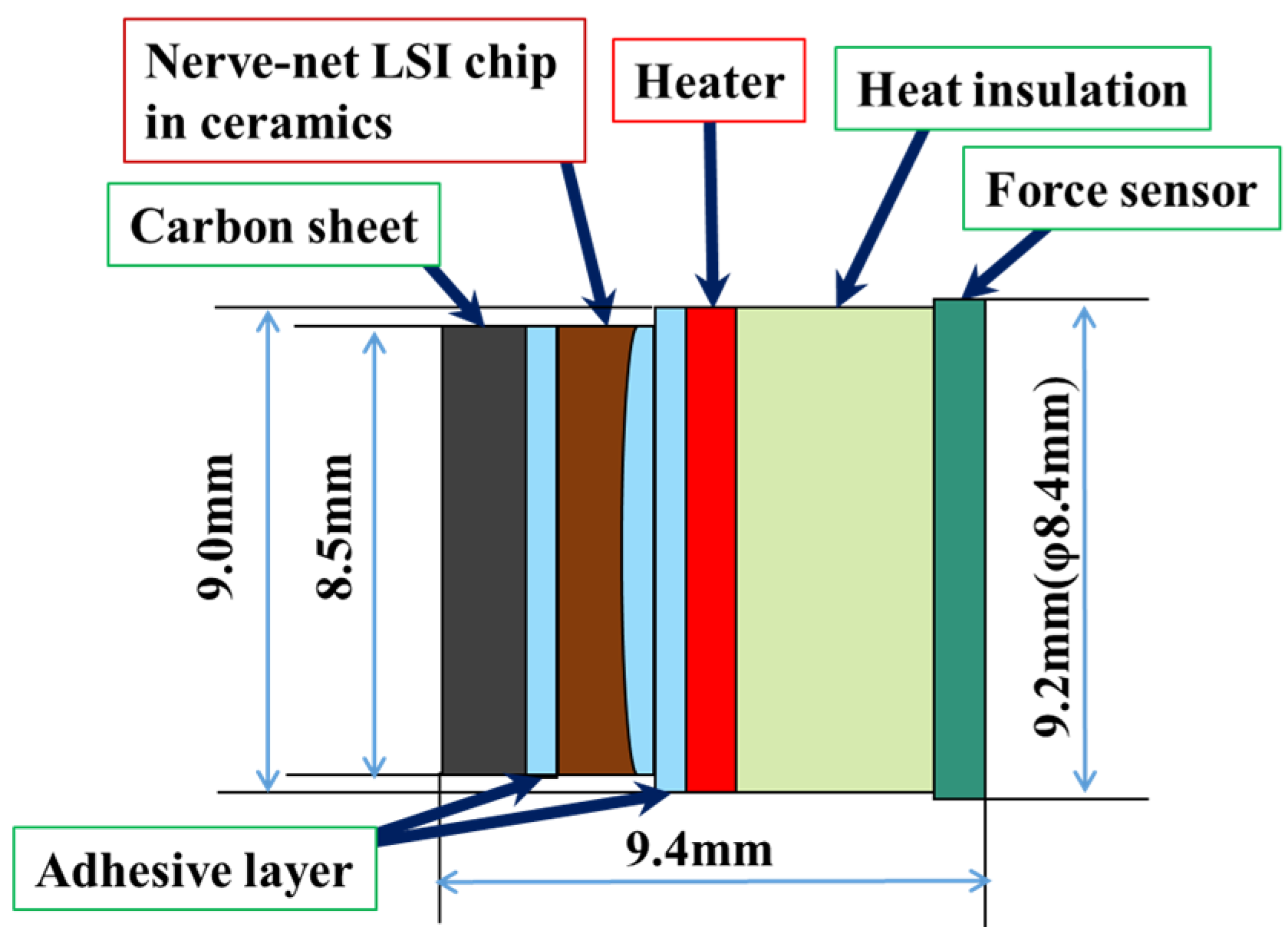

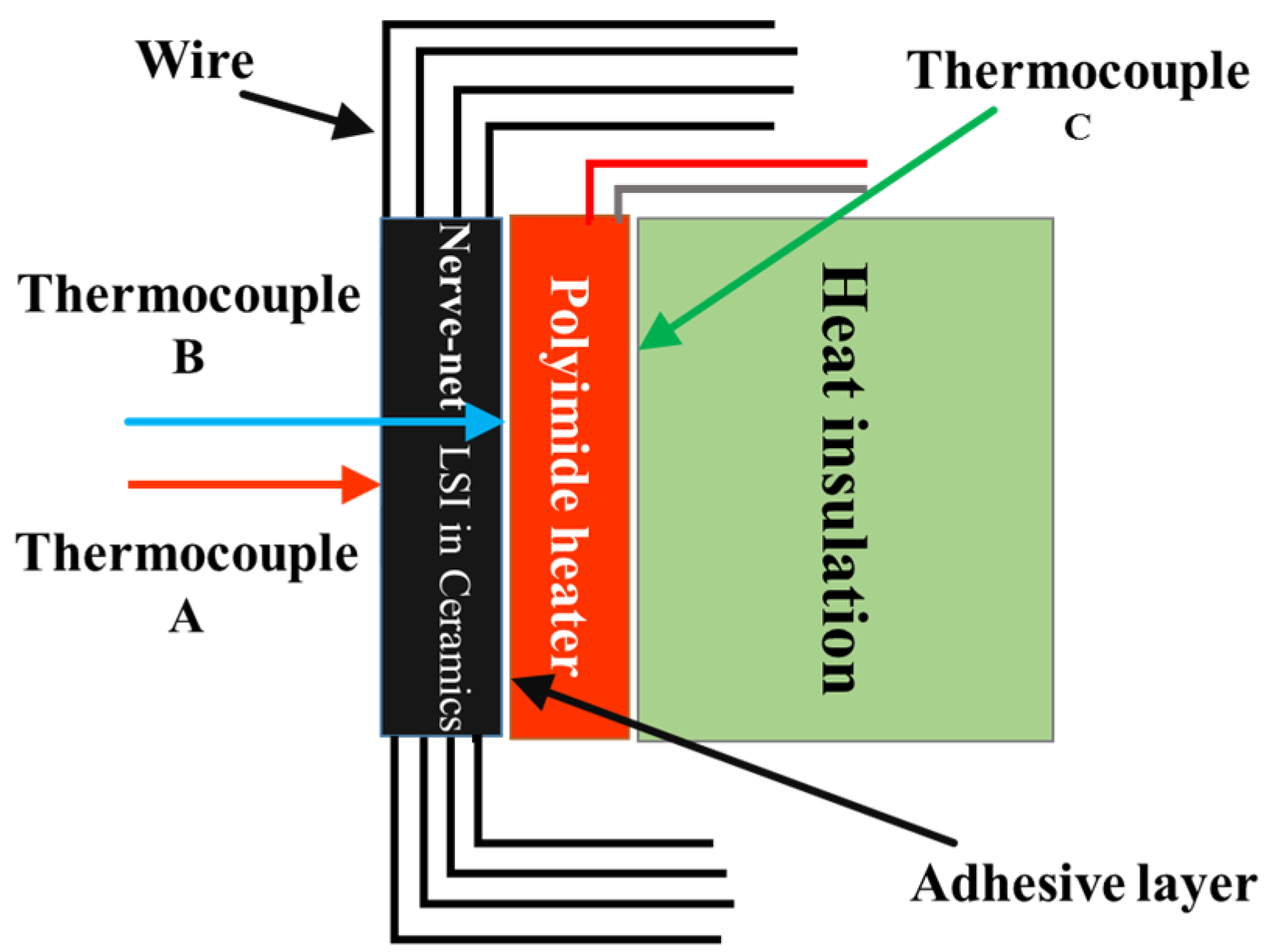

Figure 3). A stacked sensor head with the LSI chip shown in

Figure 4 was proposed for detecting forces and thermal sensations. The sensor head was designed to be installed in fingertips of the robots and to detect forces, temperatures, and heat flows by fingertip contacts. For accurate heat flow measurement, a heat insulator covers the sensor head except a carbon sheet top. As the heat flow detection is required to estimate materials, a heater installed into the sensor head is required to make the heat flow. For the heater of the stacked sensor head, the followings are important. The heater is compact as small as 8.5 mm square, low heat capacity, low power consumption, and ease to mount it into the sensor head. Conventional product heaters were not suitable for the above requirements. Compared to silicon substrate, polyimide film is superior to thermal isolation, low heat capacity and flexibility. Therefore, the thin film heater on the polyimide film is suitable for the sensor head. In the previous studies of polyimide heaters [

3,

4], gold and platinum films were used in practice. However, they were expensive and difficult to be products. We have designed and produced new heaters on a 125 μm thickness polyimide film. Cr and Cu films were compared as the heater material. The electric resistances and TCRs (resistance temperature coefficient) of the heaters were measured. Heating up the sensor head to 60 °C and down to 20 °C experiments were done with the heater. The heater materials and structures were evaluated to get the good thin film heater for the nerve-net tactile sensor [

5,

6].

2. Design and Fabrication

The small thin film heaters of Cr and Cu films were designed on the polyimide film for the sensor head. The required specifications of heaters are as follows.

