Abstract

The climatic and environmental impact of construction works is well recognized, and in particular, the energy use and carbon emissions associated with both their production (embodied energy/carbon) and their lifetime operation (operational energy/carbon). However, the impact of site works, infrastructures, and landscaping has yet to be explored; most of the focus has been on the buildings rather than what is around and underneath them. Yet, these, especially in city contexts, are extensive. They are also both costly and carbon-intensive, involving mainly concrete and steel. Through intentionally simple examples, the carbon impact of the buildings themselves was compared to that of site works both on and below the surface, such as underground parking. These also represent major land use interventions often impacting the whole project site area. It is shown that these can constitute a considerable fraction of the total carbon footprint of construction projects. Further, this fraction is likely to increase as future buildings achieve much lower operational as well as embodied energy/carbon. This paper employs life cycle analysis tools to calculate the embodied carbon in specific case studies, with comparative evidence from the literature and a discussion of pertinent issues. Some broader issues were noted relating to building typologies, materials, and the varying significance of the infrastructures and site works in different climates. The carbon impacts of the site work need to be addressed more sustainably, irrespective of varying contexts. This perspective has implications for sustainable design as well as for urban planning.

1. Introduction

The energy consumed by the construction sector has been estimated to be around 40% of total global energy consumption [1]; or even around 50% of the global energy and 50% of CO2 emissions [2]. Construction and buildings thus represent one of the largest challenges for a low-carbon future [3]. The energy associated with the life cycle of buildings and other constructions is broadly classified into two categories: embodied energy (EE) and operational energy (OE) [4]. Climate emissions can similarly be categorized as embodied carbon (EC) and operational carbon (OC) [5,6]. An important distinction is that operational impacts are largely dependent on the occupants, whereas the embodied ones are not [7]. Operational energy for heating, cooling, lighting and other purposes through a building’s lifetime has, until recently, comprised by far the greatest part of energy use and emissions. However, as lifetime operational impacts diminish and even approach zero in energy-efficient and low-impact buildings, the embodied impacts of materials and construction processes become predominant.

It should be noted that the terms energy and carbon are largely interchangeable as long as most energy systems and production processes are based on fossil fuels. One can reduce impacts both with efficiency measures and by substituting “greener” materials; but whatever the efficiency or materials, the impacts can only be greatly reduced by replacing fossil energy sources with renewables—although even these have environmental implications.

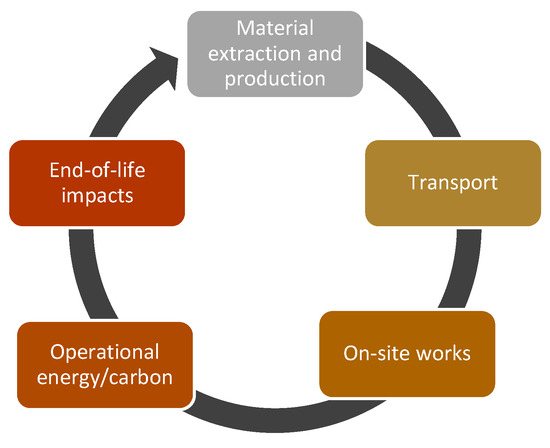

The energy and carbon impacts of construction include the following main life cycle phases: materials extraction and production; transport; on-site work; operational energy/carbon (including recurrent inputs for maintenance and alterations); and end-of-life impacts (Figure 1). Amongst these, transport and on-site impacts are normally of the order of a few per cent only [8], indicating figures of about 2 to 6% of the total lifecycle EC. End-of-life impacts, including demolition and recycling, are also often considered to be small, but this is arguable since the disposal, recycling, and treatment of hazardous components are seldom fully accounted for in the current life cycle analysis (LCA) methodologies.

Figure 1.

The energy and carbon impacts of construction in five main life cycle phases (redrawn by the authors and adapted from [9]).

The construction sector includes the entire built environment: both buildings and many works such as bridges, roads, dams, sewage networks, retaining walls and other major amenities, most of which can be broadly described as public works. In contrast to buildings, most of these consume little operational energy but often have a high EC due to the use of materials such as masonry, concrete, and steel. This paper does not address the EC of public works except those which are part of the site services, typically municipal ones, of specific construction projects. A reminder must be added that the environmental impacts of construction comprise not only those related to energy or carbon, but many others not discussed here, such as land degradation, water depletion, biodiversity loss, deforestation, waste accumulation, and pollution of many kinds [10,11].

There has been extensive research and practice in the field of sustainable buildings, which are variously described with terms such as energy-efficient, low-carbon, zero-emission, energy-plus, etc. [12,13]. However, most of the attention has focused on the buildings themselves; there has been little focus on the impact of the associated underground works, infrastructures, and site works, which, especially in urban environments, are very considerable. The same can even be the case in residential areas. Therefore, the main focus of this study is specifically on these features of construction. After a brief survey of urban site contexts, construction materials, and embodied carbon figures from the literature, this study undertook case analyses of embodied carbon, comparing that of the buildings and that of the site works. The issues and implications are then addressed. Simple case studies show that the carbon impacts of the site works and largely underground infrastructures can already form a considerable fraction of the total carbon impacts of construction projects. Further, they are almost sure to become more significant as the buildings themselves become low-carbon. This is, hence, an aspect of sustainable buildings that requires increased attention. These findings have implications for improving the sustainability of future building design as well as of urban planning.

2. The Urban Context

According to the UN [14], 55% of the world’s population now lives in urban areas and this proportion is expected to increase to 68% by 2050. It is estimated that cities account for 65% of the total global energy consumption and 70% of energy-related carbon emissions [3,15]. Infrastructures and urban density are clearly related; whilst not engaging in a detailed discussion of urban typologies, a general distinction is made here between fairly low-rise typologies, which range from suburbs to many European-type cities [16], and on the other hand typical high-rise inner-city contexts, which are increasingly common [17,18]. A brief example was provided showing that the EC of site works can even be problematic in a suburban context; however, in general, infrastructures can be fairly simple in suburban and low-rise contexts and underground parking is unnecessary. Dense inner cities, on the contrary, require far “heavier” types of infrastructures including those for water supply, drainage, sanitation, and waste, and for transport in particular, with widespread underground parking as well as the complex mobility systems of multi-lane streets, bridges, flyovers, subways, and tunnels that are an integral feature of dense cities as a chosen—not inevitable, let us add—pattern of human settlement.

In dense cities, even apparently “green” areas between tall buildings often consist only of a thin green layer that covers extensive engineering works such as underground parking and infrastructural services [17,18]. It is these contexts that are this study’s main focus. The amount and technical complexity of infrastructures, hard landscaping and underground parking are high and consequently so are the embodied carbon impacts [19].

