Variable Fractional Order Dynamic Analysis of Viscoelastic Pipes Using Shifted Bernstein Polynomial-Based Numerical Algorithm

Abstract

1. Introduction

2. Preliminaries

3. Bernstein Polynomial Characteristics and Descriptions

4. Equation of Motion

5. Numerical Algorithms

5.1. Approximate Displacement Function

5.2. Polynomial Operator Matrices for Integer-Order Bernstein Functions

6. Convergence Analysis

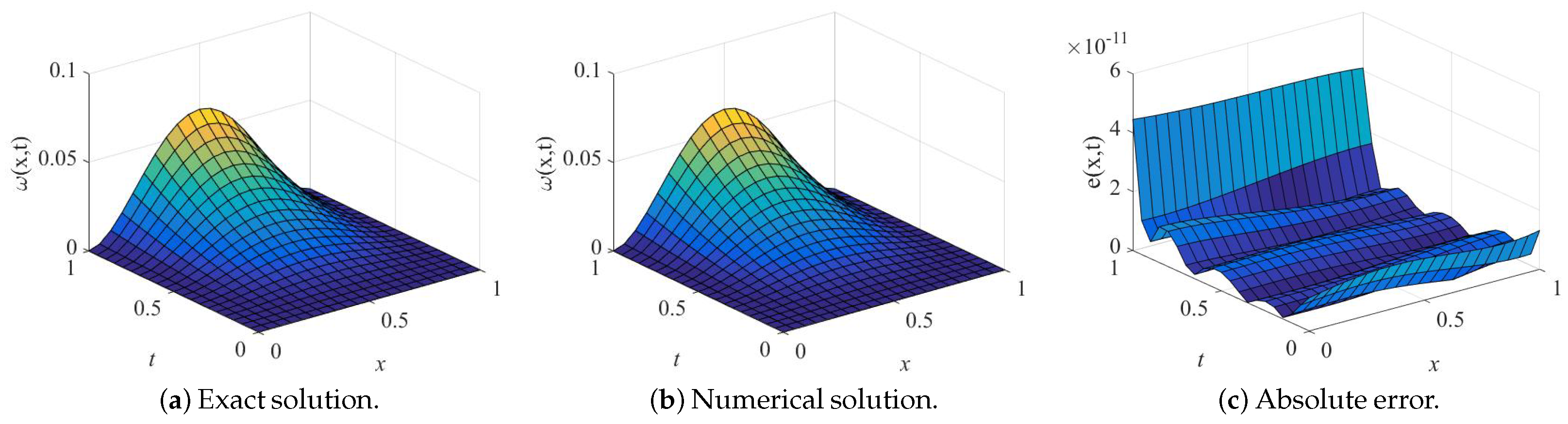

7. Numerical Examples of Dimensionless Equations

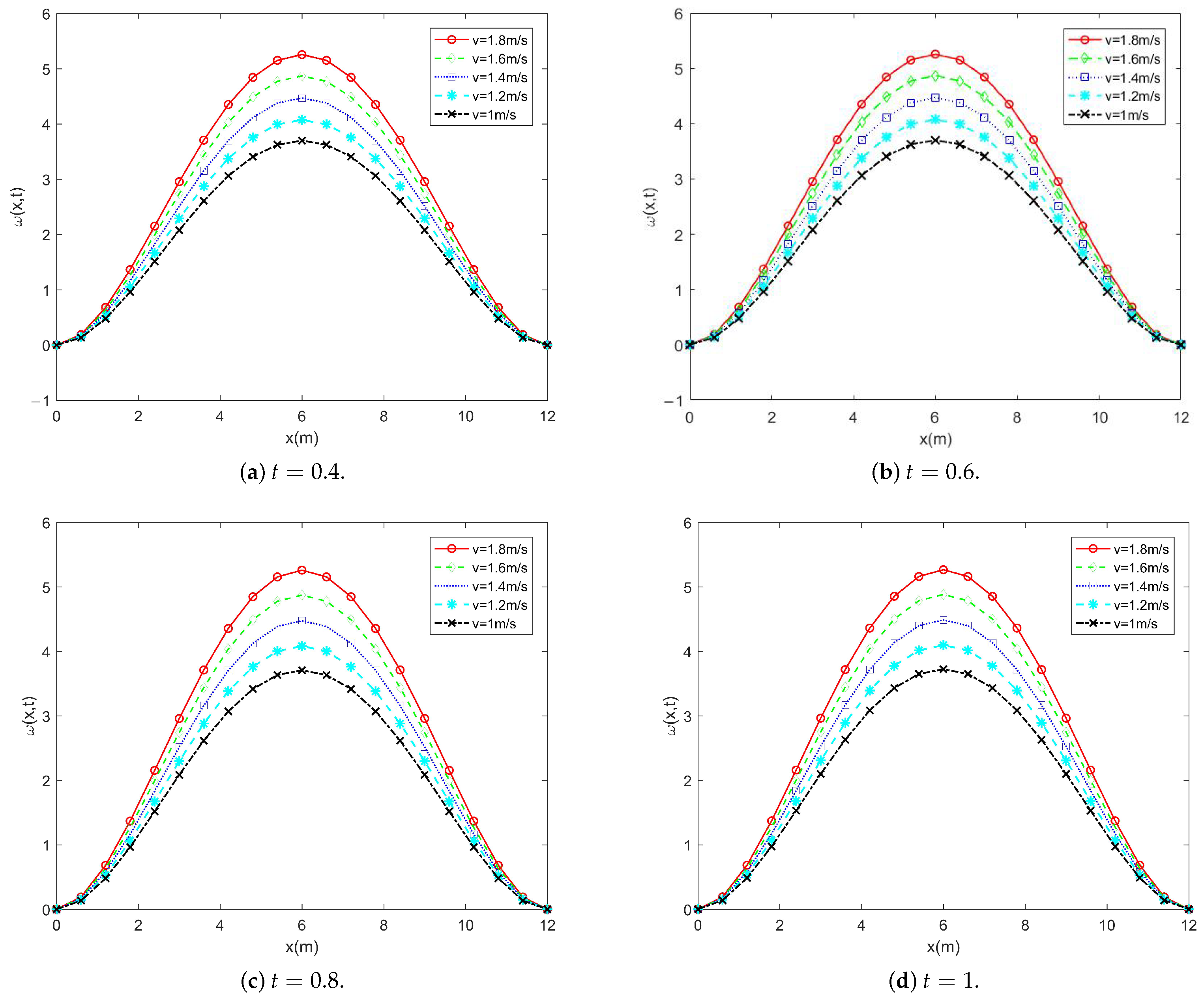

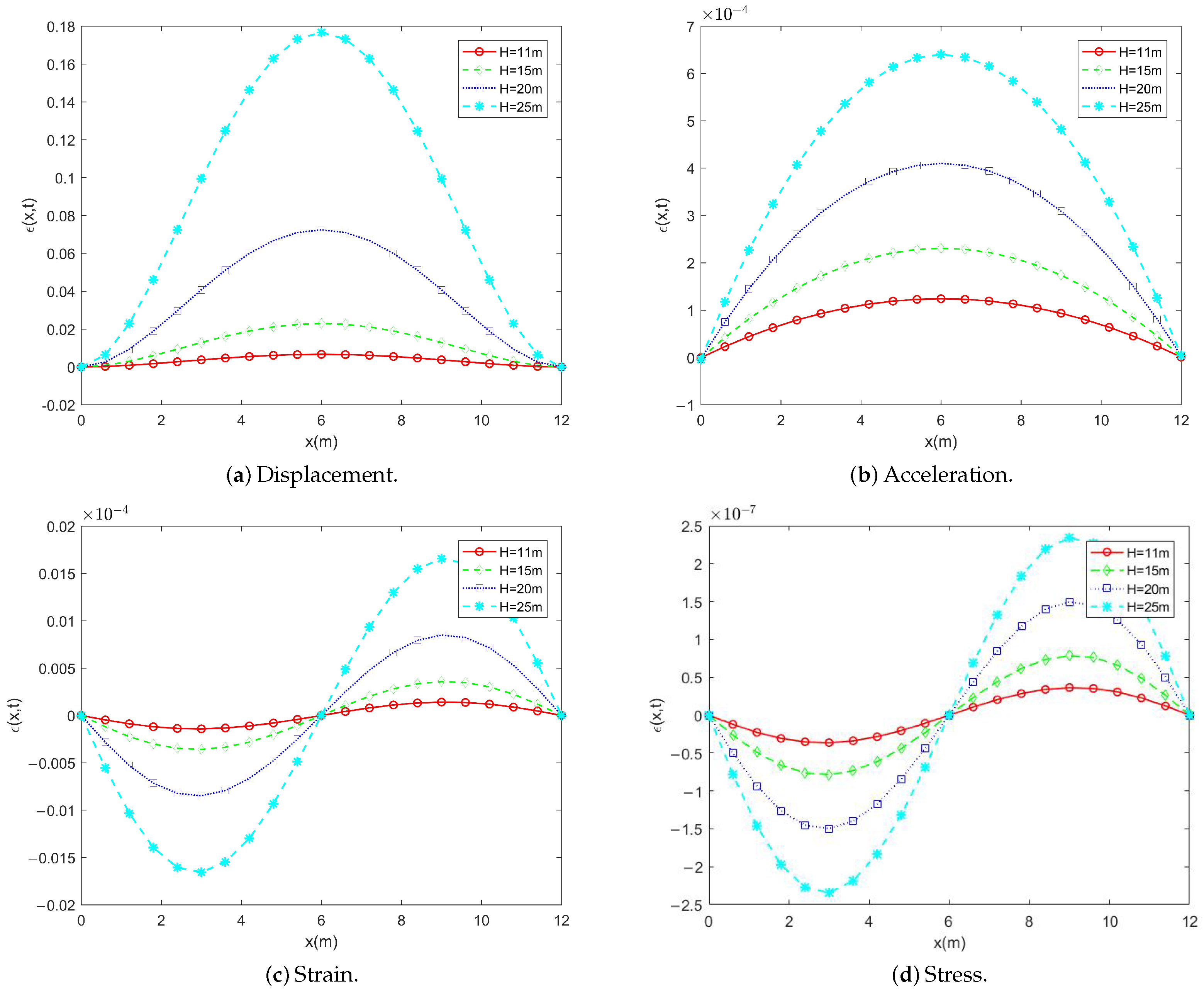

Dynamic Analysis

8. Conclusions

- A variable-order fractional operator matrix is constructed using shifted Bernstein polynomials, and discretization transforms the governing equation into an algebraic form suitable for computation. Combined with dimensionless formulation and dynamic analysis, the proposed method demonstrates high efficiency and accuracy in solving variable fractional-order models of viscoelastic fluid-conveying pipes.