Area of the heater is smaller than the area of the LSI ceramic package

Low power consumption to heat the sensor head surface up to 60 °C

Low heat capacity to get high thermal response of the sensor head

Easy mounting on the surface of the LSI ceramic package

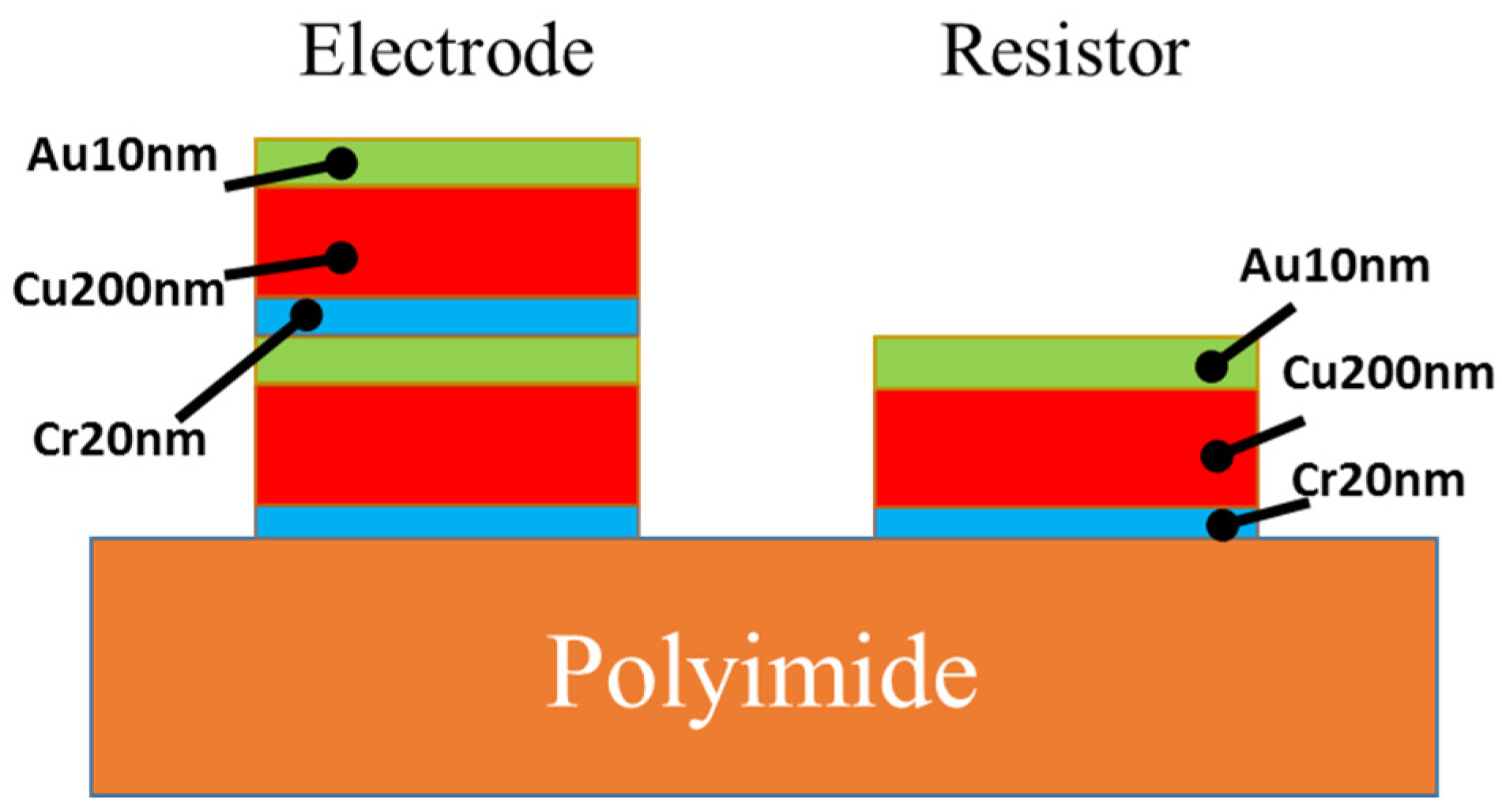

The heaters were designed as 8.5 mm square. For low power consumption, low thermal capacity, and easy mounting, the polyimide film of 125 μm in thickness was selected as the heater substrate. The polyimide film is low thermal conductivity and flexible material. Cr and Cu films were compared as the heater material. The compositions of both film resistors are shown in

Table 1. Line widths of heater patterns were changed from 400 μm to 800 μm.

