Fractal Evolution Characteristics of Weakly Cemented Overlying Rock Fractures in Extra-Thick Coal Seams Mining in Western Mining Areas

Abstract

1. Introduction

2. Engineering Background

2.1. General Situation of Zhundong Mining Area

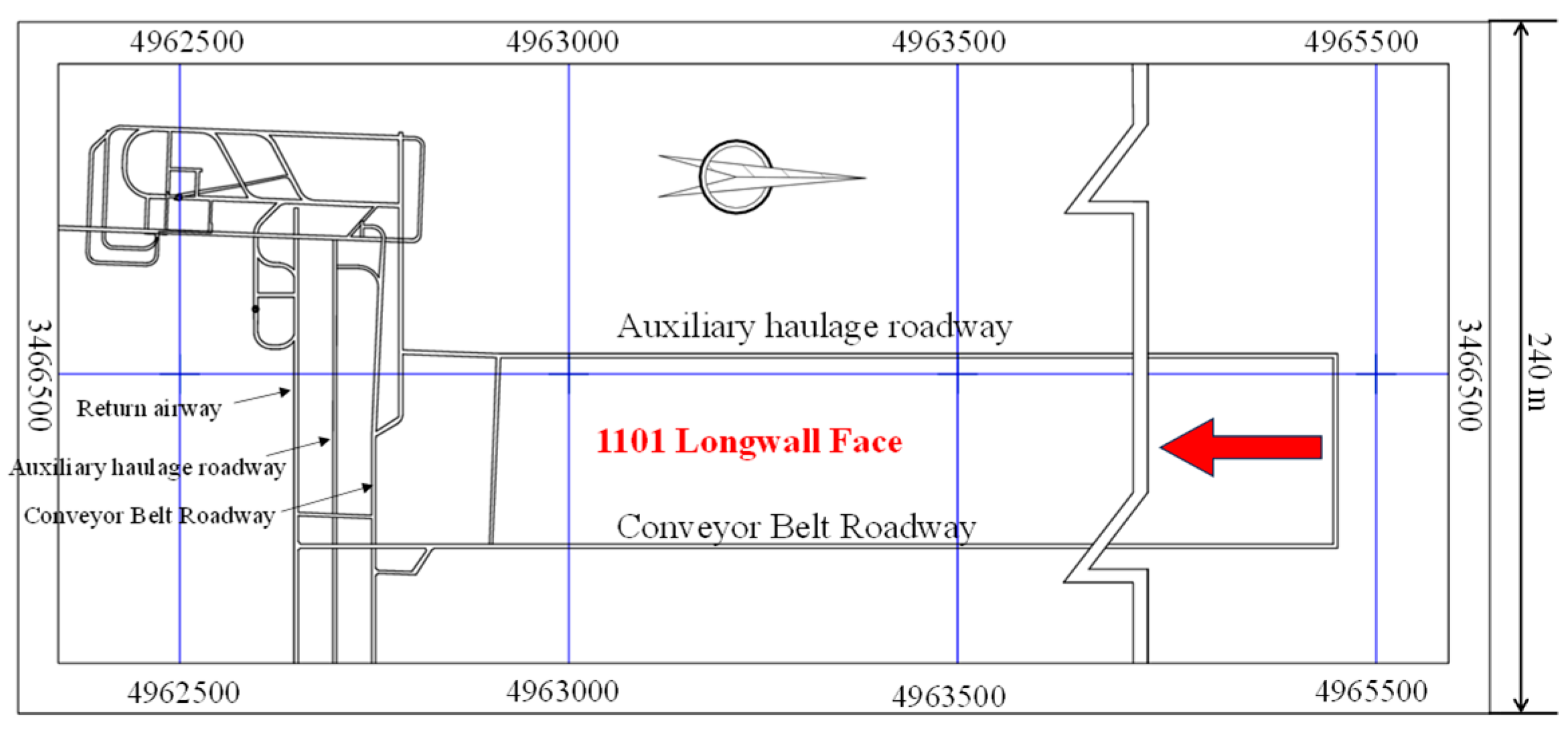

2.2. General Situation of 1101 LF

2.3. Characteristics of Weakly Cemented Overlying Rock in the Mine Field

3. Similar Simulation Research of Mining Fractures Evolution of Weakly Cemented Overlying Rock

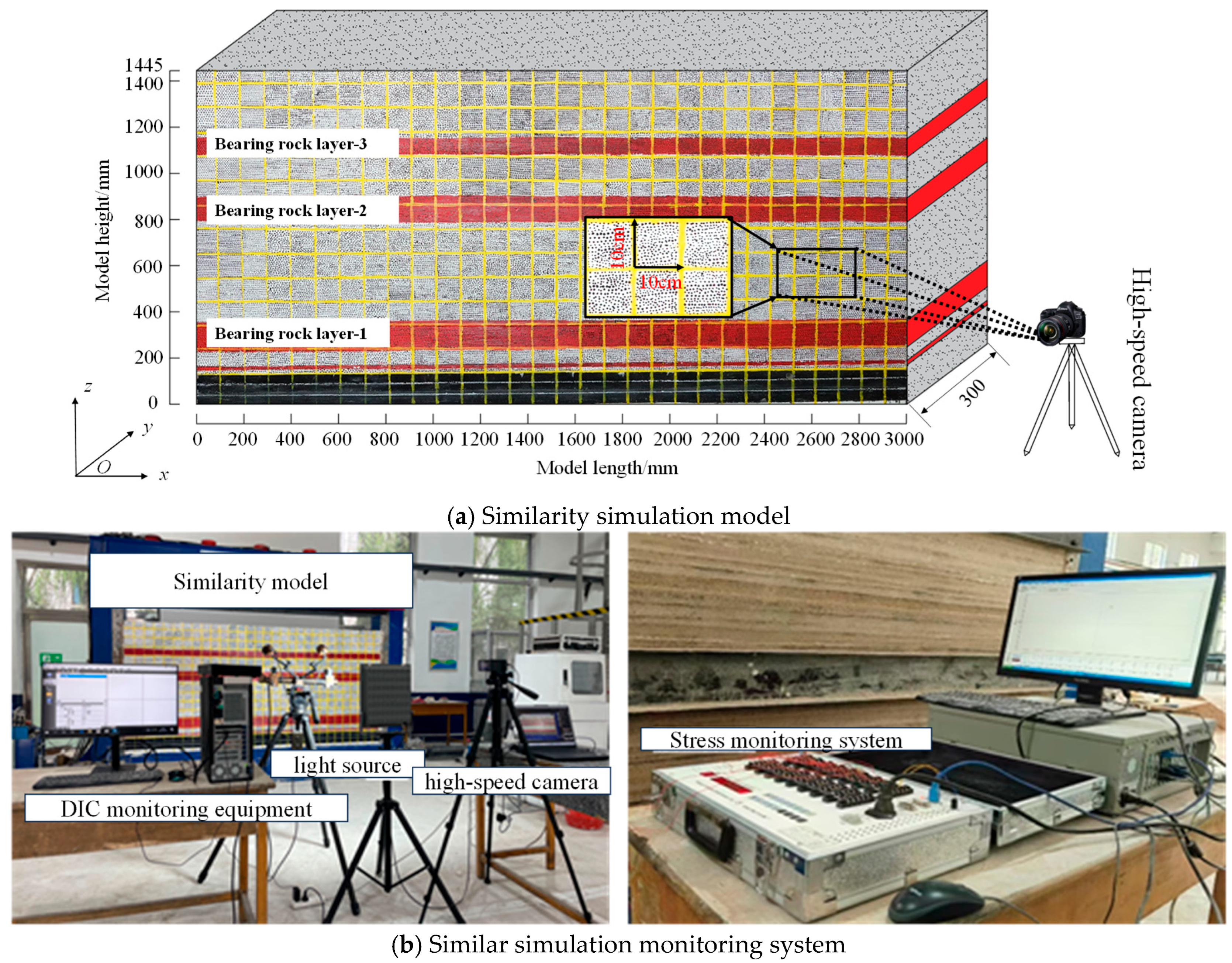

3.1. Similar Simulation Scheme

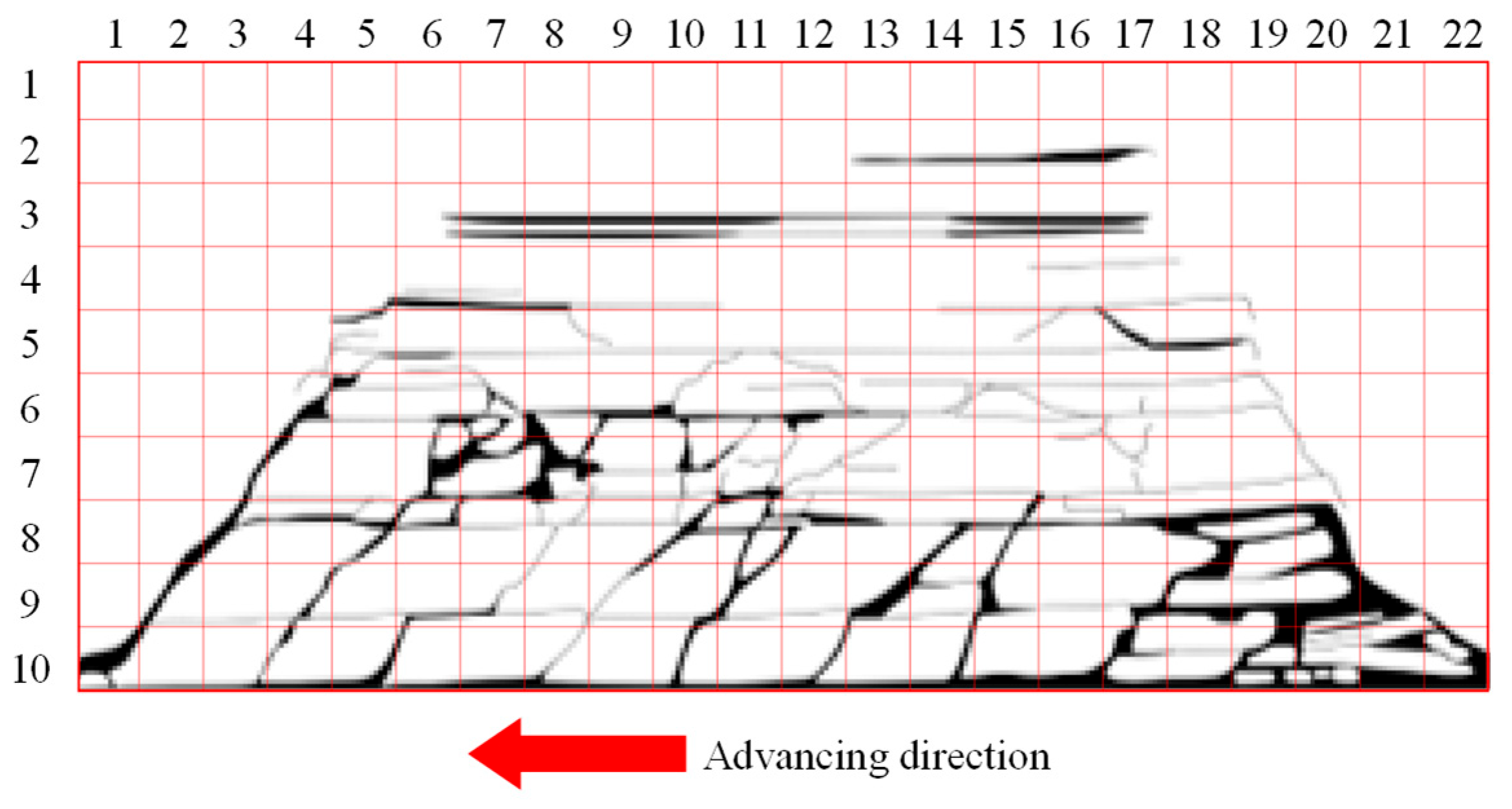

3.2. Evolution Characteristics of Mining Fractures in WCOLR

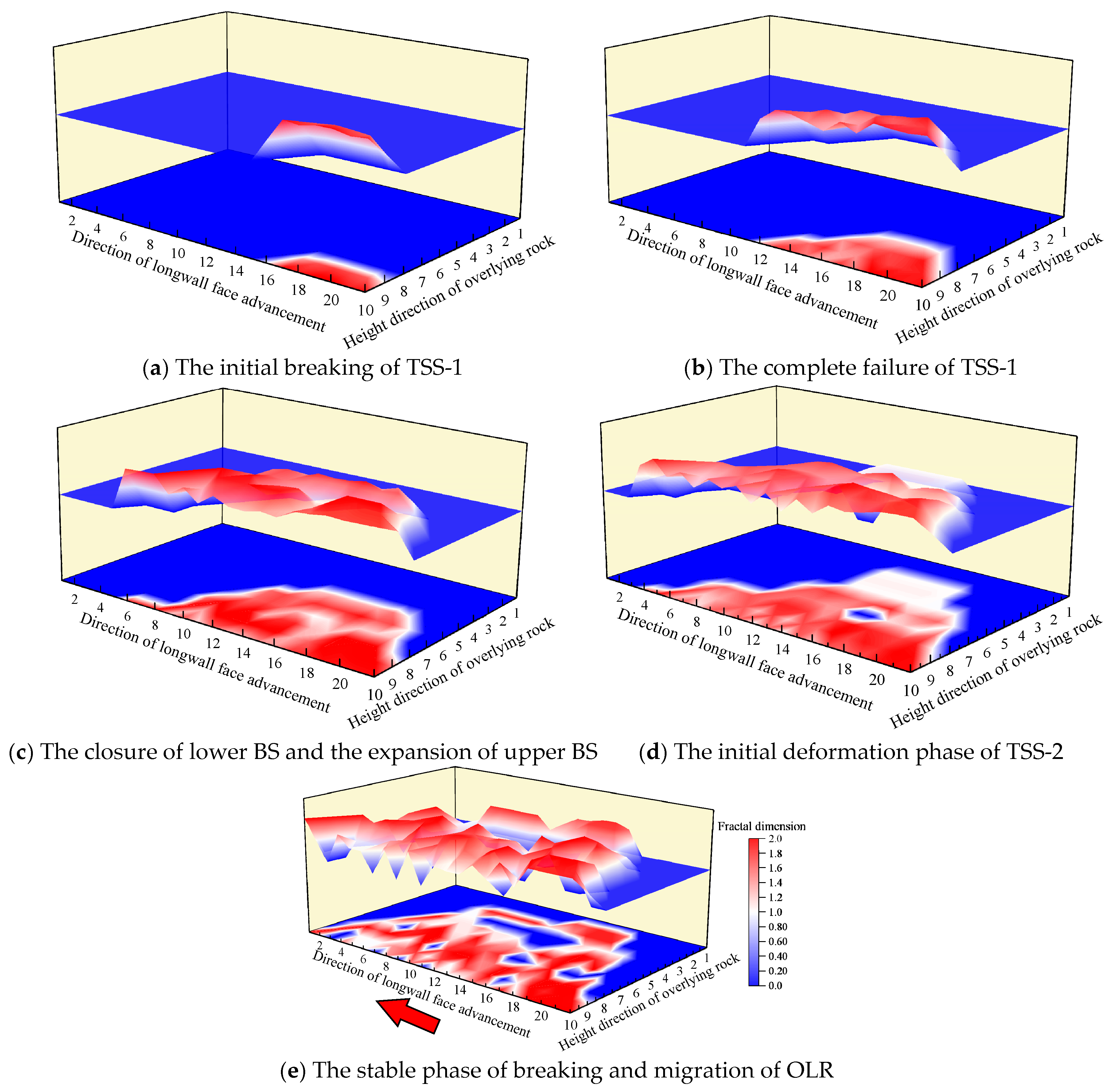

3.3. Distribution Characteristics of Fractal Dimension of WCOLR

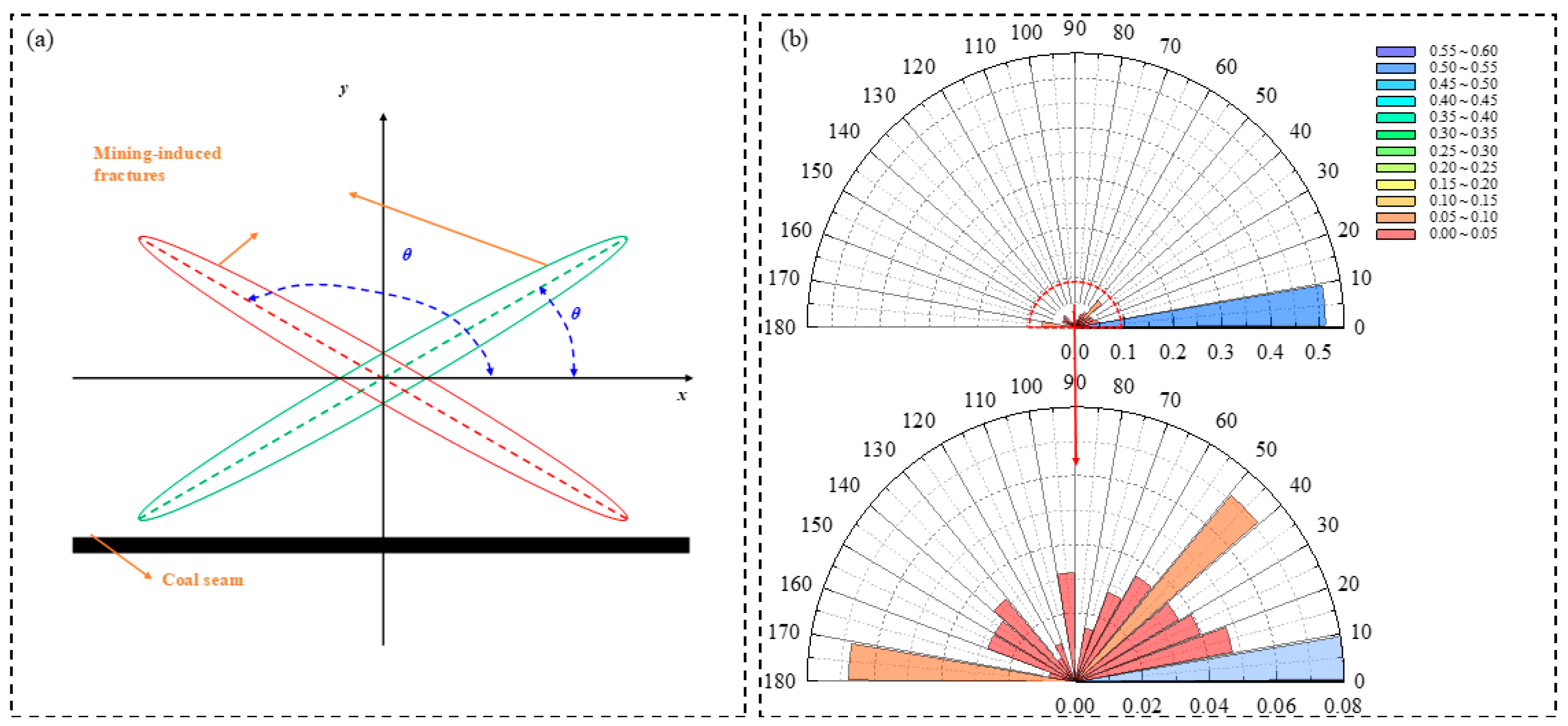

3.4. Distribution Characteristics of the Crack Angles

4. The Dynamic Evolution Mechanism of Bed Separation of Weakly Cemented Overlying Rock

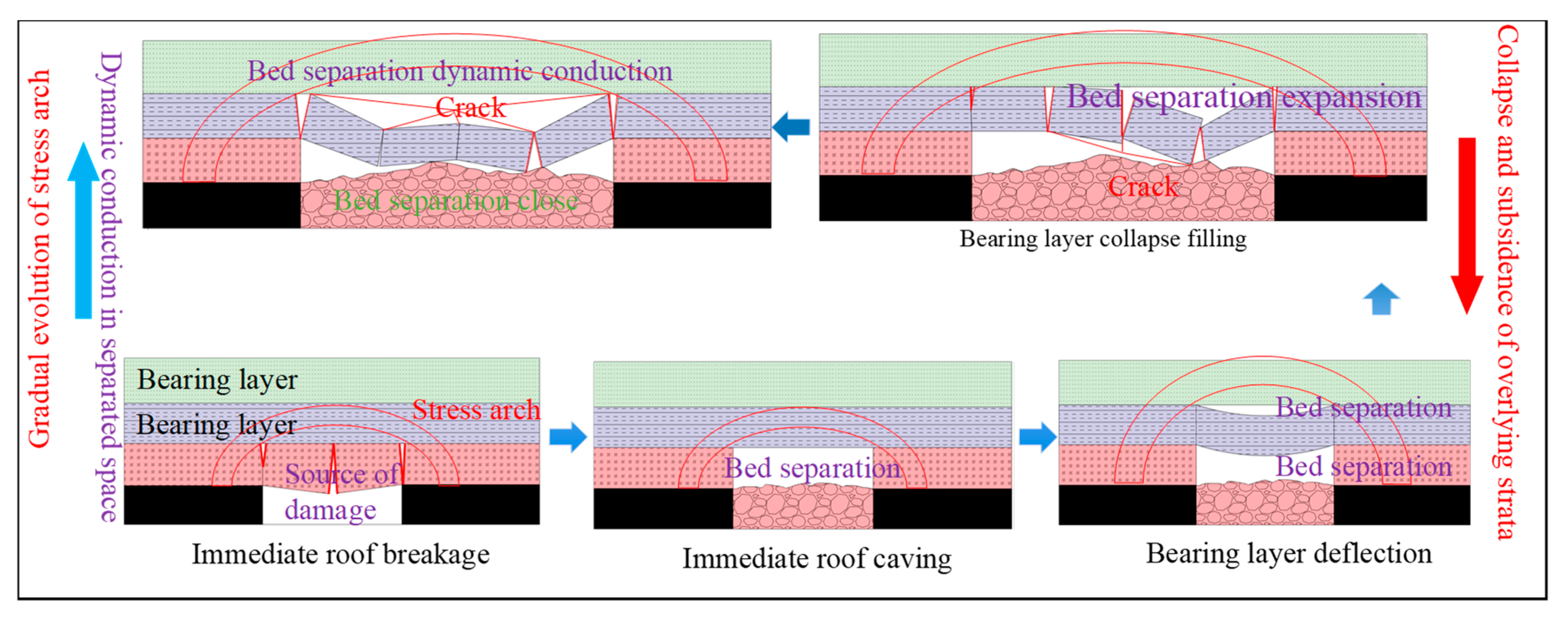

