Fractal Technology for Sustainable Growth in the AI Era: Fractal Principles for Industry 5.0

Abstract

1. Introduction

2. Fractal Technology—Master Key to Sustainable Growth

2.1. Introduction

2.2. Fractal Technology: Characteristics

2.3. Mandelbrot Sets

- Cantor Dust.

- Koch Snowflake.

- Sierpinski Carpet.

- Menger Sponge.

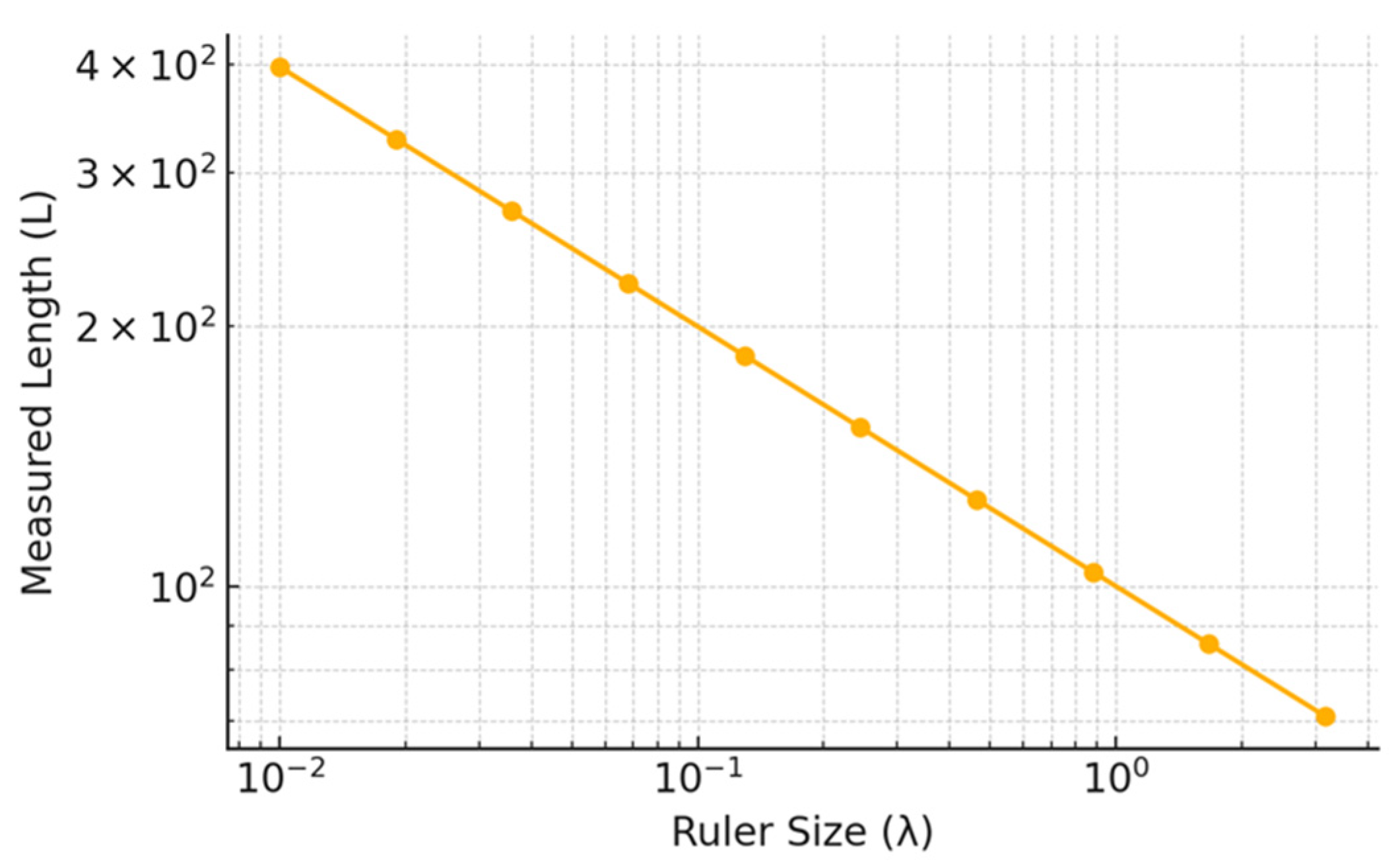

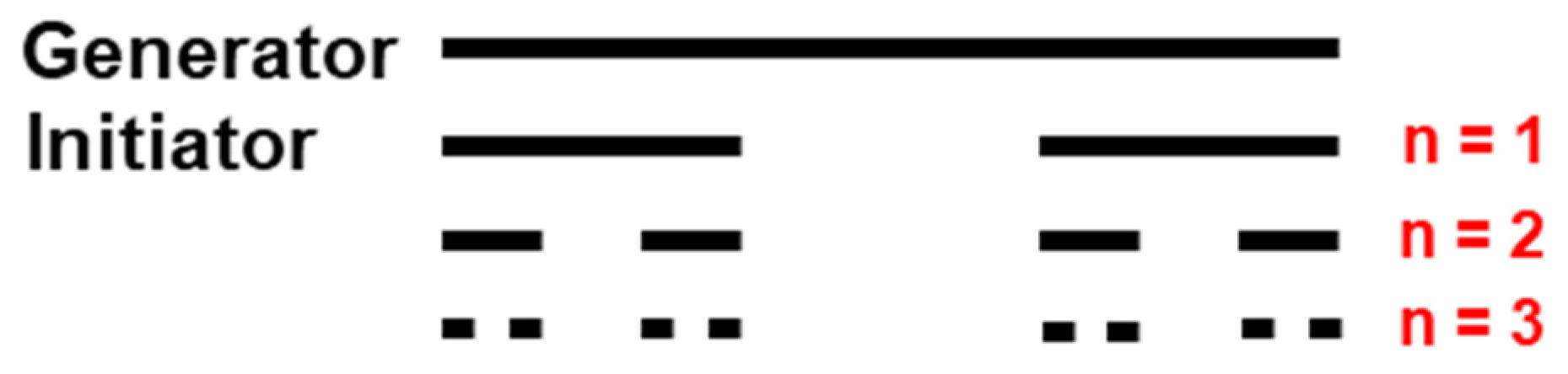

2.3.1. Example 1: Cantor Dust

- -

- Signal processing.

- -