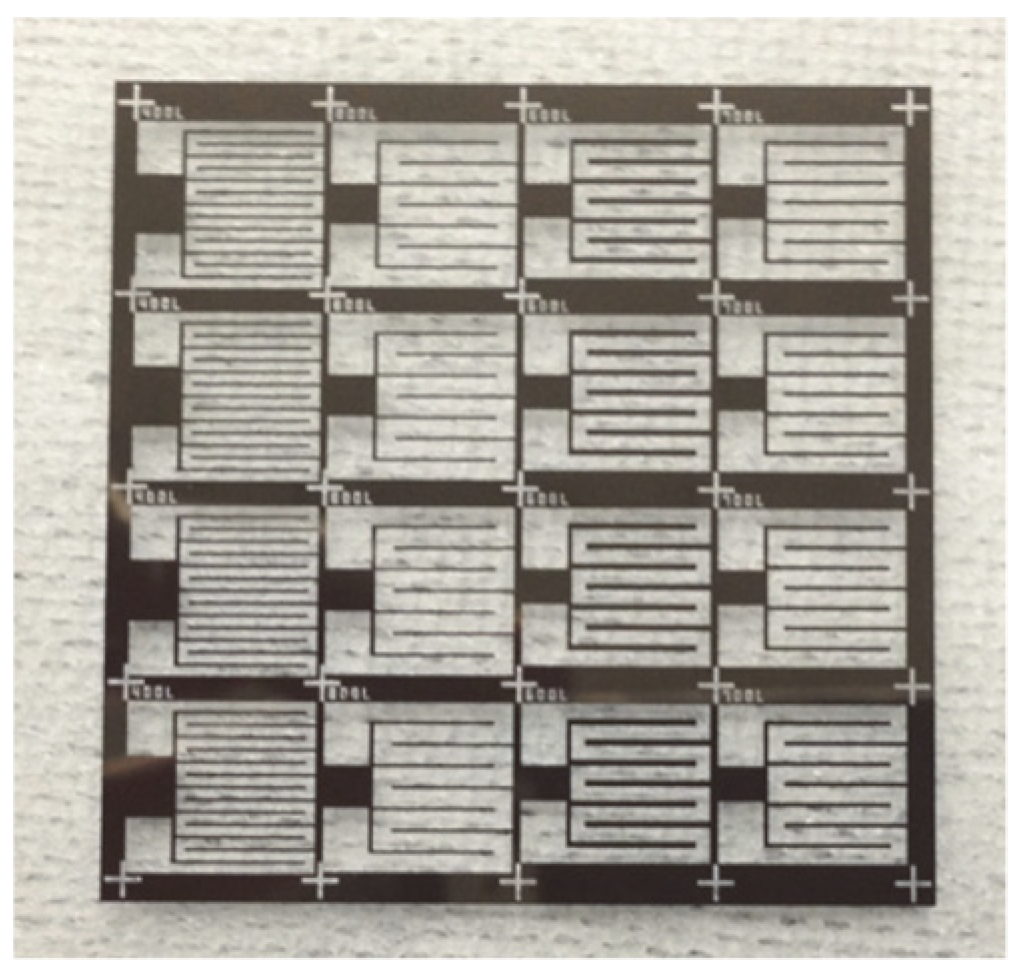

A fabrication process of the heater was as follows. Firstly, the polyimide film was glued on a silicon wafer with wax and photoresist was coated. Heater patterns of the photoresist on the polyimide film were made by photolithography with a glass mask. The glass mask of the heater is shown in

Figure 5. Secondly, metal layers for the resistors and electrodes were formed by a vacuum evaporation as shown in

Table 1 and

Figure 6. Thirdly, after the heaters on the polyimide film were detached from the silicon wafer, a polyimide tape of 55 μm in thickness was pasted on the both surfaces of the heaters for protection.

