1. Introduction

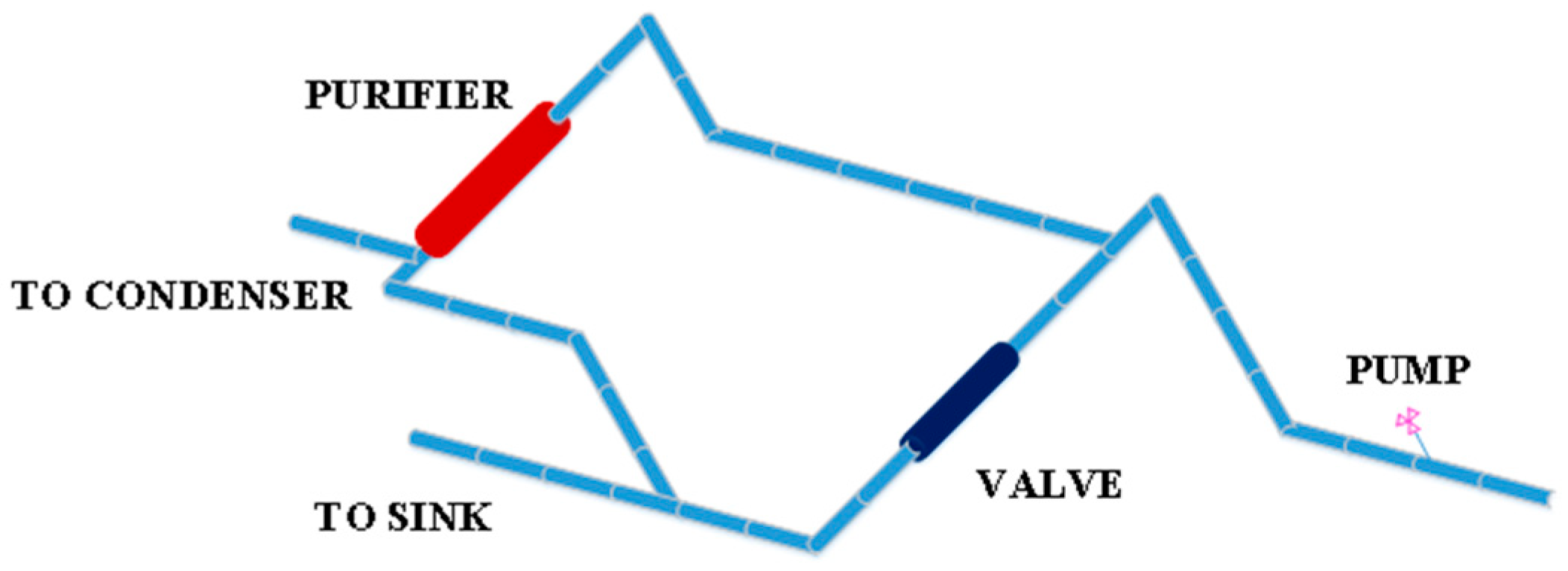

Distributed piping systems are crucial components for transporting liquids, gases, and solid particles in nuclear power plants. Efficient operation of distributed piping systems is crucial to the safety of nuclear power systems. In the process of system operation, owing to the influence of the external environment or internal factors, the pipeline components inevitably vibrate for a certain period. Owing to these vibrations, the efficiency of the system is significantly reduced. When the vibration is severe enough to exceed the limit that the pipeline can bear, it can cause fatigue failure of the distributed piping system and even lead to serious accidents. Therefore, vibration control must be implemented in distributed piping systems.

Active control is a common and effective method for controlling pipeline vibrations, which can suppress vibrations by applying an active control force to counteract the vibration force. This method is widely used for controlling vibrations in industrial systems [

1,

2,

3,

4]. Common active control methods include proportional–integral–derivative (PID) control [

5,

6], linear quadratic regression (LQR) control [

7,

8], and reinforcement-learning control [

9,

10]. Proportional–integral–derivative (PID) control is a control method with simple principles, convenient implementation, and good efficacy. Chen proposed a double closed-loop control system based on proportional–integral–derivative (PID) control to control the stick–slip vibration of a drill string [

11]. Ju et al. controlled a flexible arm independently by combining the BP algorithm with PID control and showed that the control of BP–PID has a positive impact on the vibration [

12]. Hussin et al. used a proportional–integral–derivative (PID) controller to control the vibration of a semi-active suspension system and employed the AFA algorithm to tune the PID controller. The experimental results showed that the PID–AFA could significantly reduce the sprung acceleration and human acceleration response amplitudes than the other controllers [

13]. Considering the influence of low-frequency vibrations on a pipeline, Hong et al. adopted a PID controller to reduce the vibration of the system. Proportional–integral–derivative control has a better effect than uncontrolled or passive controls [

14]. Gulbahce designed a tuner-based PID controller to control intelligent beams. The experimental results proved that the designed controller was more efficient and energy-efficient [

15]. The above experimental data and results show that PID control is a more effective vibration control method. However, it still has shortcomings, such as insufficient control accuracy and a low degree of model matching.

