1. Introduction

Despite the abundance of research in advanced control strategies, the PID (proportional-integrative-derivative) controller remains the preferred control algorithm in industrial applications [

1,

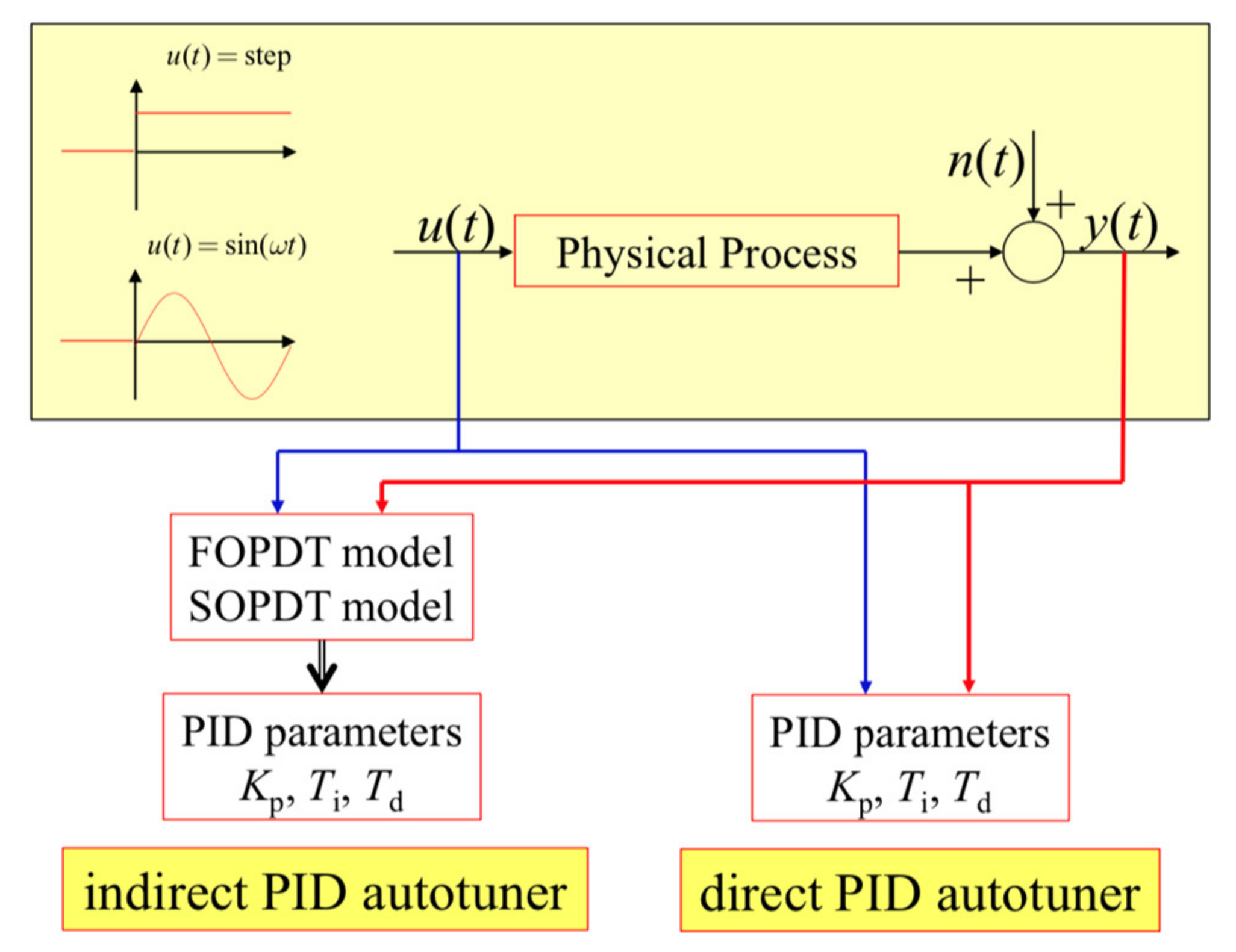

2]. To produce the desired effects, PIDs need to be adequately tuned. A mathematical model is usually needed in order to properly tune the controller. However, large industrial plants are characterized by numerous sub-systems and obtaining an accurate process model is not cost effective as it can be difficult and/or time consuming. To overcome this issue, two different approaches for autotuning PIDs were developed, as indicated in

Figure 1.

Both approaches use step or sinusoidal input data and collect the process output response. For a direct autotuner the PID parameters are determined directly from process input/output data, while for the indirect PID autotuner, simple process models are first determined and then the PID parameters are computed according to some tuning rules based on the model parameters. The majority of indirect methods use either first-order plus dead time (FOPDT) or second-order plus dead time (SOPDT) models.

Two of the most popular autotuning methods have been developed by Ziegler and Nichols [

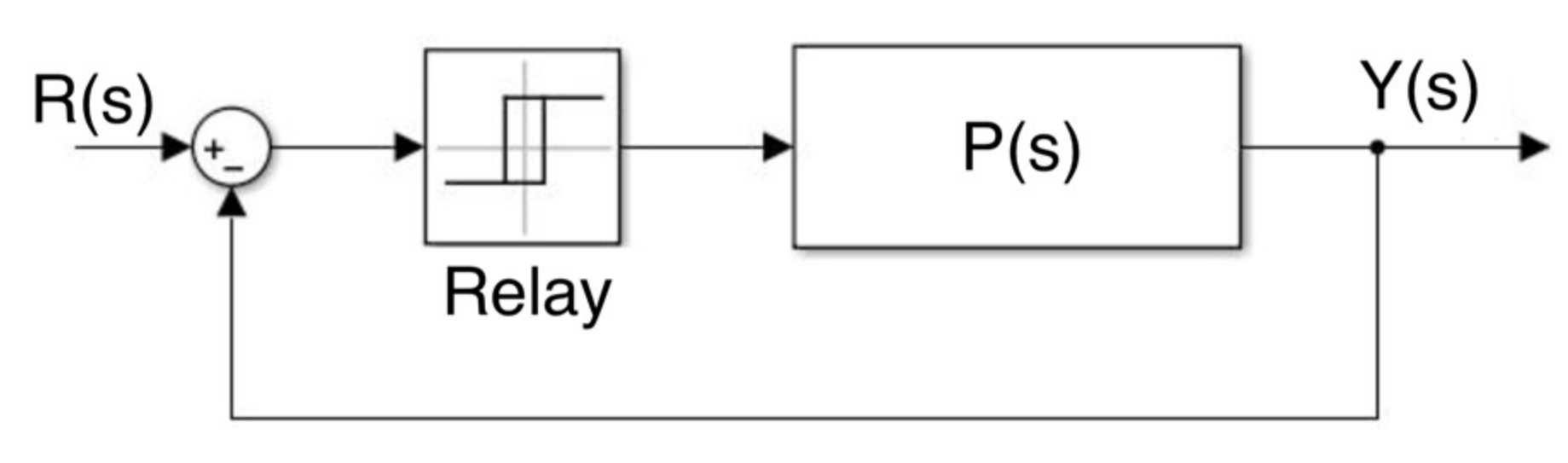

3]. One of these methods is a direct approach, based on the relay experiment, as indicated in

Figure 2. Once the relay test is performed on a process, it will lead to a sinusoidal output signal which is used to estimate the process critical frequency and the corresponding critical gain. Tuning rules based on the process critical frequency and gain are employed to compute the PID controller parameters. The Ziegler-Nichols direct autotuning method is highly popular because of its simplicity and good performance results.

Several extensions of this approach and alternative solutions have been developed over the years. One of these uses the describing function analysis and a simple relay feedback test to estimate the process critical gain and corresponding frequency [

4]. A solution for noisy signals was proposed based on a relay with hysteresis [

5]. An artificial time delay is added within the relay closed-loop system in order to determine the process gain and phase at a random oscillation frequency. Then, a PI (proportional-integrative) controller is tuned according to this process data. A modified Ziegler-Nichols method [

6]—where the ratio between the integral and derivative time constants is

r = 4—was also developed. Other research papers discuss the impact the ratio value has upon the control performance [

7]. Solutions to improve the robustness of the control system have been addressed [

2]. Åström and Hägglund [

1] use the relay test to design controllers based on robust loop shaping, with a clear tradeoff between robustness and performance.

