Abstract

This study investigates the use of waste glass powder derived from fluorescent lamps as a partial replacement for cement in mortar production, aiming to valorize this Waste from Electrical and Electronic Equipment (WEEE) and enhance sustainability in the construction sector. Mortars were formulated by substituting 25% of cement by volume with glass powders from fluorescent lamp glass and green bottle glass. The experimental program evaluated mechanical strength, durability parameters and ecotoxicological performance. Results revealed that clean fluorescent lamp mortars showed the most promising mechanical behavior, exceeding the reference in long-term compressive (54.8 MPa) and flexural strength (10.0 MPa). All glass mortars exhibited significantly reduced chloride diffusion coefficients (85–89%) and increased electrical resistivity (almost 4 times higher), indicating improved durability. Leaching tests confirmed that the incorporation of fluorescent lamp waste did not lead to hazardous levels of heavy metals in the cured mortars, suggesting effective encapsulation. By addressing both technical (mechanical and durability) and ecotoxic performance, this research contributes in an original and relevant way to the development of more sustainable building materials.

1. Introduction

The demand for cement continues to grow steadily alongside global development, highlighting the environmental challenges associated with its use and manufacturing process. In this context, the promotion of a circular economy emerges as a key strategy for the construction sector to mitigate its negative environmental impacts and achieve critical environmental goals, such as carbon neutrality by 2050, as outlined in initiatives like the European Green Deal.

Aligned with these principles, the incorporation of waste materials into cementitious matrices has become an increasingly studied and recognized practice. Specifically, regarding the use of glass waste in concrete production, the publication of ASTM C1866M-20 [1] has helped to boost this application, encouraging new sustainable approaches [2]. In addition to the large volume of glass potentially available for recycling (from bottles to flat glass), the high silica content in glass composition is one of the main drivers of research involving glass powder as a partial cement replacement. Several studies have reported that finely ground glass waste can act as a pozzolanic material [3,4]. In this form, the glass particles interact with the hydration products of cement, promoting the formation of additional calcium silicate hydrate (C-S-H), which contributes to improved mechanical strength and durability at later ages [5].

According to the study conducted by [6], glass powder obtained from ground glass packaging was utilized in the production of various concrete mixtures as a partial cement replacement. The replacement levels investigated were 0% to 25% (increasing by 5%) by weight, using different binder contents (350 and 450 kg/m3). The compressive strength was evaluated at 7, 28, and 56 days. Results showed an increase in compressive strength up to a certain replacement percentage with a decline observed at higher substitution levels. Specifically, the incorporation of 5% glass powder led to a slight enhancement in compressive strength, which is a trend that was consistent across all testing ages. Other studies have also achieved promising results not only in terms of compressive strength but also with regard to durability. In this context, high resistance to chloride penetration has been particularly noteworthy.

In reference [7], the authors evaluated the use of crushed waste glass as a partial cement replacement in mortars at levels of 0% to 20% (increasing by 10%) by weight. According to the results obtained using the rapid CTH test, incorporating waste glass, particularly at 20%, significantly improved the mortar’s resistance to Cl− ingress when compared to the reference mix. Ref. [8] reported that replacing 20% of cement with glass powder in concrete significantly enhanced its resistance to chloride-ion penetration with a reduction from 2800 to 987 Coulombs (an improvement of approximately 284%). Their study evaluated the real-world performance of concrete incorporating glass powder at multiple construction sites throughout Quebec, Canada, during the period from 2006 to 2012. In addition to environmental advantages, the modified concrete exhibited improved mechanical properties, including a 7% increase in compressive strength at 91 days, a 35% increase in tensile strength at 28 days, and a 4% improvement in flexural strength at 28 days, when compared to control mixes without glass powder.

Concerning glass derived from Waste Electrical and Electronic Equipment (WEEE), there are still relatively few studies on its incorporation and valorization in cementitious matrices. According to [9], the rapid pace of technological development has led to a global increase in electronic waste, which represents a considerable threat to both the environment and human health. Ref. [10] reported that in 2019, 53.6 million tons of WEEE were generated worldwide. In Europe alone, it is estimated that approximately 12 million tons were produced, accounting for 22.4% of the global total. Given that recycling of this type of waste is limited due to the potential presence of heavy metals, it is urgent to find viable solutions to address this issue.

Concrete and mortar are among the construction materials with the highest potential for incorporating waste. It is also well established that the cementitious matrix is effective in the stabilization and solidification of hazardous waste in the final treatment stages. Ref. [11] investigated the behavior of lead in cementitious matrices and concluded that the stabilization/solidification of lead in mortar is feasible, although a reduction in mechanical strength was observed. However, in the specific context of using glass from WEEE in cementitious matrices, no studies have yet confirmed the stabilization of lead or other heavy metals.

Research on the replacement of cement with glass powder derived from WEEE remains limited. Regarding the application of glass as a partial cement replacement, fluorescent lamps stand out as a type of WEEE with a high percentage of e-glass. The presence of mercury (Hg) in fluorescent lamps (around 15 mg per unit) raises significant environmental concerns. Furthermore, the ongoing replacement of fluorescent lamps with light-emitting diode lamps has contributed to a growing volume of waste. Recent studies have explored the use of their glass as an input in mortars [12], technical porcelains [13], geopolymers [14], and in the recovery of rare earth elements [15] with the latter being the most common application. Considering cementitious materials applications, given that industrial residues such as fly ash and slag have been widely and successfully used, the integration of waste glass from electronic equipment with these materials may represent a promising complementary pathway. Although this combination has not yet been addressed in the current literature, it presents relevant potential for future research aimed at the simultaneous valorization of multiple industrial solid wastes.