Fractional-order PID control is an advanced type of controller established by some scholars in recent years, which introduces the integral order,

λ, and differential order,

μ, into traditional PID controllers [

16,

17,

18,

19]. The fractional-order PID controller has a higher degree of freedom and matching than the conventional PID controller. Kavin et al. implemented a fractional-order PID controller in a reverse-osmosis desalination system and optimised the controller using the chaotic whale method [

20]. Chiranjeevi proposed and implemented a fractional-order proportional–integral–derivative (PID) controller that used a pollination algorithm to control the motor speed, effectively improving the performance of the system [

21]. Frikh proposed a fractional-order proportional–integral–derivative (PID) controller for wind turbine system speed control. The controller could obtain the desired phase margin and unit-gain cross-frequency, and the superiority of the method was verified by several performance evaluation indices [

22]. Zheng et al. [

23] proposed a robust fractional-order PID controller for a permanent-magnet synchronous motor speed servo system. Simulation results showed that the proposed method exhibited superior tracking and disturbance rejection performance. Thelkar designed a fractional-order PID controller to control the liquid level of a tank framework. The experiment proved that the fractional-order PID controller can better address external disturbances and expand the vitality of the framework [

24]. Xu combined the traceback method with a fractional PID controller to design a trajectory tracking control system and successfully applied it to the mobile robot model. Experimental results showed that the algorithm was effective [

25]. Despite active control methods based on fractional PID having made significant achievements in both theoretical research and practical applications, there are few studies on the application of fractional PID to the vibration control of pipeline systems.

Therefore, this study innovatively adopts fractional-order PID control to realise the vibration control of a distributed piping system. Moreover, the accuracy of the cross-point vibration transfer function between the brake and sensor obtained using the system identification toolbox was effectively improved through the optimisation algorithm. Considering the increase in controller parameters in the fractional-order PID controller, this study adopts the D-decomposition method to define the boundaries IRB, CRB, and RRB of the stable region SR, providing a design method to determine the ideal control parameters by lowering the system performance index.

The remainder of this study is organised as follows.

Section 2 describes the finite element modelling process of the distributed piping system and deduces the state-space expressions.

Section 3 presents the experimental identification of the system and further reduces the difference between the transfer function and the finite element model using the particle swarm optimisation algorithm.

Section 4 introduces the design of the fractional-order PID controller based on the D-decomposition method and describes the acquisition process of the controller parameters.

Section 5 presents experimental results on the designed fractional-order PID controller. Finally,

Section 6 provides conclusions.

3. System Identification Based on the Particle Swarm Optimization Strategy

The experiment uses the approach of system identification to build the vibration transfer function across points between the brake and the sensor in the distributed piping system. The purpose of this treatment is to analyse the performance of the system more effectively and visualize the control effect of the controller. The input and output experimental data calculated by the finite element model are identified with the aid of the system identification toolbox by choosing the appropriate number of zeros and poles, and the parameters of the transfer function are optimized using the particle swarm optimization algorithm to bring the output value of the transfer function model closer to the output value calculated by the finite element mode. The sampling time of the system is 0.001 s, and a total of 10,000 moments are taken, that is, data within 10 s.

The cross-point vibration transfer function between the system brake and the sensor identified by the system identification toolbox is

A random search swarm intelligence optimization algorithm called particle swarm optimization (PSO) mimics the foraging behaviour of birds. It is frequently utilized in a variety of complex and nonlinear optimization problems because of its advantages of quick convergence speed and excellent convergence accuracy. The velocity and position update formulas of PSO are shown in Formulas (4) and (5):

In the formula, vi is the particle update speed, c1 and c2 are the algorithm learning factors, pbesti is the individual optimal solution, gbesti is the global optimal solution, xi is the current particle position, and n is the number of particles in the population.

The PSO algorithm takes the model matching degree between the transfer function model and the finite element model as the optimization goal. The model matching the degree Formula is as follows:

In the formula,

is the finite element output at the

ith sampling time, and

is the output of the transfer function model at the ith sampling time. If the degree of similarity between the identified model and the real model is higher, the model’s fit index

J is closer to 1. The parameters of PSO are set as

c1 = 0.9,

c2 = 1.2. The cross-point vibration transfer function between the system brake and the sensor obtained after the optimization of PSO is

Then, the transfer Function (7) is converted from a discrete model to a continuous model as follows:

Table 1 compares the outcomes of transfer function optimization using the PSO approach and the system identification toolbox. The table analysis demonstrates that the transfer function optimized by PSO is closer to the vibration signal energy of the finite element model with a higher degree of matching, which can be further increased after identification by the system identification toolbox. The design environment of the subsequent controller is more closely aligned with the distributed piping system due to the model’s correctness.