The second method developed by Ziegler and Nichols [

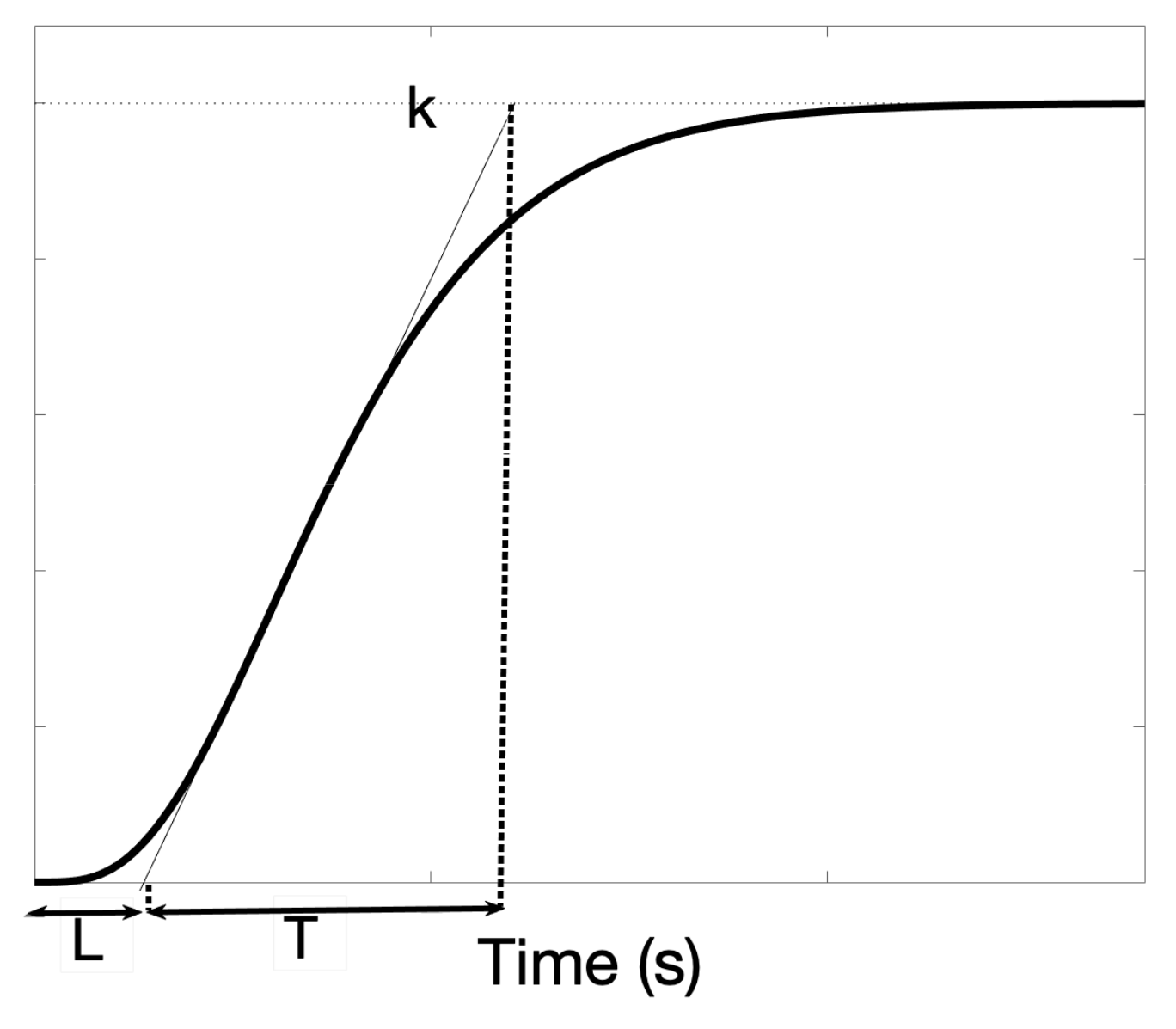

3] consists in applying a step signal on the process input and collecting the output data. The method is suitable for processes that have FOPDT dynamics or exhibit an S-shaped response, as indicated in

Figure 3. The approach goes through an indirect step, where the parameters of the FOPDT model are estimated. Finally, the PID controller parameters are computed using a set of tuning rules that depend on the FOPDT model parameters.

The demand for better control performance and increased robustness has led to several modifications of the standard PID controller, including a generalization to fractional order [

8]. Research on fractional order PID (FO-PID) controllers has demonstrated that this generalization allows for more flexibility in the design, due to the two supplementary tuning parameters involved, the fractional orders of integration and differentiation [

9,

10,

11,

12,

13]. This flexibility comes with important advantages, such as better closed-loop performance, disturbance rejection capabilities, improved control of time-delay systems and increased robustness [

9,

10,

11,

12,

13,

14]. The fractional order PID transfer function is given as:

where

and

are the fractional orders of integration and differentiation, respectively, and

kp is the proportional gain, and

Ti and

Td are the integral and derivative time constants. The “classical” tuning rules used to determine the five controller parameters are derived from the following performance specifications [

9,

12,

15,

16,

17]:

- 1.

A gain crossover frequency

ωc. This leads to the magnitude condition:

with

Hol(s) the open-loop transfer function is defined as:

Hol(s)

= P(

s).

CFO-PID(s), where

P(

s) is the process transfer function;

- 2.

A phase margin PM. This leads to the phase condition:

- 3.

Iso-damping property (or robustness to gain variations). This is specified through:

where

denotes the frequency. This last condition ensures that the overshoot of the closed-loop system remains approximately constant in the case of gain variations;

- 4.

Good output disturbance rejection. This leads to a constraint on the sensitivity function

S:

for frequencies

, with

B a scalar;

- 5.

High frequency noise rejection. This leads to a constraint on the complementary sensitivity function

T as:

for frequencies

, with

A a scalar.

Further information regarding the tuning, implementation and related topics to fractional order PIDs can be found in some excellent review papers [

15,

16,

18,

19,

20,

21,

22,

23,

24]. The phase shaper [

25] is among the first automatic controller designs that uses fractional calculus tools. The autotuning method is based on the iso-damping property, but the final controller is an integer order PID. Throughout the past two decades, a couple of FO-PID autotuning methods have emerged. Some of these provide direct and indirect tuning rules for FO-PIDs in general or for fractional order PI (FO-PI) controllers. The purpose of this manuscript is to offer a comprehensive review of these autotuning methods, to compare them and to discuss which method is ranked best for controlling a specific type of process.

The paper is structured as follows.

Section 2 and

Section 3 provide for a review of the most widely known indirect and direct autotuning methods for FO-PIDs, while

Section 4 provides for some numerical examples. Possible applications of autotuning methods are reviewed in

Section 5, along with a survey on self-tuning FO-PIDs. The last section concludes the paper.

2. Indirect Fractional Order Autotuning Methods

A popular indirect autotuning method, suitable only for FO-PIs, was developed by extending the

Ms constrained integral (MIGO)-based controller design approach [

26]. F-MIGO tuning determines the optimum parameters of the FO-PI controller such that the load disturbance rejection is optimized, with a constraint on the maximum or peak sensitivity. The F-MIGO method provides the tuning rules for the FO-PI controller provided that the process step response has an S-shaped form, as indicated in

Figure 3, that could be approximated by the following transfer function:

where

k is the process gain,

L is the delay and

T is the time constant of the process. The relative dead time can be computed as:

Systems where

L >>

T are delay dominant, whereas systems in which

T >>

L are lag dominant. Research studies performed in [

26] revealed that the FO-PI fractional order is almost independent of

L, but depends on the relative dead time. For some particular situations, where

, an integer order PI controller was determined to be more suitable for controlling the process. A summary of the results is indicated below:

The proportional and integrative gains of the FO-PI controller were also determined as a function of the relative dead time:

An indirect autotuning method that applies to the S-shaped step response process was developed in [

27]. The tuning is unnecessarily complicated as the parameters of (7) are firstly estimated and then used to determine the process critical frequency

and critical gain

, according to:

Then, the parameters of an integer order PID are determined using the previously computed process critical frequency and gain, as well as three additional design parameters referring to the ratio of the integral and derivative time constants, loop phase and gain:

where

,

rb and

are design parameters [

28]. Once the PID controller parameters are computed, a possible range for the fractional orders in the FO-PID is selected and an optimization routine is performed. The algorithm attempts to minimize the integral time absolute error with the open loop gain and phase margin imposed as design specifications.

Another indirect tuning method is proposed in [

29] for processes that produce an S-shaped step response. The method is based on determining first the process dead time

L and time constant

T, as well as the value at which the system reaches steady state

k. The standard Ziegler-Nichols equations are used then to estimate the

kp,

Ti and

Td parameters of an integer order PID. Then, the fractional orders of differentiation and integration are determined by the Nelder-Mead optimization algorithm in order to meet certain phase and gain margins. A second approach based on the standard Cohen-Coon method is also used in [

29], for processes that exhibit first order plus dead time dynamics. Based on the process parameters, the integer order PID parameters are first computed. The Nelder-Mead optimization algorithm is used afterwards to estimate the fractional orders of differentiation and integration based on certain phase and gain margin requirements. The Cohen-Coon tuning method is proposed as an alternative to the Ziegler-Nichols approach in order to improve the slow, steady state response of the latter.

An indirect autotuning method for designing only FO-PI controllers using the Ziegler-Nichols open-loop approach is described in [

30]. The parameters of the integer order PI controller are firstly determined using the standard Ziegler-Nichols approach. In order to improve the overall closed-loop response, the research suggests that the PI performance can be improved a lot with a fractional order of integration. An error filter as proposed in [

31] is used for steady state error compensation:

where

n is chosen to be small enough so that high frequency specifications are maintained and the system gain will not be altered drastically. The research in [

30] proposed a modification of (13) such that the value of

n is adjustable with respect to the fractional order of integration. The tuning of the fractional order and of the filter is performed by trial and error for a specific type of process. The method is evaluated experimentally on a steam temperature process and compared to the F-MIGO method [

26] in terms of robustness for set point changes and disturbance rejection. The proposed controller shows better performance compared to the F-MIGO autotuning method, but it also requires higher control effort.