- Data compression.

- -

- Quantum computing.

- -

- Nanotechnology.

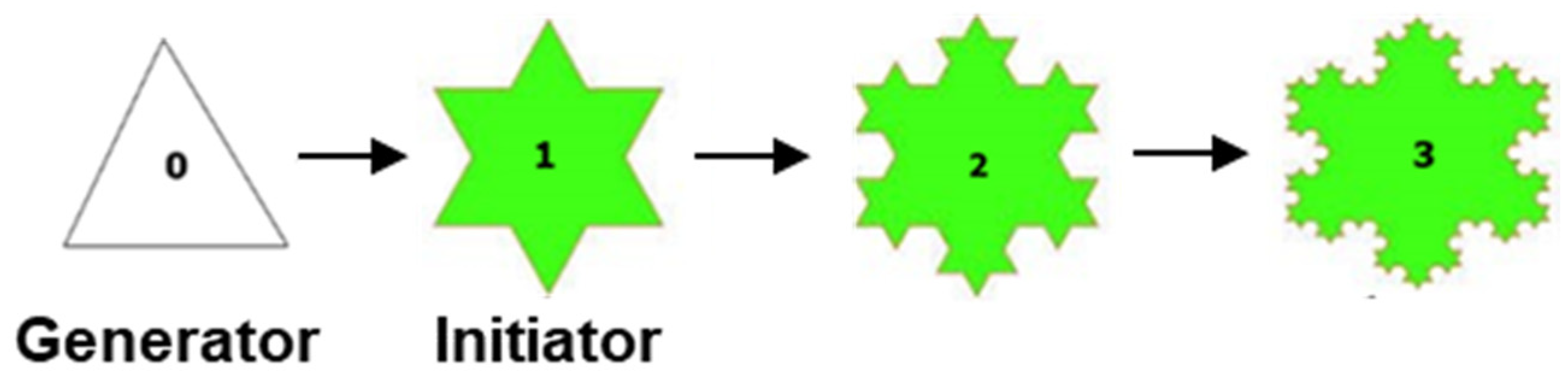

2.3.2. Example 2: Koch Snowflake

- -

- Blood vessels must fit near-infinite circulatory paths within the limited space of the body.

- -

- Lungs must provide a maximal surface area for gas exchange within a confined thoracic cavity.

- -

- Surface design for heat exchangers.

- -

- Antenna miniaturization.

- -

- Material science, such as in porous media and lightweight foams.