Some researchers have investigated the use of glass from fluorescent lamps in cementitious matrices (without combination with others wastes), reporting satisfactory results in terms of mechanical performance. Ref. [16] studied the incorporation of borosilicate and lead silicate glass chips, obtained after fluorescent lamp dismantling, into concrete. Cement was partially replaced with glass powder at levels of 20%, 30%, and 40%. Tests revealed that all glass-containing concrete mixes exhibited higher strengths than the control mix with the 40% replacement mix showing an 11% increase in strength after 56 days of curing. Later, ref. [17] investigated mortars produced with fluorescent lamp waste and observed that while their compressive strength was lower than that of the reference sample at 28 days, after 90 days of curing, mixtures containing up to 35% glass waste reached strength levels comparable to, or surpassing, the reference mortar.

In this context, the goal of this study is to experimentally evaluate the feasibility of using glass powder derived from waste fluorescent lamps as a partial replacement for cement in mortar production. The research focuses on assessing the effects of this substitution on mechanical performance, durability (particularly chloride ingress resistance), and environmental aspects, including potential ecotoxicological risks. This contribution aims to generate quantitative data to advance knowledge in the field of WEEE valorization within cementitious systems.

2. Research Significance

This study is exploratory in nature and aims to assess the feasibility of using waste glass powder from fluorescent lamps (a type of electronic waste, or WEEE) as a partial cement replacement in cementitious materials. The primary objective is not to generalize conclusions but rather to generate foundational data that can inform further, more comprehensive studies.

While bottle glass (soda-lime glass) powder has already shown promising results as a supplementary cementitious material, the potential of fluorescent lamp glass remains largely unexplored. This work addresses that gap by evaluating key performance parameters—mechanical strength, durability (particularly chloride ingress resistance), and ecotoxicological safety (including heavy metal leaching)—which are essential for assessing the viability of such waste in construction applications.

In addition, this study contributes to closing another gap in the literature: the comparative performance of fluorescent lamp glass versus bottle glass in similar cementitious matrices. By providing initial insights, this work lays the groundwork for a future research line focused on the circular use of WEEE in sustainable construction.

3. Experimental Development

3.1. Materials

3.1.1. Glass Powder Obtaining

Two types of glass waste were used in this research: fluorescent lamps and green bottles. The fluorescent lamps were supplied by a waste management company that operates in the country. In Figure 1, it is possible to see the fluorescent lamps in the company (before the separation process), as received, how they arrive at the laboratory (fragmented, after the separation process between the glass tube and electronic components that took place in the company), and the glass powder coming from the lamps (which will be used to produce mortars).

Figure 1.

Fluorescent lamp: (a) before the separation process; (b) after the separation process (fragmented); (c) and powder resulting from grinding.

The glasses were ground until they reached a similar granulometric distribution to the cement. Glass powder from green bottles (G-C) was obtained according to [18]. Concerning the glass from fluorescent lamps and considering the impact of its cleaning on the process (costs, time and by-products) and the results, the fluorescent lamp clean (FL-C) and fluorescent lamp dirty (FL-D) were studied as received. Obtaining these powders is summarized in the main stages:

- Washing (only for fluorescent lamp clean): The fragments were submerged in distilled water for 24 h, allowing the removal of surface dirt and the separation of any different material that may have been sent along with the glass;

- Drying (only for fluorescent lamp clean): The fragments were introduced into a ventilated oven operating at a stable temperature of 105 ± 1 °C, for approximately 2 h, ensuring the elimination of humidity;

- Grounding: The fragments were ground in 0.5 kg portions, with 5-minute cycles (around 15 cycles, using a grain mill with a speed equal to 36,000 rpm), interspersed with pauses, until a fineness comparable to that of Portland cement was reached.

While this study focuses on the mechanical, durability and ecotoxic performance of glass-based mortars at the laboratory scale, the practical applicability of using fluorescent lamp glass and green bottle glass in the construction industry depends significantly on the scalability and cost-efficiency of the processing steps involved, namely, sourcing, cleaning, and grinding. Concerning the sourcing, it is worth noting that green bottle glass benefits from an already established collection and recycling stream, making it more readily available for large-scale applications. In contrast, fluorescent lamp glass does not have a dedicated reuse chain, and its use in construction materials represents a valorization route for a currently underutilized hazardous waste. In the present study, both types of glass were processed with minimal treatment: simple water washing to remove surface contaminants. Regarding grinding, energy consumption is an important consideration for scalability. According to [19], the energy required to grind photovoltaic glass, a material with comparable hardness and behavior, is approximately 0.01180 kWh/kg. At the average industrial electricity cost in Portugal (€0.192/kWh, 2023), this translates to around €2.26 per ton of processed glass. In environmental terms, using the national emission factor of 0.175 kg CO2/kWh [20], the grinding stage would contribute approximately 2.06 kg CO2/ton. These values are significantly lower than those associated with clinker production, indicating that from both a financial and environmental perspective, glass grinding, when optimized, can be a feasible and sustainable option [21].

