1. Introduction

Fractional-order calculus is an extension and generalization of integer-order calculus, and fractional-order differential equations are obtained by acting the fractional-order differential operators on integer-order ones. Although the theory of fractional-order calculus had been proposed 300 years ago, and it developed slowly for a long time due to its lack of practical engineering application background and its large computational size, it now attracts extensive attention due to increases in computational power. It was not until Mandelbrot [

1] first pointed out the fact that fractional dimension exists in nature and in many fields of science and technology in 1983 that the application of fractional-order calculus attracted wide attention and developed rapidly. Fractional order systems have long memory of history data [

2,

3]. The classical derivative in one point is only affected by the information in the local neighborhood of that point, while the fractional derivative in one point is affected by the combination of all of the information of the model in historical moments. Therefore, compared with integer-order calculus, fractional-order calculus produces more accurate and reliable results for modelling of real-world systems due to the memory effect. Recently, fractional-order systems have received special attention from researchers in various fields such as physics [

4], biology [

5], neural network [

6], management, and economics [

7,

8,

9,

10,

11], etc. On the other hand, chaos theory and applied research have developed rapidly and promoted its significant contribution in various scientific fields [

12]. Nowadays, the control and synchronization of nonlinear systems are the focus of many research studies in a variety of fields [

13,

14,

15]. Some effective controllers have been designed to control and synchronize the fractional-order chaotic systems such as the coupling controller [

16], adaptive controllers [

17], linear feedback controllers [

18], sliding mode controllers [

19], fractional order PID controllers [

20,

21], and so on.

Supply chain systems are complex dynamic systems with various uncertainties [

22,

23]. In recent years, some researchers [

24,

25,

26,

27,

28] are studying nonlinear chaotic dynamics of supply chain systems and have obtained many investigations. Forrester [

29] was the first to investigate the dynamics of supply chain systems and introduced the ‘bullwhip effect’. The ‘bullwhip effect’ refers to the distortion of information in the process of transmitting information from downstream to upstream enterprises, and the distortion and gradual amplification of information in the process of transmitting information from the final customer to the original supplier in the supply chain, resulting in the phenomenon of cascading demand information. The ‘bullwhip effect’ can be explained by the chaos theory of dynamical systems. One of the most fundamental characteristics of chaos is that the trajectory of the system is very sensitive to the initial condition, i.e., even if the original state changes slightly, the final state of the system can be very different. Goksu et al. [

30] constructed a supply chain model composed of manufacturers, distributors, and customers to achieve the synchronization and control of this chaotic supply chain management system. Gao et al. [

31] proposed a new three-dimensional supply chain fractional-order difference game model composed of manufacturers, distributors, and retailers, and used the correlation theory of fractional-order difference to numerically analyze the complex dynamic behavior of this model, and discuss the effect of the output adjustment speed parameter on the dynamic behavior of the system. Recently, Yan et al. [

32] integrated the computer-aided digital manufacturing process into the three-level supply chain which is composed of manufacturers, distributors, and retailers, and considered computer-aided digital design prior to the production by manufacturers, ultimately achieving synchronization and control of the system.

There are numerous attribute properties that cannot be described by the theory of integer-order calculus, so it is necessary to theoretically study the complexity of the supply chain system using the method of bifurcation and chaos of fractional nonlinear dynamics. In a supply chain system, the variables including demand, supply, and production have long memory properties, the fluctuation of which can lead to significant instability in the operation and delivery of the system. Thus, the traditional integer-order supply chain model has limitations to accurately show the operation of the system. Moreover, the prevalence of the bullwhip effect in the supply chain management increases the risks of production, supply, inventory management and marketing of suppliers, and even leads to chaos in them. However, there are few results on fractional-order supply chain systems.

Motivated by the above discussions, to be more realistic, in this study, a fractional-order digital manufacturing supply chain system is investigated. Dynamics and complexity of this system with the variation of derivative orders and system parameter have been studied by means of bifurcation diagram and complexity measure algorithms. Furthermore, the nonlinear feedback controllers are designed to control and synchronize the chaos in this fractional order supply chain system, respectively. That is, the fractional order supply chain system has rich dynamic behaviors, and the evolution simulation is conducted for the influence of the change of fractional order and parameters on the demand order quantity, supply quantity, and digital manufacturing quantity of the supply chain enterprises. At the same time, the chaotic states appearing in the evolution process are synchronized and controlled to achieve the stability of the supply chain system. Therefore, this study contains both theoretical and practical guidance to eliminate chaotic dynamics that are unfavorable to the supply chain model.

The rest of this paper is organized as follows. In

Section 2, preliminaries and modeling are investigated. In

Section 3, the dynamical behaviors of fractional-order digital manufacturing supply chain system are studied. In

Section 4, controllers are designed to synchronize two identical systems. In

Section 5, we consider the stabilization of the system. This paper ends with a conclusion in

Section 6.