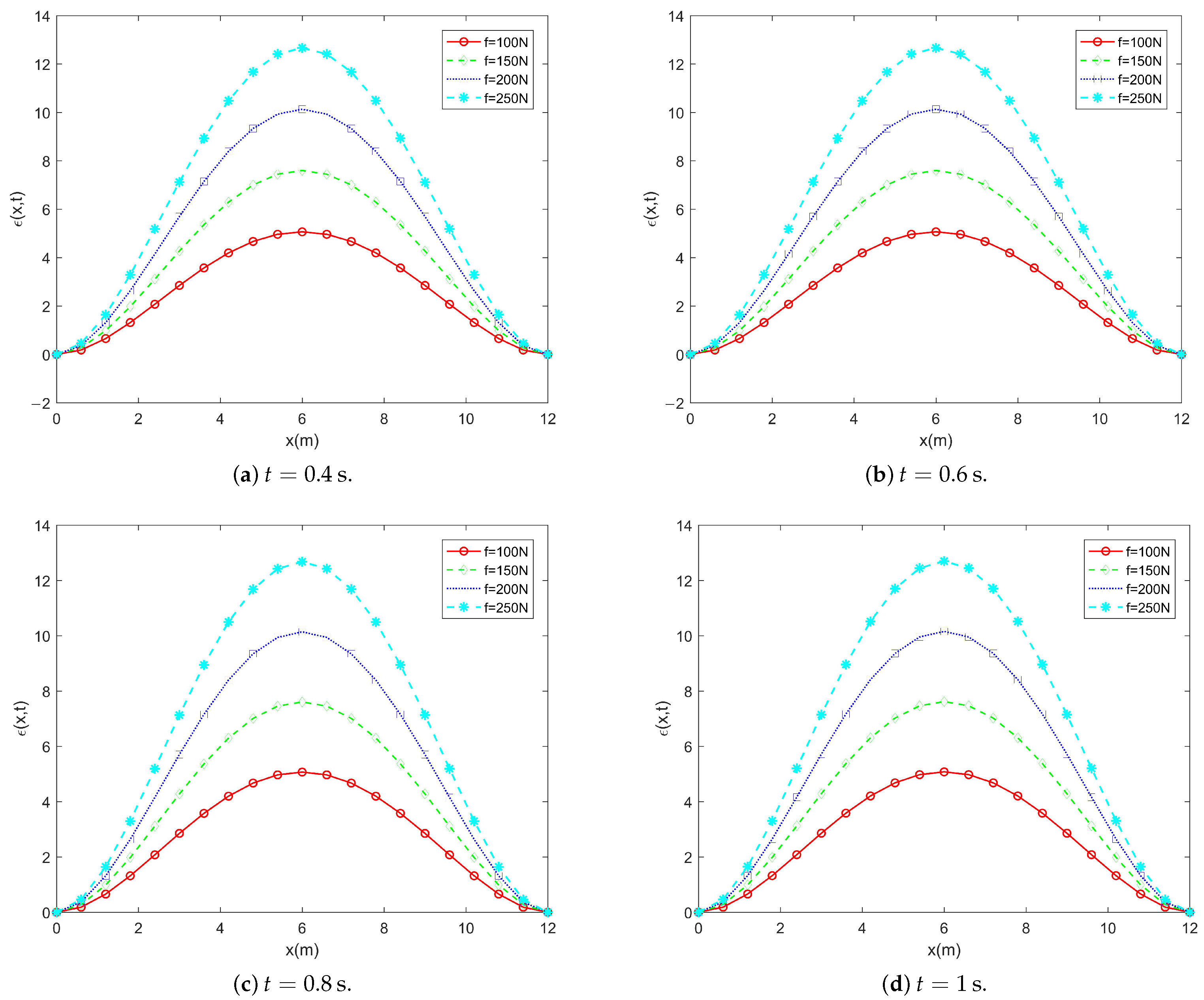

- Numerical results indicate that both fluid velocity and external loading significantly affect pipe displacement with increases in either factor leading to larger deformations over time. In addition, pipe length amplifies displacement, acceleration, strain, and stress in a nonlinear manner with peak responses typically occurring near the midspan.

- The results of this study highlight the pronounced time-dependent and memory effects of viscoelastic materials, providing valuable insights into the dynamic behavior of pipes conveying fluid.

- Future research may focus on extending the proposed Bernstein polynomial-based algorithm to more complex structures, such as multi-span or branched viscoelastic pipeline networks. Incorporating temperature-dependent or pressure-dependent fractional orders could further enhance the model’s realism. Additionally, coupling this framework with optimization techniques and experimental validation would provide a deeper understanding of the interplay between fractional-order dynamics and real-world engineering applications. The methodology can also be adapted to other fields—such as biomathematics, geophysics, and smart materials—to model systems exhibiting hereditary or memory effects under variable fractional-order behavior.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations

| Abbreviation | Full Form |

| FKV | Fractional-order Kelvin–Voigt model |

| VOFC | Variable-order fractional calculus |

| VFPDE | Variable fractional partial differential equation |

| PINN | Physics-informed neural network |

| FC | Fractional calculus |

| MATLAB | MATLAB software |

| PDE | Partial differential equation |

References

- Ananthapadmanabhan, S.; Saravanan, U. Numerical techniques for solving truss problems involving viscoelastic materials. Int. J. Non-Linear Mech. 2020, 122, 103479. [Google Scholar] [CrossRef]

