Modeling Porosity Surface of 3D Selective Laser Melting Metal Materials

Abstract

1. Introduction

2. Material Preparation and Experimental Work, Methodology, and Modeling

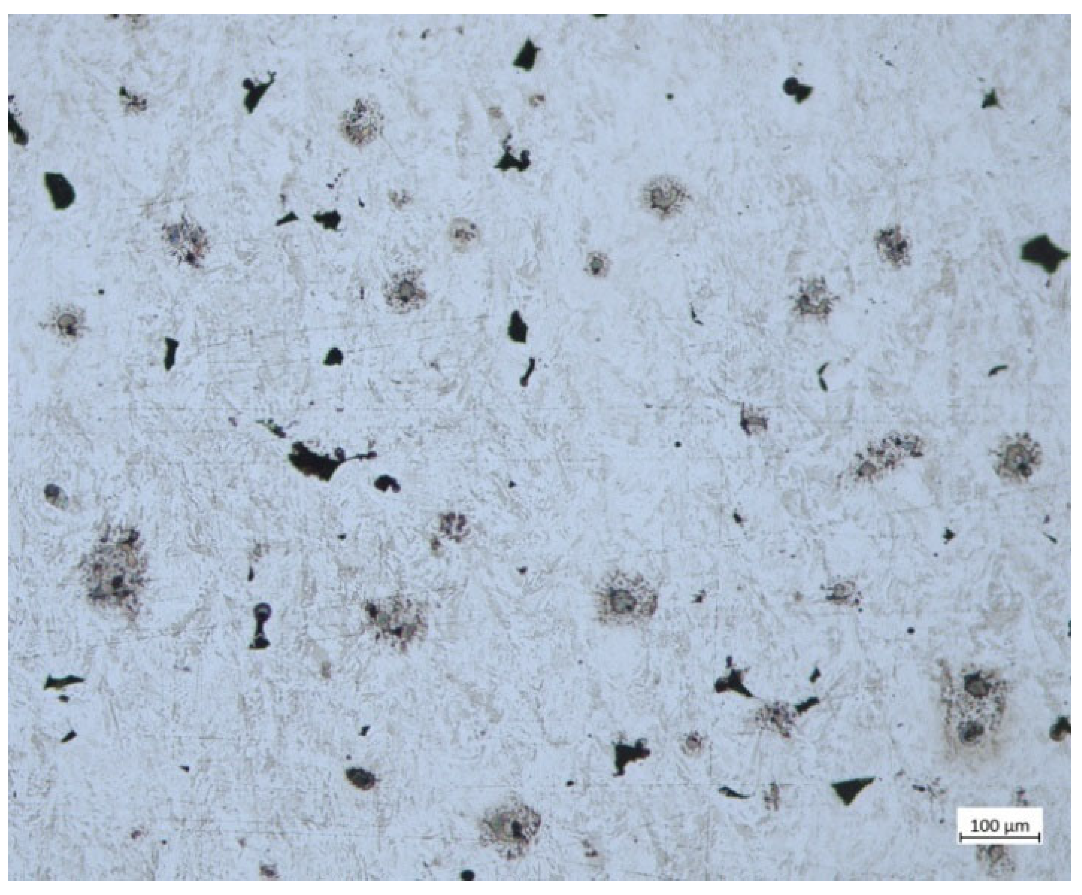

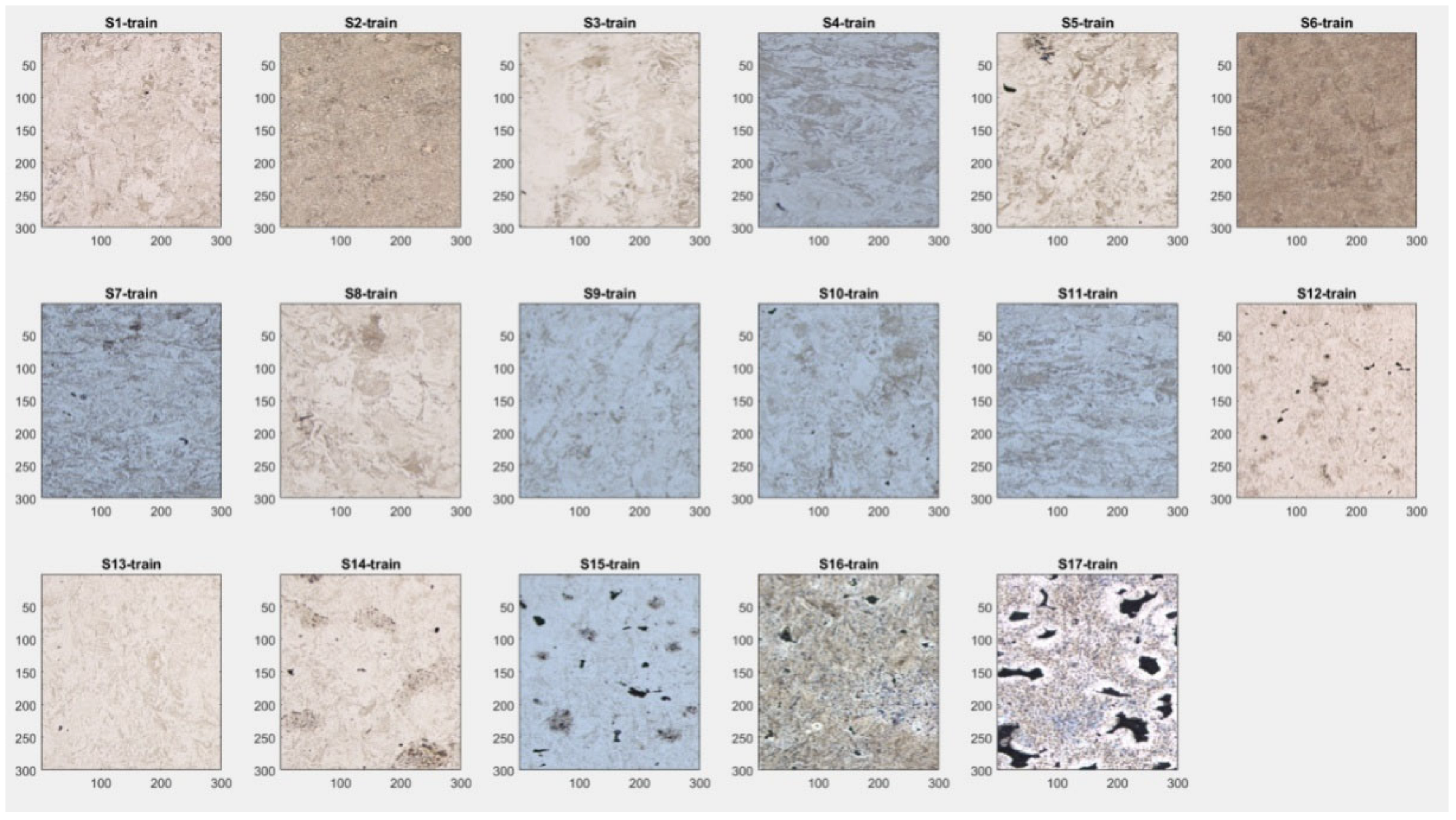

2.1. Experimental Work and Material Preparation

2.2. Methodology

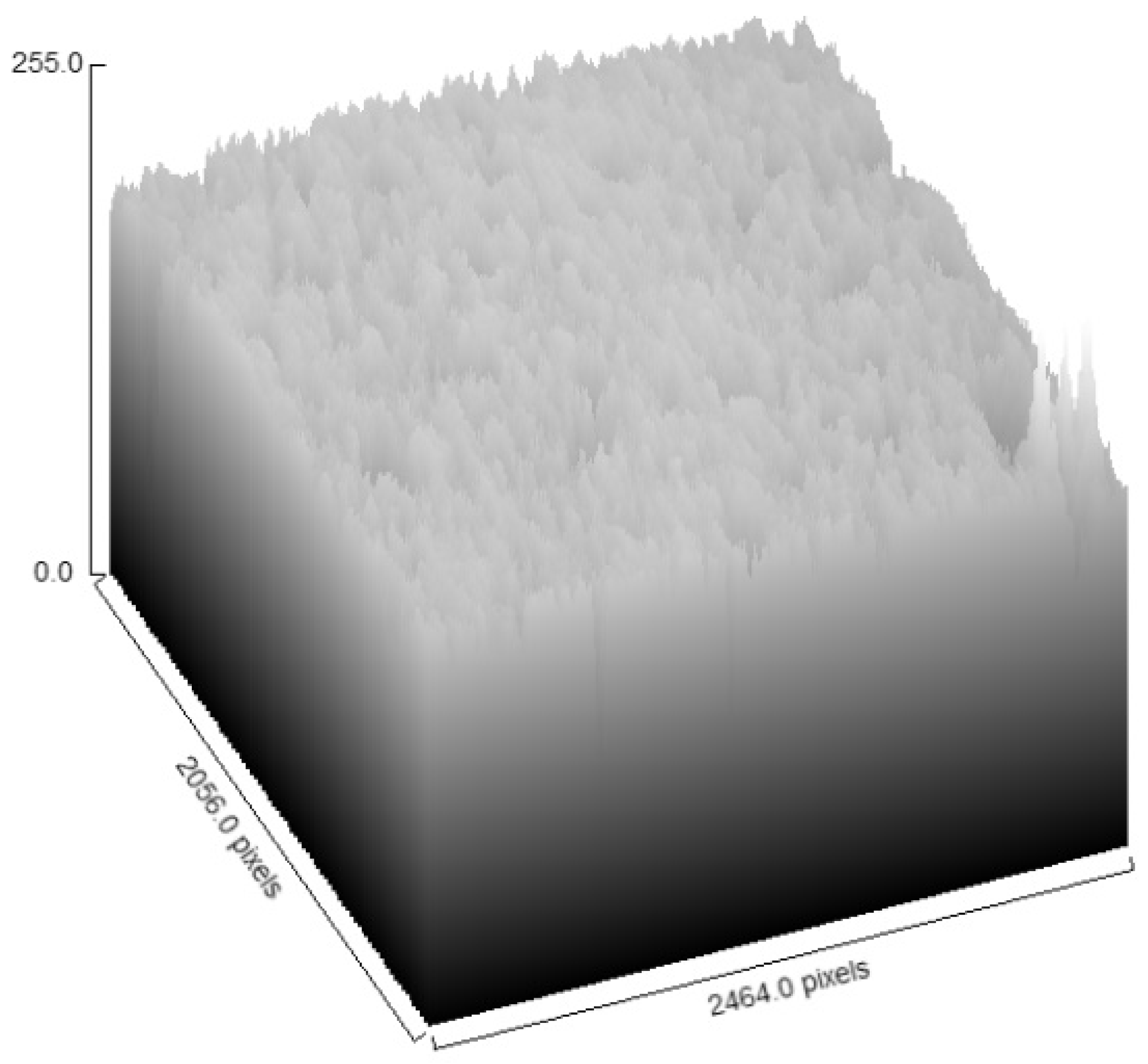

2.2.1. Fractals

- The digital image’s pixel is rectangular, which causes ‘rectangularization’ for tiny islands (A < 30) to produce erroneous estimations of D.

- There are also issues with edge effects, with biased estimations of D provided by islands that touch the image’s edges.

- “Staircase” impact of the 45° orientation’s perimeter since more pixels are needed.