4.1. The Co-Development Evolution Model of Stress Arch-BS

4.2. The Evolution Characteristics of the Stress Arch of WCOLR

4.3. Dynamic Identification of BS of WCOLR

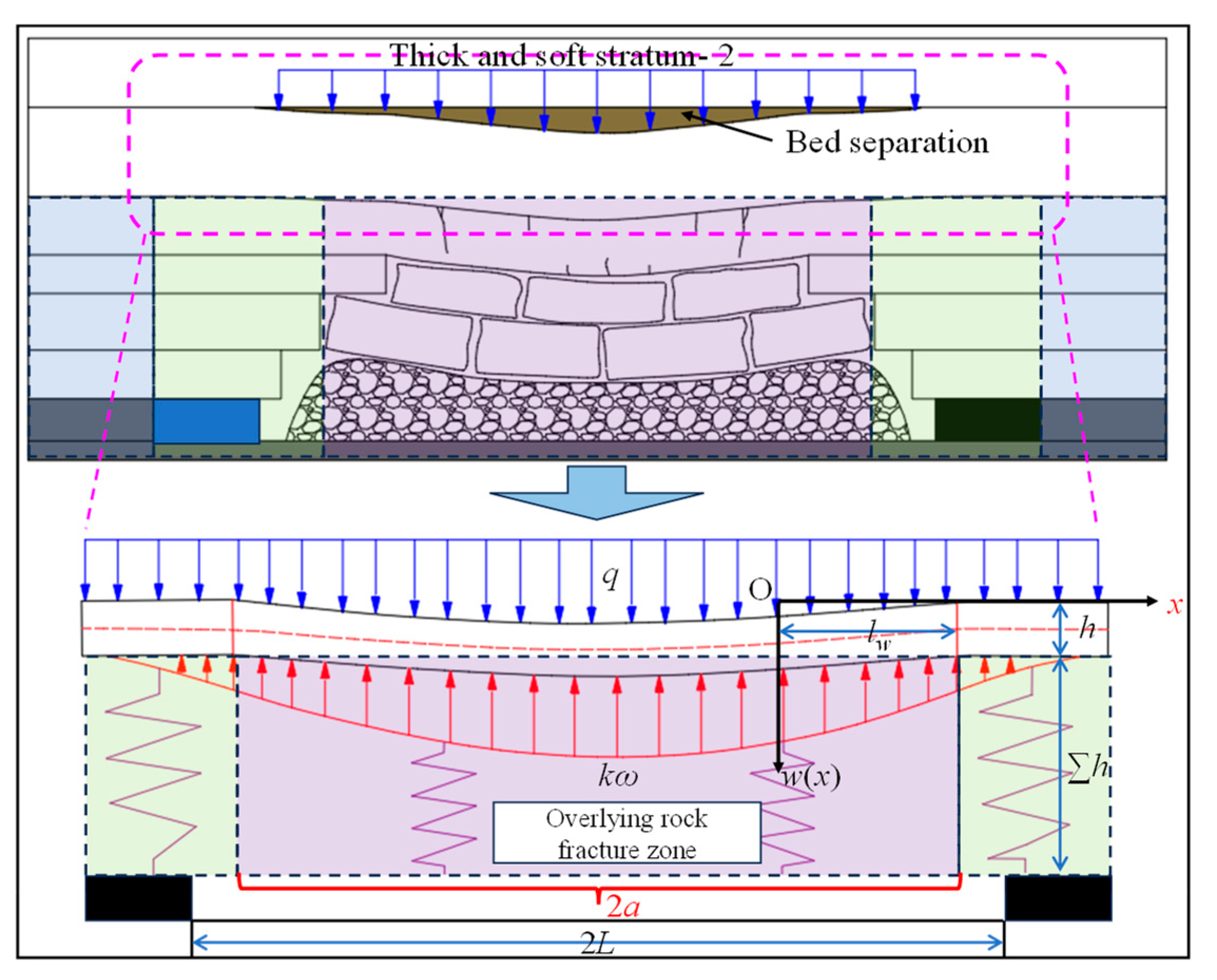

5. Theoretical Model of the Spatial Evolution of Grouting Bed Separation

6. Conclusions

- (1)

- Drilling data from the 1101 LF in Xinjiang Zhundong mining area reveal strata dominated by silty mudstone and siltstone. The compressive strength is typically less than 20 MPa, the tensile strength is generally less than 2 MPa, and the elastic modulus is generally less than 5 GPa. The proportion of weak to extremely weak strata is exceeding 90%. Macroscopically, characterized by low strength, poor cementation, susceptibility to weathering, and underdeveloped structural features such as small faults, joints, and bedding planes, this rock mass demonstrates typical attributes of a WCOLR.

- (2)