3. Embodied Carbon and Materials

The largest energy requirement in buildings has normally been OE for space heating or cooling in cold and hot climates, respectively, but low-energy buildings reduce this dramatically. Both lighting and appliances are becoming far more energy-efficient, too. As the OE approaches very low levels, the EE and EC impacts become increasingly important. The EC, in units of kgCO2e/m2 of floor area, already approaches or even exceeds 50% of the total lifetime carbon impacts in advanced sustainable buildings. This trend has been well noted for some years [7]. Ten years ago, for example, in a sustainable office building in Norway, the embodied carbon was almost equal to the operational carbon—69 vs. 75 tons CO2/year, respectively [20]. Recent projects confirm this trend [21,22]. In discussions of “net zero”-type construction, it has also been recognized that it is more difficult generally to reduce the embodied impacts than the operational ones [23]. That would require mining and material processing industries to be almost entirely run with renewable energy, which still would leave unsolved the associated problems noted above of water use, land degradation, or pollution. In the following, this study discusses carbon only; as noted above, the energy implications are broadly similar as long as energy supplies are largely fossil fuel-based.

The largest carbon items in construction projects are very often cement products and steel [24,25]. The examples in Table 1 are chosen to show that this has been evident for some years: in a Swedish study of a four-story office, concrete plus steel comprised 80% of the EC [26]. In an Italian apartment building, these two comprised 76% of the EC (the authors’ analysis, from [27]) and over 70% of the total EC in a Chinese high-rise building case study [28]. Many studies confirm this [26,29,30,31,32]. One can often substitute concrete and steel in buildings, for example, with timber, lightweight panels, or biomaterials. However, this is far more challenging and seldom possible in site works and infrastructures. Urban environments require far more of such carbon-intensive infrastructures than low-density settlements.

Materials advances and the energy transition will change this picture. However, it is of note that cement and steel products still play a major role even with the increasing use of recycled steel and low-carbon cement. This can be seen from Table 1, which includes examples from many parts of the world. On a worldwide basis, however, differences will, if anything, increase due to many countries lagging behind in introducing the best practice solutions. In the case of Portland cement, for example, whilst the CO2 emissions from the calcination process are a chemical constant, the energy to produce cement varies from around 700 kWh per ton in one of the most efficient factories, in Norway, which also uses a large proportion of hydropower and waste energy [33], to over double this in many developing countries that are still both far less efficient and largely dependent on fossil fuel-based production.

Table 1.

Descriptive statistics of EC from different studies (kgCO2e/m2).

Table 1.

Descriptive statistics of EC from different studies (kgCO2e/m2).

| Country | Floors | Main Materials | Building Type | EC kgCO2e/m2 | % of Steel + Concrete | Reference |

|---|---|---|---|---|---|---|

| Malaysia | 15 | RC framework | Office | 1487 | na * | [34] |

| Malaysia | 2 | RC framework | Office | 1088 | na | [34] |

| UK | 4–8 | Concrete, steel, glass | Residential | 700–1200 | 60–80 | [35] |

| Australia | 8 | Steel framework | Residential | 864 | na | [36] |

| South Korea | 35 | RC framework | Residential | 833 | ca. 75 | [37] |

| China | 19 | RC framework | Office | 794 | ca. 80 | [38] |

| Japan | 7 | RC framework | Office | 650 | na | [39] |

| China | 6–28 | Concrete, steel, masonry | Residential + Office | ca. 600 | ca. 70 | [28] |

| Hong Kong | 30 | RC framework | Office + Commerce | 525 | na | [40] |

| UK | na | Concrete base, masonry | Low-rise housing | 450–550 | ca. 75 | [41] |

| Sweden | 4 | Concrete, blocks, timber | Low energy | 274 | 58 | [42] |

| UK | 2 | Mix, low carbon | Residential (passivhaus) | 230 | ca. 60 | [35] |

| Norway | 2 | Timber products, RC slab | (nZEB-eco house) | 140 | 40 | [43] |

| Thailand | 2 | Lightweight on slab | Residential, low-cost, traditional | 70–100 | ca. 60 | [44] |

* na Not applicable.

Heavy buildings are mainly made of concrete and/or masonry. Typically, lightweight ones are largely made of timber and board products, but even in these, much of the EC is for the few concrete/steel items such as the foundations and floor slabs. Large buildings can have an EC well over 1000 kgCO2e/m2. The EC of smaller buildings may vary at least fivefold. The EC of existing housing made of heavy materials, such as RICS, 2012 [45], in Table 1, lies in the range of 400 to 600 kgCO2e/m2. Benchmarks for reduced EC are emerging; an example is a UK recommendation for a benchmark of 300 kgCO2e/m2 for residential buildings [46]. The UK Passivhaus standard house in Table 1 has an EC of around 233 kgCO2e/m2, of which well over half is due to concrete and steel, even though the design was developed to reduce its carbon footprint; it includes low-carbon concretes, and its carbon footprint is “far lower than the average UK domestic dwelling” [35]. The lightweight Norwegian eco-house by GAIA architects with a strong focus on eco-materials has an EC below 150 kgCO2e/m2 [43]. Lightweight tropical buildings, such as the low-cost Thai example, generally have low EC [44]. This is because their typical features are thin external walls and interior partitions of board products, lightweight roofing, no thermal insulation, basic kitchen and bathroom amenities, and single-pane windows. Exceptions aside, the typical EC figures (kgCO2e/m2) can thus be summarized broadly as follows: heavy concrete and steel buildings have EC values of 600–1000; moderate-weight and low-carbon buildings have EC values around 200–500; very lightweight or extremely low-impact buildings have EC values under 150 [47].

4. Comparative EC Studies and Methodological Issues

This study has involved an analysis of case projects and calculations of embodied energy/carbon using tools such as the ICE Inventory of Carbon and Energy [48], and the One Click LCA commercial software for the BREEAM (Building Research Establishment Environmental Assessment Method) [49]. It builds extensively on other research studies and EC figures on embodied carbon.

Whilst a few methodological issues are touched on, it is stressed that the chosen approach is to provide intentionally simplified analyses. These are sufficiently robust to present what are to be seen as preliminary findings in what is a largely uncharted but important topic, namely, the very significant carbon impacts of the site works and landscaping works of construction projects. As argued, this will also be of increasing importance. Therefore, the need for further research in future has been underlined.

In addition to an example of a suburban residential dwelling, the EC of the two urban case studies (large engineering projects) was calculated and compared to EC figures from other projects around the world. The express intent has been to provide an overall picture whilst avoiding a detailed discussion of many methodological issues that are not relevant to the focus of this study. The comparison between the different studies is recognized as being very complex. The lifetime assumptions alone make a large difference. From a sustainability perspective, the norm is often an arguably very short 50 years for “sustainable” buildings, and it is hardly appropriate for large public works construction [50,51]. The classification of components as well as their EC estimation may differ between the studies. Embodied energy and emission calculations are dependent on the methodology, database assumptions, primary energy factors, and energy supply systems. For example, the Swedish energy system is less carbon-intensive than that of China. Hence, materials manufactured in Sweden will result in a building with less embodied carbon [52,53]. There is a variety of often inconsistent datasets. The contents of the materials categories are often not described in detail in studies—nor is their provenance. Further issues include the post-use EC value of timber or other materials.