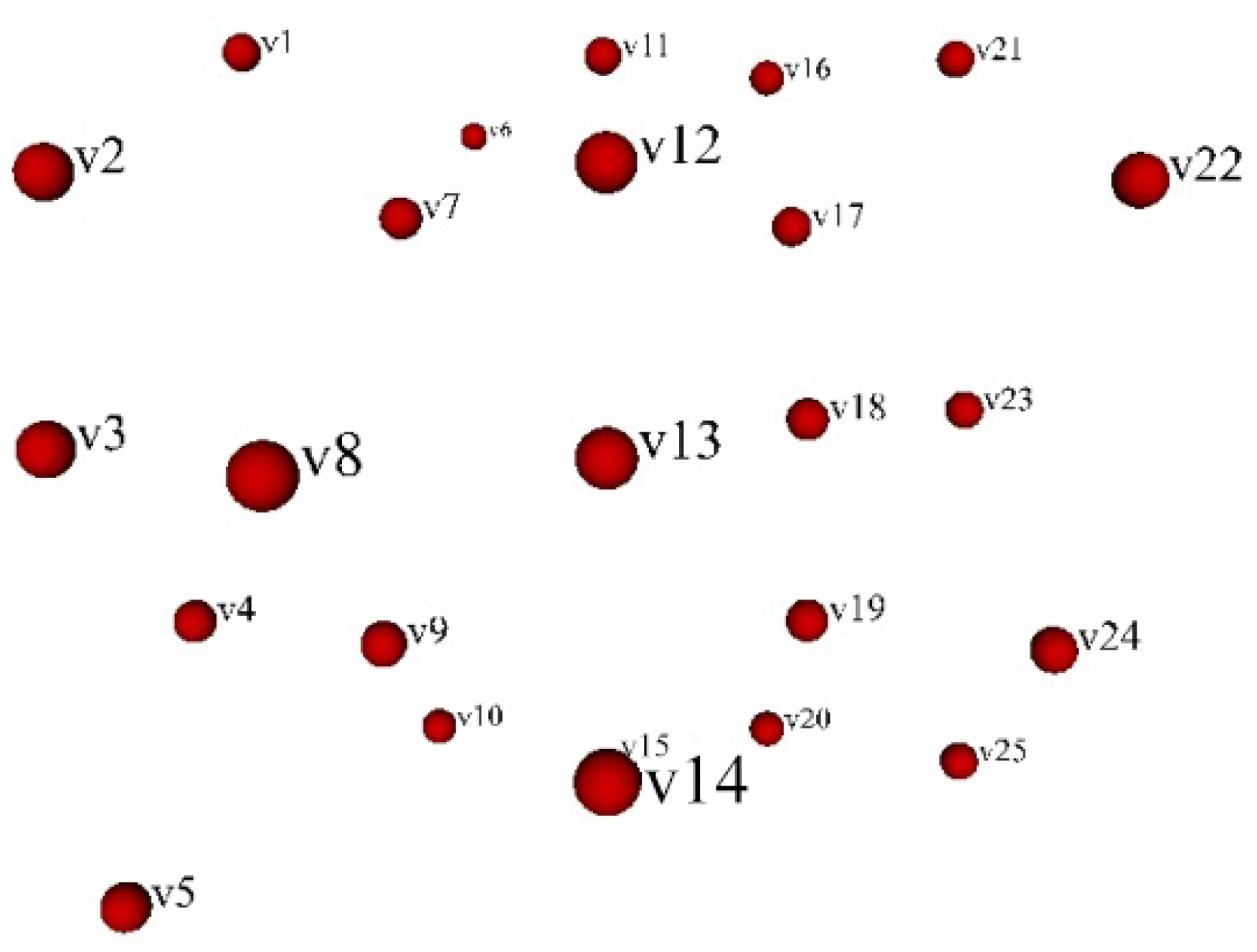

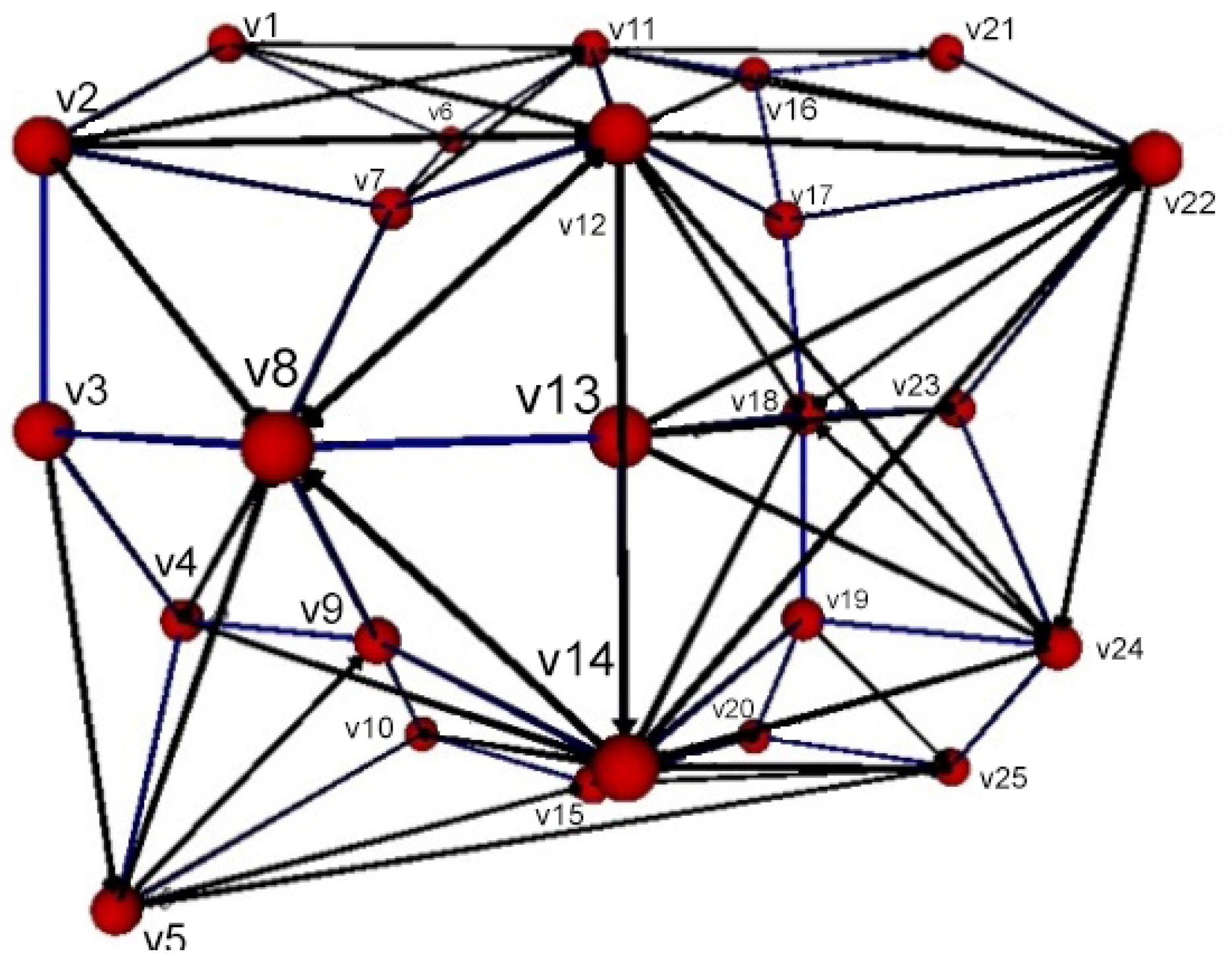

2.2.2. Network Theory

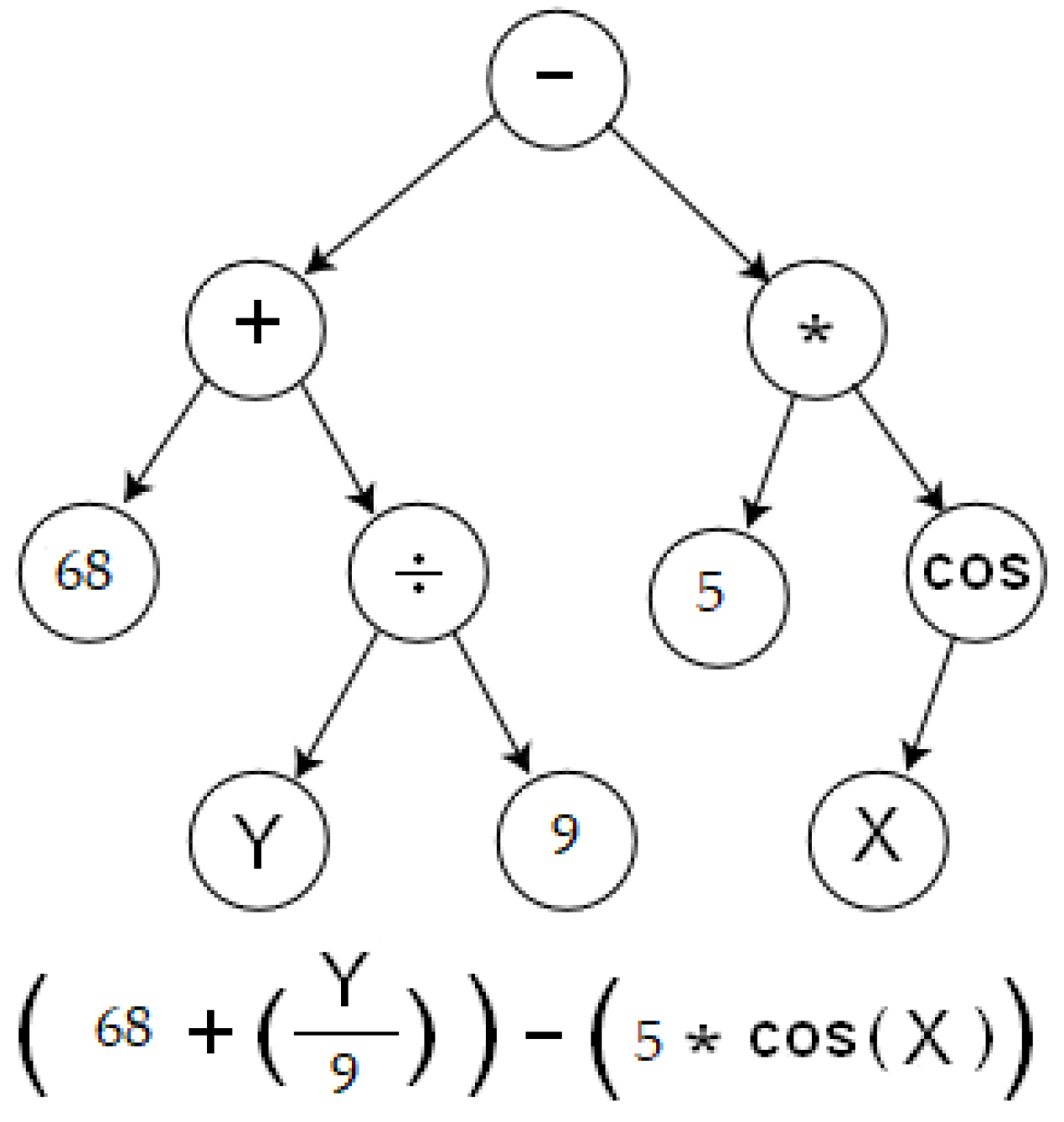

2.2.3. Modeling

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Groth, J.-H.; Magnini, M.; Tuck, C.; Clare, A. Stochastic design for additive manufacture of true biomimetic populations. Addit. Manuf. 2022, 55, 102739. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Soni, N.; Renna, G.; Leo, P. Advancements in Metal Processing Additive Technologies: Selective Laser Melting (SLM). Metals 2024, 14, 1081. [Google Scholar] [CrossRef]

- ASTM F1472; Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Alloy for Surgical Implant Applications (UNS R56400). ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM B348; Standard Specification for Titanium and Titanium Alloy Bars and Billets. ASTM International: West Conshohocken, PA, USA, 2019.