- Fractal dimension quantifies OLR mining-induced fracture evolution characteristics. During the LF advancing, the fractal dimension undergoes oscillatory evolution through five distinct stages: rapid initial growth, constrained slow growth under TSS, dimension reduction induced by fracturing and compaction of TSS, secondary growth from newly generated fractures, and stabilization upon reaching full extraction. Grid-based fractal dimension analysis further categorizes fracture zones, indicating a WCFZ height of 160~180 m.

- (3)

- Under the influence of high-intensity mining disturbance, the extent of OLR damage progressively expands. The horizontally BS fractures and vertically penetrating fractures interweave, forming a complex OLR fracture network. During LF advancing, the spatiotemporal evolution of the fracture field follows the sequence: fracture initiation, rapid development and evolution, near-field compaction, far-field propagation, and overall compaction. Mining-induced fractures predominantly concentrate at dip angles of 0–10°, 40–50°, and 170–180°. Horizontally BS fractures account for 70.2% of the total fracture population, vertically penetrating fractures constitute 13.1% and transitional fractures make up the remaining 16.7%.

- (4)

- Based on the elastic foundation beam theory, the theoretical prediction model of grouting BS under top-coal caving operations is established. The maximum cross-sectional area of BS is 680.8 m2. These results provide theoretical foundations for subsidence-reduction grouting technologies.

- (5)

- Due to the limitations of two-dimensional physical similarity simulation test conditions, this study only analyzed the characteristics of BS and fracture evolution in the direction of LF advancement. In order to more accurately reveal the damage law of WCOLR, it is necessary to further study the evolution mechanism of fractures in WCOLR in western mining areas in the future.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| T | Lateral stress | MPa |

| FH | Vertical reaction force at the arch foot | kN |

| FL | Horizontal reaction force | kN |

| h0 | The vault height | m |

