Pore Structure Characteristics and Controlling Factors of the Lower Cambrian Niutitang Formation Shale in Northern Guizhou: A Case Study of Well QX1

Abstract

1. Introduction

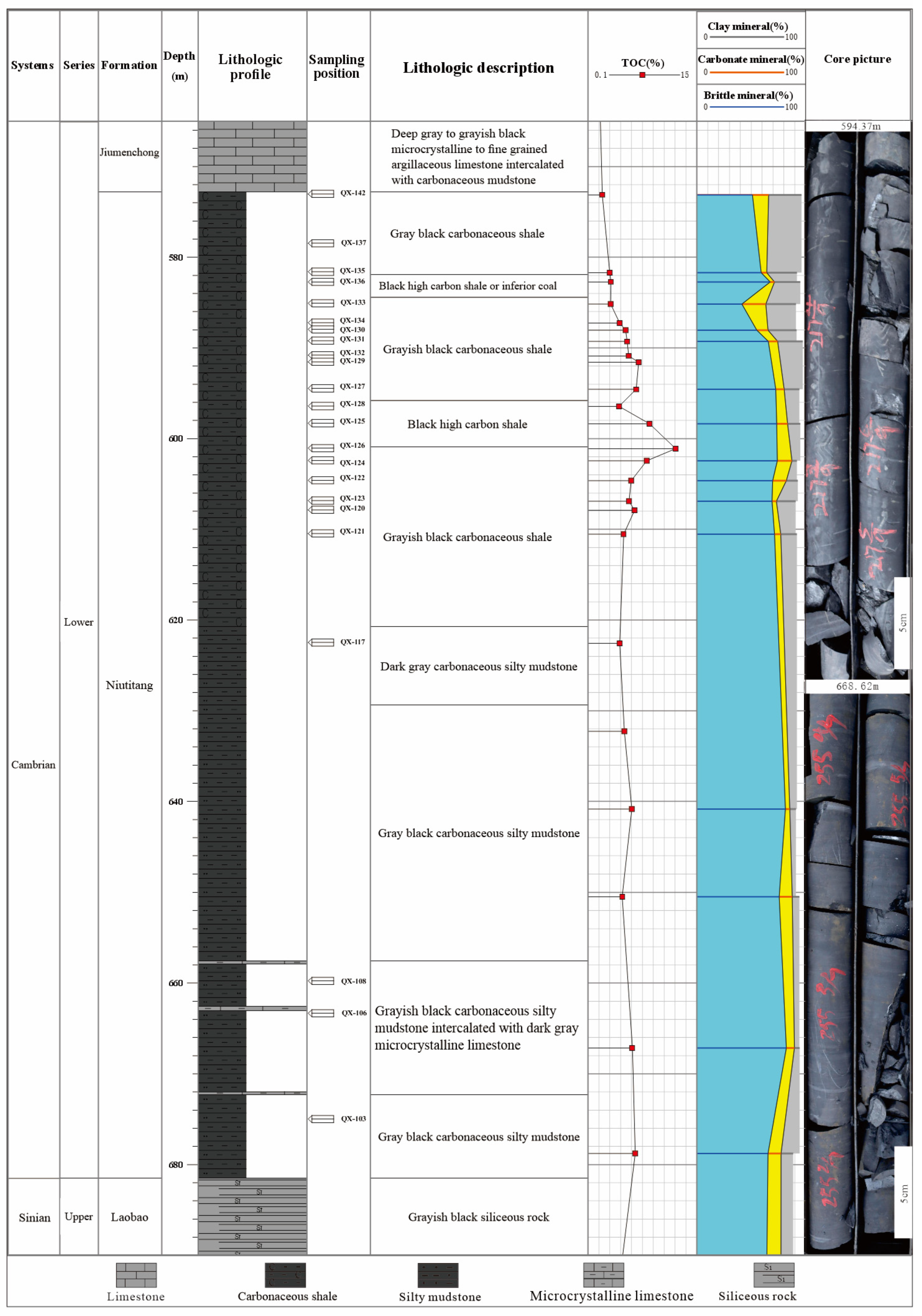

2. Geological Setting

3. Experiment and Samples

3.1. FE-SEM Experiment

3.2. HPMI Experiment

3.3. LTNA Experiment

3.4. NMR Experiment

3.5. Pore Fractal Theory

4. Result and Discussion

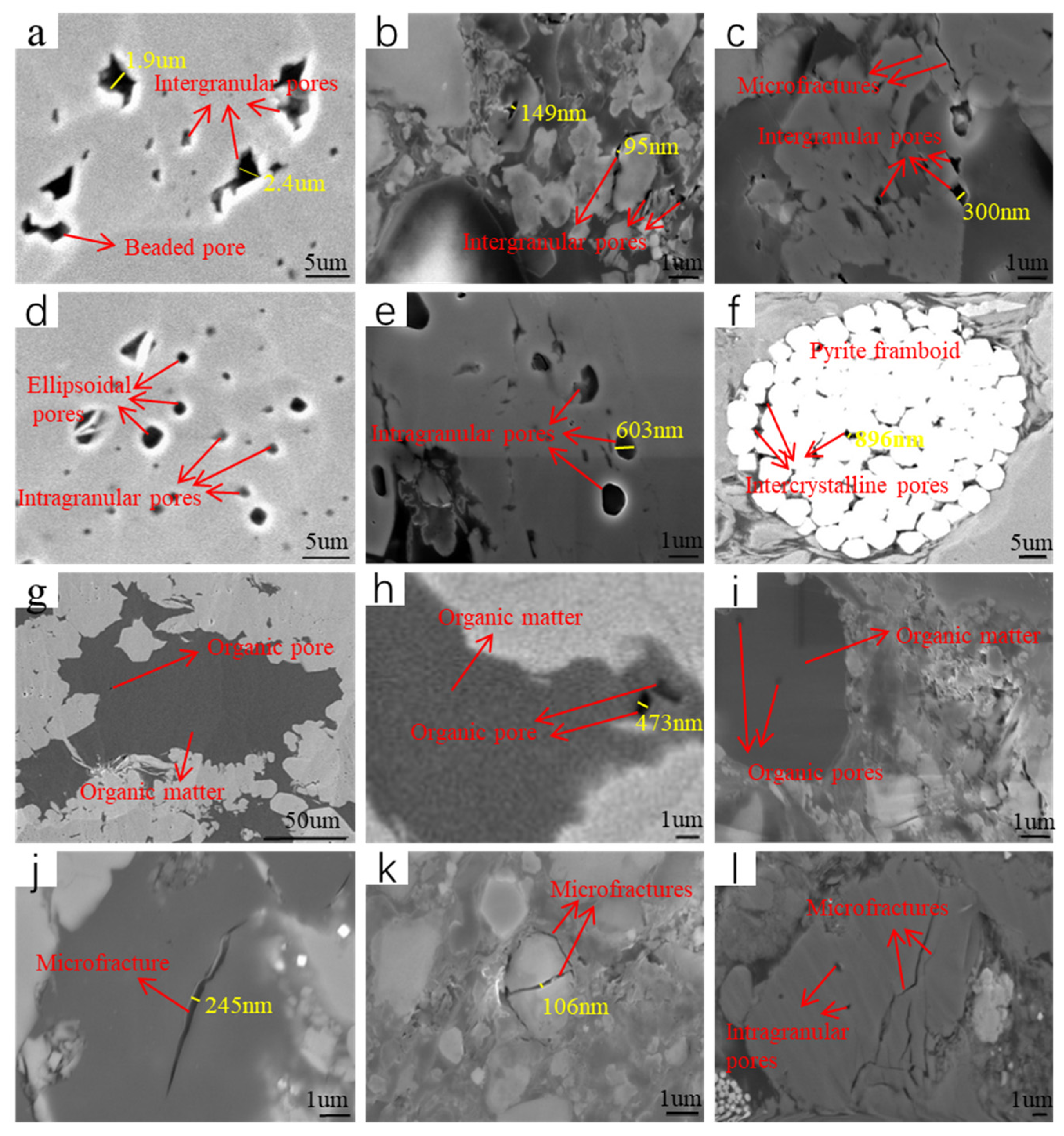

4.1. Pore Type

4.2. Pore Structure

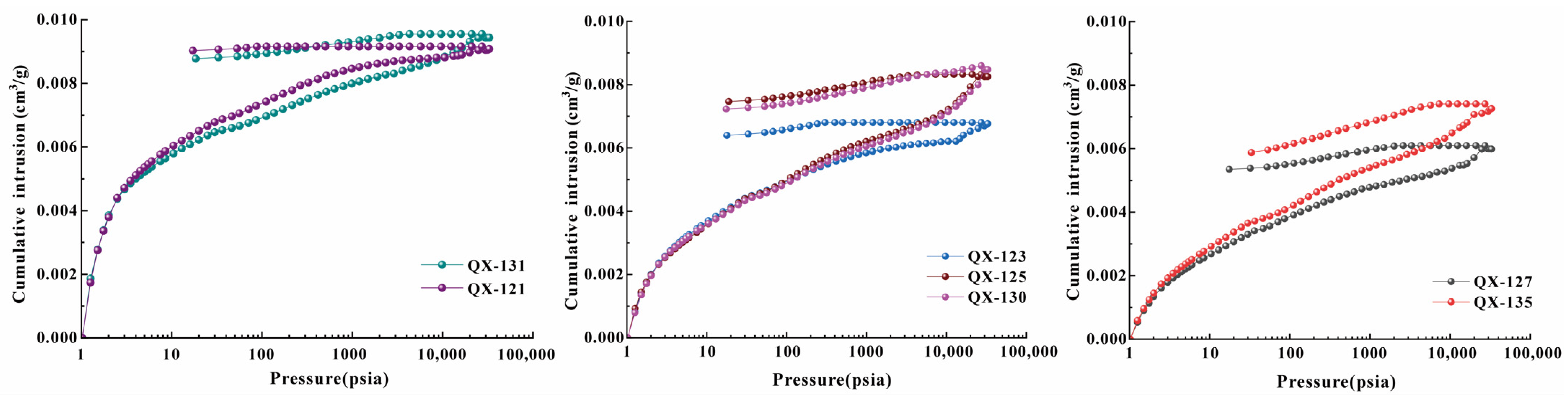

4.2.1. HPMI Characterization

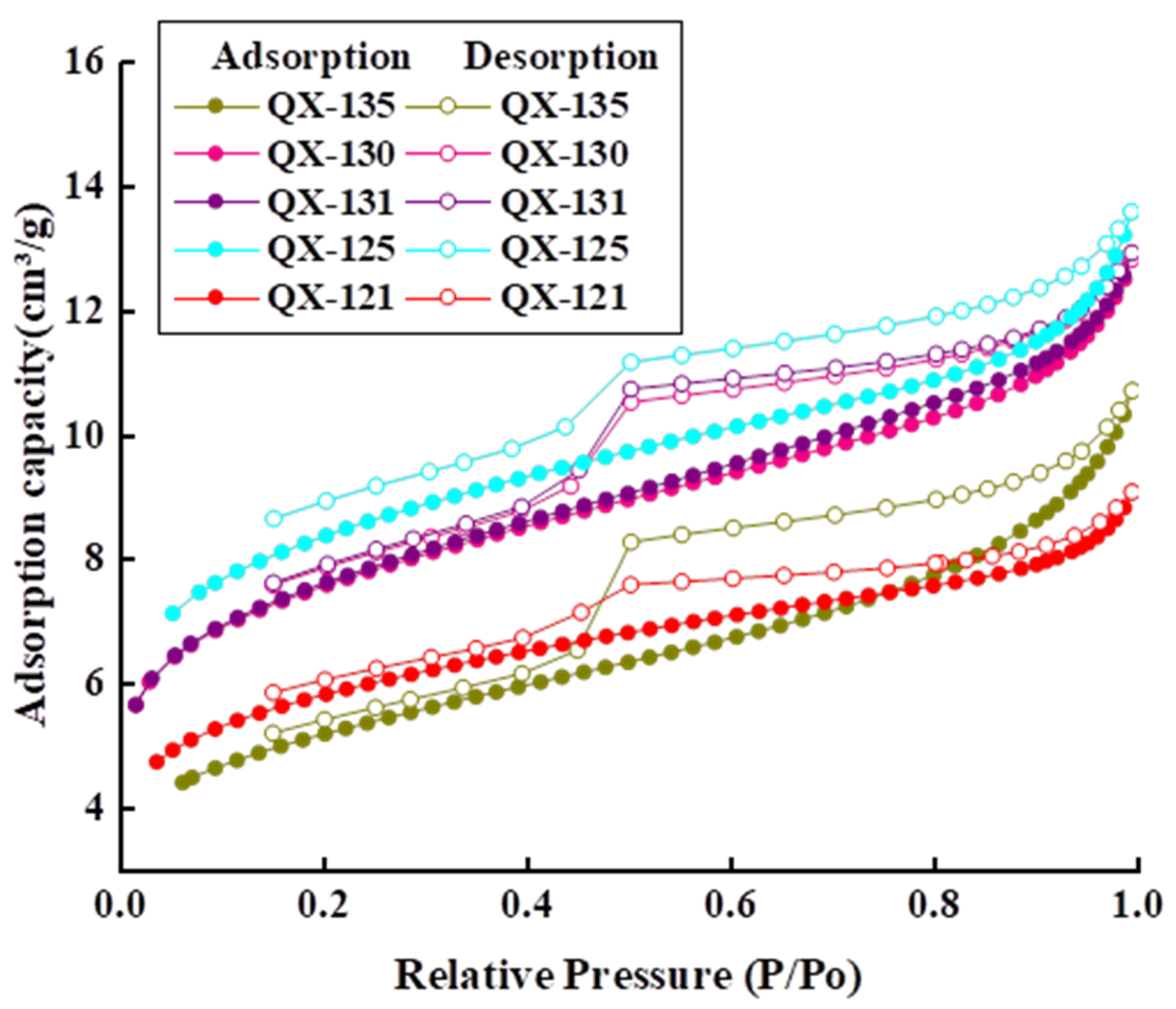

4.2.2. LTNA Characterization

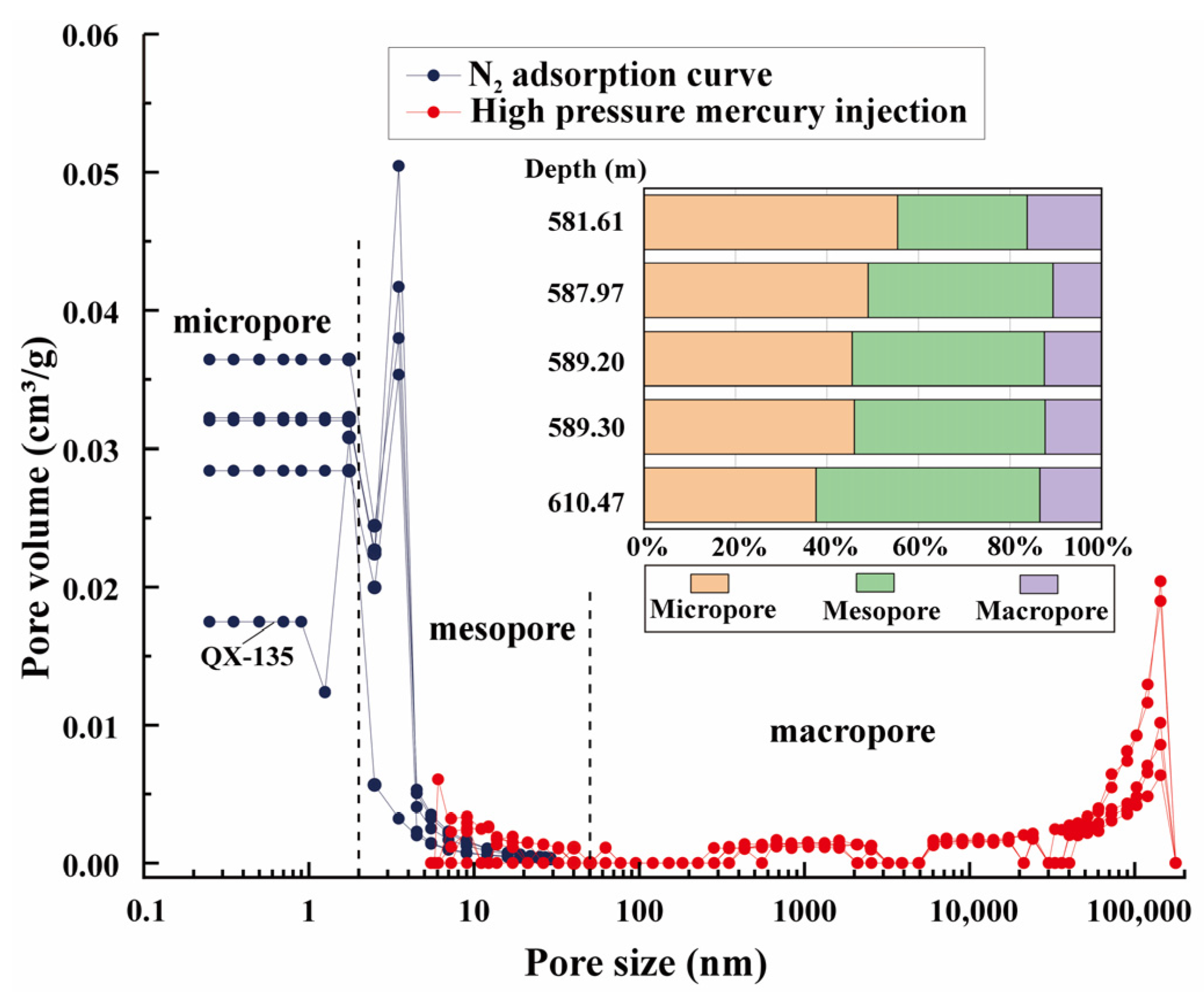

4.2.3. Integrated Characterization via HPMI and LTNA

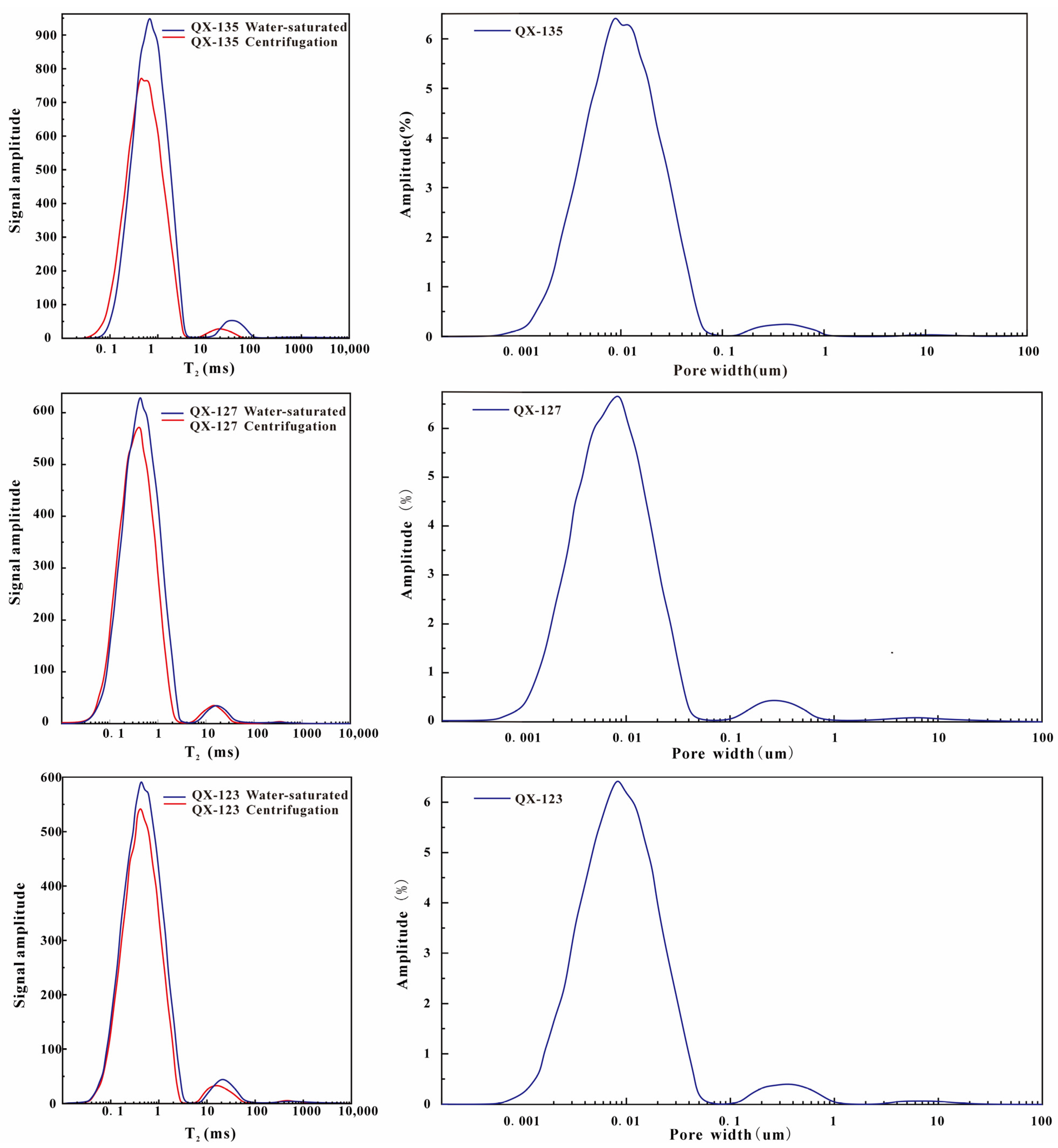

4.2.4. NMR Characterization

4.3. Fractal Characteristics

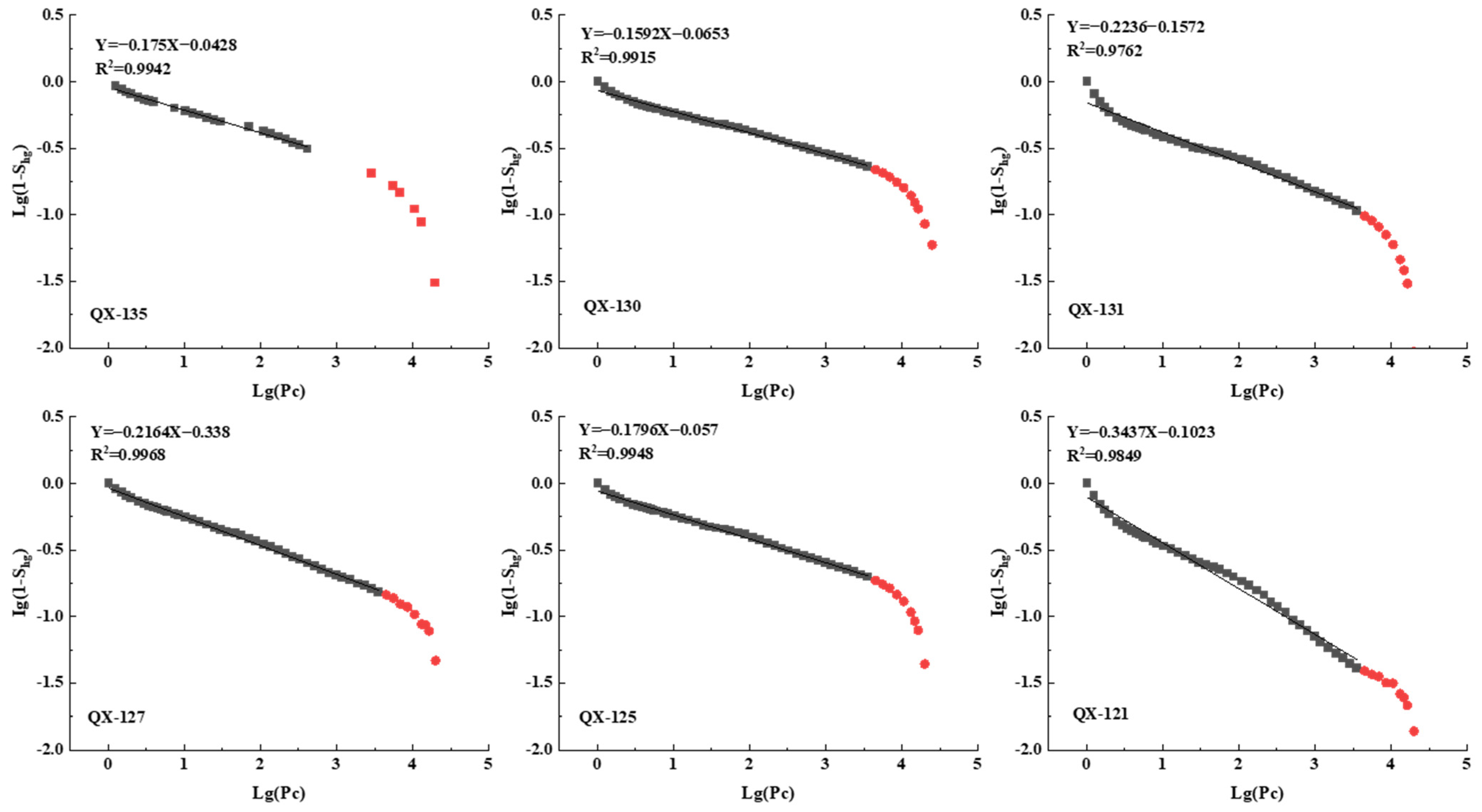

4.3.1. Fractal Dimension Calculation Based on HPMI Data

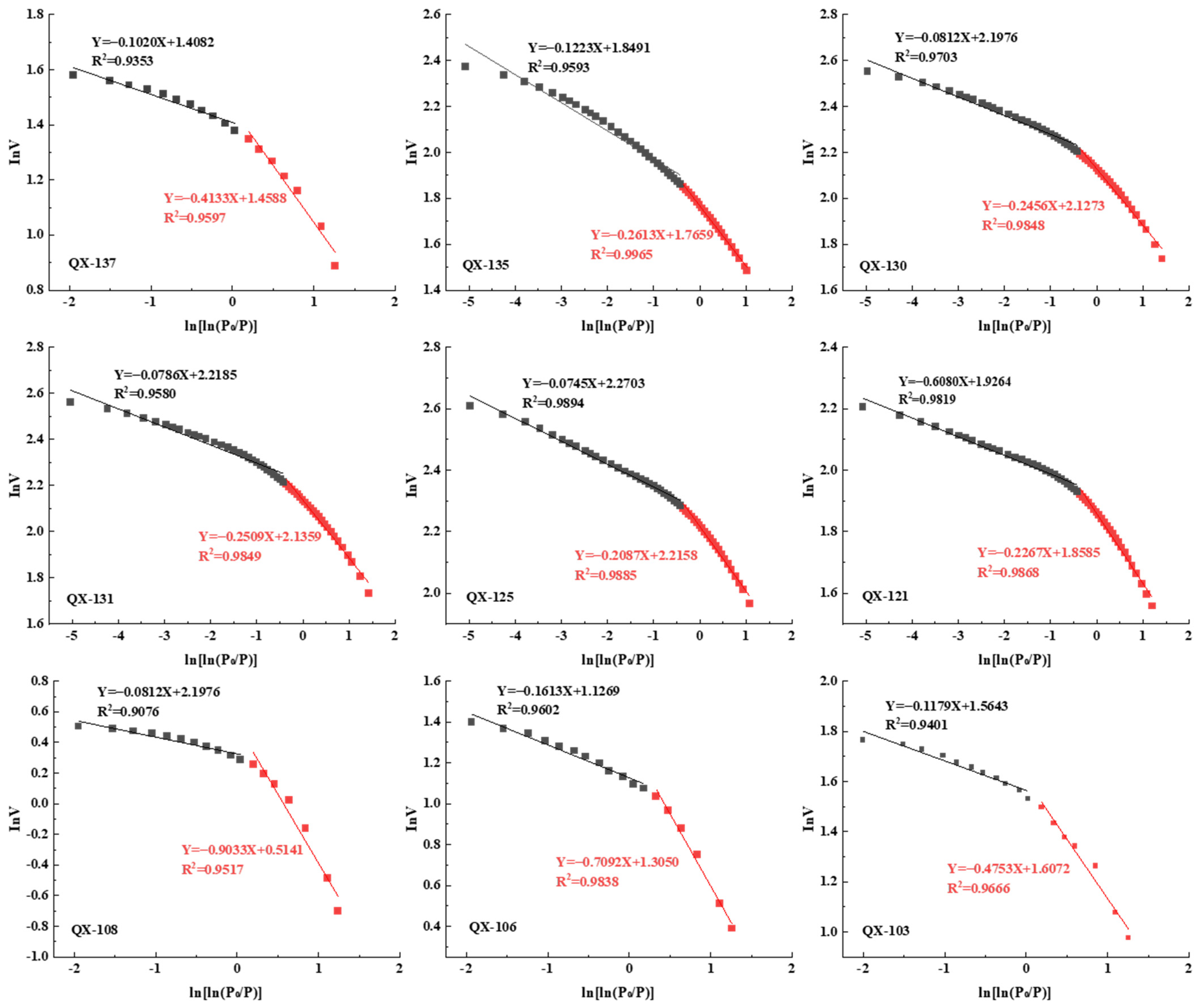

4.3.2. Fractal Dimension Calculation Based on LTNA Data

5. Influencing Factors on Pore Structure