- ISO 5832-3; Implants for Surgery—Metallic Materials. Part 3: Wrought Titanium 6-Aluminium 4-Vanadium Alloy. International Organization for Standardization: Geneva, Switzerland, 2021.

- Meregalli, V.; Alberti, F.; Madan, C.R.; Meneguzzo, P.; Miola, A.; Trevisan, N.; Sambataro, F.; Favaro, A.; Collantoni, E. Cortical complexity estimation using fractal dimension: A systematic review of the literature on clinical and nonclinical samples. Eur. J. Neurosci. 2022, 55, 1547–1583. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Hollstein, B.; Töpfer, T.; Pfeffer, J. Collecting Egocentric Network Data with Visual Tools. A Comparative Study. Netw. Sci. 2020, 8, 223–250. [Google Scholar] [CrossRef]

- Babič, M.; Marinković, D.; Kovačič, M.; ŠTER, B.; Calì, M. A new method of quantifying the complexity of fractal networks. Fractal Fract. 2022, 6, 282. [Google Scholar] [CrossRef]

- Gao, H.; Kou, G.; Liang, H.; Zhang, H.; Chao, X.; Li, C.C.; Dong, Y. Machine learning in business and finance: A literature review and research opportunities. Financ. Innov. 2024, 10, 86. [Google Scholar] [CrossRef]

- Alamri, N.M.H.; Packianather, M.; Bigot, S. Predicting the Porosity in Selective Laser Melting Parts Using Hybrid Regression Convolutional Neural Network. Appl. Sci. 2022, 12, 12571. [Google Scholar] [CrossRef]

- Oster, S.; Scheuschner, N.; Chand, K.; Altenburg, S.J. Local porosity prediction in metal powder bed fusion using in-situ thermography: A comparative study of machine learning techniques. Addit. Manuf. 2024, 95, 104502. [Google Scholar] [CrossRef]

- Lough, C.S.; Liu, T.; Wang, X.; Brown, B.; Landers, R.G.; Bristow, D.A.; Drallmeier, J.A.; Kinzel, E.C. Local prediction of Laser Powder Bed Fusion porosity by short-wave infrared imaging thermal feature porosity probability maps. J. Mater. Process. Technol. 2022, 302, 117473. [Google Scholar] [CrossRef]

- Malashin, I.; Martysyuk, D.; Tynchenko, V.; Nelyub, V.; Borodulin, A.; Gantimurov, A.; Nisan, A.; Novozhilov, N.; Zelentsov, V.; Filimonov, A.; et al. Controlled Porosity of Selective Laser Melting-Produced Thermal Pipes: Experimental Analysis and Machine Learning Approach for Pore Recognition on Pipes Surfaces. Sensors 2024, 24, 4959. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Hou, W.; Wang, X.; Chu, S.; Yang, Z. Microstructure, porosity and mechanical properties of selective laser melted AlSi10Mg. Chin. J. Aeronaut. 2020, 33, 2043–2054. [Google Scholar] [CrossRef]

- EOS GmbH. EOS M 290 the All-Rounder for 3D Printed Metal Parts. Available online: https://www.eos.info/metal-solutions/metal-printers/eos-m-290#key-features (accessed on 14 October 2020).

- Bochnia, J.; Kozior, T.; Zyz, J. The Mechanical Properties of Direct Metal Laser Sintered Thin-Walled Maraging Steel (MS1) Elements. Materials 2023, 16, 4699. [Google Scholar] [CrossRef] [PubMed]

- Agusdianita, N.; Widada, W.; Afriani, N.H.; Herawati, H.; Herawaty, D.; Nugroho, K.U.Z. The exploration of the elementary geometry concepts based on Tabot culture in Bengkulu. J. Phys. Conf. Ser. 2021, 1731, 012054. [Google Scholar] [CrossRef]

- Dobrescu, G.; Papa, F.; State, R. Fractal Analysis and Fractal Dimension in Materials Chemistry. Fractal Fract. 2024, 8, 583. [Google Scholar] [CrossRef]

- Kowal, M.; Skobel, M.; Korbicz, J.; Monczak, R. Stochastic Geometry for Automatic Assessment of Ki-67 Index in Breast Cancer Preparations Bioinformatics and Biomedical Engineering; Springer International Publishing: Cham, Switzerland, 2018; pp. 151–162. [Google Scholar] [CrossRef]