3. Dynamics Analysis of the Fractional-Order Supply Chain System

With the variation of derivative orders and system parameters, system (11) has complex dynamic behaviors such as periodic motions, period-doubling motions, and chaotic motions. If the system behaves chaotically, the supply chain system will be in a state of loss of control, which will lead to inventory, ordering, and supply chaos, and affect the decision making of supply chain enterprises at all levels, thus causing greater damage to the operation of the whole supply chain system. If the system appears in a periodic state, the supply chain system will be stable and the supply chain enterprises can make decisions based on the inventory status better. Therefore, studying the chaotic dynamic behaviors of the supply chain system can be an effective means to maintain the stability of the supply chain system and guide the scientific decision making of the supply chain enterprises.

In this section, the numerical solution of system (11) is obtained by means of ADM, and the chaotic dynamic behaviors of the system with the variation of the fractional order q and the parameter are studied through bifurcation diagrams, maximum Lyapunov exponent diagrams, phase portraits, time series diagrams and complexity diagrams.

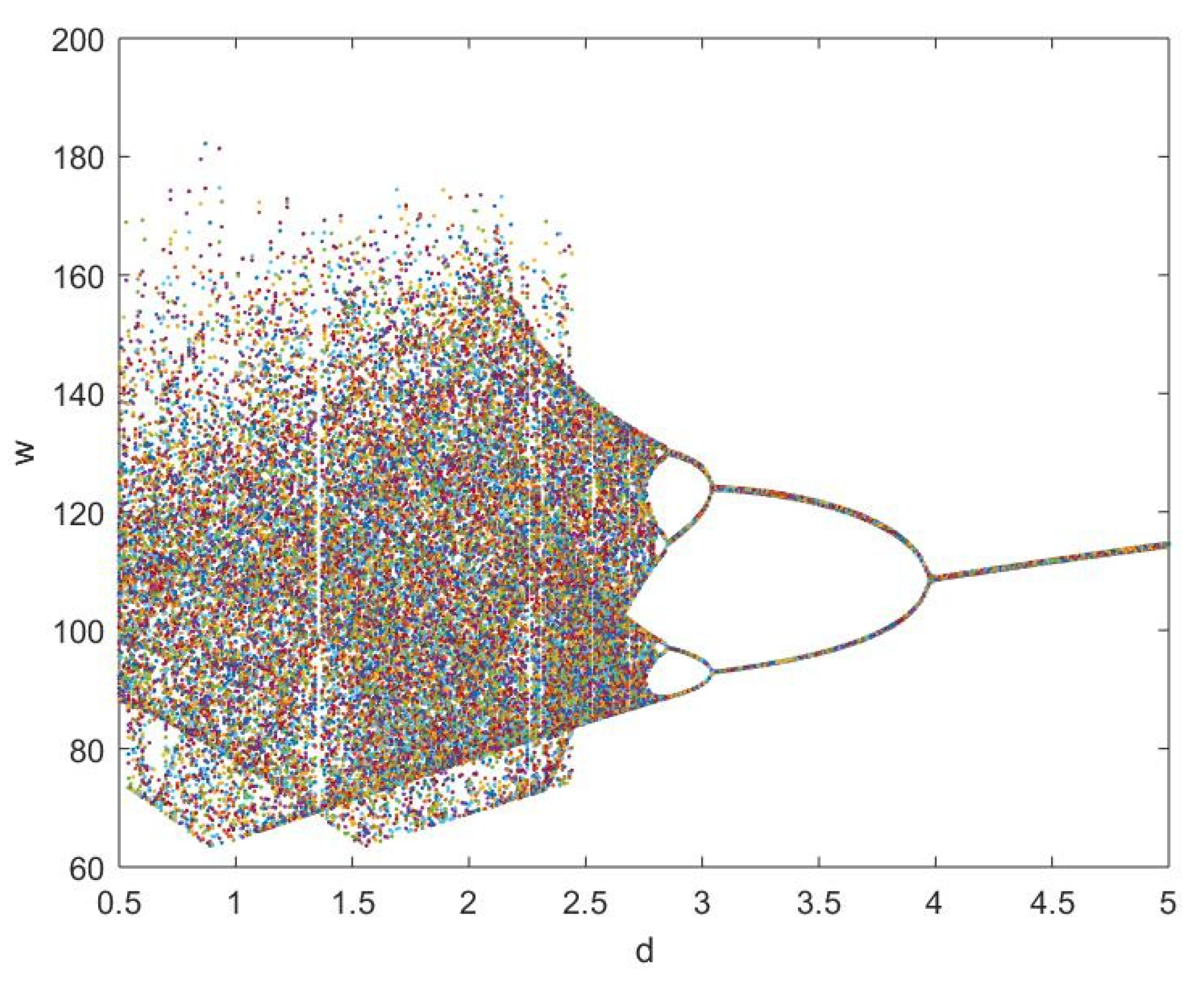

3.1. Dynamic Behaviors Analysis with Parameter

If a manufacturing company produces digitally, it will be followed by digital design into production. Moreover, the larger the parameter

, the higher the level of digital production. In this subsection, we study the impact of the rate of digital design into production on the manufacturer and the supply chain. In system (11), let the fractional order

, the initial conditions

, and the parameter

is chosen as the critical variable. The bifurcation diagram and the maximum Lyapunov exponent diagram of system (11) with the parameter

varying from 0.5 to 5 are shown in

Figure 1 and

Figure 2. The results indicate that the system shows the inverse period-doubling bifurcation, and as the parameter

decreases, the system goes from periodic state, after the period-doubling bifurcation, to chaotic state. When

, the period one is appeared, and the period-doubling bifurcation occurs for

. When

, the period two is appeared, and the period-doubling bifurcation occurs for

. When

, the period four is appeared, and the period-doubling bifurcation occurs for

. When

, the system enters to chaotic state, which can be illustrated from the maximum Lyapunov exponent.