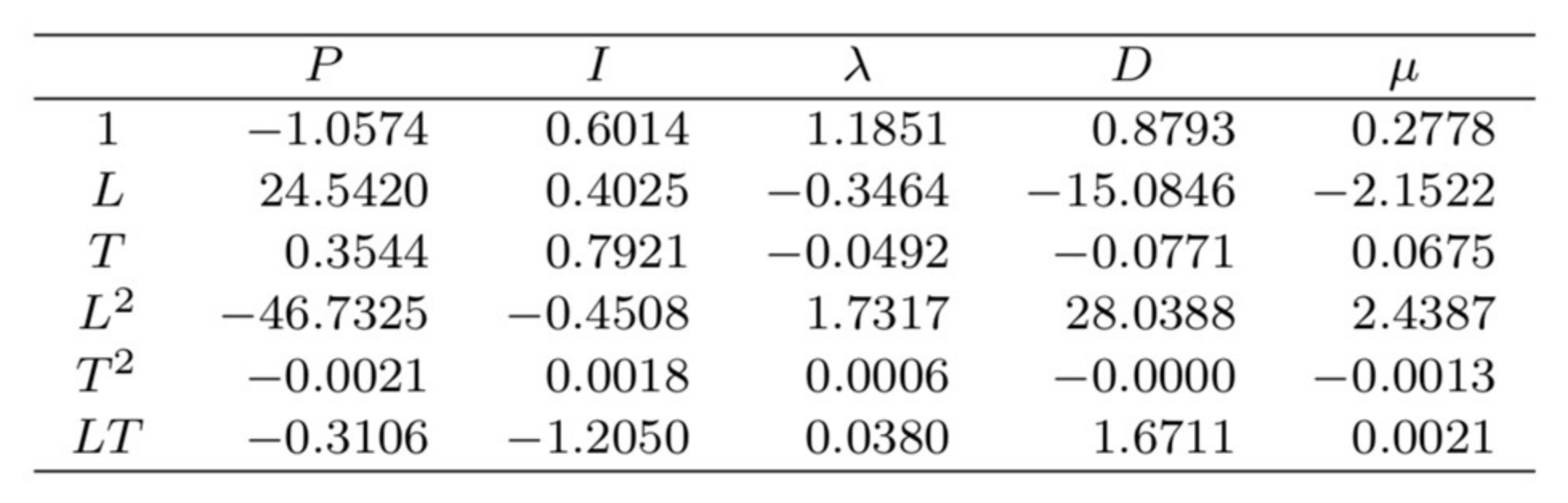

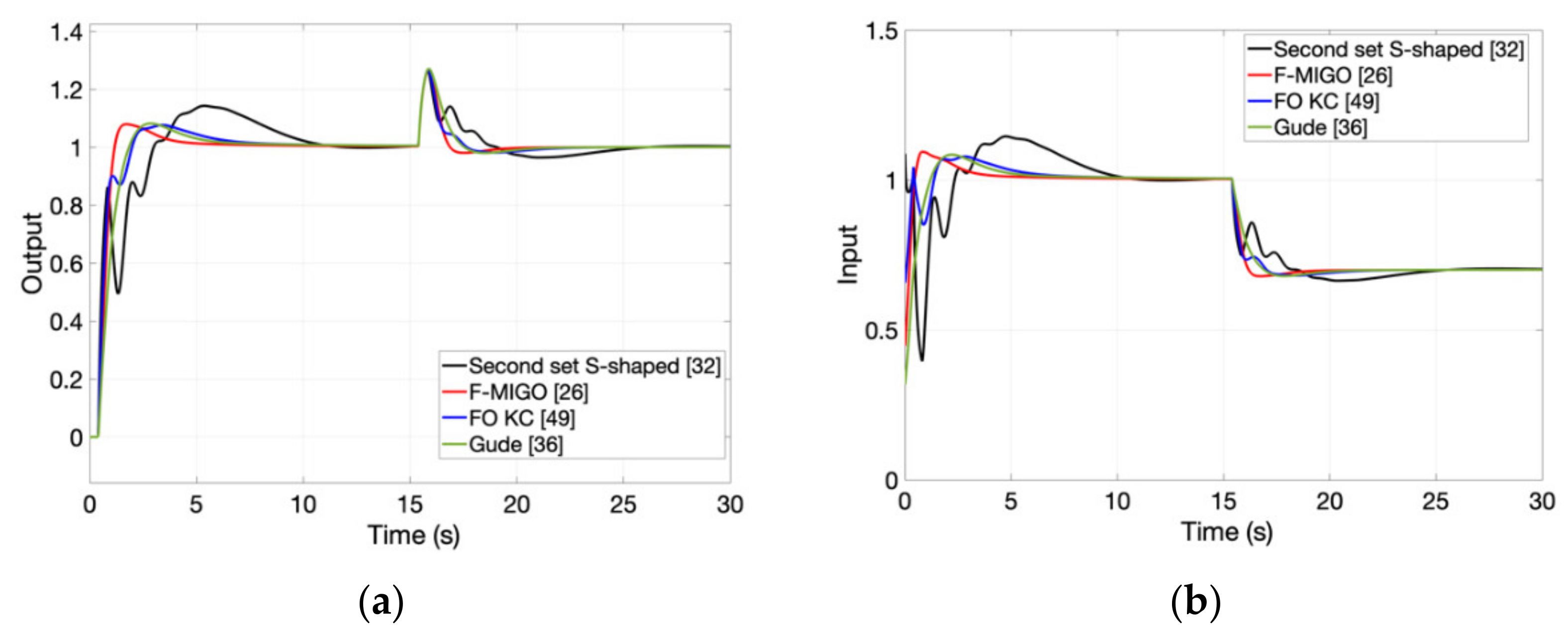

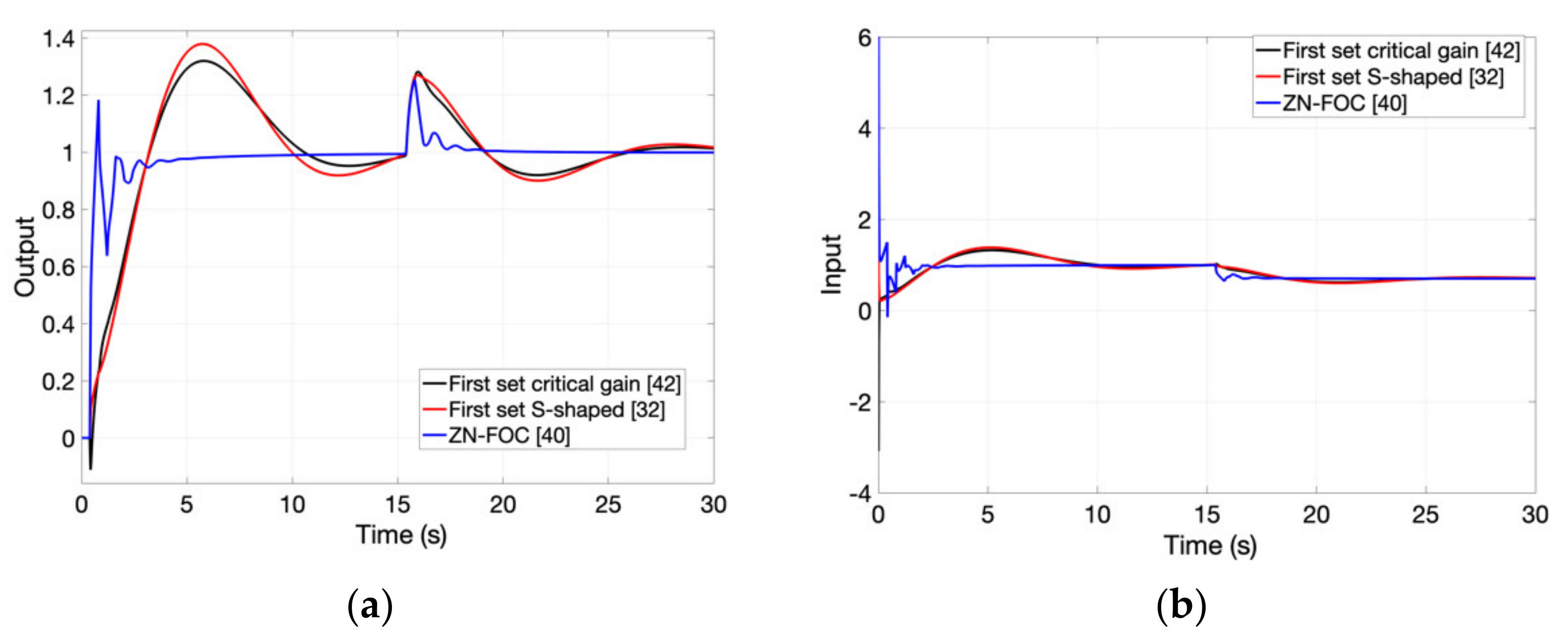

In [

32], two existing analytical methods for tuning the parameters of fractional PIDs are reviewed. Then, for two specific sets of performance criteria similar to (2)–(6), the corresponding sets of tuning rules are developed based on an optimization method applied to the FO-PID control of an

S-shaped process dynamics similar to (7). The newly developed tuning rules for fractional order PIDs use the time delay

value and the estimated process time constant,

T, much like the standard S-shaped Ziegler-Nichols approach, to produce the controller parameters. The method works provided the step response of the process is

S-shaped. These two methods were initially presented in [

33]. The first set of rules developed works if

and

, while the second set of rules can be applied for processes with

and

. Both sets of rules are determined in a similar manner. For a batch of process described as FOPDT systems, a set of performance specifications is imposed. The set included values for the gain crossover frequency, for the phase margin, a high-frequency value for the improved high-frequency noise cancellation and the corresponding maximum magnitude limit, as well as a low frequency value for improved output disturbance and the corresponding maximum magnitude. Tuning by minimization is then applied using the fmincon Matlab

® (Natick, Massachusetts, USA) function, where the magnitude equation in (2) is used as the main function to minimize, whereas the remaining conditions in (3)–(6) are used as constraints. Using least squares fit, polynomials are determined to compute the controller parameters based on the process time constant

T and time delay

L:

. Using

Figure 4 and

Figure 5, for the first set of rules and for the second one, the FO-PID controller parameters, as indicated in (1), can be finally computed:

3. Direct Fractional Order Autotuning Methods

Most of the direct autotuning methods are based on using the relay test to determine the process critical gain and critical period of oscillations, but other methods have been developed [

34].

Several generalizations of the Ziegler-Nichols ultimate gain method have been proposed over the years for the tuning of FO-PIDs. A new tuning method for such a controller that combines both the Ziegler-Nichols as well as the Astrom and Hagglund methods has been proposed in [

35]. The idea is based on obtaining the process critical frequency and critical gain and then computing the

kp and

Ti parameters using the classical Ziegler-Nichols method. For a specified phase margin, the

Td parameter is computed using the Astrom and Hagglund method. Two equations referring to the controller’s real and imaginary parts are obtained. Fine tuning of

Td is employed to achieve the best numerical solution of the equations, for each specified phase margin. Matlab

®’s built in functions, such as fsolve, are used to solve the two equations to obtain numerical values of

λ and

μ by considering the new value of

Td for each specified phase margin. An optimization Simulink model is used to obtain a better step response. The least squares method is used in the optimization model and the optimized FO-PID parameters are obtained. The approach is tedious and involves three controller designs before the final optimized FO-PID is obtained. However, the design allows for a direct specification of the loop phase margin.