- Yun, K.S.; Youn, S.K. Microstructural topology optimization of viscoelastic materials of damped structures subjected to dynamic loads. Int. J. Solids Struct. 2018, 147, 67–79. [Google Scholar] [CrossRef]

- Rajabi, K.; Hosseini-Hashemi, S. On the application of viscoelastic orthotropic double-nanoplates systems as nanoscale mass-sensors via the generalized Hooke’s law for viscoelastic materials and Eringen’s nonlocal elasticity theory. Compos. Struct. 2017, 180, 105–115. [Google Scholar] [CrossRef]

- De Lima, A.; Rade, D.; Lacerda, H.; Araújo, C. An investigation of the self-heating phenomenon in viscoelastic materials subjected to cyclic loadings accounting for prestress. Mech. Syst. Signal Process. 2015, 58, 115–127. [Google Scholar] [CrossRef]

- Fang, J.; Näsholm, S.P.; Chen, W.; Holm, S. The fractional constitutive models for nonlocal material based on scattering wave equations. Mech. Time-Depend. Mater. 2022, 26, 171–193. [Google Scholar] [CrossRef]

- Freundlich, J. Transient vibrations of a fractional Kelvin-Voigt viscoelastic cantilever beam with a tip mass and subjected to a base excitation. J. Sound Vib. 2019, 438, 99–115. [Google Scholar] [CrossRef]

- Blair, G.S.; Caffyn, J. VI. An application of the theory of quasi-properties to the treatment of anomalous strain-stress relations. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1949, 40, 80–94. [Google Scholar] [CrossRef]

- Kempfle, S.; Schäfer, I.; Beyer, H. Fractional calculus via functional calculus: Theory and applications. Nonlinear Dyn. 2002, 29, 99–127. [Google Scholar] [CrossRef]

- Di Paola, M.; Reddy, J.; Ruocco, E. On the application of fractional calculus for the formulation of viscoelastic Reddy beam. Meccanica 2020, 55, 1365–1378. [Google Scholar] [CrossRef]

- Nonnenmacher, T.; Glöckle, W. A fractional model for mechanical stress relaxation. Philos. Mag. Lett. 1991, 64, 89–93. [Google Scholar] [CrossRef]

- Simpson, R.; Jaques, A.; Nuñez, H.; Ramirez, C.; Almonacid, A. Fractional calculus as a mathematical tool to improve the modeling of mass transfer phenomena in food processing. Food Eng. Rev. 2013, 5, 45–55. [Google Scholar] [CrossRef]

- Diethelm, K.; Ford, N.J. Analysis of fractional differential equations. J. Math. Anal. Appl. 2002, 265, 229–248. [Google Scholar] [CrossRef]

- Taghvafard, H.; Erjaee, G. Phase and anti-phase synchronization of fractional order chaotic systems via active control. Commun. Nonlinear Sci. Numer. Simul. 2011, 16, 4079–4088. [Google Scholar] [CrossRef]

- Lin, Y.; Xu, C. Finite difference/spectral approximations for the time-fractional diffusion equation. J. Comput. Phys. 2007, 225, 1533–1552. [Google Scholar] [CrossRef]

- Farea, A.; Yli-Harja, O.; Emmert-Streib, F. Using Physics-Informed Neural Networks for Modeling Biological and Epidemiological Dynamical Systems. Mathematics 2025, 13, 1664. [Google Scholar] [CrossRef]

- Hu, R.; Aziz, M.H.N.; Mohamed, N.A.; Aruchunan, E. Modeling and analysis of dynamical behavior in a fractional-order COVID-19 epidemic model with media coverage: A case study of Malaysia. Alex. Eng. J. 2025, 127, 1081–1095. [Google Scholar] [CrossRef]