The numerical simulation results can reflect the actual situation of the supply chain system. When the rate that the digital design is put into production is high, it means that the products are digitally produced quickly, hence the replenishment demand of retailers can be met immediately, and consequently the demand of consumers can be met quickly, making the inventory system and the production of manufacturers stable. On the contrary, when the rate is low, the order demand of retailers cannot be met in time, so consumers may seek other alternatives, which will lead to overstock and chaos in production. Therefore, the strategy to increase the rate of digital design into production is feasible and it can make the whole supply chain system stable.

In order to observe the dynamic behaviors of system (11) directly, the phase portraits of the system with several different values of the parameter d are shown in

Figure 3. When

, the system is chaotic and the chaotic attractor is presented in

Figure 3a. The numerical analysis shows that the interaction between the quantity of demand from retailers, the quantity of products available from distributors, the quantity of completed digital designs, and the quantity of production based on digital designs. When

, the system is in the periodic four that is shown in

Figure 3b. When

, the period two is appeared, and it is shown in

Figure 3c. When

, the periodic one of the system is presented in

Figure 3d. The phase diagrams are consistent with the bifurcation diagram and the maximum Lyapunov exponent diagram. Thus, the fractional-order supply chain system has rich dynamical properties when the parameter

of system (18) is varied.

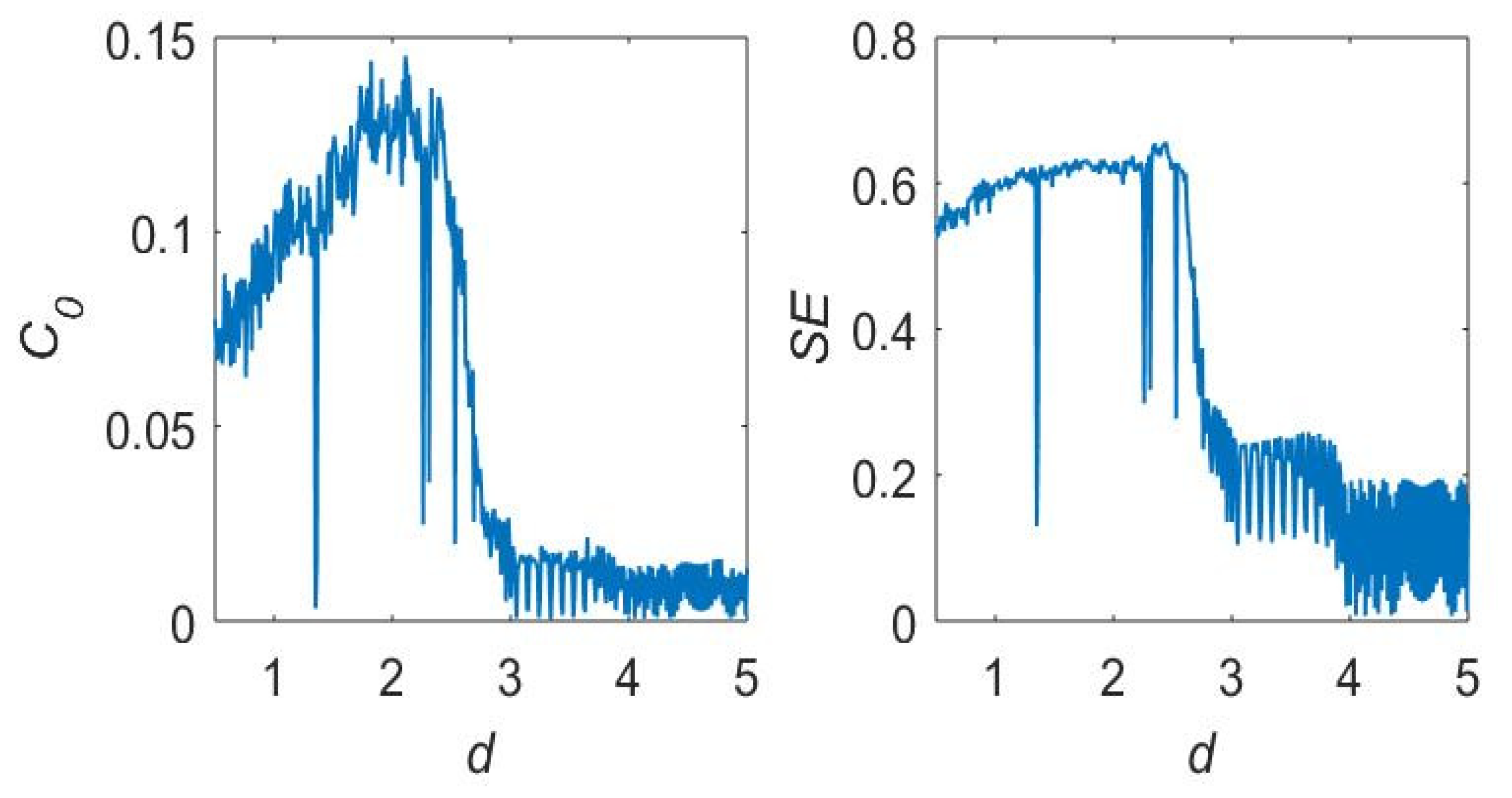

As shown in

Figure 4, the

complexity and SE complexity of system (18) have high values when

, indicating that production and inventory of manufacturers appear chaotic and difficult to predict; when