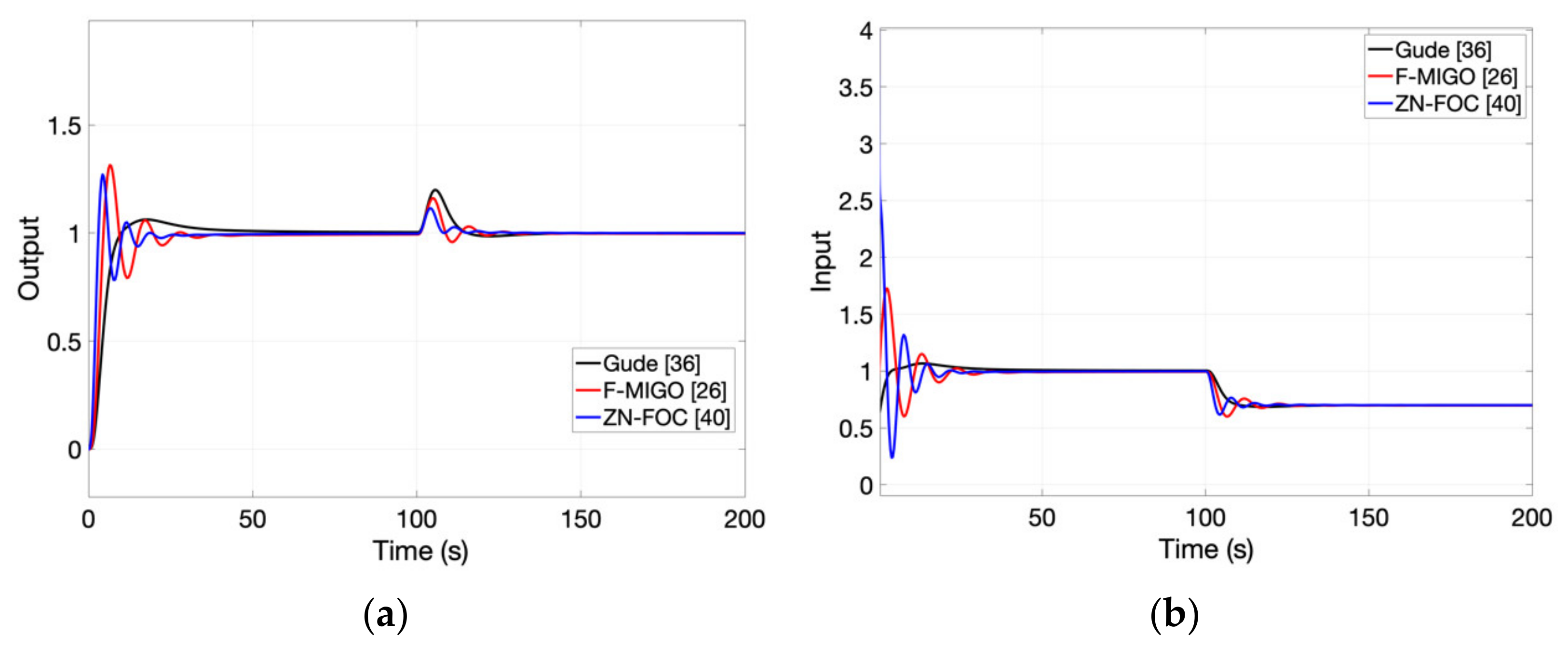

In [

36], an extension of the modified Ziegler-Nichols tuning rules for fractional-order controllers is presented. The proposed design approach is only suitable for tuning fractional order PI controllers. The tuning rules are derived without any knowledge of the process model, but they require the critical frequency

, as well as the corresponding critical gain

kcr. Based on this process information, the FO-PI autotuning objective is to determine the controller parameters such that the loop frequency response is moved to a point in the Nyquist plane where a performance criterion is minimized, according to a constraint. The performance criterion is mathematically expressed as a measure of the system ability to handle low-frequency load disturbances, subjected to a robustness constraint referring to the maximum sensitivity function of the closed-loop system. The tuning rules are given by:

where

,

,

,

and

, with

k the process gain as indicated in (7).

The method is compared with several other direct and indirect autotuning methods for integer order PIDs and it provides good performance results. The method is also compared to some similar autotuning approaches developed in [

37,

38] and the results demonstrate the superiority of the current approach.

A similar idea as the one used in [

31] is employed in [

39], where an error filter is cascaded with a FO-PI controller. Unlike the autotuning approach taken in [

31], the research in [

39] is focused on estimating the parameters of an integer order PI controller using the relay method. An estimation of the process critical gain and period of oscillation is firstly determined, which in turn leads to the computation of an integer order PI controller parameters according to the standard Ziegler-Nichols approach. The same error filter is used in [

39] as in [

31] with the same advantage. Various values for the fractional order integration are used and the results evaluated on a steam temperature process. Experimental results show that the FO-PI controller leads to better performance during the set-point change and load disturbance test in terms of output and control effort. However, poor closed-loop performance is obtained if

λ is set too low. Even though both the direct [

39] and the indirect [

31] autotuning methods are simple enough for designing the FO-PI controllers, there is no clear advice on the selection of the fractional order of integration.

A modification of the Ziegler-Nichols closed-loop method is proposed in [

40]. The method provides for an improvement of the standard Ziegler-Nichols results. The idea is based on the fact that a fractional order can help shape the “direction” of the loop frequency response in a fixed point in the Nyquist plot and thus keep the loop frequency response further away from the −1 point. The process critical frequency of oscillation, as well as the critical gain are obtained based on the relay test. To simplify the tuning method, the same fractional order of integration and differentiation is used in the FO-PID, similarly to [

41]:

where

and

. The ratio

between the integral and derivative time constants is considered to be a design parameter. The final tuning rules are exemplified for a ratio

r = 4, similarly to [

6,

41]. Unlike the standard Ziegler-Nichols approach, the tuning rules depend not only on the process critical gain

Kcr and critical period of oscillation

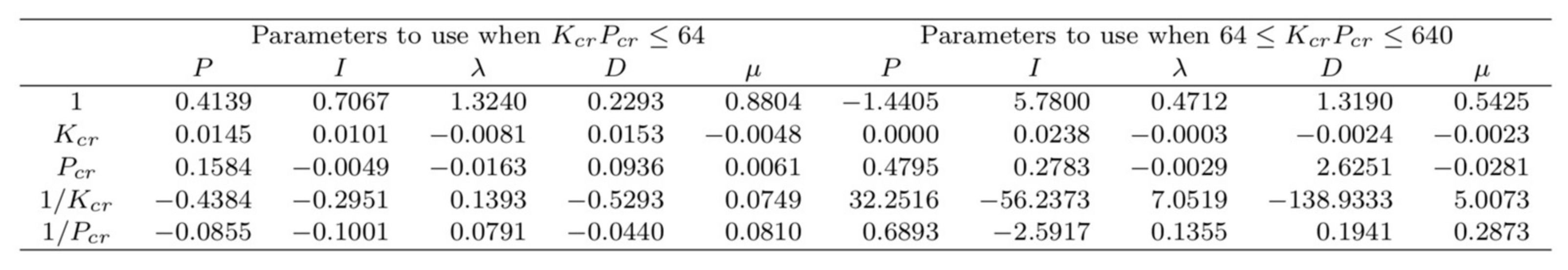

Pcr, but also on the fractional order. The parameters of the FO-PID controller can thus be easily computed, without any complex optimization procedure [

40], as indicated in

Table 1.