3.1.2. Glass Powder and Cement Characterization

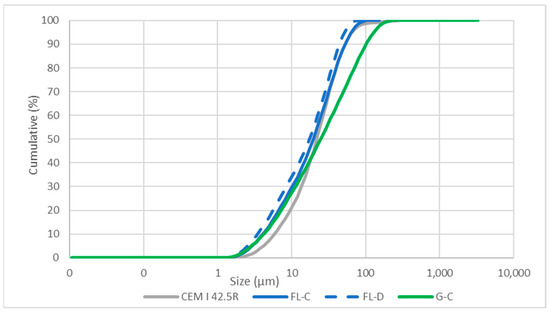

In order to compare the average particle size of the cement with the different glass powders, a laser particle size analyzer was used, using the Mastersizer 500 equipment (Malvern Panalytical, Malvern, UK). Figure 2 shows the granulometric distribution of the materials, making clear the proximity between the curves. Table 1 shows the D(50) and the specific surface of each of the materials, also determined using the laser particle size analyzer, in addition to the density, which was determined following EN 1097-6 [22].

Figure 2.

Granulometric distribution of the CEM I 42.5 R, FL-C, FL-D and G-C.

Table 1.

Physical characteristics of the CEM I 42.5 R, FL-C, FL-D and G-C.

Energy Dispersive X-ray Spectroscopy (EDS) was employed to analyze the chemical composition of the materials (Table 2). A Hitachi SU1510 equipment was used for this purpose. Due to some problems during the test, it was not possible to show the chemical composition of fluorescent lamp dirty. There is a reduction in the CaO content of the glass when compared to the cement. The opposite is true for silica (SiO2), i.e., a rise in the silica concentration within the glass when compared to the cement. According to ASTM C618-22 [23], good pozzolanic material requires at least a 70% sum of SiO2, Al2O3 and Fe2O3. The same criteria are adopted by Brazilian Standard NBR 12653 [24]. The chemical requirements established in the mentioned standards are achieved for glasses. However, considering the chemical requirements established in [1], there is a deviation in the Fe2O3 percentages for glasses that is above 1%.

Table 2.

Main components of CEM I 42.5 R, FL-C and G-C.

3.2. Mortar Production

Mortars were produced by replacing, by volume, 25% of the cement with glass powder. Four mixtures were prepared, as shown in Table 3, taking into account the use of 40 × 40 × 160 mm3, 50 × 50 × 50 mm3, and ϕ100 × 50 mm3 molds. It is important to note that a siliceous sand with a bulk density of 2640 kg/m3 was also used, and the water-to-binder ratio was kept at 0.5.

Table 3.

Mortar mixtures (kg/m3).

Considering that each cubic meter of the reference mortar contains 512 kg of cement, replacing 25% of cement with glass waste results in a reduction of 128 kg of cement per m3 of mortar. Knowing that each ton of cement produced is responsible for 0.58 tons of CO2 emissions [25], the reduction of 128 kg of cement per m3 of mortar would result in a reduction of 74.24 kg of CO2.

After mixing, the flow of each mixture was evaluated according to EN 1015-3 [26]. Following this, the molds were filled using the respective mixtures, overlaid with plastic film, and maintained in a chamber (18 ± 2 °C, 93 ± 2% RH) for two days. After this period, the mortars were unmolded and put in a tank with tap water saturated with lime. Following different periods (7, 28, and 90 days), the tests were performed.

3.3. Tests

3.3.1. Mechanical Behavior

The mechanical behavior of the mortars was studied through compression and flexural tests under EN 1015-11 [27] that were performed at different ages (7, 28 and 90 days) in order to allow the evaluation of the development of these properties over time. For this purpose, a universal testing machine (LR50K PLUS, LLOYD Instruments, AMETEK, Berwyn, PA, USA) was used. In addition, the pozzolanic activity index was also determined at 28 and 90 days, in accordance with EN 450-1 [28].

3.3.2. Durability Indicators

Regarding durability indicators, it was decided to investigate the chloride resistance through the chloride migration test and the electrical resistivity of the specimens at this stage. Taking into account the late development of pozzolanic reactions and their impact on durability, these parameters were studied for only 90 days of age.

The evaluation of Cl− ingress resistance was carried out following the Portuguese specification E 463 [29], which determines the chloride diffusion coefficient by means of the migration test in a non-steady state. Electrical resistivity was determined using the four-pin method—a Wenner probe. During the test, a low-frequency alternating current is applied between the two outer electrodes, while the voltage is measured across the two inner electrodes. Electrical resistivity measurements were performed using a RESIPOD device (Proceq SA, Schwerzenbach, Zurich, Switzerland). The reading was always taken immediately after the specimen was removed from the water, when it was completely saturated. The probe was previously calibrated and immersed in a container with water; then, it was pressed onto the specimen. The reading was recorded 3 times on each side, and the average of all readings determined the resistivity of the specimen.

3.3.3. Ecotoxicity Performance

The ecotoxicity of mortars incorporating glass waste was evaluated through leachate analysis of two types of samples:

- Fine powders (comprising glass waste and cement);

- Mortar specimens cured for 90 days.

Mortar specimens with dimensions of 50 × 50 × 50 mm3 were produced, incorporating a 25% replacement of cement by each waste type (G-C and fluorescent lamp clean), along with a reference mix (REF). For each material, three specimens were prepared. Prior to leaching tests, all specimens were crushed to ensure that at least 95% of the material mass had a particle size below 10 mm, as specified in the relevant standards.

Leaching tests for both powder and mortar samples were conducted in accordance with the EN 12457-4 [30] standard, which prescribes a liquid-to-solid (L/S) ratio of 10 L/kg for materials with particle sizes under 10 mm. Each test sample consisted of 90 ± 5 g of dry mass, placed in high-density polyethylene (HDPE) bottles filled with deionized water (compliant with ISO 3696 [31], grade 3), ensuring the appropriate L/S ratio.