- Chen, Y.M.; Wei, Y.Q.; Liu, D.Y.; Yu, H. Numerical solution for a class of nonlinear variable order fractional differential equations with Legendre wavelets. Appl. Math. Lett. 2015, 46, 83–88. [Google Scholar] [CrossRef]

- Soradi-Zeid, S.; Jahanshahi, H.; Yousefpour, A.; Bekiros, S. King algorithm: A novel optimization approach based on variable-order fractional calculus with application in chaotic financial systems. Chaos Solitons Fractals 2020, 132, 109569. [Google Scholar] [CrossRef]

- Hassani, H.; Machado, J.T.; Naraghirad, E. An efficient numerical technique for variable order time fractional nonlinear Klein-Gordon equation. Appl. Numer. Math. 2020, 154, 260–272. [Google Scholar] [CrossRef]

- Hu, R.; Aruchunan, E.; Aziz, M.H.N.; Cheng, C.; Wiwatanapataphee, B. Dynamic analysis and optimal control of a fractional-order epidemic model with nucleic acid detection and individual protective awareness: A Malaysian case study. AIMS Math. 2025, 10, 16157–16199. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Y. Dynamic analysis of the viscoelastic pipeline conveying fluid with an improved variable fractional order model based on shifted Legendre polynomials. Fractal Fract. 2019, 3, 52. [Google Scholar] [CrossRef]

- Peng, G.; Xiong, Y.; Liu, L.; Gao, Y.; Wang, M.; Zhang, Z. 3-D non-linear dynamics of inclined pipe conveying fluid, supported at both ends. J. Sound Vib. 2019, 449, 405–426. [Google Scholar] [CrossRef]

- Chang, G.H.; Modarres-Sadeghi, Y. Flow-induced oscillations of a cantilevered pipe conveying fluid with base excitation. J. Sound Vib. 2014, 333, 4265–4280. [Google Scholar] [CrossRef]

- He, F.; Dai, H.; Huang, Z.; Wang, L. Nonlinear dynamics of a fluid-conveying pipe under the combined action of cross-flow and top-end excitations. Appl. Ocean. Res. 2017, 62, 199–209. [Google Scholar] [CrossRef]

- Rahmati, M.; Mirdamadi, H.R.; Goli, S. Divergence instability of pipes conveying fluid with uncertain flow velocity. Physica A 2018, 491, 650–665. [Google Scholar] [CrossRef]

- Letelier, M.F.; Siginer, D.A.; Almendra, D.L.; Stockle, J.S. Resonance in laminar pipe flow of non-linear viscoelastic fluids. Int. J. Non-Linear Mech. 2019, 115, 53–60. [Google Scholar] [CrossRef]

- Yang, X.; Yang, T.; Jin, J. Dynamic stability of a beam-model viscoelastic pipe for conveying pulsative fluid. Acta Mech. Solida Sin. 2007, 20, 350–356. [Google Scholar] [CrossRef]

- Tang, Y.; Zhen, Y.; Fang, B. Nonlinear vibration analysis of a fractional dynamic model for the viscoelastic pipe conveying fluid. Appl. Math. Model. 2018, 56, 123–136. [Google Scholar] [CrossRef]

- Dehrouyeh-Semnani, A.M.; Dehdashti, E.; Yazdi, M.R.H.; Nikkhah-Bahrami, M. Nonlinear thermo-resonant behavior of fluid-conveying FG pipes. Int. J. Eng. Sci. 2019, 144, 103141. [Google Scholar] [CrossRef]

- Carrera, Y.; Avila-de La Rosa, G.; Vernon-Carter, E.; Alvarez-Ramirez, J. A fractional-order Maxwell model for non-Newtonian fluids. Physica A 2017, 482, 276–285. [Google Scholar] [CrossRef]

- Ren, D.; Shen, X.; Li, C.; Cao, X. The fractional Kelvin-Voigt model for Rayleigh surface waves in viscoelastic FGM infinite half space. Mech. Res. Commun. 2018, 87, 53–58. [Google Scholar] [CrossRef]