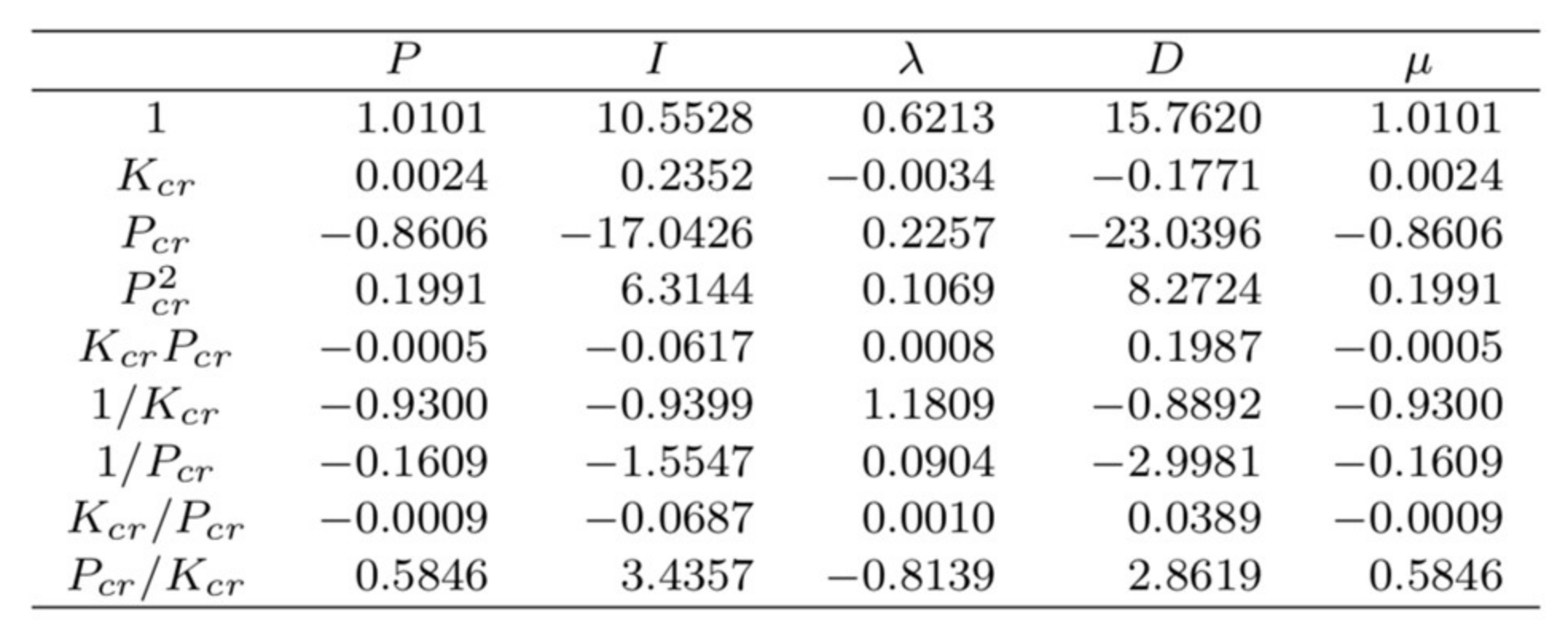

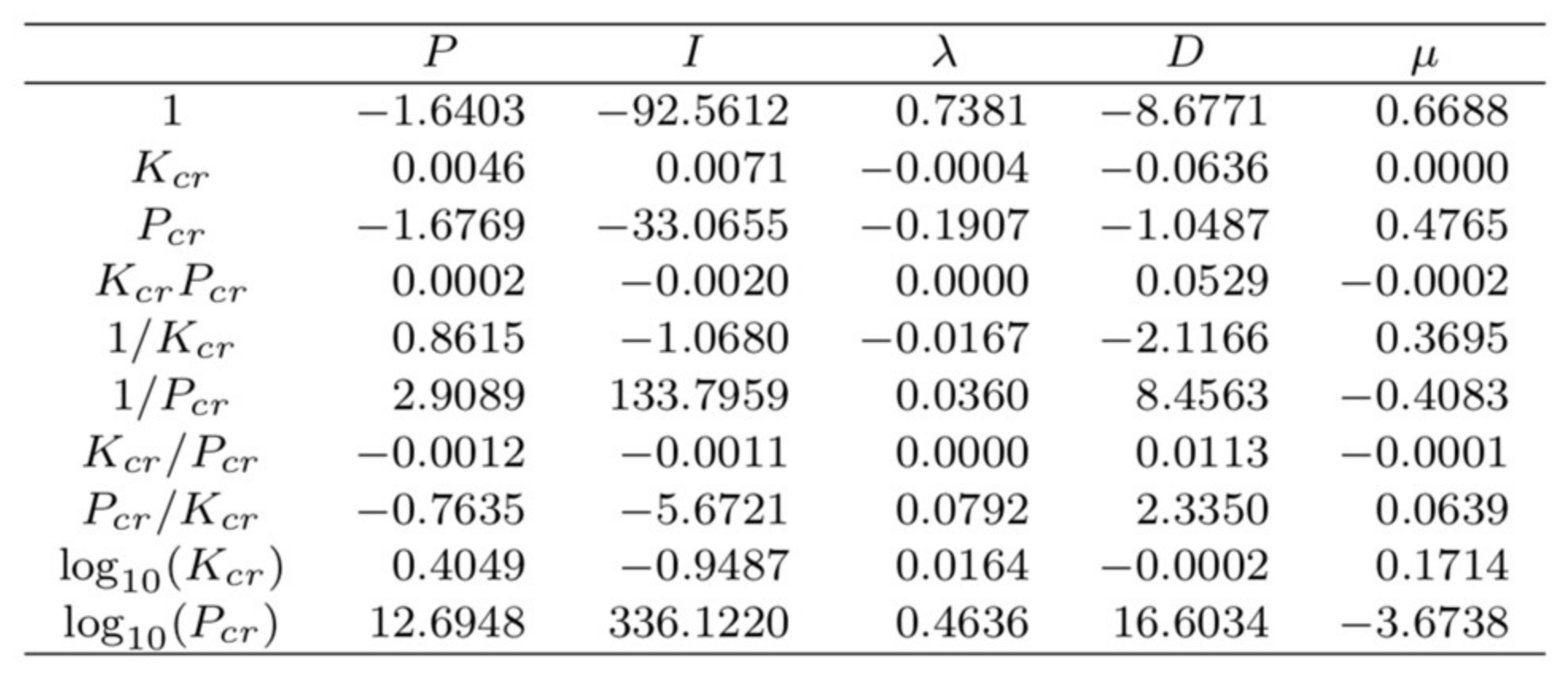

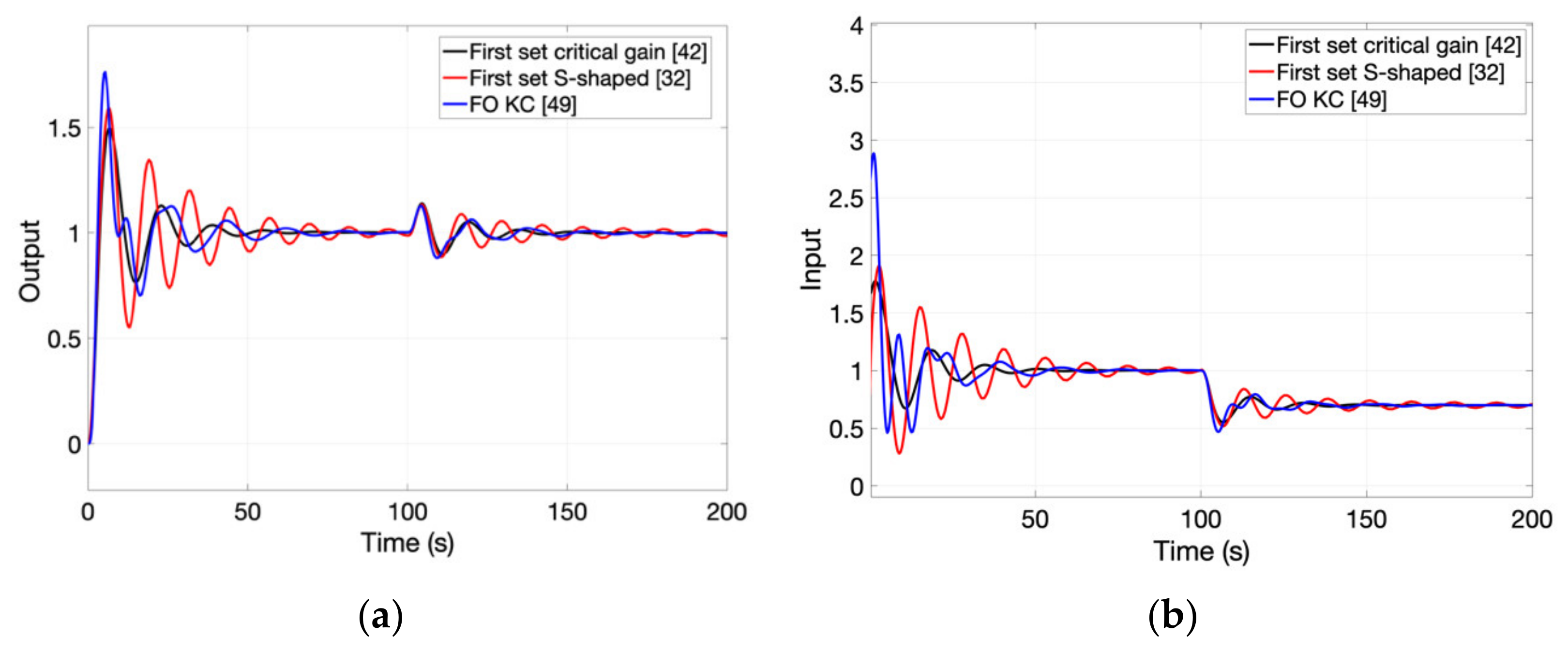

The critical process gain and period of oscillation are used in [

42] to determine the parameters of a FO-PID controller. Three sets of tuning rules are developed. Processes described as FOPDT systems are used for two of the sets, whereas for the third one, integrative processes are considered. The first set of tuning rules applies when the critical period of oscillations

and

. For the case when

, a second set of tuning rules is developed. Both of these are quite restrictive and do not often work properly for plants with a pole at the origin [

42]. The third set of rules is designed specifically for integrative processes (without time delay), but can be used only when

and

. The research in [

42] concludes that the closed-loop performance can be poor near the borders of the mentioned range. All of these rules were developed in order to meet certain performance specifications regarding the loop gain crossover frequency, phase margin, iso-damping, rejection of high-frequency noise and output disturbance. All tuning rules are developed similarly to those in [

32], by minimizing the magnitude equation in (2) and using the remaining conditions in (3)–(6) as design constraints. The controller parameters are obtained by polynomial fitting using least squares. The coefficients of the polynomials for the three sets of tuning rules are indicated in

Figure 6,

Figure 7 and

Figure 8.

The relay test is also used in [

43], but with a variation that includes also a time delay, as indicated in

Figure 9. The process frequency response at any frequency can be identified using this scheme. The main issue is to determine the correct value of the time delay that corresponds to a specific frequency. An iterative method is used [

44] and two initial values for the time delay and their corresponding frequencies are needed to start the iteration.

The autotuning method is based on specifying an iso-damping property, a gain crossover frequency and a phase margin. A fractional order PI controller is designed first, followed by a fractional order PD controller with a filter. The fractional order PI controller will be used to ensure the iso-damping property around the gain crossover frequency wcg. The slope of the phase of the plant is computed using the gain crossover frequency and the corresponding phase and a supplementary frequency and its corresponding process phase as resulting from the relay experiment. Once the slope is cancelled using the FO-PI controller, the FO-PD controller is designed to fulfill the design specifications of gain crossover frequency and phase margin. To ensure a maximum robustness to plant gain variations, a robustness criterion based on the flatness of the phase curve of the FO-PD controller is used such that the resulting phase of the open-loop system will be the flattest possible. The procedure is rather lengthy. A mechanical unit consisting mainly of a servo motor is used to experimentally validate the proposed method. The experimental results illustrate the effectiveness of this method.

The same method is described in [

45], where experimental results with the FO-PID on a similar servo motor are used to validate the efficiency of the approach. A refinement of the relay feedback test in [

43,

45] is introduced in [

46]. The improvement is based on adding a moving average filter. Simulation results for the control of a position servo with time delay are presented and validate the autotuning algorithm. The same autotuning method for determining a FO-PID controller for the servo system in [

46] is presented in [

47]. A similar approach is detailed in [

48] for the design of FO-PID controllers. Two numerical case studies are provided for a double-integrator process and a fractional order integrative process. The simulation results validate the autotuning method.