, the value of the complexity is very small, indicating that it contributes to production planning of manufacturers and supply and inventory management of supply chain enterprises.

3.2. Dynamical Behaviors with

In system (11), let the parameter

, the initial conditions

and the parameter

is chosen as the critical variable to show the effect of fractional order to the behavior of chaotic system results.

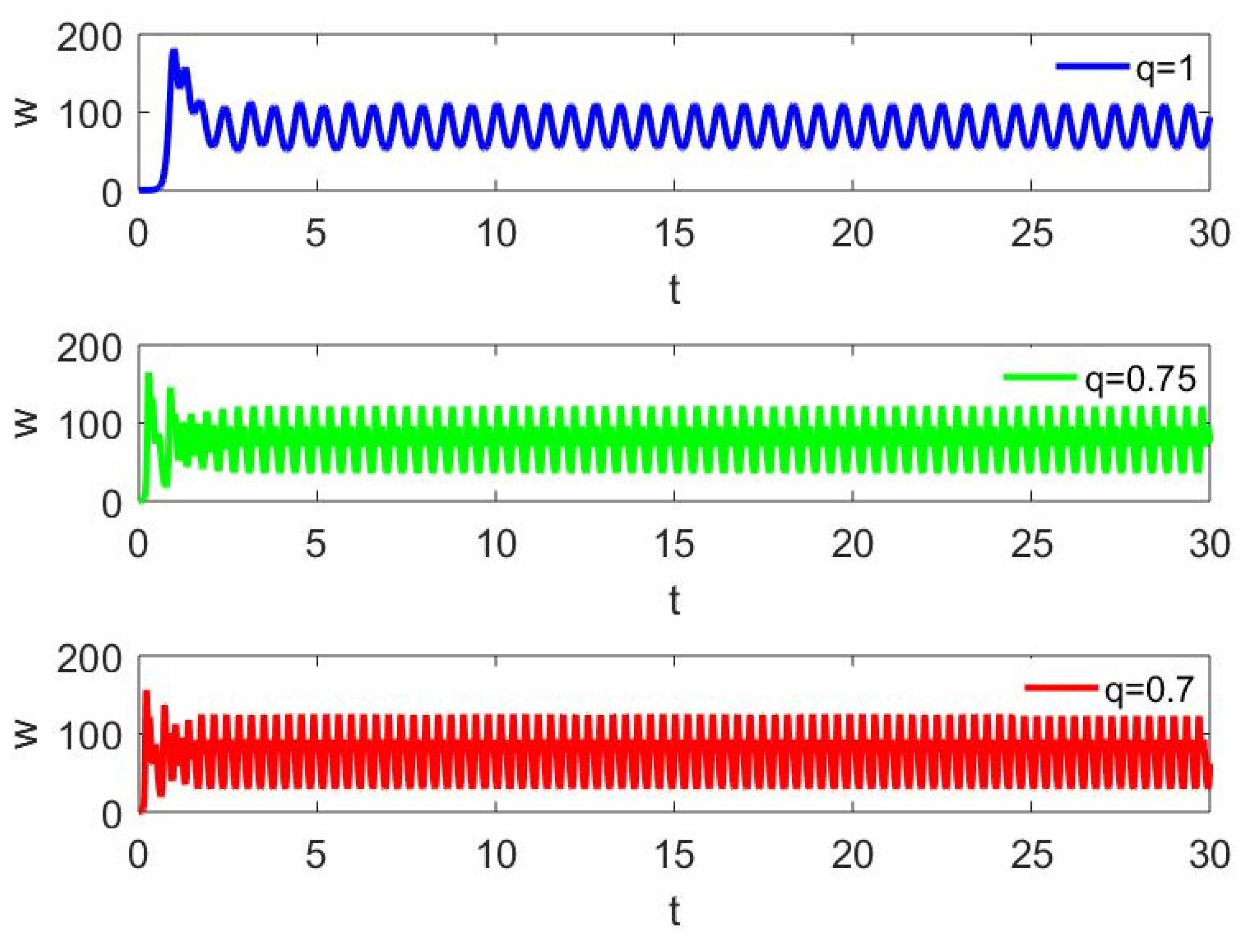

Figure 5 shows the bifurcation diagram with the order

q as the bifurcation parameter. When

, the system is mostly in a chaotic state. When

, the chaos disappears and the system appears in a periodic state. In order to study the effect of different fractional orders on the supply chain system when manufacturers have a high rate of digital design into production, we consider choosing the fractional orders that appear in periodic state, so the orders are chosen as

,

, and

, respectively.