The topic of differing approaches, measurement tools, and methods for LCA and EC studies is progressing towards more consistent standards and benchmarks. However, one particular issue in the context of this paper is that building data may include major materials only, whilst bills of quantities (BoQs) may often describe functional units and do not disaggregate the material components [31,54,55]. For example, quite EC-intensive elements such as technical fittings, lifts, or ventilation systems may be supplied as “items” without material quantities or breakdown [56]. This means that material quantities are not easily identifiable in the contract documents and bills of quantities.

Whilst it is complex to account for or harmonize these differences, a general picture has emerged of typical EC figures for different constructions and kinds of buildings. Table 1 above provides typical examples from the literature ranging from large buildings to detached houses. It is not necessary for the purposes of this paper to address these very complex methodological issues. The calculations here, mainly based on the ICE Inventory, provide sufficient evidence on the orders of magnitude involved in comparing the relative role of the site works- versus buildings-related EC.

5. Site Works and Landscaping

As regards the EC of site works in particular, some issues are, briefly, as follows. Firstly, landscaping works are often subject to a separate contract and, therefore, have a separate BoQ. Roadways, water supplies, telecommunications, and drainage works are often municipal services, which are the subject of separate contracts. The portion of these services that concerns us here will be the part that is within the project’s site boundaries. There are also many initial pre-construction inputs, such as site clearance, demolition and infrastructure preparation, or brownfield site restitution, which occur before the design phase and fall outside the compilation of project data. To date, these kinds of interventions with their EC and other impacts seem not to have been included in energy/carbon assessments of building projects.

Notably, although a few of the large projects in Table 1 do have some underground parking, none of the studies specify or disaggregate external site works or the underground parking works within their analysis. From the perspective of the present paper, a significant consideration is that underground parking is only fully necessitated by a dense city typology, which is not so much a building-related decision but a functional or zoning decision on the level of urban planning [17,57]. Dense urban typology is thus one factor influencing the high EC of such developments.

Site and landscaping works comprise one part of the EC of most building projects. The EC of these works is often low, comprising earthworks, plantations, and other “soft” interventions. “Hard” landscaping in the form of pathways, steps, seating, dams, drainage culverts, and garden walls implies more EC but in most cases this too will be quite minor in comparison with the buildings’ EC. Exceptions might include major decontamination of brownfield sites or steeply sloping sites with extensive hard landscaping and large retaining walls and others [58,59].

Large external retaining works may, on the other hand, be included in the construction BoQ, although they are, from the perspective of this study, part of the site works and not the building construction. Similarly, items such as the RC columns and beams in an underground parking garage will almost always form part of and be “concealed in” the overall building BoQ, meaning that one needs to identify and separate out which quantities relate to the foundations, and which are specific to the underground parking itself.

A large and detailed Beijing study does address specifically the part played by exterior works [60]. It encompasses an urban development of the kind that is a typical target of this paper, being a large development with a 70,000 m2 floor area comprising six high-rise commercial buildings set in a landscaped area, and is thus not unlike the study case in Ningbo, below. It employs a hybrid combination of process and input–output analyses and detailed calculations of the embodied energy. Usefully, the BoQs include both materials, on-site machinery, and labor. The overall EC of this project is approximately 700 kgCO2e/m2—a fairly heavy but typical figure given the Chinese, mainly fossil-fuel energy, context. The relevant site works subcategories, grouped under the heading of municipal engineering, are civil engineering, municipal electrical engineering, municipal water supply and drainage engineering, and gardening engineering.

Within municipal civil engineering, nearly 67% of the EC is cement and masonry products, largely hard paving and retaining works, and around 20% is metals. In water supply and drainage engineering, around 40% is metals and 40% is cement products for works such as surface drains, piping protection, culverts, etc. Metals comprise nearly 70% of the EC in the municipal electrical supply engineering, with very little cement/masonry. Around 63% of the EC in gardening engineering is cement and masonry products, mainly access roads and hard paving, and only 7% is in the metals category. The total of these site works comes to 6.6% of the entire project’s EC. Table 2 was applied since the context—Chinese location; Chinese primary energy factors; urban, high-rise buildings—is very similar.

Table 2.

Example of EC in residential site works.

Although the landscaping professions are actively addressing carbon issues, their focus often only partly coincides with that of this paper [61]. The principal concern of this study is to highlight the importance of embodied carbon in the site works of dense urban developments. In such contexts, the area and extent of landscaping works around the buildings are relatively small compared to the landscaping of parks or other large green areas. The EC in the urban context is mainly constituted by works related to buildings, including underground parking, and works which, as in the Chinese study above, may be collectively referred to as “municipal engineering”—roadways, water and power supply, drainage, etc.

Tools are lacking at present. As one review study notes, “many of the tools on the market are primarily aimed at calculating the embodied carbon of buildings rather than landscape projects” [61]. However, landscaping approaches include useful and essential aspects. One is the role that vegetation, trees in particular, has in “offsetting” the embodied carbon of projects over time. Again, this is unlikely to be a major EC factor on a dense urban site with major building structures but should certainly be included in a carbon analysis. The iTree tool [62] estimates the CO2 uptake of trees as well as important factors such as stormwater mitigation and pollutant removal. To illustrate this briefly, a medium-sized tree may typically sequester around 200 kgCO2e per year, which, over 50 years, means in the order of 10,000 kg, thereby roughly offsetting the EC of 10–20 m2 of a heavy-type building. Hence, the few trees on a typical inner city building site will not offset a significant proportion of the total project EC.

Another component that may constitute a large EC item in landscaping works, such as green belt areas or roadway projects, is that of earthworks, often involving large quantities over very large areas. In an urban project, this is, however, limited in area to the site itself, and may involve no more than the excavation for foundations and underground spaces. Yet another aspect that landscaping studies rightly include in their environmental analysis is water use (both embodied and operational) [61]. Again, this may be a major factor in large landscaping projects, but not in the urban contexts that have been addressed.

More studies are thus needed which distinguish the various exterior and underground site works that must be accumulated from within the bills of quantities of various subcontracts. However, even allowing for the complexities and issues noted above, the overall picture that emerges below is clear regarding the critical part played by site works and infrastructures in the total EC of construction projects. To conclude this section, despite differences in primary energy mixes and LCA methodologies, research comparing the EC resultant from these databases clarifies the above tendencies. Exceptions aside, typical EC figures (kgCO2e/m2) can be summarized broadly as follows: heavy concrete and steel buildings have EC values of 600–1000; moderate-weight and low-carbon buildings have EC values around 200–500; very lightweight or extremely low-impact buildings have EC values under 150 [47]. These indications form the basis for the following examination through simple case studies of the part played by site works and the largely “unseen” underground infrastructures in the total EC picture.

6. Case Studies

As noted above, many complexities are involved in calculations, such as for EC, but typical EC figures are by now quite clear. The first case is a straightforward example of a suburban residential project. The second is a large high-rise residential building development in Ningbo, China, with extensive underground areas and site works. A third test case is presented based on a concept study for a large urban development in Ningbo. This study was conducted as part of an EPSRC research program, Energy and Low-Income Tropical Housing [63], and serves to confirm the main findings of the conducted research. It is important to emphasize that the objective of this paper is not to present case studies with exhaustive calculations of embodied carbon. The estimates provided below are intentionally simplified. Even accepting a large range of variability which may emerge from detailed studies, they are sufficient for the purpose of this study, namely, to offer a comparative perspective to illustrate the relative significance of the embodied carbon of infrastructures and underground, on-site, and landscaping works in construction projects as compared to that of the buildings themselves.