- Hashemi, R.; Darabi, H.; Hashemi, M.; Wang, J. Graph theory in ecological network analysis: A systematic review for connectivity assessment. J. Clean. Prod. 2024, 472, 143504. [Google Scholar] [CrossRef]

- Babič, M.; Hluchy, L.; Krammer, P.; Matovič, B.; Kumar, R.; Kovač, P. New method for constructing a visibility graph-network in 3D space and new hybrid system of modeling. J. Comput. Inform. 2017, 36, 1107–1126. [Google Scholar] [CrossRef]

- Kovačič, M.; Župerl, U. Continuous caster final electromagnetic stirrers position optimization using genetic programming. Mater. Manuf. Process. 2023, 38, 2009–2017. [Google Scholar] [CrossRef]

- Kovačič, M.; Župerl, U.; Brezočnik, M. Optimization of the rhomboidity of continuously cast billets using linear regression and genetic programming: A real industrial study. Adv. Prod. Eng. Manag. 2022, 17, 469–478. [Google Scholar] [CrossRef]

- Kovačič, M.; Župerl, U. Modeling of tensile test results for low alloy steels by linear regression and genetic programming taking into account the non-metallic inclusions. Metals 2022, 12, 1343. [Google Scholar] [CrossRef]

- Al-Haija, Q.A.; Smadi, M.; Al-Bataineh, O.M. Identifying phasic dopamine releases using darknet-19 convolutional neural network. In Proceedings of the 2021 IEEE International IOT, Electronics and Mechatronics Conference (IEMTRONICS), Toronto, ON, Canada, 21–24 April 2021; pp. 1–5. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G. ImageNet Classification with Deep Convolutional Neural Networks. In Proceedings of the NIPS 2012, Lake Tahoe, NV, USA, 3–6 December 2012. [Google Scholar]