4. Design of the Fractional-Order PID Controller

Since the introduction of the order increases the complexity of controller parameter optimization, this section adopts a D-decomposition algorithm to select the parameters of the FOPID controller. Considering the cross-point vibration transfer function between the system brake and the sensor as a second-order system, Equation (9) gives the expression of the plant based on the model in the paper [

28]:

Among these, p and q are the orders of D(s) and N(s), respectively, and satisfy the inequalities p2 > p1 > p0 and q2 > q1 > q0. M and n are the coefficients of D(s) and N(s), respectively. When the p and q values are integers, the system is an integer-order system. When the p and q values are fractional, the system is a fractional-order system.

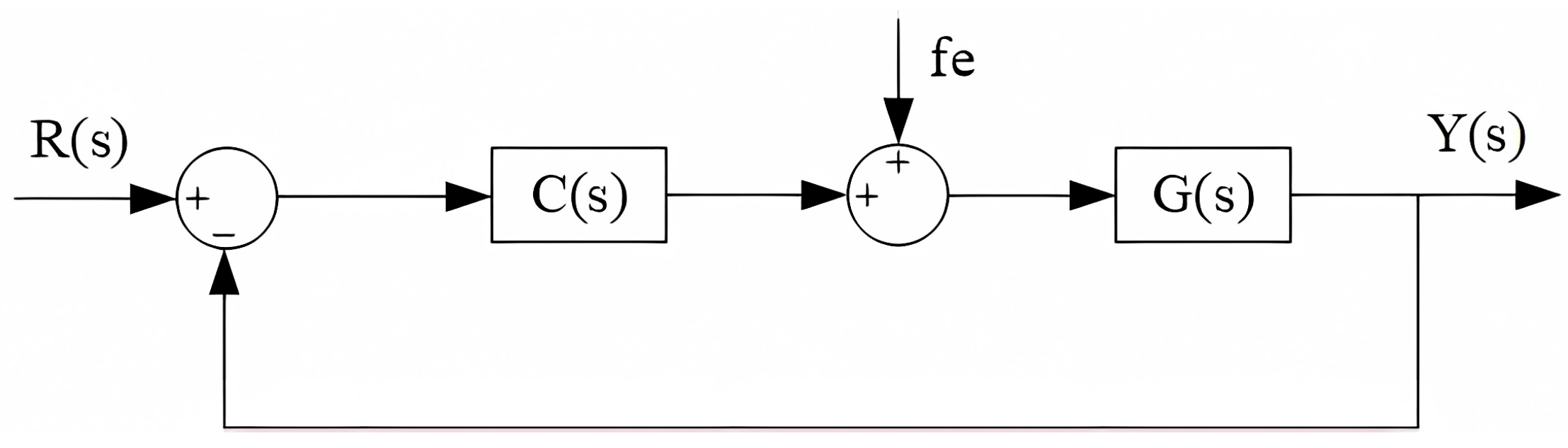

Figure 2 shows the system structure of the controlled object under the fractional-order PID controller.

In the diagram,

R(

s) stands for the system’s input,

Y(

s) is the output, and

fe is the external effect which mostly refers to the piping system’s excitation force. The controller and control object, respectively, are denoted by

C(

s) and

G(

s). In the vibration reduction control problem of the distributed piping system, to reduce the output value of vibration as much as possible, the input value (expected value)