6.1. EC: Residential Example

Although high EC in site works in urban contexts was our prime focus, the following example illustrates that the same considerations can even apply in suburban areas (Figure 2). This is worth consideration, not least because many of the buildings championed as being state-of-the-art as regards EC and OC are single houses and other quite small buildings but do not consider or provide information on the impacts of site works or infrastructures, which are nevertheless integral parts of a project. Here, a quite typical medium standard suburban villa of 250 m2 was considered, on a plot of 800 m2 (Table 2). For the EC of the building itself, two scenarios were taken: firstly, a typical medium to high residential EC figure of 450 kgCO2e/m2, and secondly, a “low-carbon”-type figure of 230 kgCO2e/m2. These may be compared to figures such as those from RICS, in Table 1. For the site works, the EC of a rendered brick perimeter wall of 1.7 m height above ground, of thickness 10 cm with 20 cm pillars at 1m intervals, plus a typical driveway area of 50 m2 was calculated. Other hard landscaping and site works would add a small amount of EC but are here assumed to be zero. The EC figures are from National Concrete Masonry Association (NCMA), 2008 [64].

Figure 2.

Standard suburban villa, of 250 m2, on a plot of 800 m2 (Source: The authors).

Although alternatives such as wooden or wire fencing would give a much lower EC, this example is far from untypical of fairly prosperous suburban areas worldwide. Hence, given a not untypical fairly “EC-heavy” house, or other small building, the site works may come to well under 20% of the total. But given the future practice of “very-low-EC” houses of under 200 kgCO2e, the site works could amount to well over one-third of the total EC impact of such projects. This gives food for thought to future designers and building owners.

6.2. EC: Urban Case

The urban development selected in Ningbo contains some 2500 apartments (Figure 3). It has 10 tower blocks of 23 to 30 floors set in landscaped areas. There is, in addition, a perimeter of lower-rise buildings, largely commercial. The urban density or floor area ratio (FAR), the total floor area divided by the site area, is about 2.6. This is three times the density of typical residential suburbs, double the density of low-rise townhouse typologies, but similar to or lower than that in traditional European cities that have low-density urban blocks of 4 to 8 floors, where the FAR can exceed 4.0 [65]. Interestingly, as previously discussed, this also means that high-rise buildings do not necessarily offer higher population densities [17]. The infrastructure implications, however, are considerable.

Figure 3.

High-rise city block, Ningbo, China (Source: Taken by the authors in 2017).

The surface coverage (SC) of the Ningbo block is below 20%, meaning that 80% of the site is not built on—at least, not above—ground. But almost the entirety of such sites is, in reality, occupied by structures underground. As noted above, the apparently large green areas are in fact all on top of thick concrete decks. A typical requirement is for one parking place per dwelling in many countries [66]. In this case, the resultant underground parking area is nearly the same as the area of the entire site.

The many other site works and infrastructures include culverts, drainage, access roads, water, electricity and sewage works, lighting, stairwells to the basements, paths, walling, and other hard landscaping. The buildings are all massive and largely in reinforced concrete; the actual EC figure is probably above the 750 kgCO2e/m2 conservatively estimated by us. The loadbearing deck carrying the landscaping is considerably thicker than residential decks. The underground garage for 2500 vehicles has thick columns and beams as well as watertight partition walls and perimeter walls. It covers almost all of the site and comprises a total of over 30,000 m3 of reinforced concrete.

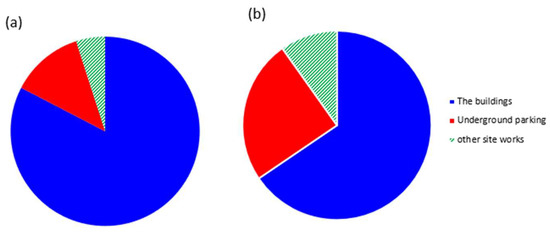

Table 3 and Figure 4 below provide a simplified comparative estimate of the EC of this project. For the buildings above ground (and including foundations), again, high and a low EC case scenarios were taken. In line with Table 1 above, these are as follows: high = 750 kgCO2e/m2 and low = 350 kgCO2e/m2. The figure of 6% for the exterior site works is based on the study of a similar large urban development in Beijing, described above [60], where these external works together amount to 6.6% of the total project EC.

Table 3.

EC in a large inner-city high-rise development, Ningbo.

Figure 4.

The proportion of carbon emissions from the buildings and from the site works of a large inner-city high-rise development, Ningbo, for (a) high (750 kgCO2e/m2) and (b) low (350 kgCO2e/m2) EC construction scenarios.

The above indicates that under current conditions and construction practices, in similar large and carbon-intensive urban building developments, the infrastructures and site works—all the parts that are not “the buildings”—may already constitute 15–20% of the total embodied carbon of such projects. Given the future low-carbon buildings above ground of even a moderately low EC standard, such as 300 kgCO2e/m2, the parking and infrastructures could total well over one-third of the total EC in this type of urban development, and indeed even more in the case of advanced low-carbon buildings.

6.3. EC Urban Case—Project Study

A further example was studied. This project proposal is a mix of residential high-rise and low-density buildings in Ningbo, on a large riverside site facing development (Figure 5) [18]. This proposal’s aims were relevant to this paper’s topic and to illustrate some advantages of low-density typology. These are worth a brief note: the low-density solution enables all apartments to face the sun, all well daylighted and all naturally cross-ventilated, with a passive and active solar design, low EC materials, and lastly, sufficient parking area under the buildings; hence, there are no EC impacts of the underground structures extending across large parts of the site. The proposed high-rise part is somewhat similar to the existing Ningbo city block analyzed above. The data in case 3 were only studied for comparative purposes to verify/solidify the findings of our major case 2, and are therefore not presented in detail. The data revealed a similar total EC picture. In this case, the buildings above ground, however, employed a design with much lower EC, around 350 kgCO2e/m2, including low-carbon concretes, minimal use of synthetic polymers, and lightweight interior partitions amongst other features with less embodied energy and carbon. As suggested above, this move to low-impact buildings leads to the site works’ contribution to the overall EC becoming considerably larger: in this case, over 28% of the total of the high-rise part of the project. This design study thus broadly confirmed the above tendencies.

Figure 5.

Project study, mixed high/low-rise buildings (Source: design by Cheshmehzangi and Butters).

7. Discussion

The focus has been the EC of site works and infrastructures, and in particular, though not uniquely, in city contexts. The findings show that this is of very considerable (and growing) significance. This offers an angle that has been little focused on to date and requires more research and analysis as a key towards more sustainable construction. There are also some interesting broader considerations that deserve attention. Carbon is naturally only one consideration for sustainable design, alongside the equally important economic and social aspects. We therefore will briefly note some issues and implications of the above for design, construction, and urban planning.