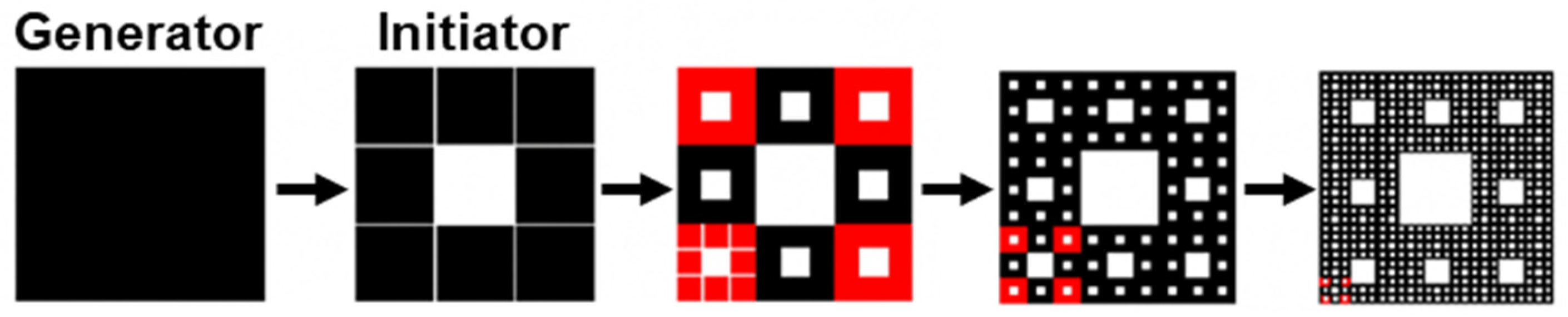

2.3.3. Example 3: Sierpinski Carpet

2.3.4. Example 4: Menger Sponge

2.4. FG and Log-Normal Distributions

Summary

2.5. Living Systems Are Fractal

3. Role of AI in Industrial Innovation

3.1. Blockchain Technologies

- -

- Sustainable Resource Management: Tracking materials from origin to end use to ensure legal, ethical, and environmental compliance.

- -

- Circular Economy Integration: Verifying recycled and reused content to meet regulatory and sustainability standards.

- -

- Supply Chain Transparency: Automating audit trails to enhance accountability and ESG (Environmental, Social, and Governance) reporting.

- -

- Carbon and Energy Accounting: Linking process data with emission metrics for accurate sustainability assessments.

3.2. Three-Dimensional Printing Technology: Adaptive Manufacturing

- -

- Rapid prototyping of new products.

- -

- Localized and on-demand fabrication for supply chain resilience.

- -

- Precision production of high-value or complex components.

3.3. Internet of Things (IoT)

- -

- Predictive Maintenance: Smart sensors detect anomalies in equipment to prevent unplanned downtime and reduce maintenance costs.

- -

- Process Optimization: IoT-enabled systems adjust operational parameters in real time to improve energy efficiency, precision, and product quality.

- -

- Supply Chain Integration: Connected devices and RFID tracking enhance visibility, traceability, and responsiveness across the value chain.

- -

- Environmental Monitoring: Networked sensors collect emissions and resource data, supporting sustainability reporting and regulatory compliance.

3.4. Robot Technologies

- -

- Automated Material Handling: Robotic arms and autonomous guided vehicles (AGVs) transport materials and components, improving safety, workflow, and efficiency.

- -

- Packaging and Assembly: End-of-line robots perform wrapping, labeling, and assembly with sensor-guided accuracy, increasing throughput and reducing defects.

- -

- Vision-Guided Inspection: AI-enabled robotic systems identify surface defects and process deviations in real time, enabling continuous quality assurance and minimizing waste.

- -

- Maintenance and Safety Operations: Mobile robots equipped with thermal and gas sensors conduct cleaning, inspection, and diagnostics in hazardous or confined areas, improving occupational safety and operational reliability.

3.5. Drone Applications

- -

- Inspection and Monitoring: Drones equipped with high-resolution cameras and thermal sensors conduct infrastructure and equipment inspections, reducing downtime and improving safety.

- -

- Environmental and Resource Management: Aerial data support precision monitoring of forests, crops, emissions, and environmental impact.

- -

- Agile Logistics: Autonomous drones facilitate rapid delivery and material transport within industrial sites, enhancing flexibility and efficiency.

- -

- Disaster and Safety Management: Real-time aerial surveillance supports emergency response, hazard detection, and risk prevention.