Figure 6 shows the phase diagram between the demand by retailers and the digital production by manufacturers of system (11) with different fractional orders. As shown, when

q = 1,

fluctuates more at

and less at

, as the order

decreases to 0.75 and then to 0.7,

fluctuates gradually less at

and more at

. In practice,

indicates that the supply of distributors cannot meet the order demand of retailers. The analysis shows that with a small order

, then the production of the manufacturers fluctuates more when the supply from the distributors to the retailers is insufficient, while the production of the manufacturers fluctuates less when the supply from the distributors is sufficient. Thus, it indicates that the fractional-order system more accurately reflects the real-world supply chain system compare to the integer-order one.

Figure 7 shows the corresponding time series diagram of the digital production of the manufacturers. As shown in the figure, the smaller the order

, the shorter the fluctuation period of the production, indicating that goods are transferred faster at all levels of the supply chain and can meet customer demand faster, resulting in a more stable inventory system and supply chain system.

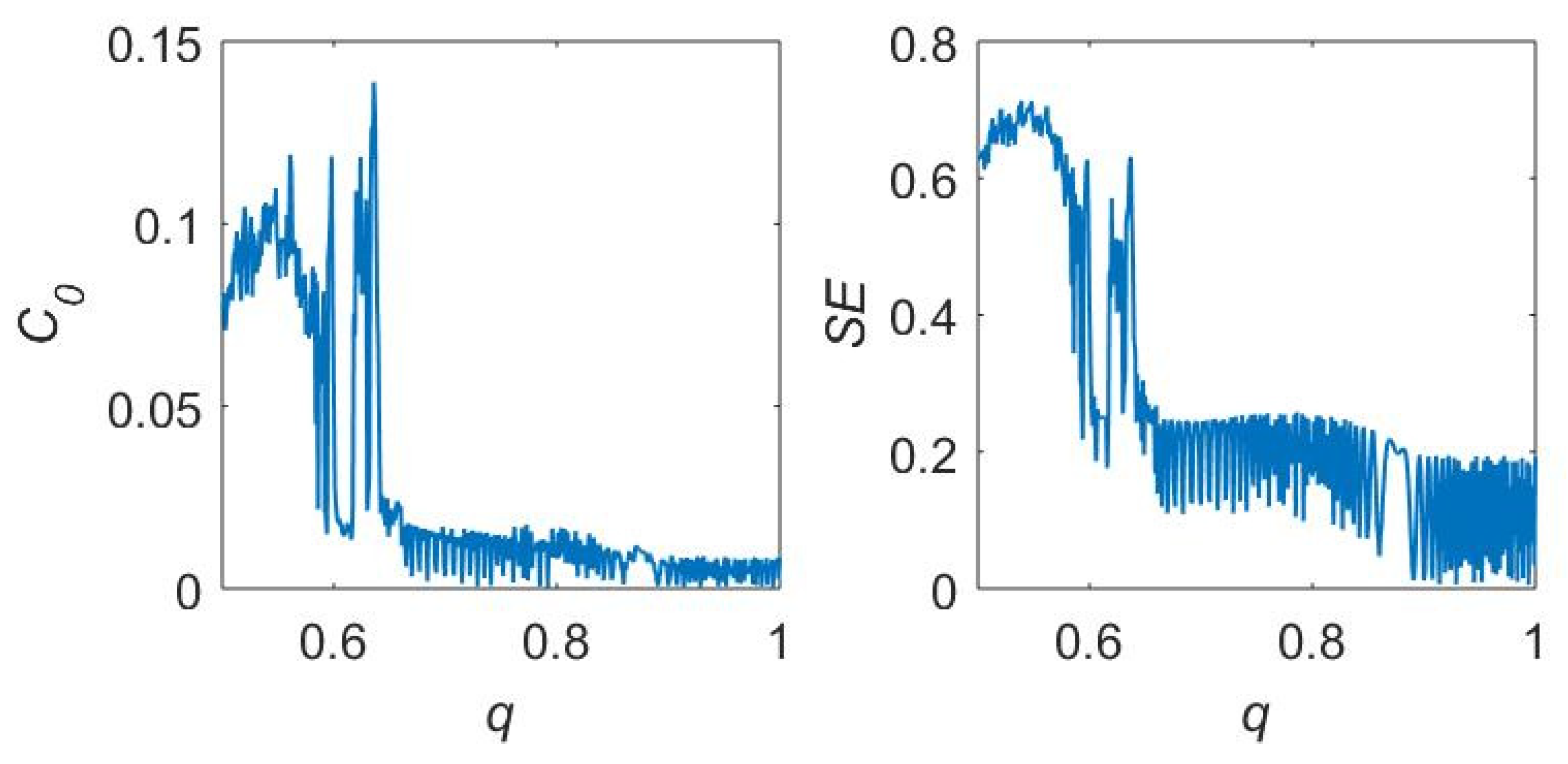

As shown in

Figure 8, the

complexity and SE complexity of system (11) are higher when

, and the values of complexity both oscillate at lower values when

. It shows that the fractional-order system has an order of magnitude higher complexity compared to the integer-order system.