7.1. Planning Implications: The Issue of Density

A widely held objective of sustainable urban form is car-free, high-density living and working in walkable cities. The extremes of the suburban sprawl and a very low density are obviously inefficient in resource use in many, though not all, ways. But high population density, as measured in dwellings per hectare (dph) or floor area ratio (FAR), can be achieved with relatively low-rise typologies [65,67]. Increasing density also implies increasing technical complexity; an implication of this study is that the infrastructures and underground works in dense high-rise city typologies may lead to a considerably higher carbon footprint than in less dense settlements. Surface parking in particular is immensely less demanding than underground parking, both in terms of carbon and costs. And very high-rise buildings have been shown to be generally more energy demanding [16,68,69]. As in broader discussions of density and sustainability (see [18]), an “optimum” kind of urban density may lie somewhere in the middle. All factors considered, this may apply to EC/OC too. This paper has only considered EC within the borders of a project site. A fuller understanding of the role of EC must also take a broader perspective, including the roadways and mobility structures, tunnels, bridges, public infrastructures and spaces, retaining works, and other components of an overall urban district.

7.2. Materials

Whilst this study has focused on carbon, as noted, the implications are broadly similar for embodied energy. Embodied energy may be reduced by various means, and, notably, by substitution with less energy-intensive materials. However, the carbon impact of site works, heavy urban ones and underground parking in particular, will be more difficult to reduce. As noted above, cements are particularly problematic regarding energy and climate emissions. Cement has long been recognized as accounting for at least 5% of all global climate emissions [70]; advances are being made towards low-carbon cement, but they still comprise a large part of the EC of construction projects. The other major EC component in construction is metals, principally steel, as well as aluminum, zinc, copper, and a few others. The environmental impacts of these are constantly improving both through efficiency gains and increased recycling. Production based on renewables is the other main avenue toward greatly reduced impacts from the construction sector. However, in relative terms, the proportion of EC in site works may change little if both buildings and the site works employ similar technical advances. Improved energy and emission characteristics of materials do not necessarily diminish pollution or other impacts on biodiversity, water resources, waste streams, or other planetary concerns.

In the field of materials, a particular case is that of synthetic polymers (plastics), also very widespread in construction, derived from fossil fuels, and with high impacts. Many of these are likely to be replaced within a generation by bioplastics derived from plant materials—a fast-expanding sector and one that offers much reduced EC [71]. Materials of this type can also find many potential applications both in buildings and in site works and infrastructures, including permeable paving, pipework, and hard landscaping elements (Figure 6).

Figure 6.

Extremely low embodied carbon in both buildings and minimal site works: Hurdal Ecovillage (GAIA architects Norway, Rolf Jakobsen. Photo by the authors, taken in 2020).

7.3. Lifecycle Considerations

This study considers the whole construction lifecycle. In this regard, complex urban infrastructures have some disadvantages in terms of the EC [16]. Firstly, the carbon impacts of materials transport and on-site construction, although two relatively minor items in the LCA balance, are also higher in the case of heavy materials such as concrete and steel. The recurrent EC for ongoing maintenance is more onerous in complex urban contexts, not least due to difficult (i.e., high-rise, underground, and/or multi-layer) accessibility, repairs, upgrading, replacement, and maintenance throughout their lifetime. The associated cumulative waste is another issue: “Over a very long life-span, this has been shown to exceed the waste flow from simple demolition” [72]. Finally, the post-use EC impacts of complex urban infrastructures can be high due to the complicated demolition and recycling or disposal of composite, polluting materials, and technical components. It may also be quite energy-intensive. And, whilst moves towards a circular economy are positive, recycling does not eliminate many of the impacts of high throughput within an overall resources economy. It may be noted, for example, that recycling concretes, such as for use as aggregates in new mixes, can require more energy than producing fresh aggregates. The same applies to recycling plasterboard [73].

The EC of materials is evolving; both recycled steel and low-carbon cement offer considerably reduced EC. However, this is not likely to significantly change their relative importance within the overall EC of construction. Firstly, because the EC of other construction materials will also be improved, meaning that from the point of view of this comparative perspective, the proportion of steel and cement in a building’s EC may remain much the same. And secondly, in many parts of the world, the production of steel and cement is still extremely carbon-intensive and will be for decades to come, even more in the case of weakened economies or conflicts, which delay the energy transition away from fossil fuels. Cement and steel will thus continue to be key items within the time window associated with climate emission targets. These considerations tend to confirm the significance of the EC of the site works and infrastructures.

7.4. Climatic Contexts

Finally, these studies led to note an interesting point regarding the relative importance of the site works and infrastructures in different climates. Since space heating and space cooling require energy inputs of a similar order, in hot climates, the OC tends to be quite similar to the cold climate OC. In both cases, the operational impacts will be reduced in future energy-efficient buildings. This confirms the growing importance of the embodied impacts generally, but the wider picture of site works, by contrast, will vary considerably depending on the climatic context:

- In hot–dry and cold climates, which tend towards more massive construction, the EC of the site works will generally represent a smaller portion of the overall EC;

- In hot–humid climates, where buildings are often lightweight, the EC of the buildings tends to be lower; hence, the EC of the site works will tend to be of greater relative importance;

- In moderate climates where there is little need for space heating or cooling at all, since the OC is far lower, the EC of both buildings and site works will tend to be an even more significant factor;

- And finally, the site and infrastructure work in low-density and rural settlements, whether in hot or cold climates, can, as a general rule, be simpler and achieve lower EC.

8. Towards Solutions

Although the focus has been to draw attention to a rarely researched “problem”, not solutions, this study is engaged in design solutions too. Therefore, a very brief section outlining some key pointers towards solutions is added here. In doing so, this section relates them to four specified areas of urban design, materials, life cycle, and climatic context, thus following up the four areas noted above.

8.1. Urban Design

At the urban design level, reducing the EC impact of site works, landscaping, and infrastructures may, in brief, be addressed in the following ways. Firstly, where possible, sites should be chosen for urban expansion in zones that are less demanding for infrastructures, for example, areas that are not rocky or waterlogged. Secondly, some plan layouts (linear, radial, cluster …) will definitely have less impact than others, and more compact urban layouts in general offer economies of scale—although the maintenance of such inner-city infrastructures is more onerous than in low-density typologies. Thirdly, there are design options as regards extensive or reduced site interventions, as well as soft- versus hard-type landscaping. Fourthly, ultimately, the key issue (including many other reasons such as fuel use and noise) is that of reducing the need for extensive roadway infrastructures and underground parking. This should ideally be by shaping cities with mixed zoning layouts, reducing commuting needs, and with effective public transport, thus reducing all roadway structures, and by all possible means of reducing the sheer volume of vehicles in the future city. And finally, settlement typologies of low density offer the inherent advantage that infrastructures can be simpler and more easily accessible for maintenance, and underground parking is largely unnecessary. This is a significant argument in contrast to the compact city paradigm, which is often cited as offering the best “sustainability”.