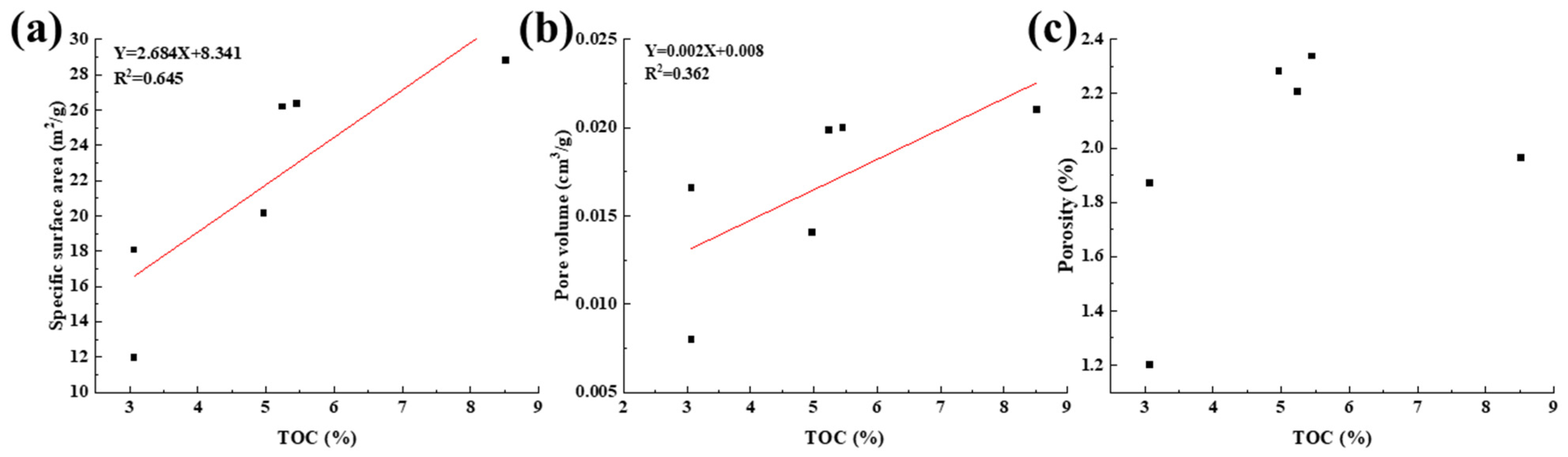

5.1. Influence of TOC on Pore Structure

5.2. Influence of Mineral Content on Pore Structure

5.2.1. Clay Mineral Content

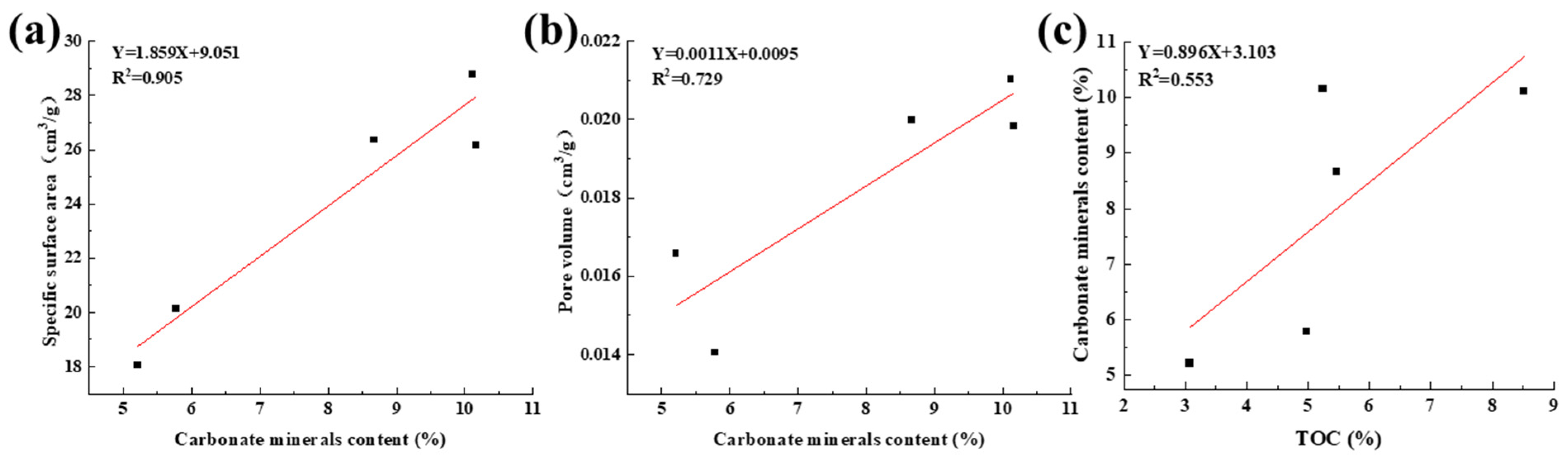

5.2.2. Carbonate Minerals Content

6. Conclusions

- (1)

- The mineral composition of the shale of the Niutitang Formation in Well QX1 is dominated by quartz and feldspar, and the pore types are mainly intergranular pores, intragranular pores, organic matter pores, and microfractures. Among them, the intergranular pores and intragranular pores are the most developed, while the organic matter pores are relatively few.

- (2)

- The N2 adsorption–desorption isotherms belong to type IV, and the types of hysteresis loops are H4 and H5, which correspond to plate-shaped intersecting conical microfractures or plate-shaped intersecting ink bottles, ellipsoidal, and beaded pores.

- (3)

- The pore size distribution showed a multi-peak distribution, with the most developed mesopores, followed by micropores and the least macropores.

- (4)