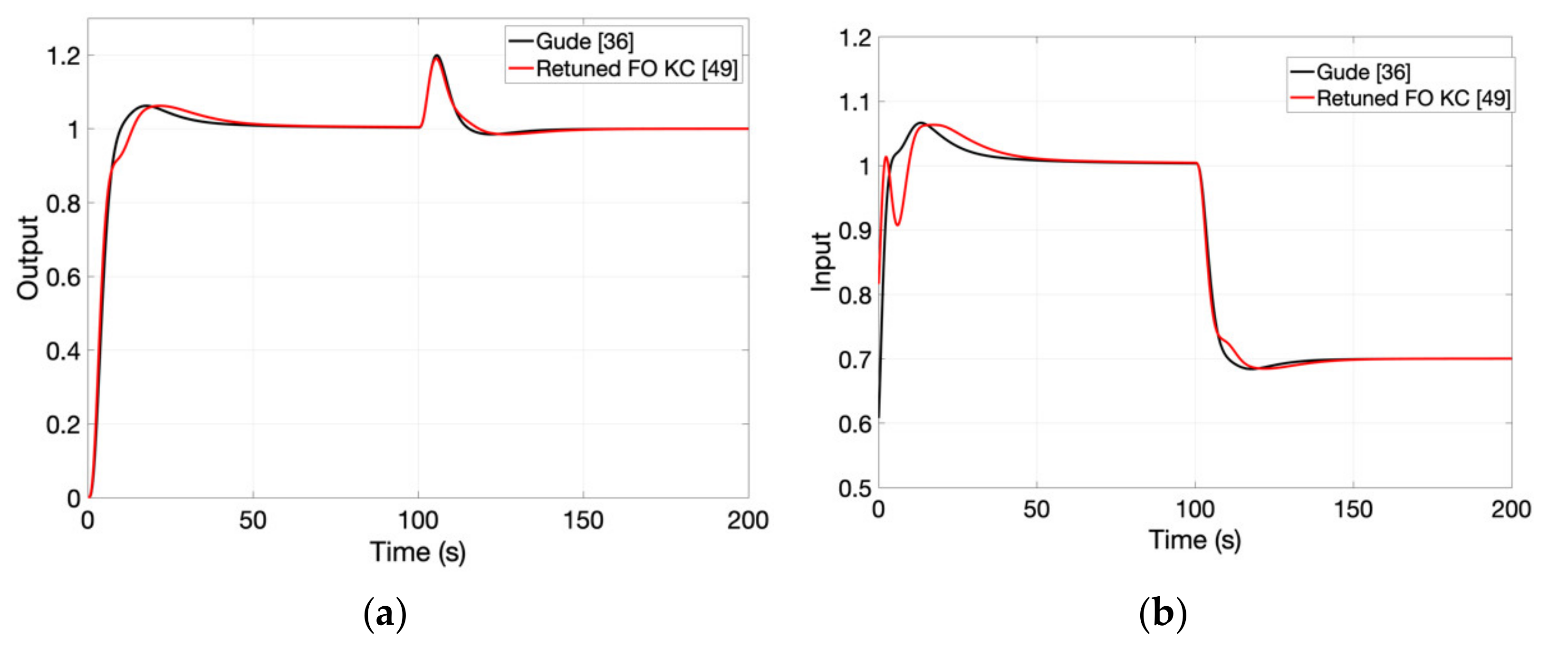

Instead of using the relay test to determine the process magnitude, phase and phase slope, a single sine test at the gain crossover frequency is used in [

34]. Novel filtering techniques are used to determine the process phase slope, as indicated in

Figure 10. To determine the parameters of either a FO-PI or a FO-PD controller, performance specifications regarding the phase margin, gain crossover frequency and iso-damping property are used. The process magnitude, phase and phase slope previously determined are used in the resulting nonlinear equations. Optimization techniques or graphical methods are then employed to determine the controller parameters. Numerical examples are used to validate the approach. A different approach is presented in [

49], where a forbidden region circle is defined based on the iso-damping property and phase margin specifications. The same sine test used in [

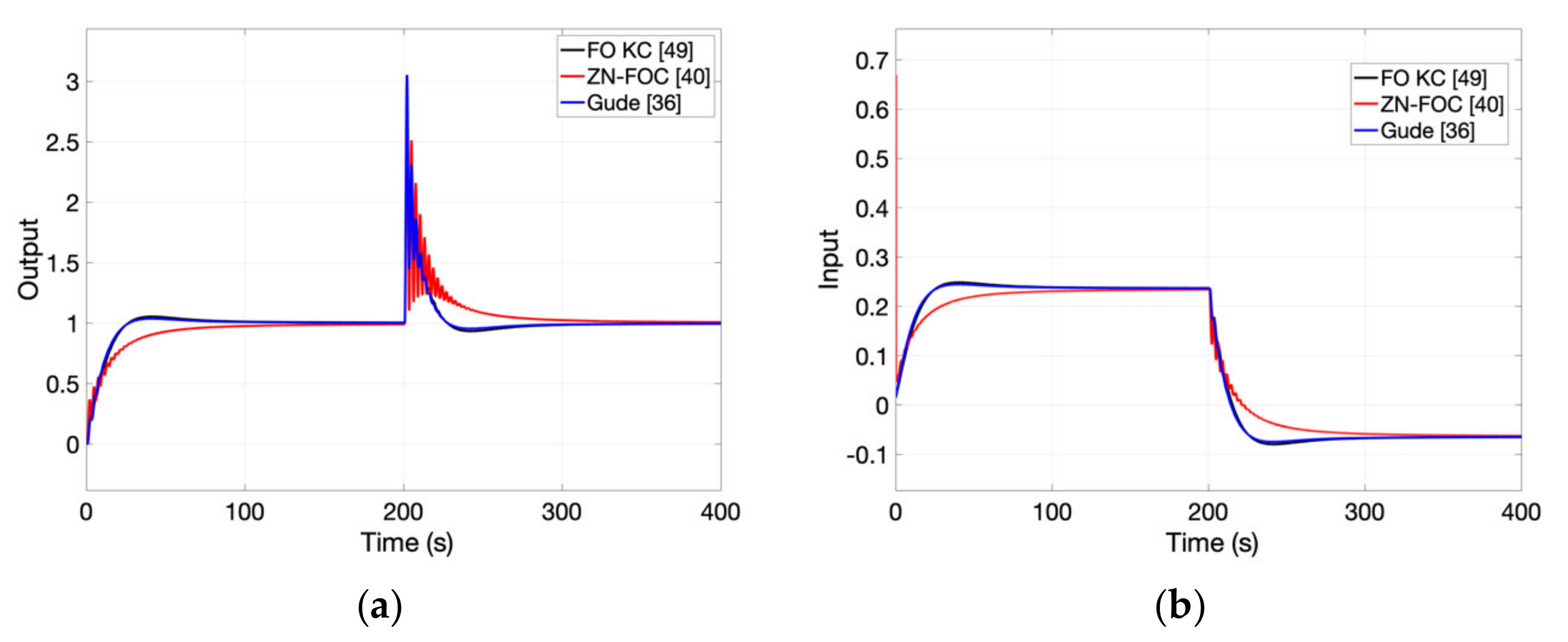

34] is required here as well, in order to estimate the process phase, magnitude and phase slope. Instead of using optimization routines, the parameters of the optimal fractional order PID controller are determined by minimizing the slope difference between the circle border and the loop-frequency response. Numerical results are presented to validate the approach.

5. Applications and Self-Tuned FO-PIDs

Autotuning methods have been used to produce fractional-order controllers for different processes. The purpose of this section is to provide some applicative examples of autotuning methods for fractional-order controllers designed mostly according to the methods presented in

Section 2 and

Section 3. The autotuning method in [

34] is applied to a multivariable time-delay process to tune the FO-PI controllers for each loop [

51]. The method in [

49] is applied for designing fractional-order controller for a multivariable refrigeration system using vapor compression [

52], a heterogeneous dynamic system [

53] and to a highly coupled multivariable system [

54]. A robust autotuning method is described and implemented for controlling an aerodynamic system in [

55]. An experimental validation of the direct autotuning method in [

49] is provided in [

55] for controlling an UR10 robot. The autotuning method in [

34] is applied to tune a FO-PD controller for vibration suppression in a smart beam [

56]. An autotuning method designed for poorly damped systems that shapes the closed-loop system in order to achieve better damping is proposed in [

57]. The design is performed in the frequency domain and requires information regarding the process magnitude and phase for five frequencies. Experimental results are given to validate the efficiency of the method.