The extraction procedure involved continuous agitation for 24 ± 0.5 h using a rotary table set at 25 rpm, which was maintained at a temperature of 20 °C. After agitation, the suspensions were allowed to rest for 15 ± 5 min to facilitate the sedimentation of solid particles. Subsequently, the eluate was separated by vacuum filtration through 0.45 µm membrane filters with no additional washing.

Each liquid sample analyzed by ICP-OES (Optima 8000, PerkinElmer, Shelton, CT, USA) was filtered using a 0.22 µm membrane. A few drops of nitric acid (HNO3, 69%, Fisher, Loughborough, UK) were added to stabilize the pKa and prevent alterations. The instrumental parameters were as follows: RF power: 1300 W, argon plasma flow: 8 L/min, auxiliary gas flow: 0.2 L/min, and nebulizer gas flow: 0.5 L/min. The plasma view was axial for all the metals. The wavelengths (nm) used for each potentially leachable metals were Ba—455.403, Cd—228.802, Cr—267.716, Cu—324.752, Ni—221.648, Pb—220.353, Zn—213.857 and Hg2—435.835. The concentrations measured were initially expressed in mg/L in the eluate and subsequently converted to mg/kg of sample.

4. Results and Discussion

4.1. Mechanical Behavior Results

4.1.1. Compressive Strength

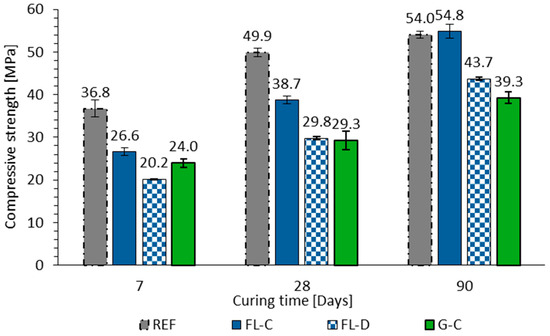

Figure 3 and Figure 4 show the compressive strength results for the studied data, considering the behavior of different mortars and their evolution over time.

Figure 3.

Compressive strength of reference mortar and mortars with partial cement replacement by glass powder (FL-C, FL-D, and G-C) at 7, 28, and 90 days of curing.

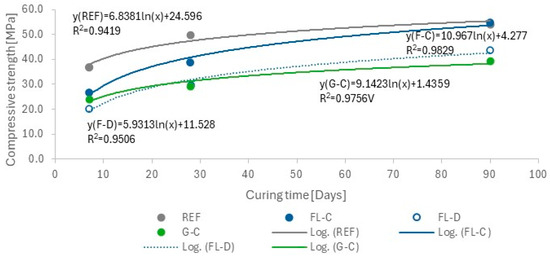

Figure 4.

Evolution of compressive strength over time (7 to 90 days) for reference mortar and mortars with partial cement replacement by glass powder (FL-C, FL-D, and G-C).

Figure 3 illustrates the progressive increase in compressive strength with time regardless of glass powder presence. Figure 4 confirms this statement and shows the close relationship between the curing period and compressive strength results for reference and glass mortars. These properties are related through a strong logarithmic fitting with R ranging between 0.94 (reference) and 0.98 (fluorescent lamp clean). However, there is a higher gain in the last ages for glass mortars compared to the reference mortar that can be observed in Figure 3. This statement aligns with the literature and is related to the pozzolanic reactions that occur slowly than hydration reactions. Hydration reactions occur when cement particles react with water, forming CSH and calcium hydroxide (CH), which contribute to early strength gain. Pozzolanic reactions happen later, when pozzolans react with the CH released during hydration, producing additional CSH that enhances durability and strength over time.

Concerning the impact of the type of glass powder used in the mortars, Figure 3 shows a better performance of fluorescent lamp mortars (clean and dirty) when compared to green bottle mortar. At 7 days, their behavior is similar despite the FL-D having the smallest compressive strength (24% smaller than FL-C and 15% smaller than G-C). At 28 days, the compressive strength of fluorescent lamp mortars is already higher than that of green bottle mortar (32%, FL-C, and 2% FL-D). At 90 days, the difference between the performances of fluorescent lamp mortars and green bottle mortar is more evident with FL-C reaching a compressive strength equal to 54.8 MPa, 40% higher than G-C. Although the promising behavior of fluorescent lamp mortars has already been reported in other studies, their comparison with mortars produced with glass from bottles (such as green bottle) has not been studied in deep. However, [32] studied mortars with 25% cement replacement by different glass types. In their compressive strength results, it is possible to compare mortars made using fluorescent lamp wastes with mortars made with soda-lime glass wastes. In Figure 3, their results show a better performance for soda-lime glass wastes. At 90 days, the soda-lime glass reached 61 MPa while the fluorescent lamp mortar reached only 54 MPa. The opposite behavior when comparing the results from Figure 3 and those of [32] may be related to the granulometric distribution of glass powders. Although both studies attempt to produce glass powders with a particle size distribution similar to that of cement, there are some differences. In the case of [32]’s study, glass from fluorescent lamps has a higher fraction of coarse grains than cement and soda-lime glass powder. In the case of this study, glass from bottles (equivalent to soda-lime glass) has a higher fraction of coarse grains when compared to cement and fluorescent lamp powder. Some authors relate particle size to mechanical behavior, with the smaller the particle, the greater the compressive strength achieved [4,12,16,33].