| H | The height from the coal seam to the surface | m |

| ϒ | The OLR bulk density | kg/m3 |

| h | The thickness of rock strata | m |

| f | The friction coefficient of coal and rock mass | |

| M | The mining height | m |

| φ0 | The internal friction angle of coal and rock mass | |

| Dc | The advancing distance of the LF | m |

| λ | Lateral pressure coefficient, 1.2 | |

| Md | The top coal caving mining height | m |

| Mf | The height of coal discharge on the fully mechanized top coal face | m |

| Kf | The residual dilatancy coefficient of top coal | |

| η | The top coal caving rate | |

| Kp | The residual dilatancy coefficient of the overlying p-th stratum of the coal seam | |

| S | The maximum height of grouting-BS | m |

| lw | The bending length of the rock beam | m |

| 2a | The BS span | m |

| 2L | The advancing distance | m |

| ∑h | The total thickness of the foundation | m |

| k | Foundation stiffness, k = E/h | n·m−1 |

| EI | The flexural rigidity of the section of the stratum | n·m2 |

| β | The characteristic parameter of the elastic foundation beam | m−1 |

| φ | The fully mining angle | ° |

| α | The breaking angle | ° |

References

- Xu, J.; Zhu, W.; Xu, J.; Wu, J.; Li, Y. High-intensity longwall mining-induced ground subsidence in Shendong coalfield, China. Int. J. Rock Mech. Min. Sci. 2021, 141, 104730. [Google Scholar] [CrossRef]

- Wang, F.; Xu, J.; Xie, J. Effects of arch structure in unconsolidated layers on fracture and failure of overlying strata. Int. J. Rock Mech. Min. Sci. 2019, 114, 141–152. [Google Scholar] [CrossRef]

- He, J.; Li, W.; Fan, K.; Qiao, W.; Wang, Q.; Li, L. A method for predicting the water-flowing fractured zone height based on an improved key stratum theory. Int. J. Min. Sci. Technol. 2023, 33, 61–71. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.; Xu, J.; Xu, Z.; Zhang, C. Research advances in mining fractures evolution law of rock strata and ecological treatment technology. Coal Sci. Technol. 2022, 50, 28–47. [Google Scholar] [CrossRef]