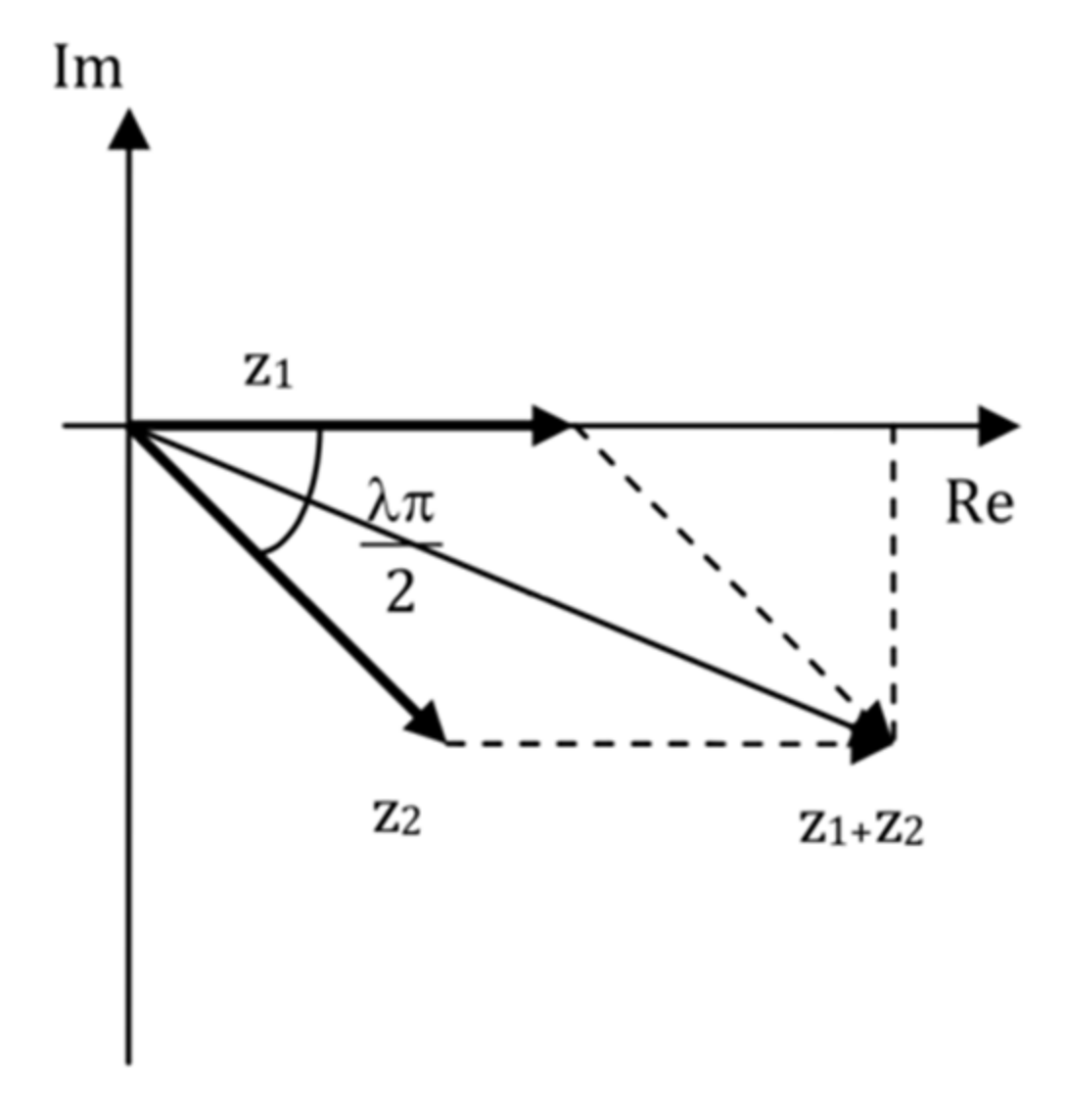

A “plug and play” solution for a multivariable FO-PI controller is developed in [

58] for controlling a multivariable twin-rotor aerodynamical system. A decentralized approach is considered and three performance specifications, as in (2)–(4), are used to compute the parameters of the two FO-PI controllers, one for azimuth and one for pitch angle control. The design is based on a novel, simplified algorithm using vector theory, where the proportional

and integral

terms are defined as vectors. The vectorial representation of the FO-PI controller as the sum of

z1 and

z2 is indicated in

Figure 19.

Then, using classical trigonometric equations based on

Figure 1, the proportional gain and integral time constant of the FO-PI controller are determined as a function of the fractional order

, using the gain crossover equation (2) and the phase margin equation in (3). The procedure is iterative and computes the

kp and

Ti parameters for small increments of

. Then, the iso-damping property in (4) is evaluated and

is selected to be the value that minimizes (4). Finally,

kp and

Ti are computed using the selected value of

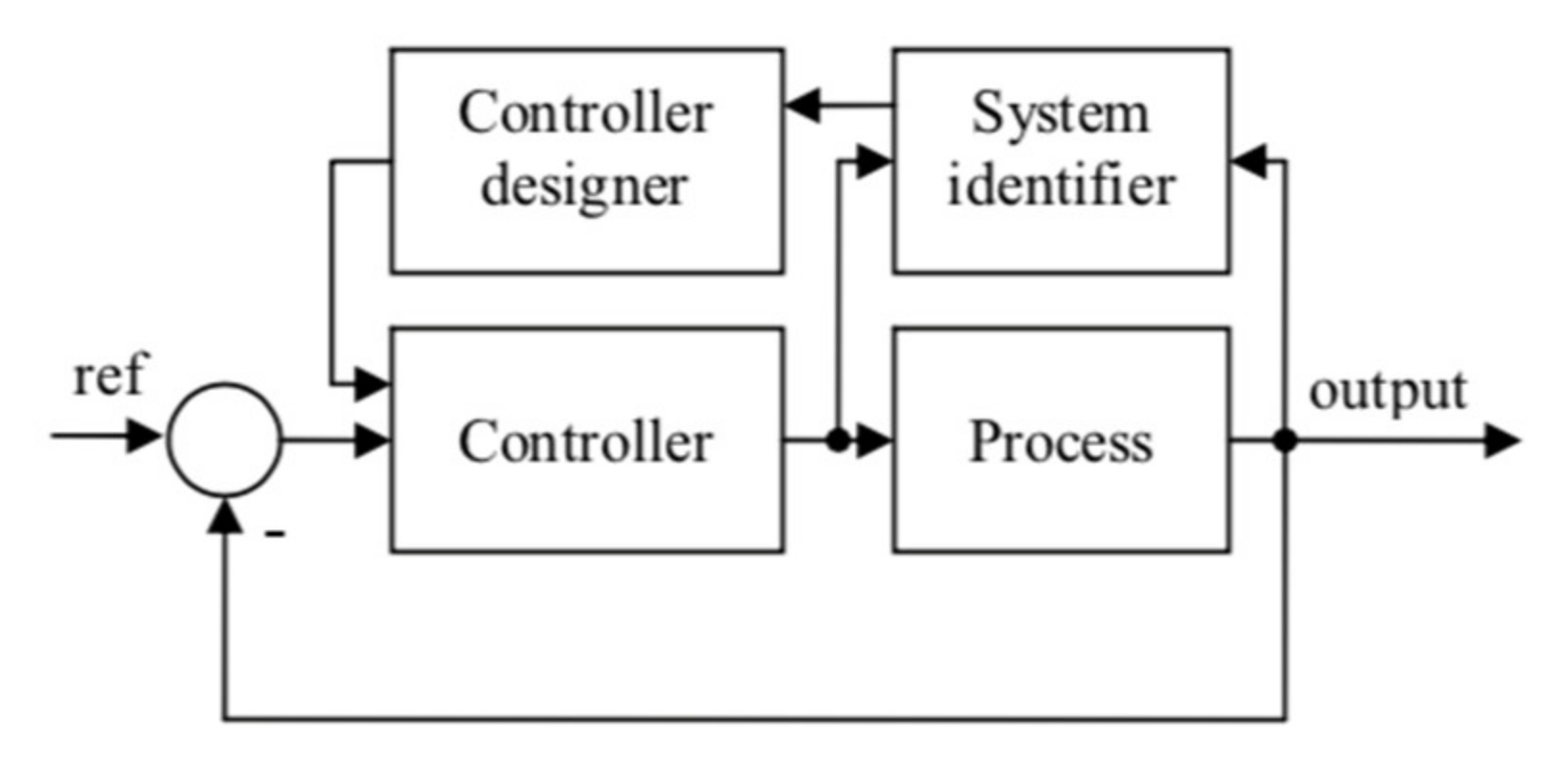

The fractional-order controller is implemented in a self-tuning structure as indicated in

Figure 20, where the “Controller designer” block includes the iterative procedure. The “System identifier” block is used to estimate the process parameters online which are then used in the iterative procedure to determine the new values for the FO-PI controller. A recursive simple least squares algorithm is implemented in the “System identifier” block.

Experimental results are provided to demonstrate the efficiency of the autotuning method. A step reference change of −1 rad for the azimuth angle and a step change of 0.2 rad for the pitch angle is considered, with the experimental results provided in

Figure 21, demonstrating that reference tracking can be achieved successfully using the proposed multivariable self-tuned FO-PI control strategy.

An autotuning approach for FO-PIDs is used to control the air-conditioning fan coil unit [

59]. A basic differential evolution algorithm is modified by varying the mutation factor and crossover rate and used to tune the five parameters of indoor temperature FO- PID controller. Numerical simulations are presented that show that the approach is reliable and the related control performance indexes meet the requirements of comfortable air-conditioning design and control criteria.

Improvements in FO-PID controller design have been considered in order to determine algorithms that perform a better tuning in real time. One solution to this issue is the self-tuned FO-PID controller. The purpose of this last part of the manuscript is to present some ideas regarding additional solutions to autotuning methods that could facilitate the industrial acceptance of FO-PID controllers. In what follows, the manuscript covers an important part of adaptive control algorithms, namely, self-tuning methods, applied to fractional-order controllers. Only the most recent findings in this area of research are reviewed.

Fuzzy logic is usually used to achieve the self-tuning property, such a FO-PI self-tuned controller is presented in [

60], in a differential mobile robot. Three different types of controllers are evaluated and compared to a classical controller, with its parameters being acquired through traditional methods. A similar self-tuned fuzzy FO-PI controller for a steam distillation process is evaluated in [

61]. The numerical results show that this controller leads to better closed-loop performance in comparison to the integer order PI, the FO-PI and self-tuning fuzzy PI. The control of the horizontal motion of a dual-axis photo voltaic sun-tracker is presented in [

62]. A new technique for online self-tuning of a FO-PID controller based on both a type-1 fuzzy and a Takaji-Sugeno Fuzzy is developed. Satisfactory results were obtained in numerical simulations. Takagi-Sugeno (TS) fuzzy technique combined with interval type-2 fuzzy sets is used in [

63] to design a new adaptive self-tuning FO-PID controller. A modified FO-PID controller is obtained using TS, while the interval type-2 fuzzy sets are used as a tuner to update the gains of the FO-PID. Three types of interval type-2 fuzzy sets tuning methods are used and applied to load-frequency control as a case study of a power system comprising a single area. Comparative studies with type-1 fuzzy sets are carried. The simulation results show that the proposed approach works well considering disturbance changes and parameter uncertainties. A fuzzy FO-PID is used in [

64] to control the position of a robotic manipulator. A fuzzy system combined with the particle swarm optimization method is used to determine the parameters of a FO-PID controller. Numerical simulations and comparisons with a fuzzy PID are performed. The simulation results show that the FO-PID is able to reduce the overshoot and the oscillatory dynamics, compared to the fuzzy PID. Three self-tuned fuzzy controllers are implemented in [

65], namely, a FO-PD, a FO-PI and a FO-PID. The controllers are then evaluated in a servo-regulatory mechanism. The simulation results show that the self-tuned fuzzy FO-PID leads to the best closed-loop performance. The control of a mover position of a direct drive linear voice coil motor (VCM) is performed in [

66] using a self-tuning FO-PID. The five FO-PID control parameters are optimized dynamically and concurrently using an adaptive differential evolution algorithm. Experimental results are provided and demonstrate that the proposed self-tuning FO-PID achieves better performance compared to PID and FOPID controllers, under both nominal and payload conditions.