4. Fractal Technology for AI Technology Development

4.1. Blockchain

4.2. Big Data

4.3. Additive Manufacturing (3D Printing)

4.4. Deep Learning and Neural Networks

4.5. IoT

4.6. Cloud Computing

5. Fractal Characteristics in Core AI Technologies

Summary

6. Future Trends in AI and Industry 5.0

6.1. Challenges Ahead

6.2. Visionary Leadership in the AI Era

6.3. From Industry 3.0 Through Industry 4.0 to Industry 5.0

- -

- Optimization of energy and resource utilization.

- -

- Reduction in downtime through predictive and adaptive control.

- -

- Improvement in product customization and quality assurance.

Concluding Remarks

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| FG | Fractal geometry |

| IoT | Internet of Things |

| DLVO | Derjaguin–Landau–Verwey–Overbeek |

| ESG | Environmental, Social, and Governance |

| FD | Fractal Dimension |

| RFID | Radio-Frequency Identification |

| XR | Extended Reality |

References

- Brynjolfsson, E.; Mcafee, A. The Second Machine Age: Work, Progress, and Prosperity in a Time of Brilliant Technologies; W.W. Norton & Company: New York, NY, USA, 2014. [Google Scholar]

- Haenlein, M.; Kaplan, A. A brief history of artificial intelligence: On the past, present, and future of artificial intelligence. Calif. Manag. Rev. 2019, 61, 5–14. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2020, 52, 101967. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; W.H. Freeman and Company: New York, NY, USA, 1982. [Google Scholar]

- Gleick, J. Chaos: Making a New Science; Penguin Books: New York, NY, USA, 1992. [Google Scholar]

- Peitgen, H.O.; Richter, P.H. The Beauty of Fractals: Images of Complex Dynamical Systems; Springer: Berlin/Heidelberg, Germany, 1986. [Google Scholar]

- Barnsley, M.F.; Devaney, R.L.; Mandelbrot, B.B.; Peitgen, H.O.; Saupe, D.; Voss, R.F. The Science of Fractal Images; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Peitgen, H.-O.; Jürgens, H.; Saupe, D. Fractals for the Classroom: Part One-introduction to Fractals and Chaos; Springer: Berlin/Heidelberg, Germany, 1991. [Google Scholar]

- Peitgen, H.-O.; Jürgens, H.; Saupe, D. Fractals for the Classroom: Part Two—Complex Systems and the Mandelbrot Set; Springer: New York, NY, USA, 1992. [Google Scholar]

- Tsallis, C. Introduction to Nonextensive Statistical Mechanics: Approaching a Complex World; Springer: Cham, Switzerland, 2009. [Google Scholar] [CrossRef]

- Raghu, M.; Schmidt, E. A Survey of Deep Learning for Scientific Discovery. arXiv 2020, arXiv:2003.11755. [Google Scholar]

- Richardson, L.F. The Problem of Contiguity: An Appendix to Statistics of Deadly Quarrels. Gen. Syst. Yearbook 1961, 6, 139–187. [Google Scholar]

- Barabási, A.L.; Albert, R. Emergence of Scaling in Random Networks. Science 1999, 286, 509–512. [Google Scholar] [CrossRef]

- Song, C.; Havlin, S.; Makse, H.A. Self-Similarity of Complex Networks. Nature 2005, 433, 392–395. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Tao, F.; Fang, X.; Liu, C.; Liu, Y.; Freiheit, T. Smart Manufacturing and Intelligent Manufacturing: A Comparative Review. Engineering 2021, 7, 738–757. [Google Scholar] [CrossRef]

- Barnsley, M.F. Fractals Everywhere, 2nd ed.; Academic Press: Cambridge, MA, USA, 1993. [Google Scholar]

- Ko, Y.C.; Park, J.M.; Shin, S.J. The Principles of Fractal Geometry and Its Applications for Pulp & Paper Industry. J. Korea TAPPI 2015, 47, 177–186. [Google Scholar] [CrossRef]

- Falconer, K. Fractal Geometry: Mathematical Foundations and Applications; John Wiley & Sons: New York, NY, USA, 2004. [Google Scholar]

- Constantine, A.G.; Hall, P.G. Fractal Geometry in Surface Metrology; Precision: St. Dedham, MA, USA, 1994. [Google Scholar]