- The fractal dimension D1 > D2, indicates that the shale pore system is characterized by a rough surface and some connectivity of the pore network.

- (5)

- Mineral content is the main factor controlling the pore structure of the shale of the Niutitang Formation in northern Guizhou. Carbonate minerals enhance pore development by increasing brittleness, providing rigid support, and forming dissolution pores. The main controlling effect of the clay minerals on the pore volume and pore specific surface area of the shale is not obvious, possibly because the shale in the study area has undergone tectonic compression, which has modified the pore system associated with clay minerals, making the relationship between them complex. In addition, there is some effect of TOC on the pore structure of shale in the study area.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FE-SEM | field emission scanning electron microscopy |

| HPMI | high-pressure mercury intrusion |

| LTNA | low-temperature nitrogen adsorption |

| NMR | nuclear magnetic resonance |

| TOC | Total organic carbon |

References

- Shang, F.; Miao, K.; Zhu, Y.; Wang, M.; Tang, X.; Wang, Y.; Gao, H.; Feng, G.; Mi, W. Pore structure, adsorption capacity and their controlling factors of shale in complex structural area. Coal Sci. Technol. 2023, 51, 269–282. [Google Scholar]

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Loucks, R.G.; Ruppel, S.C.; Wang, X.; Ko, L.; Peng, S.; Zhang, T.; Rowe, H.D.; Smith, P. Pore types, pore-network analysis, and pore quantification of the lacustrine shale-hydrocarbon system in the Late Triassic Yanchang Formation in the southeastern Ordos Basin, China. Interpretation 2017, 5, SF63–SF79. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Y.; Li, J.; Jin, Y. Accumulation conditions for shale gas and It′s future exploration of Silurian the Central-Upper Yangtze region. Dizhi Keji Tongbao 2011, 30, 90–93. [Google Scholar]

- Ross, D.J.K.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Guo, P.; Wang, D.; Wang, Z.; Huang, K.; Zhang, X.; Liu, Z. Investigation on the characteristics and development mechanism of shale gas reservoir. Dizhi Keji Tongbao 2012, 31, 118–123. [Google Scholar]