- Lewandowski, R.; Wielentejczyk, P. Nonlinear vibration of viscoelastic beams described using fractional order derivatives. J. Sound Vib. 2017, 399, 228–243. [Google Scholar] [CrossRef]

- Xu, H.; Jiang, X. Creep constitutive models for viscoelastic materials based on fractional derivatives. Comput. Math. Appl. 2017, 73, 1377–1384. [Google Scholar] [CrossRef]

- Heymans, N.; Podlubny, I. Physical interpretation of initial conditions for fractional differential equations with Riemann-Liouville fractional derivatives. Rheol. Acta 2006, 45, 765–771. [Google Scholar] [CrossRef]

- Magin, R.L. Fractional calculus models of complex dynamics in biological tissues. Comput. Math. Appl. 2010, 59, 1586–1593. [Google Scholar] [CrossRef]

- Joseph, D.; Ramachandran, R.; Alzabut, J.; Jose, S.A.; Khan, H. A fractional-order density-dependent mathematical model to find the better strain of wolbachia. Symmetry 2023, 15, 845. [Google Scholar] [CrossRef]

- Cui, Y.; Qu, J.; Han, C.; Cheng, G.; Zhang, W.; Chen, Y. Shifted Bernstein–Legendre polynomial collocation algorithm for numerical analysis of viscoelastic Euler–Bernoulli beam with variable order fractional model. Math. Comput. Simul. 2022, 200, 361–376. [Google Scholar] [CrossRef]

- Gadomski, A.; Rubí, J.; Łuczka, J.; Ausloos, M. On temperature-and space-dimension dependent matter agglomerations in a mature growing stage. Chem. Phys. 2005, 310, 153–161. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, L.; Chen, Y. Numerical analysis of fractional-order variable section cantilever beams. ICIC Express Lett. 2019, 13, 547–555. [Google Scholar]

- Sazesh, S.; Shams, S. Vibration analysis of cantilever pipe conveying fluid under distributed random excitation. J. Fluids Struct. 2019, 87, 84–101. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.M. Shifted-Chebyshev-polynomial-based numerical algorithm for fractional order polymer visco-elastic rotating beam. Chaos Solitons Fractals 2020, 132, 109585. [Google Scholar] [CrossRef]

| e(x,t) | ||||

|---|---|---|---|---|

| Notation | Name | Value | Dimension |

|---|---|---|---|

| I | Area moment of inertia | 0.0001798 | m4 |

| M | Fluid quality | 11.74416 | kg |

| m | Pipe quality | 289.00198 | kg |

| v | Fluid velocity | 1.1 | m/s |

| L | Length of the pipe | 11 | m |

| c | Damping ratio | 0.8 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Qu, J.; Chen, Y.; Cui, Y.; Yang, A.; Yan, D. Variable Fractional Order Dynamic Analysis of Viscoelastic Pipes Using Shifted Bernstein Polynomial-Based Numerical Algorithm. Fractal Fract. 2025, 9, 747. https://doi.org/10.3390/fractalfract9110747

Li Z, Qu J, Chen Y, Cui Y, Yang A, Yan D. Variable Fractional Order Dynamic Analysis of Viscoelastic Pipes Using Shifted Bernstein Polynomial-Based Numerical Algorithm. Fractal and Fractional. 2025; 9(11):747. https://doi.org/10.3390/fractalfract9110747

Chicago/Turabian StyleLi, Zhongze, Jingguo Qu, Yiming Chen, Yuhuan Cui, Aimin Yang, and Dongfei Yan. 2025. "Variable Fractional Order Dynamic Analysis of Viscoelastic Pipes Using Shifted Bernstein Polynomial-Based Numerical Algorithm" Fractal and Fractional 9, no. 11: 747. https://doi.org/10.3390/fractalfract9110747

APA StyleLi, Z., Qu, J., Chen, Y., Cui, Y., Yang, A., & Yan, D. (2025). Variable Fractional Order Dynamic Analysis of Viscoelastic Pipes Using Shifted Bernstein Polynomial-Based Numerical Algorithm. Fractal and Fractional, 9(11), 747. https://doi.org/10.3390/fractalfract9110747