8.2. Materials

As noted, infrastructures are largely in the carbon-intensive materials concrete and steel. Whilst both of these are becoming less carbon-intensive, this would, as noted, be unlikely to reduce the proportion of site works’ EC overall since the same progress will occur in the building materials above ground (if not greater, since concrete and steel can more easily be substituted). However, there are evident opportunities for improvement. Steel, for example, whilst carbon-intensive, offers the advantage of recyclability—assuming that steel structures can avoid large quantities of plasterboard or other fire-retardant coatings. Concretes offer some, but limited, recycling applications. Polymers may offer advantages as conduits, piping, permeable surface parking coverings, and even for structural elements. There have been concepts for underground parking in timber. There are also opportunities for reducing materials use by the better integration of the building’s services such as water, power, sanitation, and IT, which are often built separately. This kind of urban service coordination is, however, often unattainable.

8.3. Lifecycle

In Section 7.3 above, the obstacles to progress in this regard were noted. There are opportunities at all stages of the life cycle process, and these are emerging in ongoing research and practice. Life cycle impacts can certainly be reduced by avoiding the long-distance transport of heavy materials, and by more efficient construction such as prefabrication. These two life cycle items are fairly minor but significant, and, as noted, their relative share will increase as materials production in particular becomes far less carbon-intensive (or polluting in other ways). It has been also noted that the post-use phase requires more consideration. Two other lifecycle-related opportunities are designing for a longer lifespan and moves towards more circular materials throughput in the economy.

8.4. Climatic Context

In a simplified way, four generic cases in Section 7.4 were noted. In hot–dry and cold climates as well as in moderate climates, all the above considerations apply. In hot–humid contexts, in addition, a particular opportunity lies in solutions using more lightweight materials. Climatic considerations also relate back to urban form. A high density, for example, may hinder effective urban ventilation for city cooling in hot climates, but have an opposite, positive effect of hindering cold winds in cold climates. Similarly, a high density will, in general, tend to aggravate heat island effects in hot-climate cities.

9. Conclusions

The major goal of this paper has been to identify and illustrate, with simple case analyses, a relatively new and original perspective in the field of construction-related sustainability, namely, the often unseen or overlooked topic of site works and landscaping-related carbon/climate impacts. The aim is to underline the importance of further research, and thereby to contribute towards improved design solutions. The embodied energy and carbon of site works and infrastructures, where concrete and steel are almost unavoidable, have been highlighted. The relative importance of this part of the EC varies depending on the climatic context and on the chosen built typology. There are considerable sustainability impacts—and equally—opportunities in the area of EC that demand further research. The importance of EC is increasingly recognized. Whilst there is rapid progress in the understanding of individual buildings as regards both operational and embodied impacts of construction, to date, the impacts of site works and infrastructures have rarely been focused on energy, carbon, and LCA studies. These impacts are often “hidden” within other parts of building energy/carbon analysis. The impacts are considerable and are likely to become an ever-larger part of the overall picture.

Author Contributions

Conceptualization, C.B. and A.C.; methodology, C.B. and R.B.; software, R.B.; validation, A.C.; formal analysis, C.B. and R.B.; investigation, C.B. and R.B.; resources, C.B.; data curation, C.B. and A.C.; writing—original draft preparation, R.B.; writing—review and editing, C.B. and A.C.; visualization, R.B.; supervision, C.B.; project administration, C.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data is contained within the article.

Acknowledgments

This paper is partly an output from a project co-funded by the UK Department for International Development (DFID), the Department for Energy & Climate Change (DECC) and the Engineering & Physical Science Research Council (EPSRC, grant no. EP/L002604/1). Views expressed are not necessarily those of DFID, DECC or EPSRC.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Unalan, B.; Tanrivermis, H.; Bulbul, M.; Celani, A.; Ciaramella, A. Impact of Embodied Carbon in the Life Cycle of Buildings on Climate Change for a Sustainable Future. Int. J. Hous. Sci. Its Appl. 2016, 40, 61–71. [Google Scholar]

- Dimoudi, A.; Tompa, C. Energy and Environmental Indicators Related to Construction of Office Buildings. Resour. Conserv. Recycl. 2008, 53, 86–95. [Google Scholar] [CrossRef]

- IPCC. IPCC Fifth Assessment Report; IPCC: Geneva, Switzerland, 2014. [Google Scholar]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life Cycle Energy Analysis of Buildings: An Overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Purnell, P. Response to the Comment on “Material Nature versus Structural Nurture: The Embodied Carbon of Fundamental Structural Elements. Environ. Sci. Technol. 2012, 46, 3597–3598. [Google Scholar] [CrossRef]

- Kouta, C.; Kaite, C.P. Gender Discrimination and Nursing: A Literature Review. J. Prof. Nurs. 2011, 27, 59–63. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Greenough, R.; Taylor, S.; Ozawa-Meida, L.; Acquaye, A. Operational vs. Embodied Emissions in Buildings—A Review of Current Trends. Energy Build. 2013, 66, 232–245. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Xiao, J. Estimation and Minimization of Embodied Carbon of Buildings: A Review. Buildings 2017, 7, 5. [Google Scholar] [CrossRef]

- Chukka, N.D.K.R.; Arivumangai, A.; Kumar, S.; Subashchandrabose, R.; Reddy, Y.B.S.; Natrayan, L.; Debela, G.C. Environmental Impact and Carbon Footprint Assessment of Sustainable Buildings: An Experimental Investigation. Adsorpt. Sci. Technol. 2022, 8130180. [Google Scholar] [CrossRef]

- Johnson, D.L.; Lewis, L.A. Land Degradation: Creation and Destruction; Rowman & Littlefield: Lanham, MD, USA, 2007; ISBN 0742519481. [Google Scholar]

- Srinivasarao, C.; Jasti, V.N.S.P.; Kondru, V.R.; Bathineni, V.S.K.; Mudigiri, R.; Venati, G.V.; Priyadarshini, P.; Abhilash, P.C.; Chaudhari, S.K. Land and Water Conservation Technologies for Building Carbon Positive Villages in India. L. Degrad. Dev. 2022, 33, 395–412. [Google Scholar] [CrossRef]

- Ohene, E.; Chan, A.P.C.; Darko, A. Review of Global Research Advances towards Net-Zero Emissions Buildings. Energy Build. 2022, 266, 112142. [Google Scholar] [CrossRef]

- Hafez, F.S.; Sa’di, B.; Safa-Gamal, M.; Taufiq-Yap, Y.H.; Alrifaey, M.; Seyedmahmoudian, M.; Stojcevski, A.; Horan, B.; Mekhilef, S. Energy Efficiency in Sustainable Buildings: A Systematic Review with Taxonomy, Challenges, Motivations, Methodological Aspects, Recommendations, and Pathways for Future Research. Energy Strategy Rev. 2023, 45, 101013. [Google Scholar] [CrossRef]

- United Nations. World Urbanization Prospects: The 2018 Revision (ST/ESA/SER.A/420); United Nations: New York, NY, USA, 2019. [Google Scholar]