From

Figure 4 and

Figure 8, we find that the complexity results are consistent with the bifurcation diagrams, indicating that the complexity can reflect the dynamic characteristics of the fractional-order digital manufacturing supply chain system.

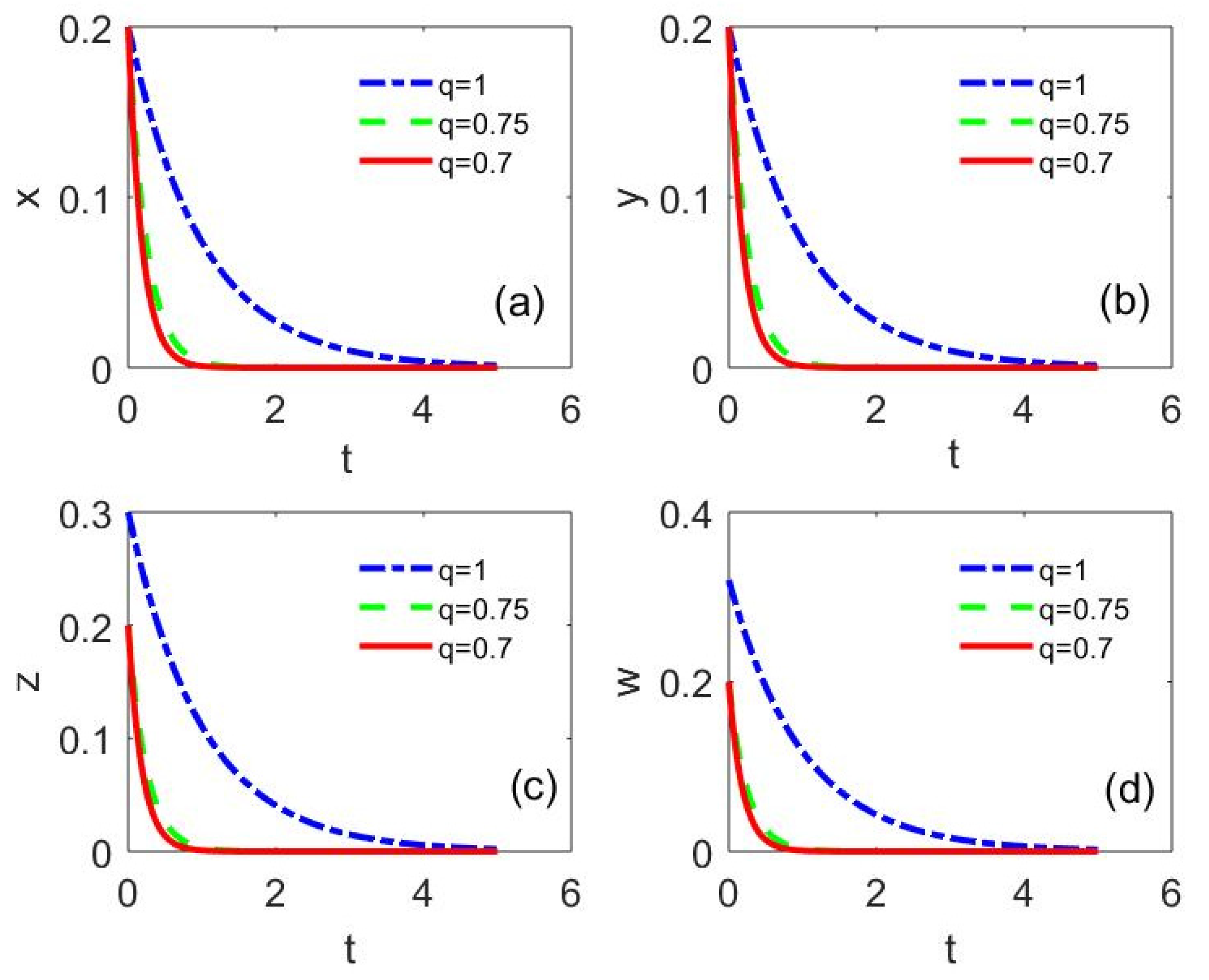

4. Synchronization of the Chaotic Fractional-Order Digital Manufacturing Supply Chain System

From the analysis in

Section 3, it is understood that the fractional-order digital manufacturing supply chain system is chaotic when the rate at which the digital design of the manufacturer is put into production is low. Without applying appropriate synchronization controllers to the system, the trajectories of the system with different initial values will exhibit different behaviors. In order to achieve synchronization between two supply chain systems with different initial conditions, the controllers can be designed to synchronize the two chaotic systems.

We establish the fractional-order error system by two chaotic fractional-order supply chain systems with different initial conditions, which are called the driving supply chain system and the responding supply chain system, respectively. Let

, then the drive supply chain system is defined as follows

And the response supply chain system is given as

where

,

,

,

are the controllers to be determined later.

Denote the error variables as

where,

,

,

,

denote errors between the drive system and the response system. The fractional-order error system is obtained by subtracting the drive supply chain system from the response supply chain system

To synchronize the drive system (12) and the response system (13), suitable controllers are chosen so that the fractional-order error system (15) is asymptotically stable at the origin. In this paper, we consider the controllers as

Then the fractional-order error system (15) becomes

The fractional-order error system (17) is asymptotically stable based on Lemma 1, which implies that synchronization between (12) and (13) will be realized. This completes the proof.