Regarding the cleaning process of fluorescent lamp waste and its impact on compressive strength, it can be said that it is important and should be taken into account when producing mortars. Figure 3 shows that FL-C achieves higher compressive strength values than FL-D regardless of age. This difference is higher over time: 24% (7 days), 30% (28 days) and 25% (90 days). This behavior may be related to impurities that may be present in the fluorescent lamp waste furnished by the treatment company, which have not been removed, and they are replacing the cement as if they were fluorescent lamp glass waste when in fact they are not. In this study, cleaning does not mean decontamination (concerning mercury and other contaminants). The cleaning used removed superficial impurities and solid waste that do not belong in the fluorescent lamp. In future studies, it is important to carry out an initial screening of the waste material received and understand the percentage of the waste that does not refer to the fluorescent lamp.

Regarding the effectiveness of using fluorescent lamp waste as a partial substitute for cement in cementitious materials such as mortars, the compressive strength results are promising. Although at early ages, reference mortar stands out with higher strengths (at 28 days, the difference varies between 29% for FL-C and 32% for G-C), at more advanced ages, FL-C reaches a value slightly higher than reference mortar, 54.8 MPa. Although rare, there are some previous studies on the use of fluorescent lamp glass powder in cementitious materials. The results achieved by [17] corroborate the behavior identified in this research. The authors produced mortars with different replacements of cement by fluorescent lamp powder (15, 25, 35, and 50%) and found compressive strength values higher than the reference (57 MPa) after 90 days for replacements of 15% (57–62 MPa) and 25% (57–59 MPa). The pozzolanic activity was confirmed by calculating the activity index and studying the CH consumption. The trend is also observed in concretes. Ref. [16] produced concretes with 20, 30, and 40% replacement of cement by fluorescent lamp glass powder, achieving higher strengths than the reference concrete mix (except for the 40% concrete). Although they did not study the pozzolanic activity of the material, according to the authors, this increase in compressive strength is due to the functioning of the material as a microfiller. In the case of [32], the performance of mortars with 25% cement replacement by fluorescent lamp powder is lower than the reference. At 90 days, this mortar reaches 54 MPa, while the reference reaches 63 MPa. As previously mentioned, in this case, the difference may be related to the granulometric distribution.

Comparing the performance of fluorescent lamp waste with common supplementary cementitious materials is an important step to evaluate its real potential as a sustainable alternative. Considering the common supplementary cementitious materials like fly ash, the results reached by the fluorescent lamp are promising when compared to the literature data. Ref. [34] studied the feasibility of incorporating industrial glass waste in the production of sustainable mortars, comparing them with traditional mortars (without replacement) and with mortars containing 25% cement replacement by fly ash. Regarding compressive strength, the value achieved for fly ash by [34], 54.54 MPa (90 days), is very close to that obtained for FL-C in this study, 54.80 MPa (90 days). These results are promising, as they indicate that the performance of FL-C is comparable to one of the most widely used supplementary cementitious materials, suggesting its potential as an effective partial cement replacement in future sustainable construction applications.

4.1.2. Flexural Strength

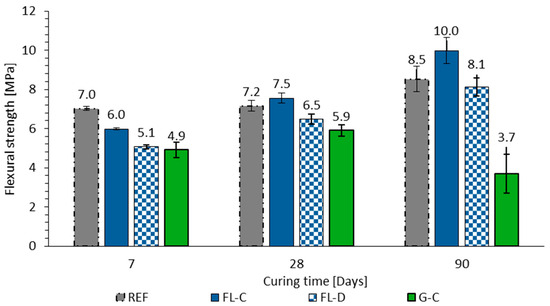

Figure 5 and Figure 6 show the flexural strength results for the studied data, considering the behavior of different samples and their evolution over time. The analysis of this data is important because there are no data about the theme in the recent literature.

Figure 5.

Flexural strength of reference mortar and mortars with partial cement replacement by glass powder (FL-C, FL-D, and G-C) at 7, 28, and 90 days of curing.

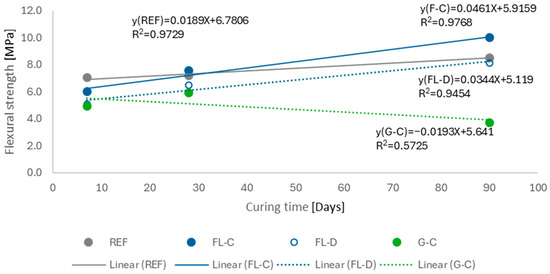

Figure 6.

Evolution of flexural strength over time (7 to 90 days) for reference mortar and mortars with partial cement replacement by glass powder (FL-C, FL-D, and G-C).

Figure 5 shows an increase in flexural strength over time regardless of glass powder presence. Figure 6 confirms this statement and shows the close relationship between the curing period and flexural strength results for reference and fluorescent lamp mortars (clean and dirty), which is similar to the compressive strength behavior. However, in this case, the properties are related through a strong linear fitting with R2 ranging between 0.94 (fluorescent lamp dirty) and 0.97 (fluorescent lamp clean and reference).

Concerning the influence of the type of glass powder used in the mortars, Figure 5 shows a similar performance of fluorescent lamp mortars when compared to green bottle mortar in the early ages (7 and 28 days). However, at 90 days, the fluorescent lamp mortars continue to increase the flexural strength, while the green bottle mortar reduces the values when compared to 28 days. This behavior of green bottle mortar is unexpected and could be related to some technical problem during the mortar test performance. According to EN 1015-11 [27], compressive strength testing is carried out using the specimens split during the flexural strength test. Given that the compressive strength results presented in Figure 3 show a consistent and expected development up to 90 days, it can be inferred that the integrity of the mortar specimens was not compromised. Therefore, the anomalous reduction in flexural strength observed for the green bottle mortar at 90 days may be attributed to a technical issue during the execution of the flexural test rather than an intrinsic problem with the material itself.