- Sun, L.; Ji, H.; Yang, B. Physical and mechanical characteristic of rocks with weakly cemented strata in Western representative mining area. J. China Coal Soc. 2019, 44, 866–874. [Google Scholar] [CrossRef]

- Li, Q.; Guo, J.; Zhang, C.; Yang, Y.; Ma, J.; Ren, Z. Research findings on the application of the arch structure model in coal mining, a review. Sustainability 2022, 14, 14714. [Google Scholar] [CrossRef]

- Qin, Y.; Xu, N.; Zhang, Z.; Zhang, B. Failure process of rock strata due to multi-seam coal mining: Insights from physical modelling. Rock Mech. Rock Eng. 2021, 54, 2219–2232. [Google Scholar] [CrossRef]

- Ren, Z.; Zhang, C.; Wang, Y.; Yang, S.; Li, Q. Collaborative movement characteristics of overlying rock and loose layer based on block–particle discrete-element simulation method. Int. J. Coal Sci. Technol. 2025, 12, 17. [Google Scholar] [CrossRef]

- Zhang, C.; Ren, Z.; Li, Q.; Guo, J. Research progress on the evolution and control of overlying rock arch structure in coal mining. J. Green Mine 2024, 2, 357–367. [Google Scholar] [CrossRef]

- Wang, F.; Xu, J.; Chen, S.; Ren, M. Method to predict the height of the water conducting fractured zone based on bearing structures in the overlying strata. Mine Water Environ. 2019, 38, 767–779. [Google Scholar] [CrossRef]

- Wang, Q.; Ren, Z.; Bai, Q.; Li, Q. Characterizing the effect of longwall retreating speeds on overburden and surface synergistic subsidence behaviors with a thick coal seam: Intensive field measurements. J. Geophys. Eng. 2024, 21, 169–183. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Qin, Q.; Wang, Y.; Gao, X. Study on overlying strata movement patterns and mechanisms in super-large mining height stopes. Bull. Eng. Geol. Environ. 2023, 82, 142. [Google Scholar] [CrossRef]

- Li, L.; Kong, D.; Liu, Q.; Cai, H.; Chen, L. Study on law and prediction of surface movement and deformation in mountain area under repeated mining of shallow coal seam. Bull. Eng. Geol. Environ. 2023, 82, 76. [Google Scholar] [CrossRef]

- Dong, F.; Yin, H.; Ren, H.; Cheng, W.; Tai, S.; Miao, T.; Zhang, Y.; Wu, B. Trapezoidal failure behavior and fracture evolution mechanism of overburden in extra-thick coal mining in weakly cemented strata. Rock Mech. Rock Eng. 2024, 57, 11239–11260. [Google Scholar] [CrossRef]

- Xu, Z.; Sun, Y.; Gao, S.; Zhang, C.; Bi, Y.; Chen, Z.; Wu, J. Law of mining induced water conduction fissure in arid mining area and its significance in water-preserved coal mining. J. China Coal Soc. 2019, 44, 767–776. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Meng, H.; Qin, Q.; Cheng, X.; Huang, R.; Dong, H.; Sun, W.; Qiao, W. Fracture structure of the overburden in the layered mining of extremely thick coal seams: Developmental patterns of caving zones and hydraulically conductive fracture zones and fracture characteristics. Coal Geol. Explor. 2024, 52, 106–117. [Google Scholar] [CrossRef]

- Guo, W.; Han, M.; Yang, W.; Ma, Z. Research and application of maximum surface subsidence model under the condition of repeated mining in weakly cemented strata. Coal Sci. Technol. 2023, 51, 1–10. [Google Scholar] [CrossRef]

- Xu, Z.; Han, Y.; Chen, T.; Chen, G.; Huan, B.; Zhao, R.; Sun, Y. Mining-induced overburden failure and height prediction in jurassic weakly cemented roof. J. Eng. Geol. 2023, 31, 1474–1485. [Google Scholar] [CrossRef]

- Li, H.; Sun, J.; Guo, G.; Tang, C.; Zheng, H.; Zhang, L.; Meng, F. Evolution characteristics and development height prediction method of water-conducting crack zone in thick weak cemented overlying strata. Coal Sci. Technol. 2025, 53, 289–300. [Google Scholar] [CrossRef]

- Gui, H.; Lin, M.; Song, X. Identification and application of roof bed separation (water) in coal mines. Mine Water Environ. 2018, 37, 376–384. [Google Scholar] [CrossRef]

- Fan, K.; He, J.; Li, W.; Chen, W. Dynamic evolution and identification of bed separation in overburden during coal mining. Rock Mech. Rock Eng. 2022, 55, 4015–4030. [Google Scholar] [CrossRef]

- Zhai, X.; Zhao, X.; Zhai, Y.; Qian, H.; Liu, Q.; Ren, Z.; Guo, Z. Separation and fracturing mechanical models of overlying hugely-thick conglomerate stratum in fully mechanized caving mining and their application. J. China Univ. Min. Technol. 2023, 52, 241–254. [Google Scholar] [CrossRef]