R(

s) is set to zero, that is,

R(

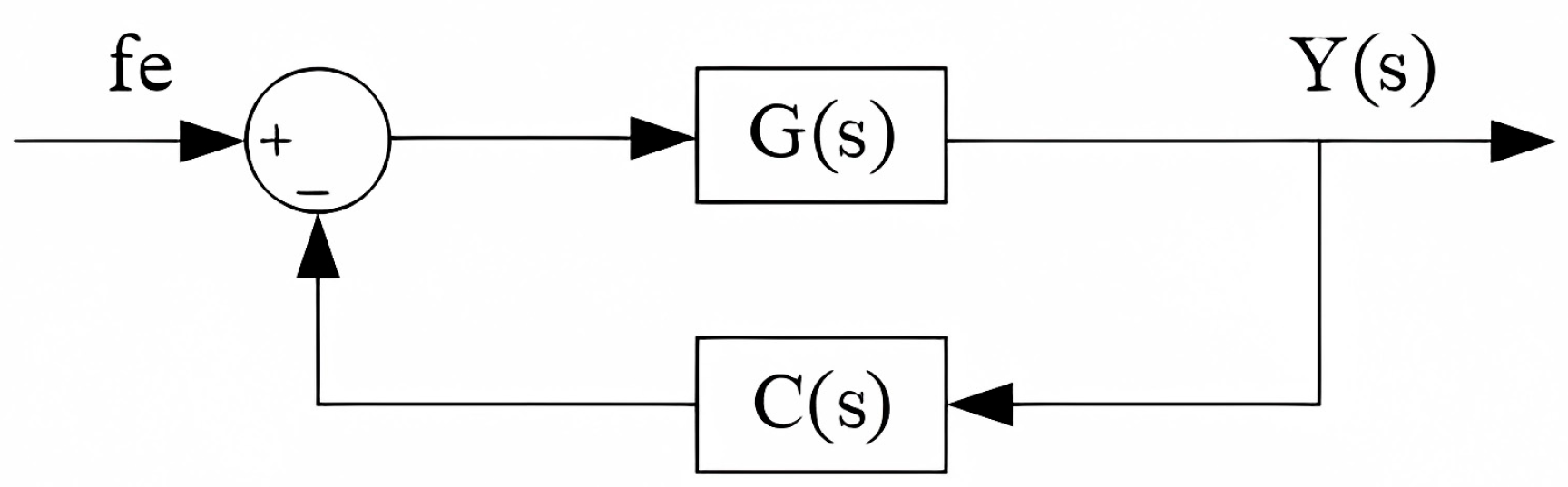

s) = 0, the system structure diagram can be equivalent to

Figure 3.

According to Formula (2), the fractional-order PID controller can be expressed as

. Therefore, the open-loop transfer function of the system can be determined from the figure as follows:

The closed-loop transfer function of the system is

Then, an operator of system (11) is defined as

It is possible to derive the operator

L(

s) expression with respect to the controller parameters

kp,

ki,

kd,

λ and

μ.

The values of the controller parameters kp, ki, kd, λ and μ determine the position and area of the stability region (SR) of the system. Real root boundaries (RRB), infinite root boundaries (IRB), and complicated root boundaries (CRB) make up the majority of the boundaries of SR. The three boundaries are described in the D-decomposition approach as follows:

RRB: When

s = 0, the parameter condition when the operator

L = 0 is made,

IRB: In the literature [

28], the author shows that the condition for the existence of IRB is

pn ≤

qn +

μ, and

pn and

qn are the highest orders of polynomial

D(

s) and

N(

s), respectively. On this basis, IRB can be expressed as

To ensure the existence of the differential part in the controller, that is, the coefficient kd ≠ 0, the differential order μ needs to satisfy the condition μ ≤ pn − qn.

CRB: Bring

s =

jω into Formula (13) and make its value equal to 0, then CRB can be defined as

The expressions for the controller parameters

kp,

ki,

kd,

λ,

μ and

ω can be derived from Formula (16):

where

Through derivation, the expressions of the controller parameters

kp and

ki can be obtained as

4.1. Design of Parameters kp, ki, kd

When the controller order parameters

λ and

μ are given, the value range of

kd can be obtained through SR as

. According to the definition of the phase angle margin

Pm and the crossover frequency

ωc,

When bringing Formula (11) into Formula (21),

The relationship between the controller parameters

kp,

ki on

kd,

λ,

μ is then derived:

where

The following formula can be used to determine the controller parameter

kd to ensure that the system has the better performance:

where

The argument of

can be expressed as

where

n is an integer and

To achieve optimal robustness, the controller parameter

kd can be calculated using the following formula:

When the value of

kd is obtained by calculation, the values of the controller parameters

kp and

ki can be obtained according to Formula (12):

The value range of parameter

ω is

, and the values of

and

satisfy the following conditions:

4.2. Design of Parameters λ and μ

The values of

kp,

ki and

kd only depend on the order

λ and

μ according to Formulas (30) and (31). The time multiplied by the integral of the absolute value of the error (ITAE) is chosen as the performance index of the controller to achieve the best response performance of the control system, i.e.,

Among them,

e(

t) is the error signal in the control system. By finding the

λ and

μ values that minimize the performance index

JITAE value, the values of parameters

kp,

ki and

kd are further determined according to Formulas (30) and (31):

4.3. Design Process

In this section, the specific steps to obtain the parameters of the fractional-order controller using the D-decomposition method are given as follows.

Step 1 Initialize the following data, including

Set the phase angle margin Pm and the crossover frequency ωc.

Step 2 In order to ensure the existence of the differential part in the fractional order controller, according to Formula (15), it obtains kd ≠ 0 and the differential order must satisfy the condition μ ≤ pn − qn. When the order parameters λ and μ gradually increase from low to high, the value range of the controller parameter kd is calculated according to SR.