Fluorescent lamp mortars also show very satisfactory performance when compared reference mortars for 28 days. FL-C showed flexural strength equal to 7.5 MPa, 4% higher than the reference mortar, while FL-D showed 6.5 MPa, which is only 10% less than the reference mortar. At 90 days, FL-C reached 10 MPa (18% higher than REF) and FL-D reached 8.1 MPa (5% less than reference). Similar to compressive strength results, it is also possible to verify that there is an impact of the cleaning process of fluorescent lamp waste on the flexural strength behavior.

Since there are no results in the literature until now concerning the flexural strength behavior of cementitious materials with fluorescent lamp glass powder, it is not possible to discuss these results considering other scenarios. However, regarding the effectiveness of using fluorescent lamp waste as a partial substitute for cement in sustainable mortars, the flexural strength results are promising.

4.1.3. Strength Activity Index

One of the indirect methods used to investigate the pozzolanic behavior of materials is the determination of the strength activity index. Table 4 presents the results achieved for the mortars studied, at 28 and 90 days, as well as the minimal thresholds established by EN 450-1 [28]. The strength activity index values of FL-C are above these thresholds for 28 and 90 days, thus presenting a clear pozzolanic activity that is highlighted at 90 days. In the case of FL-D and G-C, the minimal thresholds are not reached regardless of the age. However, for the FL-D, the value is very close to the minimal threshold for 90 days, indicating that a slight reactivity is present. Considering its satisfactory compressive strength performance at 90 days (Figure 3), there may be two main factors acting: a slight reactivity (Table 4) and a filler effect. Concerning common glass powder, the increase in compressive strength is primarily attributed to the filler effect, which promotes a denser and less porous cementitious matrix [35]. To understand the role of reactivity and filler effect for fluorescent lamp mortars, it is necessary to determine the quantity of Portlandite remaining in the sample after various ages and to study the porosity of these mortars (using, such as mercury intrusion porosimetry).

Table 4.

Strength activity index (SAI) for studied mortars and threshold references.

4.2. Durability Indicators Results

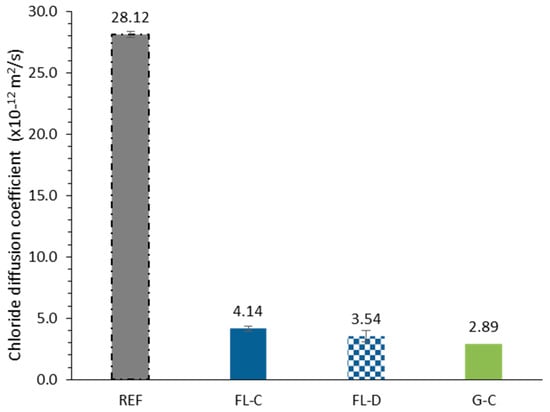

4.2.1. Chloride Diffusion Coefficient

Figure 7 shows the chloride diffusion coefficients for 90 days of age. The analysis of these data is important because there are no data about the chloride resistance performance in the recent literature. Knowing that chlorides are the most dangerous aggressive agents for reinforced concrete structures, these results are very relevant for evaluating the durability of cementitious materials with glass powders from fluorescent lamps.

Figure 7.

Chloride diffusion coefficient of reference mortar and mortars with partial cement replacement by glass powder (FL-C, FL-D, and G-C) at 90 days of curing.

Analyzing Figure 7, the impact of glass powder on the chloride diffusion performance is evident. Regardless of the type of glass used in the mortar, there is an important reduction in the chloride diffusion coefficient when compared to the reference mortar. The reduction is around 85%, 87%, and 89% for FL-C, FL-D and G-C, respectively. The G-C mortar was highlighted as the biggest reduction. Considering that glass powders do not have an expressive strength activity index quantity (Table 4), this behavior is not related to the chlorides binding but related to the reduction in the porosity (associated with the increase in the compressive strength for fluorescent lamp mortars; see Figure 3). Regarding the cleaning process, unlike what happened for the properties presented previously, FL-D has a lower coefficient than FL-C; that is, it has better performance. It is worth noting that the difference is not very significant in the context with both values being within the same order of magnitude.

The efficiency of cementitious materials with bottle glass powder has already been highlighted in other works and is reaffirmed here. The authors of [18] studied concretes with 50% replacement of cement by glass powder, using different cement contents, and concluded that a noticeable decrease in the chloride diffusion coefficient is observed in concretes containing 50% glass powder with this effect being more significant at higher binder contents. For concrete with 250 kg/m3 of cement and 50% replacement by glass powder, a 58% reduction in chloride permeability was observed compared to the reference concrete without glass powder. Similarly, [36] reported a 37.5% decrease at 28 days for concrete with a 40% replacement of cement by glass powder. The authors of [37] reported a 90% decrease in Cl− migration in concretes where 60% of the cement was replaced with glass powder in comparison to specimens without any glass powder. With the results presented in Figure 7, it is possible to state that the use of glass from fluorescent lamps, even in lower percentages, follows the trend, presenting excellent performance in terms of resistance to chlorides.

The performance of fluorescent lamp mortars can also be compared with mortars that use 25% fly ash as a cement substitute, using data from [34]. In this case, the results are encouraging. While mortars with fly ash have a diffusion coefficient of 19.32 × 10−12 m2/s, mortars incorporating fluorescent lamp waste present values around 4 × 10−12 m2/s. This significant difference suggests that fluorescent lamp waste may serve as a viable alternative to conventional supplementary cementitious materials such as fly ash. However, further investigation is needed to understand the mechanisms behind this substantial reduction, making this a promising starting point for future research.