- Kaye, B.H. A Random Walk Through Fractal Dimensions; Wiley: New York, NY, USA, 1989. [Google Scholar]

- Hubbe, M.A.; Gardner, D.J.; Shen, W. Contact Angles and Wettability of Cellulosic Surfaces: A Review of Proposed Mechanisms and Test Strategies. BioResources 2015, 10, 8657–8749. [Google Scholar] [CrossRef]

- Allan, G.G.; Ko, Y.C. The Microporosity of Pulp. The Forces Influencing the Intra and Inter-Fiber Pore Structure and Pore Size Distribution in Pulp and Paper. Cell. Chem. Technol. 1995, 29, 470–485. [Google Scholar]

- Adamson, A.W.; Gast, A.P. Physical Chemistry of Surfaces, 6th ed.; Wiley-Interscience: New York, NY, USA, 1997. [Google Scholar]

- Emerson, R.W. Nature; James Munroe and Company: Boston, MA, USA, 1841. [Google Scholar]

- Zhou, Y.; Liu, C.; You, L. Evolution of Fractal Pore Structure in Sedimentary Rocks. Earth Space Sci. 2022, 9, e2021EA002014. [Google Scholar] [CrossRef]

- West, D.M. The Future of Work: Robots, AI, and Automation; Brookings Institution Press: Washington, DC, USA, 2018. [Google Scholar]

- He, Z.; Turner, P. Blockchain Applications in Forestry: A Systematic Literature Review. Appl. Sci. 2022, 12, 3723. [Google Scholar] [CrossRef]

- Lu, Y. The Blockchain: State-of-the-Art and Research Challenges. J. Ind. Inf. Integr. 2019, 15, 80–90. [Google Scholar] [CrossRef]

- Narayanan, A.; Bonneau, J.; Felten, E.; Miller, A.; Goldfeder, S. Bitcoin and Cryptocurrency Technologies: A Comprehensive Introduction; Princeton University Press: Princeton, NJ, USA, 2016. [Google Scholar]

- Tapscott, D.; Tapscott, A. Blockchain Revolution: How the Technology Behind Bitcoin Is Changing Money, Business, and the World; Penguin: New York, NY, USA, 2016. [Google Scholar]

- Saberi, S.; Kouhizadeh, M.; Sarkis, J.; Shen, L. Blockchain Technology and Its Relationships to Sustainable Supply Chain Management. Int. J. Prod. Res. 2019, 57, 2117–2135. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Lopez, C.; Lu, H.; Elgueta, S.; Chen, H.; Boshkoska, B.M. Blockchain Technology in Agri-Food Value Chain Management: A Synthesis of Applications, Challenges and Future Research Directions. Comput. Ind. 2021, 129, 103442. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Nath, S.D.; Nilufar, S. An Overview of Additive Manufacturing of Polymers and Associated Composites. Polymers 2020, 12, 2719. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, J.; Yao, Q.; Ji, C.; Liu, J.; Zhu, Q. 3D Printing with Cellulose Materials. Cellulose 2018, 25, 4275–4301. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Ferrer, A.; Tyagi, P.; Yin, Y.; Salas, C.; Pal, L.; Rojas, O.J. Nanocellulose in Thin Films, Coatings, and Plies for Packaging Applications: A Review. BioResources 2017, 12, 2143–2233. [Google Scholar] [CrossRef]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem. Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef] [PubMed]

- Rejeb, A.; Rejeb, K.; Simske, S.J.; Treiblmaier, H. Drones for Supply Chain Management and Logistics: A Review and Research Agenda. Int. J. Logist. Res. Appl. 2023, 26, 708–731. [Google Scholar] [CrossRef]

- Thoben, K.D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Autom. Technol. 2017, 11, 4–16. [Google Scholar] [CrossRef]

- Caballero-Martin, D.; Lopez-Guede, J.M.; Estevez, J.; Graña, M. Artificial Intelligence Applied to Drone Control: A State of the Art. Drones 2024, 8, 296. [Google Scholar] [CrossRef]

- Awasthi, S.; Gramse, N.; Reining, C.; Roidl, M. UAVs for Industries and Supply Chain Management. arXiv 2022, arXiv:2212.03346. [Google Scholar]

- Fernández-Caramés, T.M.; Blanco-Novoa, Ó.; Froiz-Míguez, I.; Fraga-Lamas, P. Towards an Autonomous Industry 4.0 Warehouse: A UAV and Blockchain-Based System for Inventory and Traceability Applications in Big Data-Driven Supply Chain Management. arXiv 2024, arXiv:2402.00709. Available online: https://arxiv.org/abs/2402.00709 (accessed on 18 October 2025).