Step 3 The values of the controller parameters kp, ki and kd under the conditions of traversal and are calculated sequentially through Formulas (34) and (35), and the performance index JITAE of the controller is calculated according to Formula (33).

Step 4 The planned fractional-order PID controller’s parameter value is determined by finding the values of kp, ki, kd, λ and μ, that minimize the performance index JITAE.

5. Experimental Results

According to Formula (8), the controlled object of the system is

As can be seen from Formula (36), the coefficient of

s2 is much lower than the other coefficients, so it is simplified here. The transfer function

G(

s) can be approximated as

The transfer functions

serve as the foundation for the fractional-order PID controller, and their initialisation

yields the following information:

Set the phase angle margin Pm = 7π/10 and the crossover frequency ωc = 1500, and calculate the RRB, IRB.

RRB: ki = 0, IRB: kd = none.

From Step 2, the value range of the order parameter of the fractional-order PID controller must be

and

. Calculate the position of the system stability interval SR under the conditions of different integral and differential orders and determine the value range of

ω as [

ωmin ,

ωmax]. Taking

λ = 1.5 and

μ = 0.5 as examples, the

kdsup value of the transfer functions is obtained as

kdsup = 13.

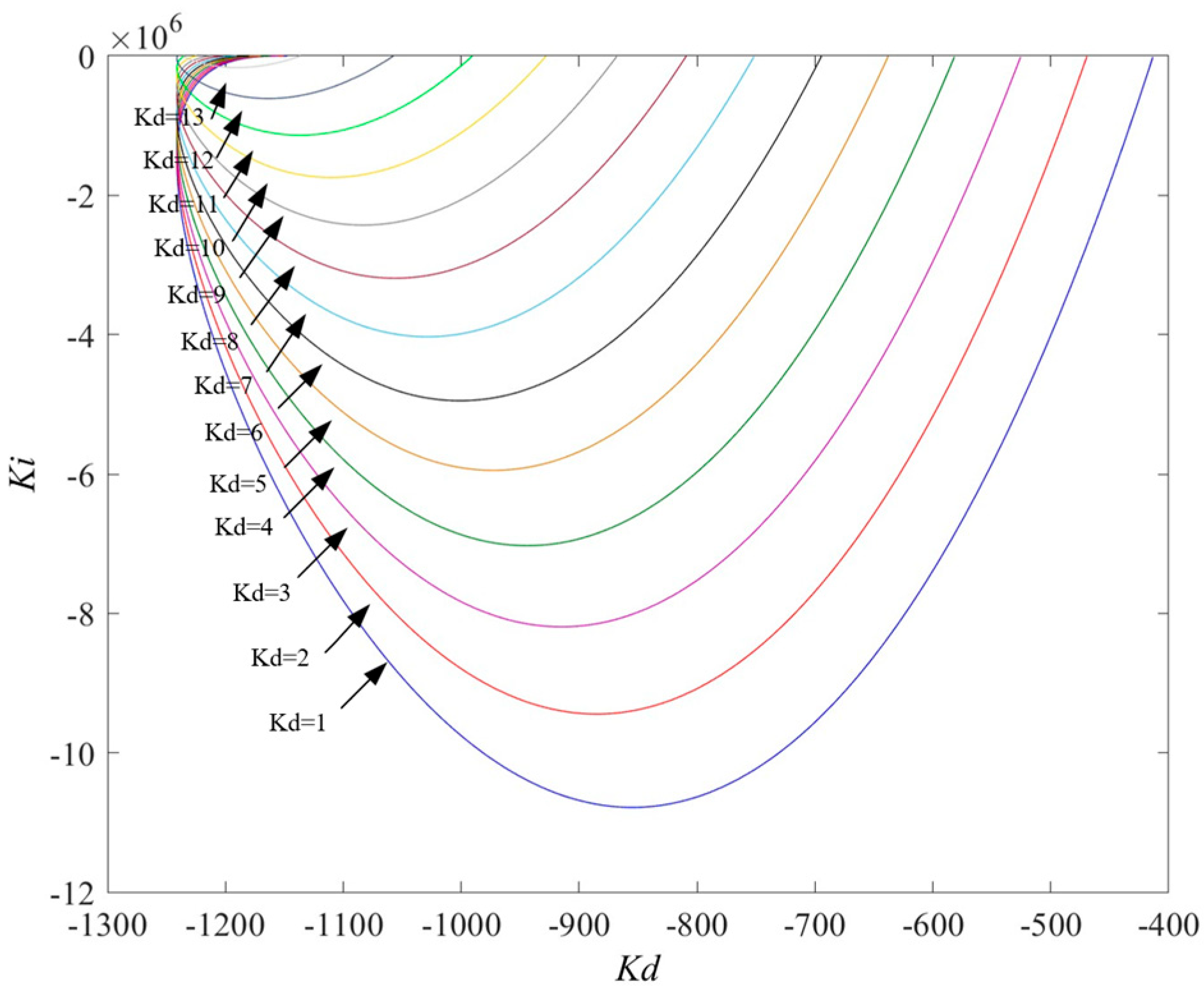

Figure 4 shows the SR of the transfer functions

under different

kd values. From the graph analysis, as

kd increases, the SR area of the system gradually decreases.