- Yang, R.; He, S.; Hu, D.; Zhang, H.; Zhang, J. Characteristics and the main controlling factors of micro-pore Structure the shale in Wufeng Formation-Longmaxi Formation in Jiaoshiba Area. Dizhi Keji Tongbao 2015, 34, 105–113. [Google Scholar]

- Xia, W.; Yu, B.; Wang, Y.; Sun, M. Study on the depositional environment and organic accumulation mechanism in the Niutitang and Longmaxi Formation, north Guizhou province:A case study of well Renye 1 and well Xiye 1. Mineral. Petrol. 2017, 37, 77–89. [Google Scholar]

- Zhang, P.; Huang, Y.; Zhang, J.; Wei, X.; Yang, J.; He, R.; Hu, Y. Difference analysis of hydrocarbon generation and reservoir capacity between the Cambrian Niutitang Formation and the Silurian Longmaxi Formation in Northwest Guizhou. Mar. Orig. Pet. Geol. 2019, 24, 83–90. [Google Scholar]

- He, H.; Xiao, J.; Yang, H.; Lan, Q.; Huang, M. Sedimentary environment and shale gas exploration potential of Lower Cambrian Niutitang Formation in northern Guizhou. Chenji Yu Tetisi Dizhi 2024, 44, 267–277. [Google Scholar]