3. Results

3.1. Thin Film Morphology and Electric Reistance Results

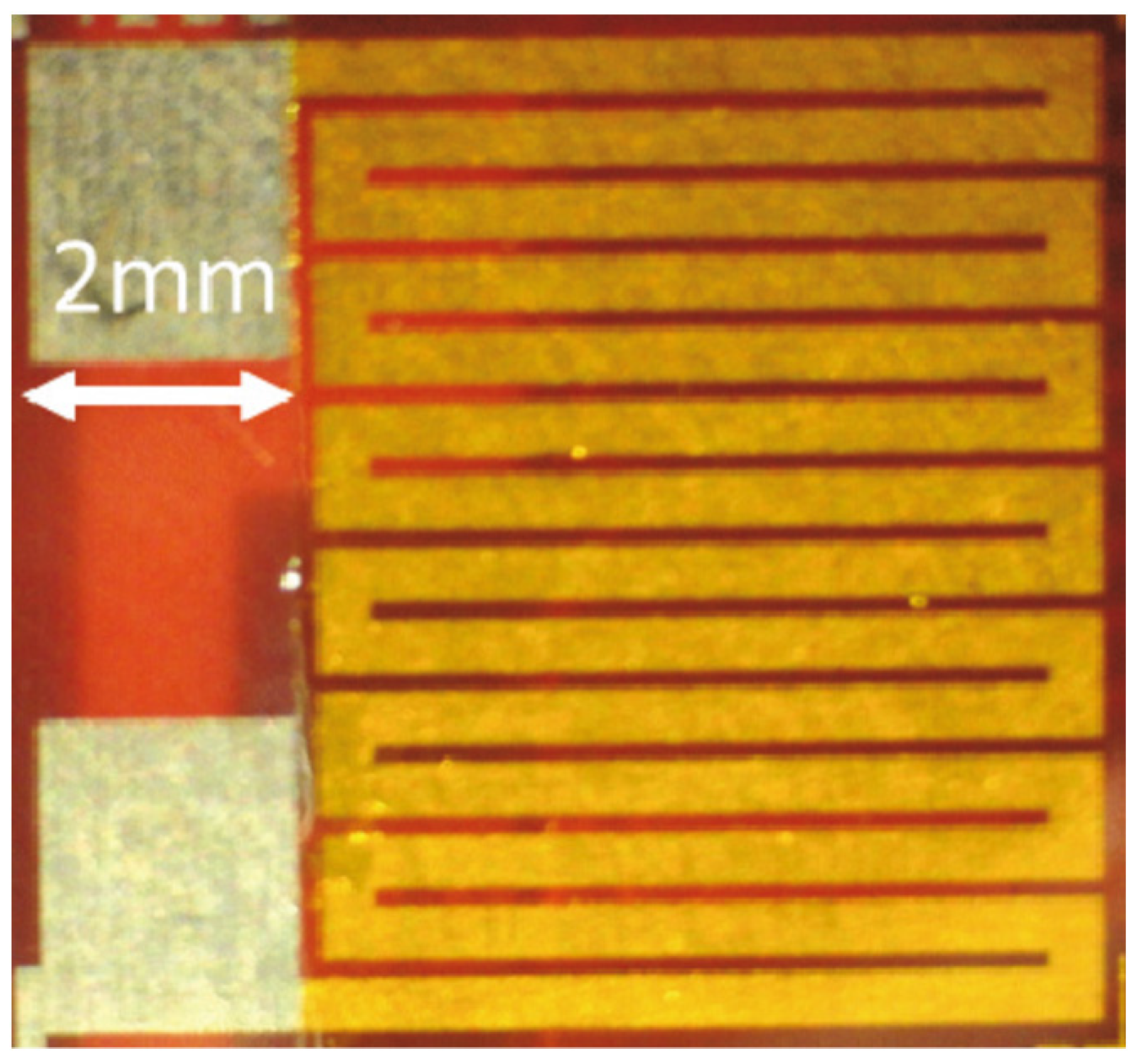

A photograph of the heater with line width 400 μm is shown in

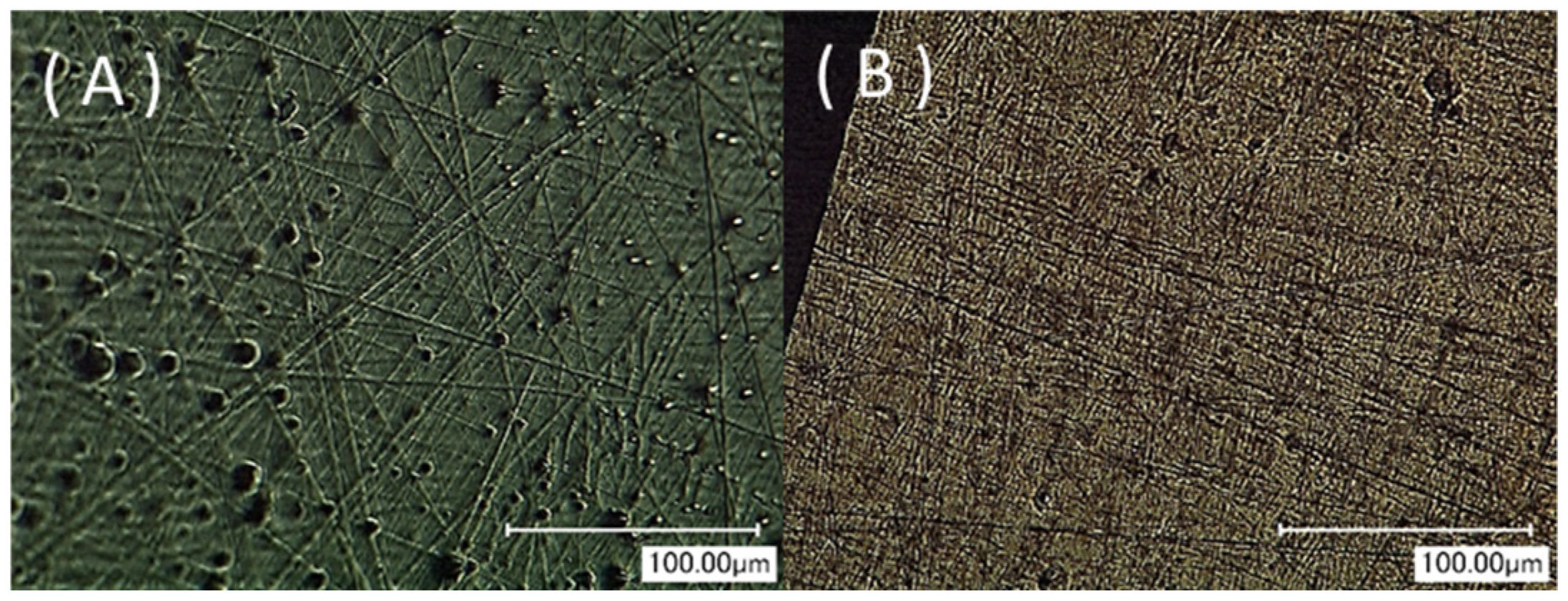

Figure 7. Photomicrographs of the Cr and Cu film heater surfaces are shown in

Figure 8. A lot of scratches and particle like dots were seen on the both surface films. Especially, the Cr film heater was damaged by scratches and particle like dots. The Cr film heaters had problems as electrical breaking of wire or very high resistance. The Cu film heaters worked well. Electric resistances of the Cu film heaters were presented in

Table 2 in order of patterns as shown in

Figure 5. The obtained electrical resistances of the Cu film heaters were about 7 times larger than calculated resistances which were estimated from a reported electrical resistivity of Cu bulk. By the four probes measurement, 90% of the total resistance of the heater was the resistance of the Cu thin film and 10% of the one was an interface resistance between the heater layer and electrode layers.