According to Formula (34), the relationship between the optimal

kd value and

λ,

μ under the conditions of different order parameters

λ and

μ is obtained, as shown in

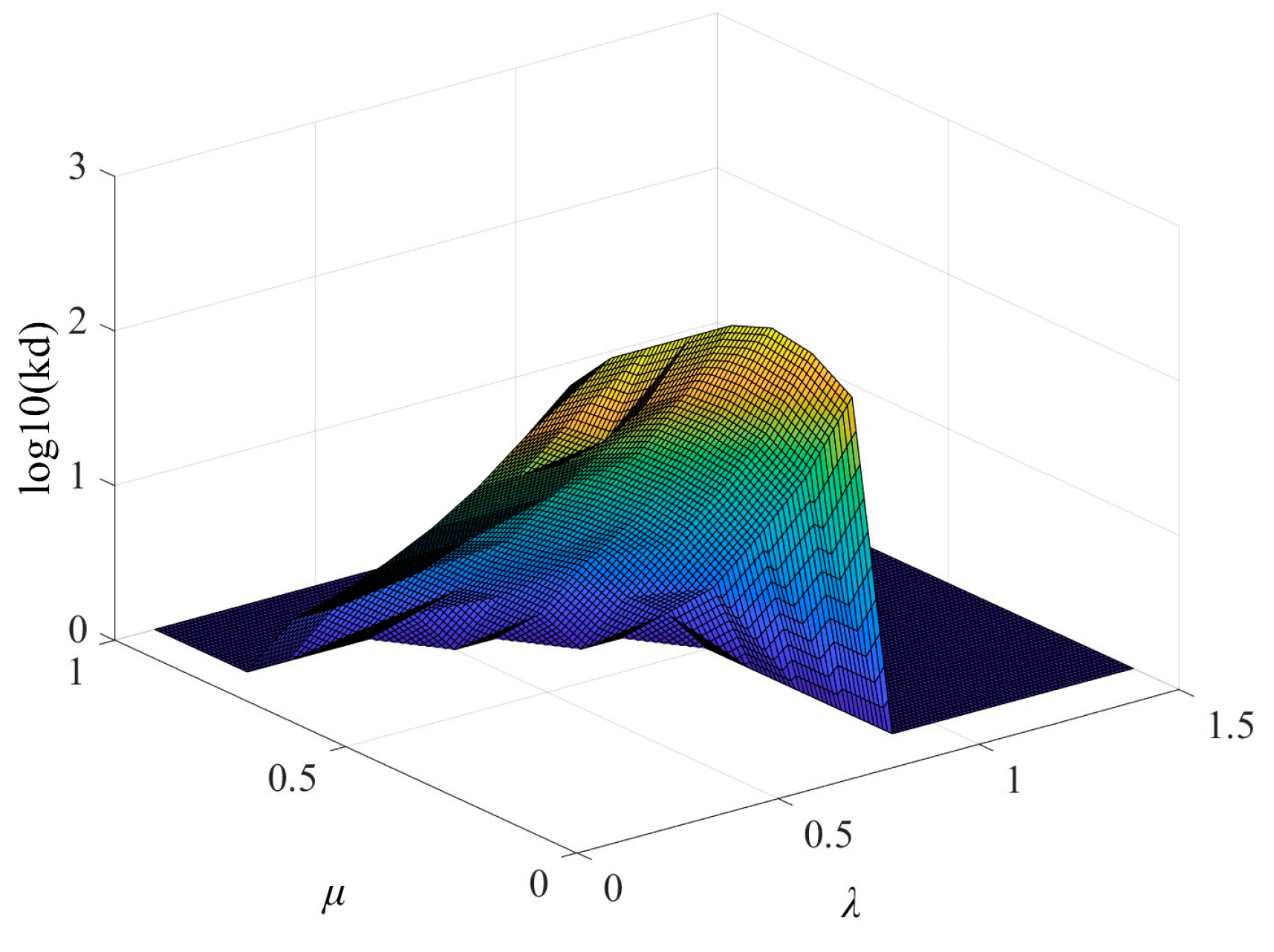

Figure 5.

Given the parameters

kdbest,

λ and

μ, the performance index

JITAE of the control system under different conditions is calculated.

Figure 6 depicts the link between

JITAE and parameters

λ,

μ. The graph analysis reveals that the integral order

λ has a significant impact on the

JITAE of the system while the differential order

μ has less of an impact.