- Zhang, D.; Zou, N.; Du, W.; Zhao, F.; Chen, Y.; Shi, F.; Wang, Y.; Lin, R. Geological features and evaluation of Niutitang Formation shale gas in Fenggang block, northern Guizhou. Tianranqi Diqiu Kexue 2022, 33, 886–898. [Google Scholar]

- Shen, Z.; Li, X.; Zhang, S.; Zhou, L.; Lai, H. Composition characterictic and nitrogen-rich of shale gas in Niutitang Formation, northern Guizhou area. Acta Geol. Sin. 2024, 98, 1867–1879. [Google Scholar]

- Yang, C.; Xie, H.; Gao, Z.; Luo, T.; Tian, J. Analysis of shale gas exploration potential in Zunyi area. Meitan Jishu 2022, 41, 97–100. [Google Scholar]

- Wu, C.; Liu, X.; Wei, Z.; Tuo, J. Mechanism of organic matter enrichment and organic pore development in the Lower Cambrian Niutitang shales in northern Guizhou. Earth Sci. Front. 2023, 30, 101–109. [Google Scholar]

- Zhou, F.; Zhao, L.; Wu, Z.; Xia, P.; Wang, K.; Ning, S.; Shi, H. Organic matter pore and its influencing factors in over-mature shale of the Niutitang Formation, northern Guizhou area. Tianranqi Diqiu Kexue 2025, 36, 240–256. [Google Scholar]

- Sun, W.; Zuo, Y.; Wu, Z.; Liu, H.; Zheng, L.; Shui, Y.; Xi, S.; Lou, Y.; Luo, X. The distribution characteristics of brittle minerals in the Lower Cambrian Niutitang Formation in northern Guizhou. J. Nat. Gas Sci. Eng. 2021, 86, 103752. [Google Scholar] [CrossRef]

- Ning, F.; Zou, N.; Zhang, D.; Wang, G.; Mu, Y. Shale characterization of the Lower Cambrian Niutitang Formation in northern Guizhou. Tezhong Youqicang 2020, 27, 62–67. [Google Scholar]

- Qin, C.; Yu, Q.; Liu, W.; Yan, J.; Zhang, H. Reservoir characteristics of organic-rich mudstone of Niutitang Formation in northern Guizhou. Xinan Shiyou Daxue Xuebao Ziran Kexueban 2017, 39, 13–24. [Google Scholar]

- Cao, Y.; Jin, Z.; Zhu, R.; Liu, K.; Liang, X. Progress and prospects in the research on pore structures of organic-rich mud shales. Chenji Yu Tetisi Dizhi 2024, 44, 231–252. [Google Scholar]

- Wu, S.; Zhu, R.; Cui, J.; Mao, Z.; Liu, K.; Wang, X. Ideas and prospect of porous structure characterization in unconventional reservoirs. Dizhi Lunping 2020, 66, 151–154. [Google Scholar]

- Ge, M.; Bao, S.; Shi, D.; Ma, Y.; Zhang, J.; Zhang, Q.; Zhang, L.; Lin, Y.; Wang, T. Multi−scale characterization of shale pore structure of Niutitang Formation in southeastern Guizhou and its influence on shale gas enrichment. Geol. China 2024, 51, 57–72. [Google Scholar]

- Zhu, H.; Jia, A.; Wei, Y.; Jia, C.; Jin, Y. Application of low-pressure gas adsorption experiment to characterizing pore structure of the shale. Dongbei Shiyou Daxue Xuebao 2017, 41, 36–45. [Google Scholar]

- Zhao, X.; Yang, Z.; Lin, W.; Xiong, S.; Xia, D. Fractal study on pore structure of tight sandstone based on full-scale map. Int. J. Oil Gas Coal Technol. 2019, 22, 123. [Google Scholar] [CrossRef]

- Lin, W.; Zhao, X.; Li, M.; Zhuang, Y. Pore Structure Characterization and Fractal Characteristics of Tight Limestone Based on Low-Temperature Nitrogen Adsorption and Nuclear Magnetic Resonance. Fractal Fract. 2024, 8, 8070371. [Google Scholar] [CrossRef]

- Han, C.; Li, G.; Dan, S.; Yang, Y.; He, X.; Qi, M.; Liu, G. Study of Fractal and Multifractal Features of Pore Structure in Tight Sandstone Reservoirs of the Permian Lucaogou Formation, Jimsar Sag, Junggar Basin, Northwest China. ACS Omega 2022, 7, 31352–31366. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Guan, P.; Zhang, J.; Liang, X.; Ding, X.; You, Y. A Review of the Progress on Fractal Theory to Characterize the Pore Structure of Unconventional Oil and Gas Reservoirs. Acta Sci. Nat. Univ. Pekin. 2023, 59, 897–908. [Google Scholar]

- Jiang, W.; Zhang, Y.; Ma, T.; Chen, S.; Hu, Y.; Wei, Q.; Zhuang, D. Pore Structure and Its Fractal Dimension: A Case Study of the Marine Shales of the Niutitang Formation in Northwest Hunan, South China. Fractal Fract. 2025, 9, 49. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Zou, J.; Gentzis, T.; Rezaee, R.; Bubach, B.; Carvajal-Ortiz, H. Multifractal analysis of gas adsorption isotherms for pore structure characterization of the Bakken Shale. Fuel 2018, 219, 296–311. [Google Scholar] [CrossRef]

- Yang, C.; Zou, N.; Zhang, D.; Chen, Y.; Du, W.; Zhu, B. Reservoir Characteristics and Exploration Potential Evaluation of Lower Cambrian Niutitang Shale in Northern Guizhou: A Case Study of Well QX1. Energies 2024, 17, 1166. [Google Scholar] [CrossRef]

- Dai, C.; Hu, M.; Chen, J.; Wang, M.; Wang, X. The important geologic events of Guizhou province and its geologic significance. Guizhou Geol. 2015, 32, 1–9. [Google Scholar]

- Zhao, S. The Structural Features and Lower Paleozoic of Black Shale Fracture Characteristics and Distribution in Qianbei Area. Master’s Thesis, China University of Geosciences, Beijing, China, 2013. [Google Scholar]

- Lin, R.; Wang, Y.; Shi, F.; Liu, D.; Zhang, D.; Feng, X.; Zhou, Z.; Chen, Y.; Zhao, F.; Zhang, Z.; et al. Breakthrough and revelation of ultra-shallow shale gas exploration in complex structural area of northern Guizhou: Taking Well RX1 as an example. Geol. China 2023, 50, 1–25. [Google Scholar] [CrossRef]

- Shu, L. An analysis of principal features of tectonic evolution in South China Block. Dizhi Tongbao 2012, 31, 1035–1053. [Google Scholar]

- Xie, G.; Jia, D.; Zhang, Q.; Wu, X.; Shen, L.; Lu, Y.; Zou, X. Physical modeling of the Jura-type folds in eastern Sichuan. Acta Geol. Sin. 2013, 87, 773–788. [Google Scholar]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; And, D.M.; Jarvie. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Guo, R.; Xie, Q.; Qu, X.; Chu, M.; Li, S.; Ma, D.; Ma, X. Fractal characteristics of pore-throat structure and permeability estimation of tight sandstone reservoirs: A case study of Chang 7 of the Upper Triassic Yanchang Formation in Longdong area, Ordos Basin, China. J. Pet. Sci. Eng. 2020, 184, 106555. [Google Scholar] [CrossRef]

- Jin, L.; Guiwen, W.; Zhuoying, F.; Zhenglong, Z.; Jing, C.; Shuchen, W. Fractal analysis of tight shaly sandstones using nuclear magnetic resonance measurements. AAPG Bull. 2018, 102, 175–193. [Google Scholar]