3.2. Heater Performance Results

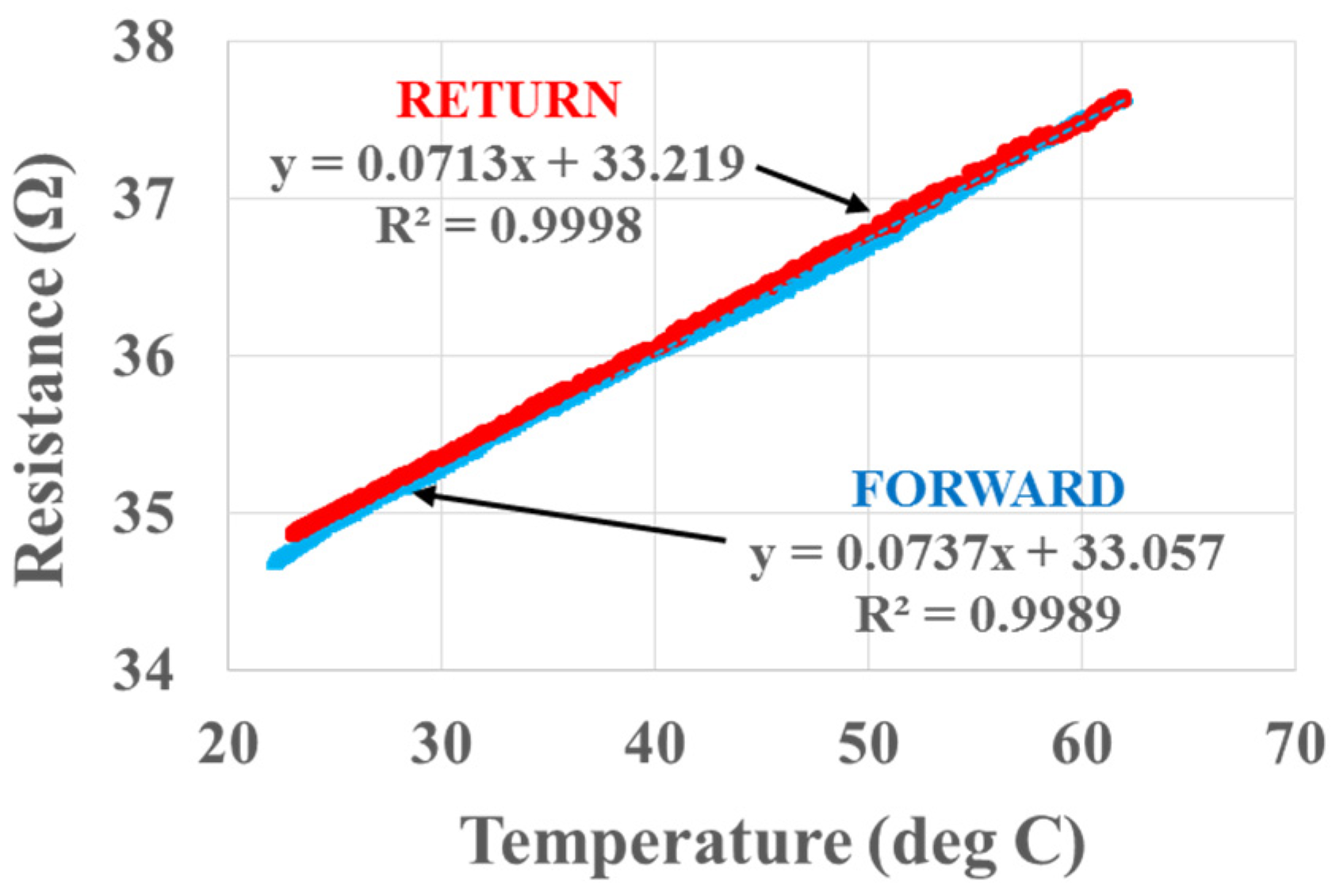

The TCRs of the Cu film heater of line width 800 μm were measured and results were shown in

Figure 9. Alumel-chromel thermocouples of 0.1 mm in diameter were used for temperature measurement of the heaters. It was found that the TCR of the heater was about 2.2 × 10