Under the condition of Pm = 7π/10 and ωc = 1500, when the order parameters of the transfer function are λ = 1.6 and μ = 0.5, the minimum value of the performance index JITAE is JITAE = 6.913 × 10−9.

Consequently, the intended fractional-order PID controller parameters can be obtained as

By setting the order to one and using the same method, the parameters of the PID controller are designed as follows:

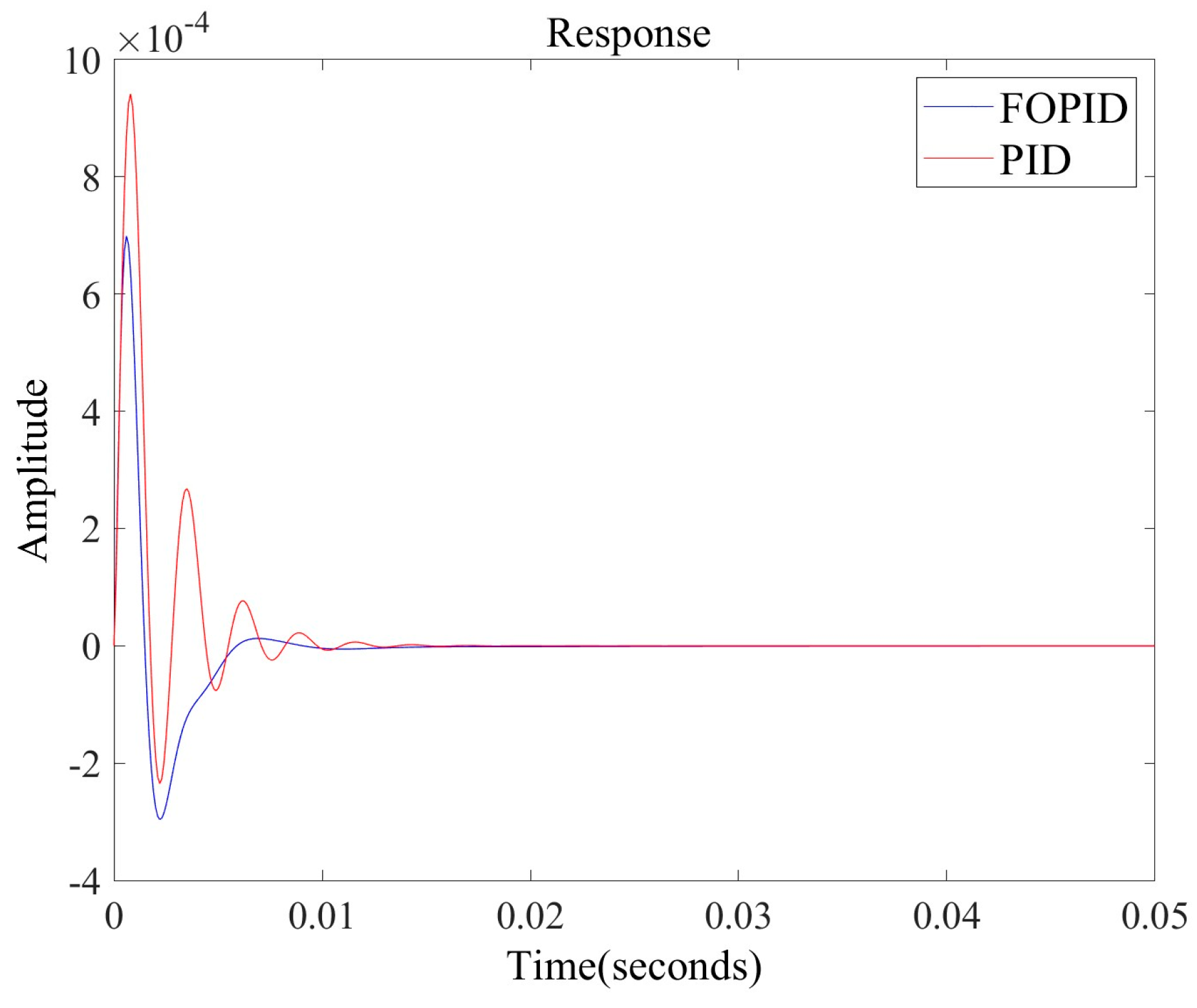

Figure 7 shows the responses of the transfer functions

under fractional-order and integer-order PID controls, indicating that the control system has a significant overshoot and many oscillations following the addition of the integer-order PID controller. Excessive overshoot significantly affects the system’s performance. In some practical engineering systems, an excessive overshoot may lead to devastating consequences that are not allowed. More oscillations and longer adjustment times also significantly reduced the system’s stability. The addition of the fractional-order PID controller reduces the system’s overshoot and the number of oscillations based on the PID controller, shortens the system’s adjustment time, significantly enhances the system’s performance, and boosts the quality and efficiency of control owing to the introduction of two parameters of the fractional-order PID controller, which makes the controller province more compatible with the controlled object and improves the controlled freedom.