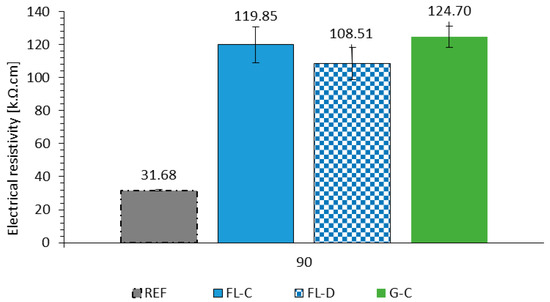

4.2.2. Electrical Resistivity

Figure 8 shows the electrical resistivity for 90 days of age. The analysis of these data is important because there are no data about the electrical resistivity performance in the recent literature. This is an important characteristic of cementitious materials that is often associated with their durability. Materials with high resistivity are associated with reduced porosity and, consequently, high durability. Resistivity tends to increase when the material has lower porosity, as electrical conduction in mortar occurs primarily through the pore water, which transports ions. Thus, the formation of a denser microstructure with reduced pore connectivity hinders ion movement, leading to higher resistivity [38]. The higher electrical resistivities are verified for mortars with glass powder (fluorescent lamp clean, fluorescent lamp dirty, and green bottle clean) regardless of the type of glass and the cleaning process. These mortars show the electrical resistivity of 3.78, 3.42 and 3.93, which are higher than that of the reference mortar, respectively. The values reached are very similar, and the difference between them is not statistically significant. The reduction in the porosity can be one of the causes related to this behavior. A second justification for the effect of resistivity being so high in concretes with glass powder would be the chemical condition of the glass; its atomic structure prevents the free conduction of electrical current, giving it the property of an electrical insulator even when used in powder form. The authors of [39] studied concrete with various replacement levels (5%, 10%, 15%, 20%) of cement with glass powders GP1 (from waste glass fiber) and GP2 (from recycled glass) and also reached higher electrical resistivities for concretes with glass powder after 90 days. It is worth highlighting the significant increase in resistivity observed in concretes modified with glass powders even at low replacement levels (5%). Concerning cementitious materials containing glass powder from fluorescent lamps, there are no data in the recent literature.

Figure 8.

Electrical resistivity of reference mortar and mortars with partial cement replacement by glass powder (FL-C, FL-D, and G-C) at 90 days of curing.

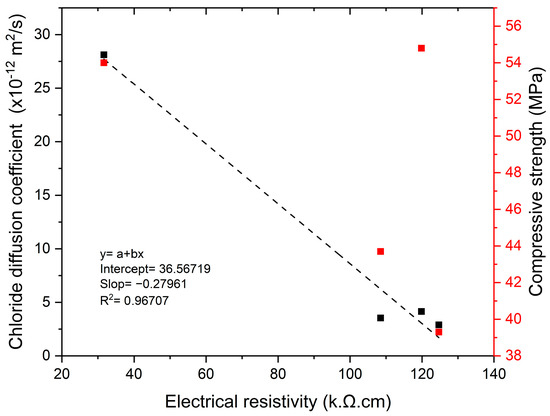

The relationship between electrical resistivity and the chloride migration coefficient [40], as well as with compressive strength [41], is usually very close for OPC mortars and concrete. Figure 9 correlates these data for the mortars containing glass powder and shows that for the mortars studied, this statement is also true for the relationship between electrical resistivity and the chloride migration coefficient. A linear fit to the data demonstrates strong consistency between the two measurements. This agreement suggests the reliability of electrical resistivity for a durability assessment of cement-based materials at a significantly reduced time. However, the relationship between electrical resistivity and compressive strength is not correlated and needs to be better explored.

Figure 9.

Correlation (dashed line) between electrical resistivity, chloride diffusion coefficient (black) and compressive strength (red).

In conventional mortars, a close relationship between compressive strength and electrical resistivity is often observed [42], which is largely due to their shared dependence on porosity and microstructural refinement. However, in mortars containing glass, this correlation appears weaker (Figure 9). This deviation may be related to the intrinsic insulating nature of the glass particles, which contributes to higher electrical resistivity independently of mechanical strength. That is, even when the porosity or packing density does not improve significantly, the electrical resistivity may still increase due to the dielectric effect of the glass. This unique behavior suggests that resistivity measurements in glass-modified systems must be interpreted with caution, as they may not directly reflect mechanical performance.

4.3. Ecotoxicity Performance Evaluation

The potential release of heavy metals and other hazardous substances is a significant concern in handling all inorganic waste and by-products, such as fluorescent lamps. The presence of Pb and Hg in fluorescent lamp glass has brought challenges regarding the potential uses of this type of glass, which is mainly due to the problem of leaching of these heavy metals. The leaching test results of powders (glass and cement) and mortars are shown in Table 5.

Table 5.

Concentration (mg/kg) of selected elements in leachates, tested based on EN 12457-4 [30] and classification of materials according to DL 102-D/2020 [42]: Inert waste (green); non-hazardous waste (yellow); and hazardous waste (red).

According to Table 5, all mortars have values within the acceptable limits to be classified as inert waste except for the values obtained for Hg. Given that the Hg concentrations in the samples are significantly higher than those typically reported in the literature, it can be concluded that the analytical technique used is not the most suitable for detecting this metal. Accurate mercury (Hg) analysis by ICP-OES requires a spray chamber to ensure proper aerosol formation. However, the equipment currently in use lacks a spray chamber, which can significantly compromise the method and also introduce substantial analytical errors.