- Shi, D.; Xu, Q.; Guo, R.; Liu, E.; Zhu, D.; Wang, Y.; Wang, B.; Ouyang, Z. Pore structure characteristics and main controlling factors of Permian organic-rich shale in Lower Yangtze Region. Tianranqi Diqiu Kexue 2022, 33, 1911–1925. [Google Scholar]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Xue, B.; Zhang, J.; Tang, X.; Yang, C.; Chen, Q.; Man, X.; Dang, W. Characteristics of microscopic pore and gas accumulation on shale in Longmaxi Formation, northwest Guizhou. Acta Pet. Sin. 2015, 36, 138–149. [Google Scholar]

- Li, Y.; Hu, Z.; Liu, X.; Cai, C.; Mu, Y.; Zhang, Q.; Zeng, S.; Guo, J. The pore structure characteristics of deep shale in Longmaxi Formation of Luzhou area. Duankuai Youqitian 2022, 29, 584–590. [Google Scholar]

- Borjigin, T.; Lu, L.; Yu, L.; Zhang, W.; Pan, A.; Shen, B.; Wang, Y.; Yang, Y.; Gao, Z. Formation, preservation and connectivity control of organic pores in shale. Pet. Explor. Dev. 2021, 48, 687–699. [Google Scholar] [CrossRef]

- Zeng, W.; Ding, W.; Zhang, J.; Li, Y.; Wang, R.; Jiu, K. Analyses of the characteristics and main controlling factors for the micro/nanopores in Niutitang shale from China’s southeastern Chongqin and northern Cuizhou regions. Earth Sci. Front. 2019, 26, 220–235. [Google Scholar]

- Zeng, T.; Fang, Y.; Nan, Y.; Yao, Y. Study on pore structure characteristics of the typical shale of Yanchang Formation and Longmaxi Formation. J. Eng. Geol. 2024, 32, 1176–1185. [Google Scholar]

- Wang, F.P.; Reed, R.M.; John, A.; Katherine, G. Pore Networks and Fluid Flow in Gas Shales. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009; Society of Petroleum Engineers: Richardson, TX, USA, 2009. SPE-124253-MS. [Google Scholar]

- Smyer, K.; Hamlin, H.; Eastwood, R.; Mcdaid, G. Variability of geologic properties of shale gas and tight oil plays. Trans. Gulf Coast Assoc. Geol. Soc. 2019, 69, 191–209. [Google Scholar]

- Wang, Y.; Zhu, Y.; Chen, S.; Li, W. Characteristics of the Nanoscale Pore Structure in Northwestern Hunan Shale Gas Reservoirs Using Field Emission Scanning Electron Microscopy, High-Pressure Mercury Intrusion, and Gas Adsorption. Energy Fuels 2014, 28, 945–955. [Google Scholar] [CrossRef]

- Yang, K.; Lu, X.; Xu, J.; Yin, H.; Hu, W. Preliminary verification of common calculation methods of pore size distribution of shale based on gas adsorption isotherm. Meitan Xuebao 2013, 38, 817–821. [Google Scholar]

- Yang, F.; Ning, Z.; Wang, Q.; Kong, D.; Peng, K.; Xiao, L. Fractal characteristics of nanopore in shale. Tianranqi Diqiu Kexue 2014, 25, 618–623. [Google Scholar]

- Zhao, D.; Guo, Y.; Xie, D.; Su, C.; Yang, Y.; Yu, Y. Fractal characteristics of shale reservoir pores based on nitrogen adsorption. Dongbei Shiyou Daxue Xuebao 2014, 38, 100–108. [Google Scholar]

- Thommes, M. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2016, 87, 1051–1069. [Google Scholar] [CrossRef]

- Zhao, L. Pore-Fissures Characteristics of the Shale/Mudstone Reservoirs and Their Influence on Shale Gas Enrichment in Jiangxi Province. Master’s Thesis, China University of Mining and Technology, Beijing, China, 2015. [Google Scholar]

- Kuila, U.; Prasad, M. Specific surface area and pore-size distribution in clays and shales. Geophys. Prospect. 2013, 61, 341–362. [Google Scholar] [CrossRef]

- Rouquerol, J.; Baron, G.; Denoyel, R.; Giesche, H.; Groen, J.; Klobes, P.; Levitz, P.; Neimark, A.V.; Rigby, S.; Skudas, R. Liquid intrusion and alternative methods for the characterization of macroporous materials (IUPAC Technical Report). Pure Appl. Chem. 2011, 84, 107–136. [Google Scholar] [CrossRef]

- Fu, S.; Fang, Q.; Li, A.; Li, Z.; Han, J.; Dang, X.; Han, W. Accurate characterization of full pore size distribution of tight sandstones by low-temperature nitrogen gas adsorption and high-pressure mercury intrusion combination method. Energy Sci. Eng. 2020, 8, 80–100. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, X.; Chen, Y.; Wang, Y.; Xu, R. Research on pore structure and fractal characteristics of shale based on Nuclear Magnetic Resonance experiments-taking the Wufeng Formation-Longmaxi Formation of Well YT2 in Jingmen area as an example. Coal Geol. China 2023, 35, 26–33. [Google Scholar]

- Ye, Y.; Chen, W.; Wang, H.; Song, J.; Ming, Y.; Dai, X.; Li, Z.; Sun, H.; Ma, X.; Liu, T.; et al. Characteristics and determinants of shale reservoirs in the Upper Permian Dalong Formation, Sichuan Basin. Shiyou Yu Tianranqi Dizhi 2024, 45, 979–991. [Google Scholar]

- He, W.; Wang, M.; Wang, X.; Meng, Q.A.; Wu, Y.; Lin, T.; Li, J.; Zhang, J. Pore Structure Characteristics and Affecting Factors of Shale in the First Member of the Qingshankou Formation in the Gulong Sag, Songliao Basin. ACS Omega 2022, 7, 35755–35773. [Google Scholar] [CrossRef]

- Wu, S.; Zhu, R.; Cui, J.; Cui, J.; Bai, B.; Zhang, X.; Jin, X.; Zhu, D.; You, J.; Li, X. Characteristics of lacustrine shale porosity evolution, Triassic Chang 7 Member, Ordos Basin, NW China. Petroleum Explor. Dev. 2015, 42, 185–195. [Google Scholar] [CrossRef]

- Li, X.; Zhu, H.; Zhang, K.; Li, Z.; Wang, Z. Pore characteristics and pore structure deformation evolution of ductile deformed shales in the Wufeng-Longmaxi Formation, southern China. Mar. Pet. Geol. 2021, 127, 104992. [Google Scholar] [CrossRef]

- Milliken, K.L.; Rudnicki, M.; Awwiller, D.N.; Zhang, T. Organic matter–hosted pore system, Marcellus Formation (Devonian), Pennsylvania. AAPG Bull. 2013, 97, 177–200. [Google Scholar] [CrossRef]

- Ji, L.; Zhang, T.; Milliken, K.; Qu, J.; Zhang, X. Experimental investigation of main controls to methane adsorption in clay-rich rocks. Appl. Geochem. 2012, 27, 2533–2545. [Google Scholar] [CrossRef]

- Wang, D. Study on Micro Pore Structure Characteristics and Controlling Factors of Shale Reservoir in Lower Sha4 Member of Damintun Sag. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2022. [Google Scholar]

- Liu, W.; Li, S.; Liu, C.; Liu, J.; Xu, L.; Li, Y.; Zhong, K.; Wu, Q.; He, Y. Pore structure characteristics and influencing factors of deep shale gas reservoir in the Longyi 1 subsection of northern part of western Chongqing region, Sichuan Basin. China Sciencepap. 2025, 20, 1–14. [Google Scholar]