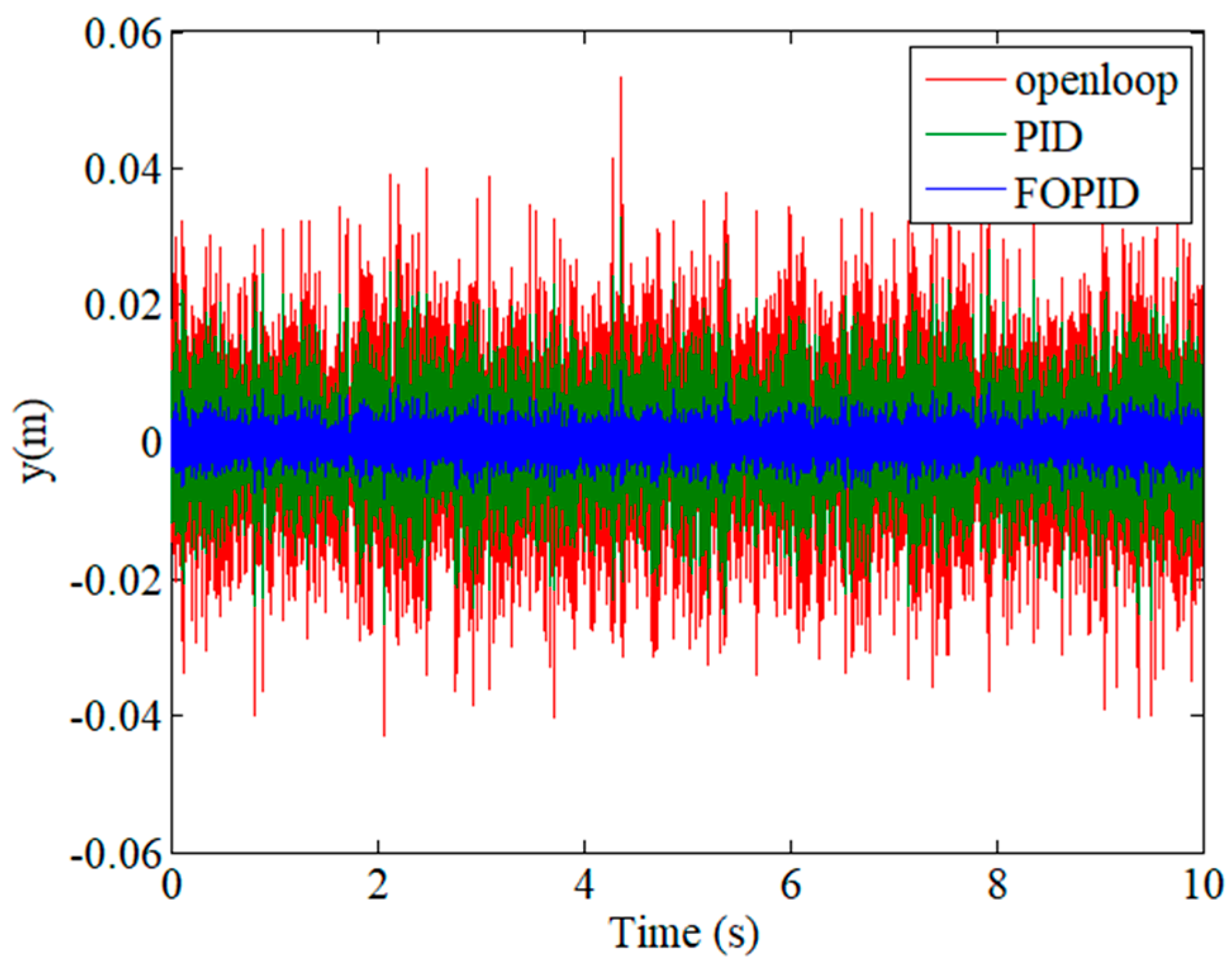

Figure 8 shows the output of the system vibration for a distributed piping system without a controller, with a PID controller and with a fractional-order PID controller. The PID controller can reduce the vibration of the piping system. According to the analysis shown in the figure, its control effect is limited. However, this approach is insufficient for demanding control systems. The fractional-order PID controller, based on the PID controller, can further reduce the vibration output of the piping system. The vibration amplitude can be maintained within a particular range, thereby reducing damage to the pipeline and improving its continuous use time. Therefore, the reference of the integral order

λ and differential order

μ in a fractional-order PID controller can improve the control precision of the controller and obtain a better control effect.