The control of an inverted pendulum system is described in [

67], where two self-tuned FO-PD controllers are designed to vertically balance the pendulum and for accurate positioning. The proportional and derivative gains of the two controllers are dynamically adjusted using particle swarm optimization after each sampling interval using piecewise nonlinear functions of their respective state-variations. Hardware-in-the-loop experiments are performed and the proposed approach is compared to fixed gain dual-PD and dual-FO-PD control schemes.

A direct autotuning method for a FO-PI controller is used in [

68] to control the speed of a permanent magnet synchronous motor. Only the measured input-output data of the closed-loop servo system is required to tune the FO-PI controller. The FO-PI parameters are determined using a virtual reference feedback tuning with an incorporated Bode ideal transfer function, which allows the properties of the resulting system to be approximated to the desired fractional-order reference model. Optimal performance constraints, such as sensitivity criteria, frequency-domain and time-domain characteristics are considered in the autotuning. Experimental results are provided to illustrate the efficiency of the proposed model-free FO-PI control method for the servo system. The extremum seeking approach is used as a non-model-based method that searches online for the FO-PID parameters that minimizes a cost function related to the performance of the controller [

69]. Simulation examples are provided to demonstrate the effectiveness of the proposed algorithm.

A novel self-tuning FO-PID controller using the optimal model reference adaptive control (MRAC) is applied to power system load-frequency control [

70]. The requirements for the control systems are embedded in the model reference, mathematically described as a first- or second-order system. A harmony search optimization method is used to determine the parameters of MRAC. Three methods for self-tuning FO-PID control are presented. The first two methods assume some of the FO-PID parameters to be fixed and adjust the remaining ones, while the third method was developed to adjust all five parameters of the FO-PID controller, at the same time. The simulation results show that the latter method achieves better disturbance rejection, as well as improved handling of system uncertainty.

The control of coupled and non-linear 2-link rigid robot is tackled in [

71] using a novel non-linear FO-PID that includes a non-linear hyperbolic function cascaded with a FO-PID. The fractional orders allow for greater flexibility in the controller design, while the adaptive feature is incorporated in the non-linear function. The parameters of the FO-PID are determined according to the multi-objective non-dominated sorting genetic algorithm II (NSGA-II) for small variations in control and error signal. Comparisons with a non-linear PID, FO-PID, non-linear hyperbolic function cascaded with an integer order PID or traditional PID are performed. The simulation results demonstrate that the proposed method provides robust and efficient control of the robotic arm.

A fractional fuzzy controller is designed in [

72], without using an actual model of the robot and only well-known structural properties of mechanical systems. The entire implementation is model-free and tackles the control of robotic manipulators. To ensure improved disturbance rejection, a fuzzy logic formulation is used with an online adaptation of the outputs to achieve a better closed-loop response. To demonstrate the efficiency of the approach, simulations and experimental results are presented. An innovative design method, suitable for many industrial applications is presented in [

73]. A self-tuning fractional-order controller is designed using fractional order pole placement and indirect adaptation profiles. Simulation results are provided for an air-lubricated capstan drive for precision positioning. The results show that, indeed, better closed-loop performance is possible using the proposed method instead of a similar one based on integer order pole placement.

A fractional-order self-tuned fuzzy PID controller is designed for a three-link rigid robotic manipulator system in [

74]. The controller is tuned using a cuckoo search algorithm to minimize the weighted sum of the integral of absolute error and the integral of absolute change in controller output. The same tuning procedure is used to tune a fractional-order fuzzy PID and an integer-order self-tuning fuzzy PID. Comparative simulation results are provided and demonstrate better trajectory tracking, disturbance rejection, noise suppression and robustness to model uncertainty in the case of the proposed fractional-order self-tuned fuzzy PID controller.

In [

75], an online identification of the parameters of a fractional order process is performed based on a particle swarm optimization algorithm. Then, a fractional order self-tuning regulator is designed using differential evolution algorithms. Simulation results show that the proposed method is robust and leads to good closed-loop results.

A self-tuning controller is designed in [

76] using fuzzy logic for the control of microgrid systems. A fractional-order controller is developed in combination with a fuzzy logic algorithm for load-frequency control of the off-grid microgrid. An optimal way to estimate the input and output scale coefficients of the fuzzy controller and fractional orders of the fractional-order controller is developed based on a novel meta-heuristic whale algorithm. The case study consists in a microgrid containing a diesel generator, wind turbine, photovoltaic systems and energy storage devices. Simulation results show that the proposed optimized fractional-order self-tuning fuzzy controller manages to outperform the classical PID controller in terms of operation characteristics, settling time and load-disturbance attenuation.

The active suspension system of a quarter car is considered as the case study in [

77], where a self-tuned robust fractional-order fuzzy proportional-derivative controller is developed. The design of the controller attempts to minimize the root mean square of vertical vibration acceleration of car body. Tracking force, ratio between tire dynamics and static loads and suspension travel are considered as design constraints. Genetic algorithms are used to optimize the parameters online for a sinusoidal road surface. However, simulations were performed for random road surfaces and bumps. The proposed self-tuned fractional-order fuzzy proportional-derivative controller achieved better results compared to passive solutions, as well as to its integer order counterpart.

The cuckoo search algorithm is also proposed in [

78] in the design of a self-tuned fractional-order fuzzy PID controller. The optimization algorithm is based on the minimization of an objective function defined as the sum of integral of squared error and integral of the squared deviation of controller output. The final controller consists in a Takagi-Sugeno model-based fuzzy adaptive controller containing non-integer-order differ-integral operators. For comparative purposes, the integer order counterpart of this controller is also designed. Simulation results indicate the increased robustness of the self-tuned fractional-order fuzzy PID controller when applied to the control of an integrated power system.

6. Conclusions

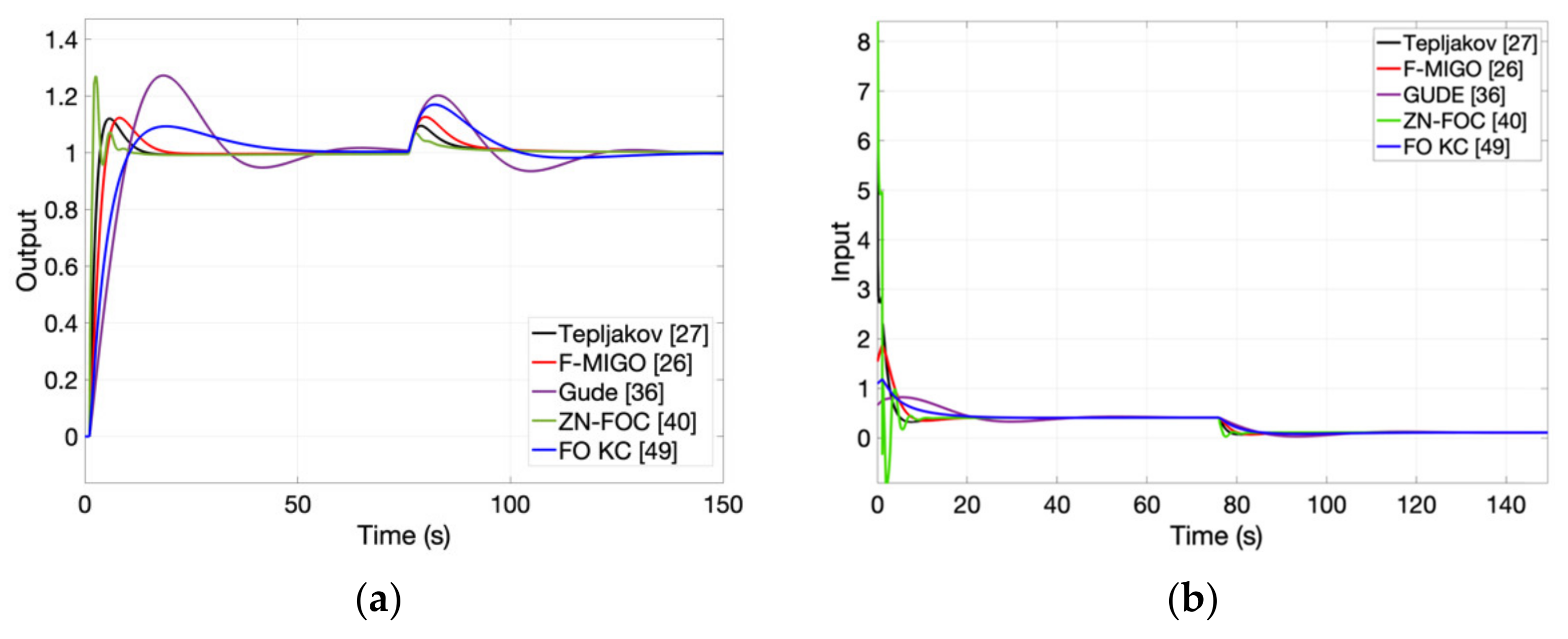

Fractional-order controllers have emerged as a generalization of the standard PID, allowing for greater flexibility and improved performance and robustness. The tuning of these FO-PIDs is not an easy task, since the complexity of the design increases along with the number of tuning parameters. Several tuning methods have been developed, but the majority of them require a process transfer function. In some cases, obtaining an accurate mathematical model of the process is time consuming and tedious, especially in the industrial sector. To cope with this issue, autotuning methods for FO-PIDs have emerged. In this paper, a survey of the existing autotuning methods for FO-PIDs is presented. Several autotuning approaches are compared for lag-dominant and delay-dominant FOPDT processes, for higher order systems, for integrative time-delay processes or poorly damped ones.

For each type of process, the autotuning methods are compared in terms of closed-loop performance regarding reference tracking and disturbance rejection. Robustness was not considered as a means for comparison, since some of the reviewed methods do not address directly this issue, while others do. This aspect would have led to unfair comparisons and possibly different remarks on the opportunity of using one autotuning method, instead of another.

Some of these autotuning methods have also been validated experimentally. Research in this area is still under way and the current autotuning methods stand as the premises for further innovation in this area. Further research regarding the robustness of the autotuning methods will be considered.