- Hoornweg, D.; Sugar, L.; Gómez, C.L.T. Cities and Greenhouse Gas Emissions: Moving Forward. Plan. Clim. Chang. A Read. Green Infrastruct. Sustain. Des. Resilient Cities 2018, 23, 62–71. [Google Scholar] [CrossRef]

- Butters, C.; Cheshmehzangi, A. (Eds.) Cooler Cities: What Kinds of City? Urban Form, Climate and Wellbeing. In Palgrave Series in Asia and Pacific Studies; Springer: Berlin/Heidelberg, Germany, 2018; pp. 173–190. [Google Scholar]

- Cheshmehzangi, A.; Butters, C. Sustainable Living and Urban Density: The Choices Are Wide Open. Energy Procedia 2016, 88, 63–70. [Google Scholar] [CrossRef]

- Cheshmehzangi, A.; Butters, C. Chinese Urban Residential Blocks: Towards Improved Environmental and Living Qualities. Urban Des. Int. 2017, 22, 219–235. [Google Scholar] [CrossRef]

- Cheshmehzangi, A.; Butters, C.; Xie, L.; Dawodu, A. Green Infrastructures for Urban Sustainability: Issues, Implications, and Solutions for Underdeveloped Areas. Urban For. Urban Green. 2021, 59, 127028. [Google Scholar] [CrossRef]

- Future Cities Program Final Report, in Norwegian, Analyses of a New Low Impact Office Block, Oslo, Norway. Ostensjoveien 27, Hovedresultater og Sammenl. av Altern. 2014. Available online: https://www.futurebuilt.no/content/download/5266/file/__stensj__veien_27_klimagassberegninger___Hovedresultater_og_sammenligning_av_alternativer_NCC_TR_og_KS_ved_Civitas_v29_01_2014.pdf (accessed on 4 October 2023).

- Pan, W.; Teng, Y. A Systematic Investigation into the Methodological Variables of Embodied Carbon Assessment of Buildings. Renew. Sustain. Energy Rev. 2021, 141, 110840. [Google Scholar] [CrossRef]

- Li, K.; Ma, M.; Xiang, X.; Feng, W.; Ma, Z.; Cai, W.; Ma, X. Carbon Reduction in Commercial Building Operations: A Provincial Retrospection in China. Appl. Energy 2022, 306, 118098. [Google Scholar] [CrossRef]

- Cole, R.J. Regenerative Design and Development: Current Theory and Practice. Build. Res. Inf. 2012, 40, 1–6. [Google Scholar] [CrossRef]

- Hammond, G.P.; Jones, C.I. Embodied Energy and Carbon in Construction Materials. Proc. Inst. Civ. Eng. Energy 2008, 161, 87–98. [Google Scholar] [CrossRef]

- Kerr, J.; Rayburg, S.; Neave, M.; Rodwell, J. Comparative Analysis of the Global Warming Potential (GWP) of Structural Stone, Concrete and Steel Construction Materials. Sustainability 2022, 14, 9019. [Google Scholar] [CrossRef]

- Wallhagen, M.; Glaumann, M.; Malmqvist, T. Basic Building Life Cycle Calculations to Decrease Contribution to Climate Change—Case Study on an Office Building in Sweden. Build. Environ. 2011, 46, 1863–1871. [Google Scholar] [CrossRef]

- Blengini, G.A. Life Cycle of Buildings, Demolition and Recycling Potential: A Case Study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F. Life-Cycle Assessment and Control Measures for Carbon Emissions of Typical Buildings in China. Build. Environ. 2015, 86, 89–97. [Google Scholar] [CrossRef]

- Kang, G.; Kim, T.; Kim, Y.W.; Cho, H.; Kang, K.I. Statistical Analysis of Embodied Carbon Emission for Building Construction. Energy Build. 2015, 105, 326–333. [Google Scholar] [CrossRef]

- Ekundayo, D.; Babatunde, S.O.; Ekundayo, A.; Perera, S.; Udeaja, C. Life Cycle Carbon Emissions and Comparative Evaluation of Selected Open Source UK Embodied Carbon Counting Tools. Constr. Econ. Build. 2019, 19, 220–242. [Google Scholar] [CrossRef]

- Cang, Y.; Luo, Z.; Yang, L.; Han, B. A New Method for Calculating the Embodied Carbon Emissions from Buildings in Schematic Design: Taking “Building Element” as Basic Unit. Build. Environ. 2020, 185, 107306. [Google Scholar] [CrossRef]

- Limphitakphong, N.; Thaipradit, P.; Kanchanapiya, P.; Tantisattayakul, T.; Chavalparit, O. Embodied Carbon Emissions of Construction Materials: A Case Study of Buildings in Thailand. Int. J. GEOMATE 2020, 18, 187–193. [Google Scholar] [CrossRef]

- Tokheim, L.-A.; Mathisen, A.; Gautestad, T. Combined Calcination and CO2 Capture in Cement Clinker Production by Use of Electrical Energy. In Proceedings of the 10th Trondheim Conference on CO2 Capture, Transport and Storage, Trondheim, Norway, 17–19 June 2019. [Google Scholar]

- Wan Omar, W.M.S. A Hybrid Life Cycle Assessment of Embodied Energy and Carbon Emissions from Conventional and Industrialised Building Systems in Malaysia. Energy Build. 2018, 167, 253–268. [Google Scholar] [CrossRef]

- RICS. Methodology to Calculate Embodied Carbon of Materials; Royal Institution of Chartered Surveyors: London, UK, 2012; ISBN 9781842197950. [Google Scholar]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life Cycle Greenhouse Gas Emissions and Energy Analysis of Prefabricated Reusable Building Modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Tae, S.; Baek, C.; Roh, S. Life Cycle CO2 Evaluation on Reinforced Concrete Structures with High-Strength Concrete. Handb. Low Carbon Concr. 2017, 31, 17–38. [Google Scholar] [CrossRef]

- Chang, Y.; Ries, R.J.; Lei, S. The Embodied Energy and Emissions of a High-Rise Education Building: A Quantification Using Process-Based Hybrid Life Cycle Inventory Model. Energy Build. 2012, 55, 790–798. [Google Scholar] [CrossRef]

- Suzuki, M.; Oka, T. Estimation of Life Cycle Energy Consumption and CO2 Emission of Office Buildings in Japan. Energy Build. 1998, 28, 33–41. [Google Scholar] [CrossRef]

- Yan, H.; Shen, Q.; Fan, L.C.H.; Wang, Y.; Zhang, L. Greenhouse Gas Emissions in Building Construction: A Case Study of One Peking in Hong Kong. Build. Environ. 2010, 45, 949–955. [Google Scholar] [CrossRef]

- Berardinelli, L.; Pozzoli, E.; Beretta, C.; Consonni, D.; Carini, M.; Rossini, G.; Scalamogna, M. Long-Term Outcome of Living Donors Older Than 60 Years; Royal Institution of Chartered Surveyors: London, UK, 2010; Volume 42, ISBN 9781842197950. [Google Scholar]

- Dodoo, A.; Gustavsson, L.; Sathre, R. Carbon Implications of End-of-Life Management of Building Materials. Resour. Conserv. Recycl. 2009, 53, 276–286. [Google Scholar] [CrossRef]