- Chen, X.; Yuan, K.; Qin, Y.; Lin, T.; Jin, C.; Pan, W.; Guo, J.; Cao, S. Shale lithofacies characteristics and its influence on pore structure of the Carboniferous Dawuba Formation in Liupanshui area, Guizhou Province. Mar. Orig. Pet. Geol. 2021, 26, 335–344. [Google Scholar]

- Bai, L.; Gao, Z.; Wei, W.; Yang, B. A comparative study of the pore structure of deep–medium shale in the Longmaxi Formation of the southern Sichuan basin. Tezhong Youqicang 2023, 30, 54–62. [Google Scholar]

- Zhang, M.; Hu, M.; Wei, S.; Cai, Q.; Fu, W.; Shi, F.; Zhang, L.; Ding, H. Factors Controlling the Pore Development of Low-Mature Marine–Continental Transitional Shale: A Case Study of the Upper Permian Longtan Shale, Western Guizhou, South China. J. Mar. Sci. Eng. 2023, 11, 1862. [Google Scholar] [CrossRef]

| Sample | Depth (m) | Total Pore Volume (cm3/g) | Specific Surface Area (m2/g) | Average Pore Diameter (nm) | Porosity (%) |

|---|---|---|---|---|---|

| QX135 | 581.69 | 0.0073 | 0.435 | 66.8 | 1.8692 |

| QX130 | 588.05 | 0.0085 | 0.728 | 46.6 | 2.2052 |

| QX131 | 589.30 | 0.0094 | 0.317 | 119.2 | 2.3373 |

| QX127 | 594.57 | 0.0060 | 0.315 | 76.0 | 1.4556 |

| QX125 | 598.38 | 0.0083 | 0.511 | 64.6 | 1.9635 |

| QX123 | 606.90 | 0.0068 | 0.287 | 94.2 | 1.6823 |

| QX121 | 610.55 | 0.0091 | 0.147 | 246.9 | 2.2825 |

| Sample | Depth | Pore Volume (cm3/g) | Total Pore Volume (cm3/g) | Specific Surface Area (m2/g) | Total Specific Surface Area (m2/g) | Average Pore Diameter (LTNA) (nm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Micropore | Mesopore | Macropore | Micropore | Mesopore | Macropore | |||||

| QX-135 | 581.69 | 0.0092 | 0.0047 | 0.0027 | 0.0166 | 9.6521 | 7.5975 | 0.8186 | 18.0682 | 3.6690 |

| QX-130 | 588.05 | 0.0097 | 0.0080 | 0.0021 | 0.0198 | 11.8571 | 13.5645 | 0.7521 | 26.1737 | 3.0307 |

| QX-131 | 589.03 | 0.0091 | 0.0084 | 0.0025 | 0.0200 | 11.5521 | 14.0828 | 0.7253 | 26.3603 | 3.0346 |

| QX-125 | 598.38 | 0.0097 | 0.0088 | 0.0026 | 0.0211 | 12.9752 | 14.9452 | 0.8442 | 28.7736 | 2.9223 |

| QX-121 | 610.55 | 0.0053 | 0.0069 | 0.0019 | 0.0141 | 7.8966 | 11.7496 | 0.4966 | 20.1428 | 2.7904 |

| Mean | 593.54 | 0.0086 | 0.0074 | 0.0024 | 0.0183 | 10.7866 | 12.3879 | 0.7274 | 23.9037 | 3.0894 |

| Sample | Volume (cm3) | Water-Saturated Porosity (%) | Post-Centrifugation Porosity (%) | Bound Fluid Saturation (%) | Free Fluid Saturation (%) |

|---|---|---|---|---|---|

| QX-135 | 12.004 | 3.628 | 2.781 | 86.051 | 13.949 |

| QX-127 | 12.004 | 1.799 | 1.617 | 95.154 | 4.846 |

| QX-123 | 14.382 | 1.735 | 1.452 | 88.151 | 11.849 |

| Sample | Fractal Fitting Equations for High-Pressure Pressurized Mercury | Fractal Dimension | ||

|---|---|---|---|---|

| >50 nm | <50 nm | D1 | D2 | |

| QX-135 | y = −0.1705x − 0.0428 | y = −0.8912x + 2.5155 | 2.8275 | 2.1088 |

| QX-130 | y = −0.1592x − 0.0653 | y = −2.1035x + 7.4693 | 2.8408 | 0.8965 |

| QX-131 | y = −0.2236x − 0.1572 | y = −1.2588x + 3.7215 | 2.7764 | 1.7412 |

| QX-127 | y = −0.2164x − 0.0338 | y = −2.1909x + 7.6074 | 2.7836 | 0.8091 |

| QX-125 | y = −0.1796x − 0.0570 | y = −1.9646x + 6.809 | 2.8204 | 1.0354 |

| QX-121 | y = −0.3437x − 0.1023 | y = −1.2526x + 3.3841 | 2.6563 | 1.7474 |

| Sample | Nitrogen Adsorption Fractal Fitting Equation | Fractal Dimension | ||

|---|---|---|---|---|

| P/P0 < 0.5 | P/P0 > 0.5 | D1 | D2 | |

| QX-137 | y = −0.1020x + 1.1082 | y = −0.4133x + 1.4588 | 2.8777 | 2.7387 |

| QX-135 | y = −0.1223x + 1.8491 | y = −0.2613x + 1.7659 | 2.8904 | 2.0967 |

| QX-130 | y = −0.0812x + 2.1976 | y = −0.2456x + 2.1273 | 2.9188 | 2.7544 |

| QX-131 | y = −0.0786x + 2.2185 | y = −0.2509x + 2.1359 | 2.9214 | 2.7491 |

| QX-125 | y = −0.0745x + 2.2703 | y = 0.2087x + 2.2158 | 2.9255 | 2.7913 |

| QX-121 | y = −0.0608x + 1.9264 | y = −0.2267x + 1.8585 | 2.9392 | 2.7733 |

| QX-108 | y = −0.1096x + 0.3256 | y = −0.9033x + 0.5141 | 2.8980 | 2.5867 |

| QX-106 | y = −0.1613x + 1.1269 | y = −0.7092x + 1.3050 | 2.8387 | 2.2908 |

| QX-103 | y = −0.1179x + 1.5643 | y = −0.4753x + 1.6072 | 2.8821 | 2.5247 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Y.; Zou, N.; Zhang, D.; Chen, Y.; Ye, Z.; Feng, X.; Du, W. Pore Structure Characteristics and Controlling Factors of the Lower Cambrian Niutitang Formation Shale in Northern Guizhou: A Case Study of Well QX1. Fractal Fract. 2025, 9, 524. https://doi.org/10.3390/fractalfract9080524

Yin Y, Zou N, Zhang D, Chen Y, Ye Z, Feng X, Du W. Pore Structure Characteristics and Controlling Factors of the Lower Cambrian Niutitang Formation Shale in Northern Guizhou: A Case Study of Well QX1. Fractal and Fractional. 2025; 9(8):524. https://doi.org/10.3390/fractalfract9080524

Chicago/Turabian StyleYin, Yuanyan, Niuniu Zou, Daquan Zhang, Yi Chen, Zhilong Ye, Xia Feng, and Wei Du. 2025. "Pore Structure Characteristics and Controlling Factors of the Lower Cambrian Niutitang Formation Shale in Northern Guizhou: A Case Study of Well QX1" Fractal and Fractional 9, no. 8: 524. https://doi.org/10.3390/fractalfract9080524

APA StyleYin, Y., Zou, N., Zhang, D., Chen, Y., Ye, Z., Feng, X., & Du, W. (2025). Pore Structure Characteristics and Controlling Factors of the Lower Cambrian Niutitang Formation Shale in Northern Guizhou: A Case Study of Well QX1. Fractal and Fractional, 9(8), 524. https://doi.org/10.3390/fractalfract9080524