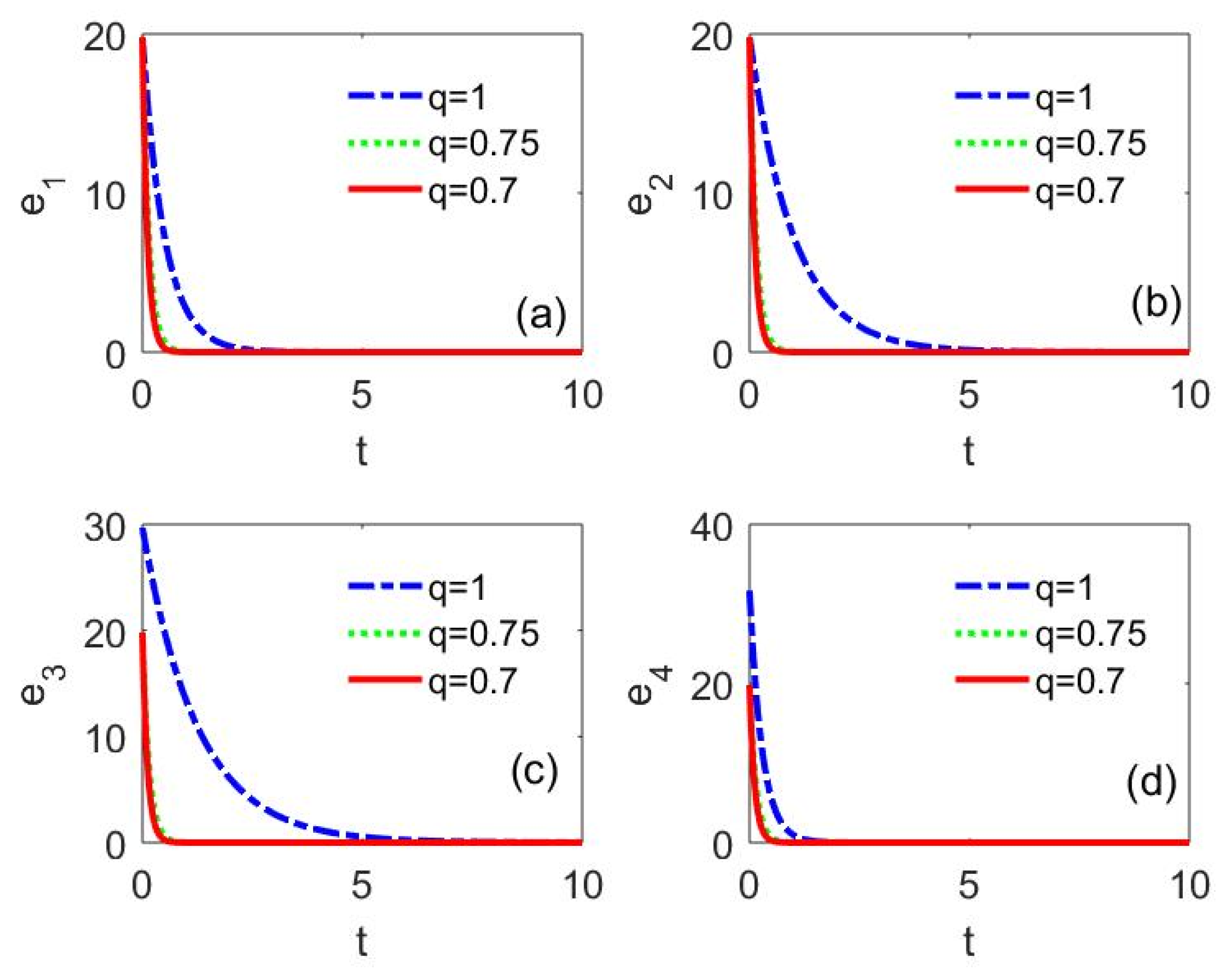

Furthermore, the effect of the fractional orders on the synchronization of two chaotic fractional-order supply chain systems with different initial conditions is studied. Let the parameter

, then both the drive system and the response system are chaotic. Let the initial values of the drive system

, and the initial values of the response system

. The fractional order

is chosen as

,

, and

, respectively. The numerical solution of system (17) is obtained by the ADM, and the time series diagrams of system (17) with different fractional orders are shown in

Figure 9. As shown in the figure, for two identical fractional-order chaotic supply chain systems (although there are differences in their initial states), the errors gradually converge to zero as time grows. This indicates that the two chaotic systems reach synchronization under the designed controllers, and the smaller the fractional order, the faster the synchronization. This implies that despite the factors such as the bullwhip effect, inventory can be synchronized faster when the order of the fractional-order supply chain systems is decreased, allowing the enterprises to reduce risk more effectively.