- Bahri, Y.; Dyer, E.; Kaplan, J.; Lee, J.; Sharma, U. Explaining Neural Scaling Laws. arXiv 2021, arXiv:2102.06701. [Google Scholar]

- Baptista, R.P.; Rocha, L.Q.; Menezes, D.P.; Trevisan, L.A.; Tsallis, C.; Deppman, A. Evidence of Fractal Structures in Hadrons. Eur. Phys. J. A 2024, 60, 93. [Google Scholar] [CrossRef]

- Swan, M.; De Filippi, P. Toward a Philosophy of Blockchain: A Symposium Introduction. Metaphilosophy 2017, 48, 603–619. [Google Scholar] [CrossRef]

- Hassan, S.; De Filippi, P. Decentralized Autonomous Organization. Internet Policy Rev. 2021, 10, 1–10. [Google Scholar] [CrossRef]

- Gabaix, X. Power Laws in Economics: An Introduction. J. Econ. Perspect. 2016, 30, 185–206. [Google Scholar] [CrossRef]

- Clauset, A.; Shalizi, C.R.; Newman, M.E.J. Power-Law Distributions in Empirical Data. SIAM Rev. 2009, 51, 661–703. [Google Scholar] [CrossRef]

- Limpert, E.; Stahel, W.A.; Abbt, M. Log-Normal Distributions Across the Sciences: Keys and Clues. BioScience 2001, 51, 341–352. [Google Scholar] [CrossRef]

- Khan, R.; Khan, S.U.; Zaheer, R.; Khan, S. Future Internet: The Internet of Things Architecture, Possible Applications and Key Challenges. In Proceedings of the 2021 IEEE International Conference on Big Data, Orlando, FL, USA, 10–13 December 2021; pp. 2201–2209. [Google Scholar]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental Optimization of Fused Deposition Modelling Processing Parameters: A Design-for-Manufacturing Approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Momeni, F.; Hassani, N.S.M.; Liu, X.; Ni, J. A Review of 4D Printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Touvron, H.; Lavril, T.; Izacard, G.; Martinet, X.; Lachaux, M.A.; Lacroix, T. LLaMA: Open and Efficient Foundation Language Models. arXiv 2023, arXiv:2302.13971. [Google Scholar]

- Lin, J.; Yu, W.; Zhang, N.; Yang, X.; Zhang, H.; Zhao, W. A Survey on Internet of Things: Architecture, Enabling Technologies, Security and Privacy, and Applications. IEEE Internet Things J. 2017, 4, 1125–1142. [Google Scholar] [CrossRef]

- Perera, C.; Zaslavsky, A.; Christen, P.; Georgakopoulos, D. Sensing as a Service Model for Smart Cities Supported by Internet of Things. Trans. Emerg. Telecommun. Technol. 2020, 31, e3860. [Google Scholar] [CrossRef]

- Baccarelli, E.; Naranjo, P.G.V.; Scarpiniti, M.; Shojafar, M.; Abawajy, J.H. Fog of Everything: Energy-Efficient Networked Computing Architectures, Research Challenges, and a Case Study. IEEE Access 2017, 5, 9882–9906. [Google Scholar] [CrossRef]

- Armbrust, M.; Fox, A.; Griffith, R.; Joseph, A.D.; Katz, R.; Konwinski, A.; Lee, G.; Patterson, D.; Rabkin, A.; Stoica, I.; et al. A View of Cloud Computing. Commun. ACM 2010, 53, 50–58. [Google Scholar] [CrossRef]

- Villari, M.; Fazio, M.; Dustdar, S.; Rana, O.; Ranjan, R. Osmotic Computing: A New Paradigm for Edge/Cloud Integration. IEEE Cloud Comput. 2016, 3, 76–83. [Google Scholar] [CrossRef]

- Schwab, K.; Malleret, T. COVID-19: The Great Reset; World Economic Forum: Geneva, Switzerland, 2020. [Google Scholar]

- Levitt, T. Marketing Myopia. Harvard Bus. Rev. 1960, 38, 45–56. Available online: https://hbr.org/2004/07/marketing-myopia (accessed on 27 October 2025).