| Specimen | Power (W) X1 | Speed (mm/s) X2 | FD X3 | Density η X4 |

|---|---|---|---|---|

| S1 | 320 | 1000 | 1.52 | 0.25 |

| S2 | 320 | 1150 | 1.47 | 0.54 |

| S3 | 320 | 1300 | 1.69 | 0.73 |

| S4 | 270 | 850 | 1.75 | 0.62 |

| S5 | 270 | 1000 | 1.71 | 0.72 |

| S6 | 270 | 1150 | 1.54 | 0.65 |

| S7 | 270 | 1300 | 1.51 | 0.56 |

| S8 | 220 | 700 | 1.68 | 0.81 |

| S9 | 220 | 850 | 1.82 | 0.92 |

| S10 | 220 | 1000 | 1.65 | 0.62 |

| S11 | 220 | 1150 | 1.71 | 0.38 |

| S12 | 220 | 1300 | 1.84 | 0.67 |

| S13 | 170 | 700 | 1.59 | 0.36 |

| S14 | 170 | 850 | 1.45 | 0.56 |

| S15 | 170 | 1000 | 1.54 | 0.38 |

| S16 | 170 | 1150 | 1.63 | 0.87 |

| S17 | 170 | 1300 | 1.57 | 0.75 |

| Specimen | Porosity (%) |

|---|---|

| S1 | 0.02 |

| S2 | 0.04 |

| S3 | 0.17 |

| S4 | 0.04 |

| S5 | 0.07 |

| S6 | 0.06 |

| S7 | 0.52 |

| S8 | 0.07 |

| S9 | 0.03 |

| S10 | 0.08 |

| S11 | 0.34 |

| S12 | 1.79 |

| S13 | 0.35 |

| S14 | 0.07 |

| S15 | 1.37 |

| S16 | 4.06 |

| S17 | 7.33 |

| Specimen | GP Porosity | CNN Porosity |

|---|---|---|

| S1 | 0.019932 | 0.0529 |

| S2 | 0.040051 | 0.0163 |

| S3 | 0.174835 | 0.1362 |

| S4 | 0.042027 | 0.0739 |

| S5 | 0.044027 | 0.0603 |

| S6 | 0.057547 | 0.1635 |

| S7 | 0.259549 | 0.4482 |

| S8 | 0.074928 | 0.0511 |

| S9 | 0.029815 | 0.2078 |

| S10 | 0.07989 | 0.2698 |

| S11 | 0.350045 | 1.1405 |

| S12 | 0.061404 | 2.8863 |

| S13 | 0.049603 | 0.4912 |

| S14 | 0.072834 | 0.2193 |

| S15 | 0.042733 | 1.1446 |

| S16 | 4.33582 | 2.8921 |

| S17 | 0.073286 | 6.1677 |

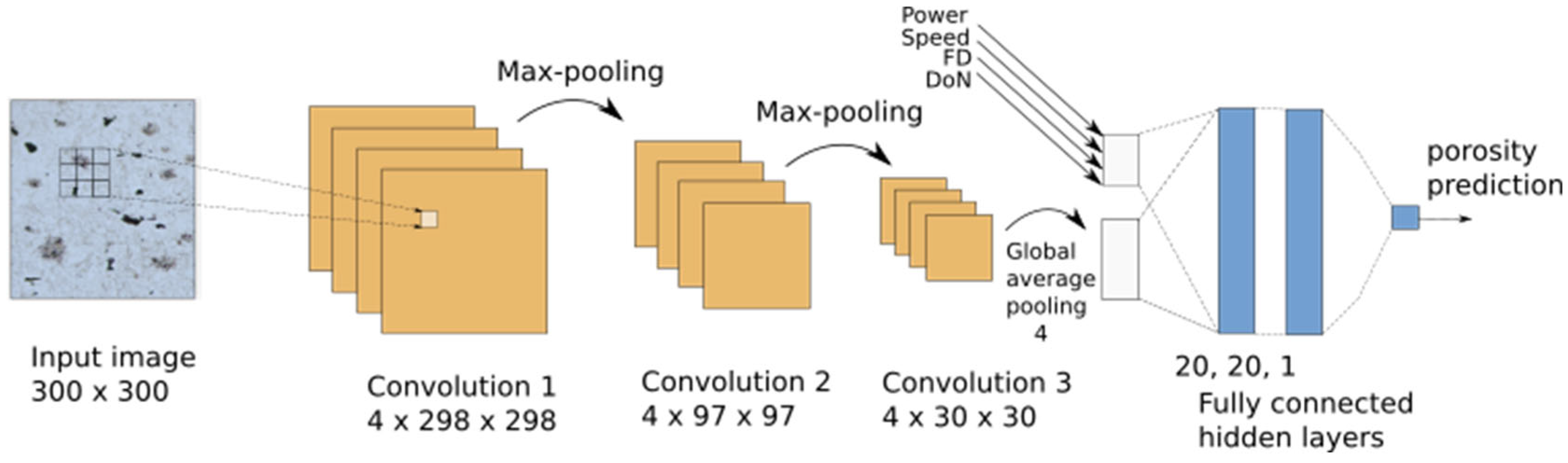

| Layer (Type) | Output Shape | Param # | Connected to |

|---|---|---|---|

| input_1 (InputLayer) | (300, 300, 1) | 0 | |

| rescaling (Rescaling) | (300, 300, 1) | 0 | input_1 |

| conv2d (Conv2D) | (298, 298, 4) | 40 | rescaling |

| max_pooling2d (MaxPooling2D) | (99, 99, 4) | 0 | conv2d |

| conv2d_1 (Conv2D) | (97, 97, 4) | 148 | max_pooling2d |

| max_pooling2d_1 (MaxPooling2D) | (32, 32, 4) | 0 | conv2d_1 |

| conv2d_2 (Conv2D) | (30, 30, 4) | 148 | max_pooling2d_1 |

| global_average_pooling2d (Global) | (4) | 0 | conv2d_2 |

| flatten (Flatten) | (4) | 0 | global_average_pooling2d |

| input_2 (InputLayer) | (4) | 0 | |

| concatenate (Concatenate) | (8) | 0 | flatten, input_2 |

| dense (Dense) | (20) | 180 | concatenate |

| dense_1 (Dense) | (20) | 420 | dense |

| dense_2 (Dense) | (1) | 21 | dense_1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babič, M.; Šturm, R.; Gălățanu, T.-F.; Száva, I.-R.; Száva, I. Modeling Porosity Surface of 3D Selective Laser Melting Metal Materials. Fractal Fract. 2025, 9, 331. https://doi.org/10.3390/fractalfract9060331

Babič M, Šturm R, Gălățanu T-F, Száva I-R, Száva I. Modeling Porosity Surface of 3D Selective Laser Melting Metal Materials. Fractal and Fractional. 2025; 9(6):331. https://doi.org/10.3390/fractalfract9060331

Chicago/Turabian StyleBabič, Matej, Roman Šturm, Teofil-Florin Gălățanu, Ildikó-Renáta Száva, and Ioan Száva. 2025. "Modeling Porosity Surface of 3D Selective Laser Melting Metal Materials" Fractal and Fractional 9, no. 6: 331. https://doi.org/10.3390/fractalfract9060331

APA StyleBabič, M., Šturm, R., Gălățanu, T.-F., Száva, I.-R., & Száva, I. (2025). Modeling Porosity Surface of 3D Selective Laser Melting Metal Materials. Fractal and Fractional, 9(6), 331. https://doi.org/10.3390/fractalfract9060331