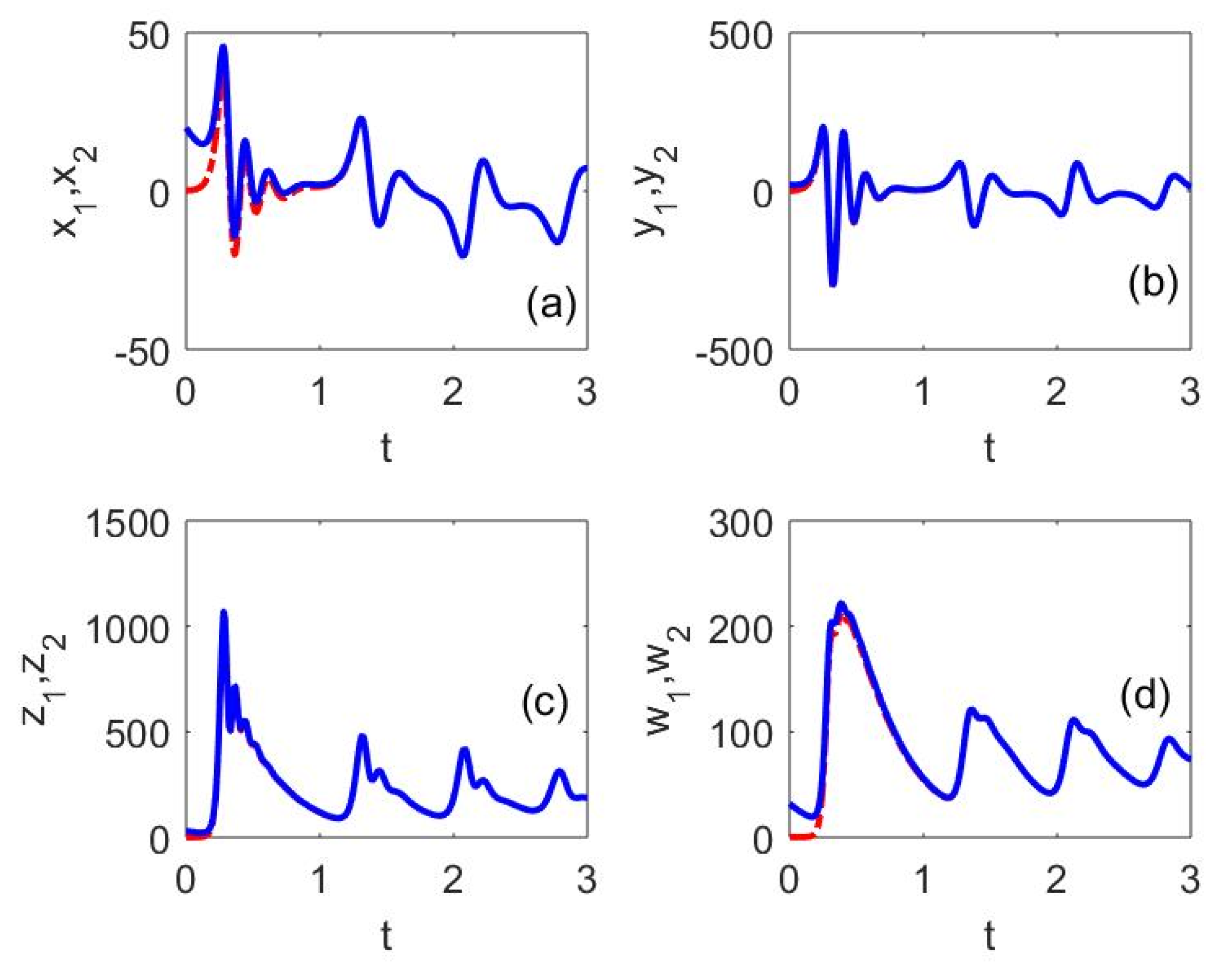

In order to see the comparison of the time histories of the drive system and the response system more visually and to further verify the synchronization, the fractional order

is chosen to be 0.75 and the time series of systems (12) and system (13) are plotted in the same figure, as shown in

Figure 10. The green line in the figure represents the time series of the drive supply chain system under its initial conditions, and the yellow line represents the time series of the response supply chain system under its initial conditions, and the comparison reveals that the time series of the two systems overlap after

as time grows. Again, it shows that the designed synchronization controllers are effective and can synchronize the two systems.

6. Conclusions

In the present research, a fractional-order digital manufacturing supply chain system model was established. Through well-known tools and methods, including the phase portrait, bifurcation diagram, and maximum Lyapunov exponent diagram, the characteristics of the system were explored. The behavior of the system and the effects of the fractional-order derivative on the results of the system were displayed. It was demonstrated that the fractional-order system more accurately reflects the real-world supply chain system compared to the integer-order one. Furthermore, controllers were designed to synchronize two systems with different initial conditions. In addition, the equilibrium point analysis was carried out, and to suppress the chaotic behavior, feedback controllers were designed to stabilize the supply chain system. Our research results can help achieve more stable inventory systems and supply chain systems. In the future, we aim to further study the complexity evolution of fractional-order chaotic supply chain systems. Also, future research can be devoted to the control and synchronization of the proposed model through some more simple controllers with less parameters, such as fractional-order fuzzy controllers, fractional-order PID controllers, and fractional-order controllers.