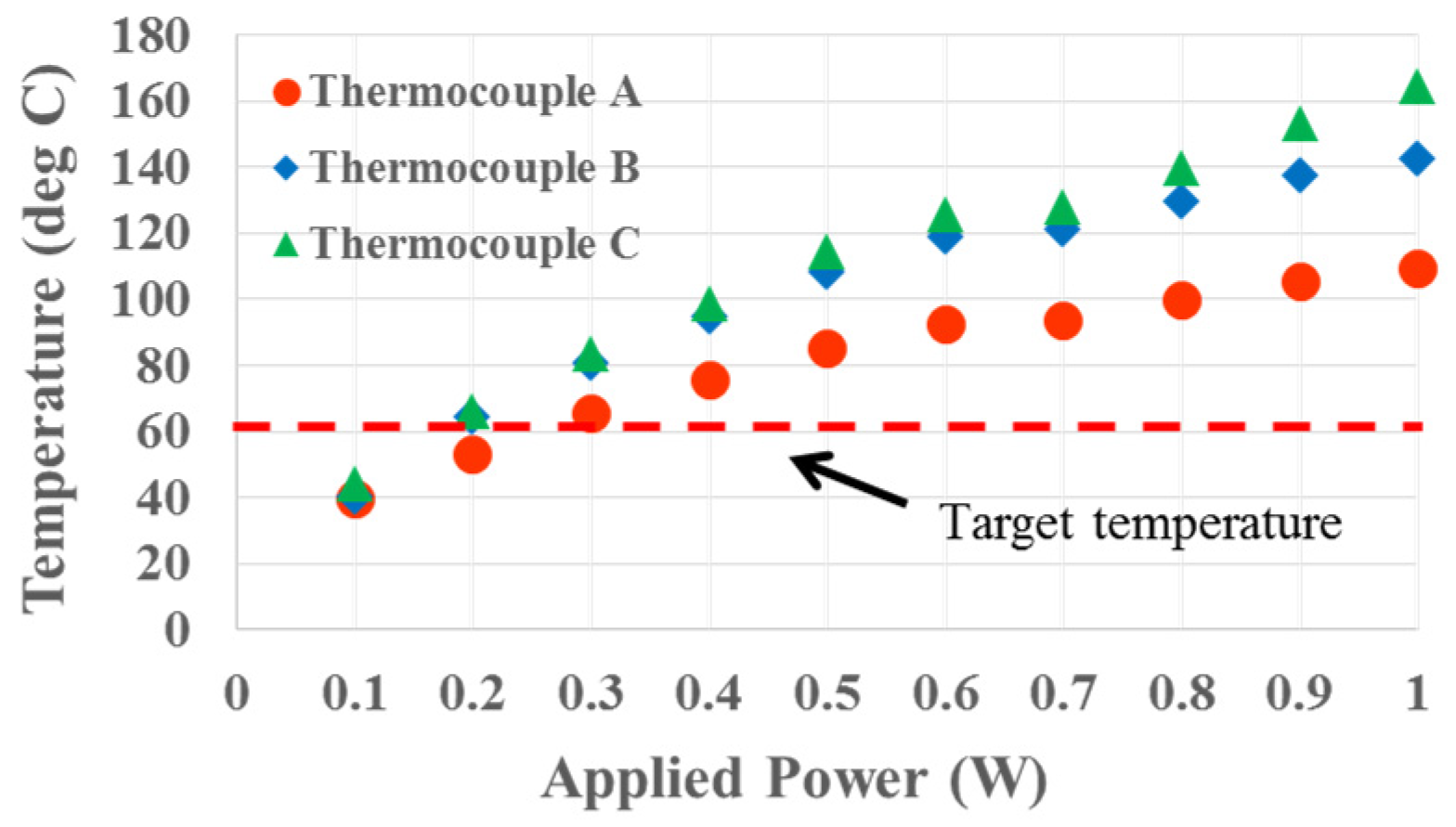

−3/°C (<60°C) and almost no hysteresis property was obtained. The heater was attached to the LSI ceramics package and temperatures were measured with a setup as shown in

Figure 10, while an experiment of heating up and down. The Cu film heater was successfully achieved a required target temperature of above 60 °C at the sensor head surface with only 0.3 W as shown in

Figure 11.

4. Conclusions

It was realized that the Cu thin film heater on the polyimide heated up the stacked sensor head successfully. The heater was fabricated with flexible in 8.5 mm square and about 0.2 mm thickness. The obtained electrical resistances of the heater were about 7 times larger than calculated resistances which were estimated from a reported electrical resistivity of Cu bulk. It was found that the TCR of the heater was about 2.2 × 10−3/°C (<60 °C). The heater achieved target temperature 60 °C at the sensor head surface with only 0.3 W, and obtained almost no hysteresis properties. The small sensor head with the nerve-net LSI chip is enable to detect forces, temperatures, and heat flows, simultaneously. The thin film heater and small temperature sensors will be combined to create ultra-small sensor head for robot fingers and artificial robot skin.

Acknowledgments

A part of this work was supported by Toyota Technological Institute Nano Technology Hub in “Nanotechnology Platform Project” sponsored by the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan. The present study is supported in part regarding the experiments of thermal sensing by the New Energy and Industrial Technology Development Organization (NEDO). The development of the sensor platform LSI and the integration technology was performed in R&D Center of Excellence for Integrated Microsystems, Tohoku University under the program “Formation of Innovation Center for Fusion of Advanced Technologies” supported by Special Coordination Funds for Promoting Science and Technology with collaboration with Toyota Motor Corporation and Toyota Central R&D Labs., Inc.

Conflicts of Interest

The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Muroyama, M.; Makihata, M.; Nakano, Y.; Matsuzaki, S.; Yamada, H.; Yamaguchi, U.; Nakayama, T.; Nonomura, Y.; Fujiyoshi, M.; Tanaka, S.; et al. Development of an LSI for Tactile Sensor Systems on the Whole-Body of Robots. IEEJ Trans. Sens. Micromach. 2011, 131, 302–309. [Google Scholar] [CrossRef]

- Muroyama, M.; Nakayama, T.; Hata, Y.; Nonomura, Y.; Bartley, T.; Tanaka, S. A CMOS-LSI for a Sensor Network Platform of Social Robot Applications. In Proceedings of the Smart Systems Integration 2016, Munich, Germany, 9–10 March 2016; pp. 320–327. [Google Scholar]

- Yu, S.; Wang, S.; Lu, M.; Zuo, L. A novel polyimide based micro heater with high temperature uniformity. Sens. Actuators A 2017, 257, 58–64. [Google Scholar] [CrossRef]

- Han, J.S.; Tan, Z.Y.; Sato, K.; Shikida, M. Thermal characterization of micro heater arrays on a polyimide film substrate for fingerprint sensing applications. J. Micromech. Microeng. 2004, 15, 282–289. [Google Scholar] [CrossRef]

- Yamadera, H.; Sugimoto, N.; Kageyama, Y. Preparation of MEMS Thin Film Heater by All Dry Processes and Application to GAS Sensor. IEEJ Trans. Sens. Micromach. 2011, 131, 246–250. [Google Scholar] [CrossRef]

- Kawato, Y.; Arimura, H.; Kudo, T. Sintering of Conductive Cu Nano Ink by Photo-sintering Process and Observation of Interface between Cu Film and PI. J. Smart Proc. 2013, 2, 173–177. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).