- Jiang, J.-Q.; Wang, P.; Wu, Q.-L.; Zhang, P.-P. Evolution laws and prediction of separated stratum space under overlying high-position magmatic rocks. Chin. J. Geotech. Eng. 2015, 37, 1769–1779. [Google Scholar] [CrossRef]

- Yao, Y.; Yan, H.; Chen, J.; Xu, J. Mining-induced off-layer space evolution law and gangue grouting filling control mechanism. Bull. Eng. Geol. Environ. 2023, 82, 457. [Google Scholar] [CrossRef]

- Dai, X.; Gao, R.; Du, F.; Yu, B.; Meng, X.; Tai, Y. Evolution and control of overburden fracture in extra-thick coal seam mining with hard roofs: Ground grouting sealing and case study. Bull. Eng. Geol. Environ. 2024, 83, 262. [Google Scholar] [CrossRef]

- Ma, H.; Sui, W.; Ni, J. Environmentally sustainable mining: A case study on surface subsidence control of grouting into overburden. Environ. Earth Sci. 2019, 78, 320. [Google Scholar] [CrossRef]

- Ma, H. Surface subsidence control technology of multi-bed separation grouting. Coal Geol. Explor. 2021, 49, 150–157. [Google Scholar] [CrossRef]

- Guo, W.; Li, L.; Yang, W.; Bai, E.; Wu, D. Determination of grouting layer and stability analysis of slurry-resisting overburden in separation grouting. J. China Coal Soc. 2025, 50, 264–280. [Google Scholar] [CrossRef]

- Guo, W.; Wu, D.; Guo, M.; Hu, Y.; Yang, W.; Wang, B. Multi-bed separation grouting in “three soft” thick coal seams mining and their application. Coal Sci. Technol. 2025, 53, 1–12. [Google Scholar] [CrossRef]

- Li, J.; Wang, D.; Li, L.; Guo, W. Comparative study on development characteristics of high-intensive mining fissures in different overburden types. Coal Sci. Technol. 2021, 49, 9–15. [Google Scholar] [CrossRef]

- Ran, Q.; Liang, Y.; Zou, Q.; Zhang, B.; Li, R.; Chen, Z.; Ma, T.; Kong, F.; Liu, H. Characteristics of mining-induced fractures under inclined coal seam group multiple mining and implications for gas migration. Nat. Resour. Res. 2023, 32, 1481–1501. [Google Scholar] [CrossRef]

- Meng, X.; Hu, S.; Liu, F.; Feng, G.; Guo, S. Distribution patterns of the dominant mining fracture fields in pressure relief methane migration. Rock Mech. Rock Eng. 2024, 57, 10115–10132. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, H.; Xie, H. Research on fractal characterization of mined crack network evolution in overburden rock stratum under deep mining. Rock Soil Mech. 2009, 30, 2403–2408. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, H.; Liang, Y.; Wang, K.; Zou, Q. Characterization and quantification of mining-induced fractures in overlying strata: Implications for coalbed methane drainage. Nat. Resour. Res. 2020, 29, 2467–2480. [Google Scholar] [CrossRef]

- Li, X.; Chen, P. Study on regularity of structural behaviors around coal face under the shallow-buried loose roof. Chin. J. Rock Mech. Eng. 2004, 23, 3305–3309. [Google Scholar]

- Yang, Y.; Li, J.; Kang, T.; Ji, C. Effect of working face length on underground pressure characteristics by fully-mechanized top-coal caving mining under shallow-buried thick bedrock loose roof. Chin. J. Geotech. Eng. 2012, 34, 709–716. [Google Scholar]

- Xu, L.; Zhang, K.; Liu, X.; Chen, B.; Fan, T.; Gui, S. Deformation characteristic of key strata and control effect of surface subsidence in mining with grouting into overburden bed-separation. J. China Coal Soc. 2023, 48, 931–942. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L.; Zhang, D.; Su, F.; Wang, W. Mechanism of bedding cracking and development laws of lateral fracture in overlying strata induced by longwall mining. J. China Coal Soc. 2023, 48, 527–541. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Ren, Z.; He, J.; Zhao, X. Fractal Evolution Characteristics of Weakly Cemented Overlying Rock Fractures in Extra-Thick Coal Seams Mining in Western Mining Areas. Fractal Fract. 2025, 9, 531. https://doi.org/10.3390/fractalfract9080531

Zhang C, Ren Z, He J, Zhao X. Fractal Evolution Characteristics of Weakly Cemented Overlying Rock Fractures in Extra-Thick Coal Seams Mining in Western Mining Areas. Fractal and Fractional. 2025; 9(8):531. https://doi.org/10.3390/fractalfract9080531

Chicago/Turabian StyleZhang, Cun, Zhaopeng Ren, Jun He, and Xiangyu Zhao. 2025. "Fractal Evolution Characteristics of Weakly Cemented Overlying Rock Fractures in Extra-Thick Coal Seams Mining in Western Mining Areas" Fractal and Fractional 9, no. 8: 531. https://doi.org/10.3390/fractalfract9080531

APA StyleZhang, C., Ren, Z., He, J., & Zhao, X. (2025). Fractal Evolution Characteristics of Weakly Cemented Overlying Rock Fractures in Extra-Thick Coal Seams Mining in Western Mining Areas. Fractal and Fractional, 9(8), 531. https://doi.org/10.3390/fractalfract9080531