- Day, G.S. Closing the Marketing Capabilities Gap. J. Mark. 2011, 75, 183–195. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, X.; Li, Y. The Process of Visionary Leadership Increases Innovative Performance in the Context of Digital Transformation. Sustainability 2024, 16, 8690. [Google Scholar] [CrossRef]

- Schwab, K. The Fourth Industrial Revolution; Crown Business: New York, NY, USA, 2017. [Google Scholar]

- Breque, M.; De Nul, L.; Petridis, A. Industry 5.0: Towards a Sustainable, Human-Centric and Resilient European Industry; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Schein, E.H. Organizational Culture and Leadership, 4th ed.; Jossey-Bass: San Francisco, CA, USA, 2010. [Google Scholar]

- Peters, T.J.; Waterman, R.H. In Search of Excellence: Lessons from America’s Best Run Companies; Harper Business: New York, NY, USA, 2007. [Google Scholar]

- Kuhn, T.S. The Structure of Scientific Revolutions; University of Chicago Press: Chicago, IL, USA, 1962. [Google Scholar]

- Ko, Y.C.; Kim, H.J.; Allan, G.G. 4th Industrial Revolution and the Sustainable Growth Strategy for the Pulp & Paper Industry. J. Korea TAPPI 2019, 51, 121–128. [Google Scholar] [CrossRef]

- Schein, E.H.; Schein, P.A. Organizational Culture and Leadership, 5th ed.; Wiley: Hoboken, NJ, USA, 2017. [Google Scholar]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human–Robot Co-Working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- García-Muiña, F.E.; Medina-Salgado, M.S.; Ferrari, A.M.; Cucchi, M. Sustainability Transition in Industry 4.0 and Smart Manufacturing with the Triple Bottom Line: A Systematic Literature Review and Research Agenda. Sustainability 2019, 11, 822. [Google Scholar] [CrossRef]

| Core AI Technology | Fractal Characteristics | Explanation |

|---|---|---|

| Blockchain | Recursive structure, decentralized hierarchy, scalability | Blockchain forms a chain of data blocks, each linked recursively to the previous block. Each node mirrors the logic of the entire system, which is an inherently fractal design. |

| Big Data | Scale-invariance, power-law distribution, recursive pattern recognition | Big data analytics reveals patterns that repeat across temporal and spatial scales. Data distributions typically follow log-normal or power-law forms, reflecting fractal behavior. |

| 3D Printing | Layered construction, material efficiency, micro-to-macro precision | 3D printing iteratively builds objects layer by layer, mirroring fractal growth processes in nature that optimize form and function from the bottom up. |

| Deep Learning and Neural Networks | Hierarchical layers, recursive learning, emergent complexity | Deep neural networks are organized in layers, with each layer refining the information from the previous layer, similar to how fractals evolve complexity through iteration. |

| IoT | Distributed networks, local-to-global feedback, adaptive scaling | IoT systems mirror fractal systems by integrating small, locally intelligent devices that generate large-scale insights through decentralized interactions. |

| Cloud Computing | Scalable architecture, mirrored resource layers, elastic responsiveness | Cloud computing relies on recursive, layered resource allocation across distributed servers. This ensures consistency in form and function across scale. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ko, Y.C.; Kweon, S.W.; Moon, B.G.; Park, J.-M.; Kim, H.J. Fractal Technology for Sustainable Growth in the AI Era: Fractal Principles for Industry 5.0. Fractal Fract. 2025, 9, 695. https://doi.org/10.3390/fractalfract9110695

Ko YC, Kweon SW, Moon BG, Park J-M, Kim HJ. Fractal Technology for Sustainable Growth in the AI Era: Fractal Principles for Industry 5.0. Fractal and Fractional. 2025; 9(11):695. https://doi.org/10.3390/fractalfract9110695

Chicago/Turabian StyleKo, Young Chan, Soon Wan Kweon, Byoung Geun Moon, Jong-Moon Park, and Hyoung Jin Kim. 2025. "Fractal Technology for Sustainable Growth in the AI Era: Fractal Principles for Industry 5.0" Fractal and Fractional 9, no. 11: 695. https://doi.org/10.3390/fractalfract9110695

APA StyleKo, Y. C., Kweon, S. W., Moon, B. G., Park, J.-M., & Kim, H. J. (2025). Fractal Technology for Sustainable Growth in the AI Era: Fractal Principles for Industry 5.0. Fractal and Fractional, 9(11), 695. https://doi.org/10.3390/fractalfract9110695