- Butters, C.; Woodville, P. Analysis of a Very Low Embodied Energy House in Norway; Warwick University: Coventry, UK, 2016. [Google Scholar]

- Rakkwamsu, P.; Chiarakorn, S.; Aransiri, K.; Nalinee, A. Evaluation of Greenhouse Gas Emission from Residential Buildings in Thailand. In Proceedings of the Asian Conference on Sustainability, Energy & the Environment, Osaka, Japan, 1 August 2012; pp. 12–15. [Google Scholar]

- Brooks, M.; Abdellatif, M.; Alkhaddar, R. Application of Life Cycle Carbon Assessment for a Sustainable Building Design: A Case Study in the UK. Int. J. Green Energy 2021, 18, 351–362. [Google Scholar] [CrossRef]

- Anderson, N.; Wedawatta, G.; Rathnayake, I.; Domingo, N.; Azizi, Z. Embodied Energy Consumption in the Residential Sector: A Case Study of Affordable Housing. Sustainability 2022, 14, 5051. [Google Scholar] [CrossRef]

- Takano, A.; Winter, S.; Hughes, M.; Linkosalmi, L. Comparison of Life Cycle Assessment Databases: A Case Study on Building Assessment. Build. Environ. 2014, 79, 20–30. [Google Scholar] [CrossRef]

- Hammond, G.; Jones, C. Inventory of Carbon & Energy: ICE; Sustainable Energy Research Team, Department of Mechanical Engineering, University of Bath: Bath, UK, 2008. [Google Scholar]

- OneClick LCA OneClick LCA. Available online: https://www.oneclicklca.com/ (accessed on 4 October 2023).

- Akadiri, P.O.; Chinyio, E.A.; Olomolaiye, P.O. Design of a Sustainable Building: A Conceptual Framework for Implementing Sustainability in the Building Sector. Buildings 2012, 2, 126–152. [Google Scholar] [CrossRef]

- Marsh, R. Building Lifespan: Effect on the Environmental Impact of Building Components in a Danish Perspective. Archit. Eng. Des. Manag. 2017, 13, 80–100. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Barreneche, C.; Miró, L.; Morera, J.M.; Bartolí, E.; Inés Fernández, A. Low Carbon and Low Embodied Energy Materials in Buildings: A Review. Renew. Sustain. Energy Rev. 2013, 23, 536–542. [Google Scholar] [CrossRef]

- Su, X.; Zhang, X. A Detailed Analysis of the Embodied Energy and Carbon Emissions of Steel-Construction Residential Buildings in China. Energy Build. 2016, 119, 323–330. [Google Scholar] [CrossRef]

- Kumanayake, R.; Luo, H.; Paulusz, N. Assessment of Material Related Embodied Carbon of an Office Building in Sri Lanka. Energy Build. 2018, 166, 250–257. [Google Scholar] [CrossRef]

- Drewniok, M.P.; Azevedo, J.M.C.; Dunant, C.F.; Allwood, J.M.; Cullen, J.M.; Ibell, T.; Hawkins, W. Mapping Material Use and Embodied Carbon in UK Construction. Resour. Conserv. Recycl. 2023, 197, 107056. [Google Scholar] [CrossRef]

- Syngros, G.; Balaras, C.A.; Koubogiannis, D.G. Embodied CO2 Emissions in Building Construction Materials of Hellenic Dwellings. Procedia Environ. Sci. 2017, 38, 500–508. [Google Scholar] [CrossRef]

- Manville, M.; Shoup, D. Parking, People, and Cities. J. Urban Plan. Dev. 2005, 131, 233–245. [Google Scholar] [CrossRef]

- Kayaçetin, N.C.; Tanyer, A.M. Embodied Carbon Assessment of Residential Housing at Urban Scale. Renew. Sustain. Energy Rev. 2020, 117, 109470. [Google Scholar] [CrossRef]

- Lin, H.T.; Lin, Y.J. Component-Level Embodied Carbon Database for Landscape Hard Works in Taiwan. Environ. Dev. Sustain. 2022, 24, 4918–4941. [Google Scholar] [CrossRef]

- Han, M.Y.; Chen, G.Q.; Shao, L.; Li, J.S.; Alsaedi, A.; Ahmad, B.; Guo, S.; Jiang, M.M.; Ji, X. Embodied Energy Consumption of Building Construction Engineering: Case Study in E-Town, Beijing. Energy Build. 2013, 64, 62–72. [Google Scholar] [CrossRef]

- Nikologianni, A.; Plowman, T.; Brown, B. A Review of Embodied Carbon in Landscape Architecture. Practice and Policy. C-J. Carbon Res. 2022, 8, 22. [Google Scholar] [CrossRef]

- I-Tree. Available online: https://www.itreetools.org/ (accessed on 4 October 2023).

- Bhikhoo, N. Energy Efficiency in Low Income Tropical Housing (Vol. 8, Issue July). Master’s Thesis, University of Cambridge, Cambridge, UK, 2015. [Google Scholar]

- Concrete and Masonry Movements. In Concrete and Masonry Movements; Butterworth-Heinemann: Oxford, UK, 2014. [CrossRef]

- Wang, R.; Yuan, Q. Parking Practices and Policies under Rapid Motorization: The Case of China. Transp. Policy 2013, 30, 109–116. [Google Scholar] [CrossRef]

- Jabareen, Y.R. Sustainable Urban Forms: Their Typologies, Models, and Concepts. J. Plan. Educ. Res. 2006, 26, 38–52. [Google Scholar] [CrossRef]

- Rode, P.; Keim, C.; Robazza, G.; Viejo, P.; Schofield, J. Cities and Energy: Urban Morphology and Residential Heat-Energy Demand. Environ. Plan. B Plan. Des. 2014, 41, 138–162. [Google Scholar] [CrossRef]

- Cheshmehzangi, A.; Butters, C. Refining the complex urban: The study of urban residential typologies for reduced future energy and climate impacts. In Proceedings of the 8th Conference of the International Forum on Urbanism, Incheon, Republic of Korea, 22–24 June 2015. [Google Scholar]

- Godoy-Shimizu, D.; Steadman, P.; Hamilton, I.; Donn, M.; Evans, S.; Moreno, G.; Shayesteh, H. Energy Use and Height in Office Buildings. Build. Res. Inf. 2018, 46, 845–863. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon Dioxide Emissions from the Global Cement Industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Kretschmer, B. Cascading Use: A Systematic Approach to Biomass beyond the Energy Sector; Biomass Futures Final Workshop, March 2012, European Parliament; Institute for European Environmental Policy: Brussels, Belgium, 2012. [Google Scholar]

- Thomsen, A.; Schultmann, F.; Kohler, N. Deconstruction, Demolition and Destruction. Build. Res. Inf. 2011, 39, 327–332. [Google Scholar] [CrossRef]

- Gao, W.; Ariyama, T.; Ojima, T.; Meier, A. Energy Impacts of Recycling Disassembly Material in Residential Buildings. Energy Build. 2001, 33, 553–562. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).