Analyzing the values obtained for the powders, barium (Ba) is not present in significant quantities in the glass powders but is later found in higher concentrations in the mortars. In these cases, Ba may originate from cement, which contains 11.38 mg/kg. Despite this increase in mortars, the threshold between inert and non-hazardous material is not exceeded.

It is also observed that cadmium (Cd), chromium (Cr), and nickel (Ni) are, in some cases, present at levels that cause the powdered material to shift from being classified as inert to non-hazardous. However, when these powders are incorporated into mortars (replacing 25% of the cement), the metals appear to be encapsulated and are no longer detected in the leachate from the mortar.

Regarding Pb, the powders present leaching levels between 0.6 and 0.16, which allows them to be considered inert waste according to [42]. In addition, a reduction in the concentration of Pb found in the leachate of the respective mortars is observed, which is a good indicator for the valorization of the glasses studied. It is in accordance with [11], who studied the stabilization and solidification of Pb in cement matrices, concluding that Pb stabilization and solidification in mortar is possible. Regarding Hg, it is crucial to study in depth the behavior of Hg in this context, because its encapsulation in mortar is the key to the valorization of this glass in the cementitious materials.

These results help to fill an important gap regarding the environmental impact of using fluorescent lamp waste in cementitious materials. These results are very promising due to the high content of incorporated waste (25%) without compromising leaching and the possibility of eliminating the treatment to remove heavy metals from this waste. Current treatments to remove these metals are very expensive [43], which could make them economically unfeasible. Therefore, there is a high potential for valorizing this waste through the use of glass powder from fluorescent lamps for the production of cementitious materials.

5. Conclusions

The results of this exploratory study suggest that fluorescent lamp glass waste, particularly when subjected to a water-cleaning process, shows promising potential as a partial replacement for cement in mortar formulations. Mortars incorporating this type of glass powder (FL-C and FL-D) achieved relevant mechanical strength values (54.8 MPa), particularly at later curing ages (90 days), due to pozzolanic activity and filler effects. In addition to mechanical performance, significant enhancements in durability indicators were also observed, including reductions in chloride diffusion and increased electrical resistivity, which are factors that may contribute positively to long-term performance. However, it is important to note that these findings are preliminary and based on short- to medium-term data; further studies are necessary to fully validate long-term behavior. Importantly, ecotoxicological assessments showed that some heavy metals present in the glass waste were effectively immobilized within the cementitious matrix, suggesting limited environmental risk in the tested conditions. From a practical standpoint, the use of this type of WEEE-derived glass contributes to reducing the environmental impact of construction materials by lowering cement consumption, diverting hazardous waste from landfills, and promoting circular economy practices. While more research is required for broader application, these initial findings support the feasibility of integrating glass waste into sustainable construction strategies.

Author Contributions

Conceptualization, R.M., A.C. and A.L.; methodology, A.L. and D.F.; investigation, R.M., A.C., A.L. and D.F.; writing—R.M.; writing—review and editing, A.C., C.Q. and J.A.; supervision, R.M. and A.C.; funding acquisition, R.M. (GlassCON_4low). All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded through Multiannual Funding of the Landscape, Heritage and Territory Laboratory (Lab2PT), Ref. UID/04509, financed by national funds (PIDDAC) through the FCT/MCTES. This work also was supported from FEDER, COMPETE2030-FEDER-00773100, through the GlassCON_4low project, no. 16557.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing is not applicable.

Acknowledgments

The authors would like to thank the company NATURPAIVA of the MOVILEX group for providing the studied residue.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- ASTM C1866M-20; Standard Specification for Glass Aggregates for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Ferreira, D.L.; Malheiro, R.; Lemos, A.L.M.; Camões, A.; Ribeiro, M.J.P.M.; Nóbrega, A.F. Avaliação do Desempenho de Argamassas Produzidas com pó de Vidro de reee como Substituto Parcial do Cimento. SIMPÓSIO BRASILEIRO DE TECNOLOGIA DAS ARGAMASSAS, 15. 2025. Available online: https://eventos.antac.org.br/index.php/sbta/article/view/6944/5182 (accessed on 25 June 2025).

- Zhang, Y.; Xiao, R.; Jiang, X.; Li, W.; Zhu, X.; Huang, B. Effect of particle size and curing temperature on mechanical and microstructural properties of waste glass-slag-based and waste glass-fly ash-based geopolymers. J. Clean. Prod. 2020, 273, 122970. [Google Scholar] [CrossRef]

- Malheiro, R.; Moreira, B.; Pontes, K.; Jesus, C.; Camões, A. Utilização do pó de Vidro como Substituto Parcial do Cimento: Uma Abordagem Experimental Acerca da Resistência Mecânica. In Proceedings of the Congresso Luso-Brasileiro de Materiais de Construção Sustentáveis, CLBMCS, Salvador, Brazil, 10 November 2022; Available online: https://hdl.handle.net/1822/81939 (accessed on 25 June 2025).

- Matos, A.M. Estudo de Argamassas com Substituição Parcial de Cimento por Resíduos de Vidro Moídos. Master’s Thesis, FEUP, Porto, Portugal, 2010. Available online: http://hdl.handle.net/10216/59733 (accessed on 19 May 2025).

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Omran, A.; Tagnit-Hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- Islam, H.; Prova, Z.; Sobuz, H.; Nijum, N.; Aditto, F. Experimental investigation on fresh, hardened and durability characteristics of partially replaced E-waste plastic concrete: A sustainable concept with machine learning approaches. Heliyon 2025, 11, e41924. [Google Scholar] [CrossRef]

- Forti, V.; Balde, C.P.; Kuehr, R.; Bel, G. The Global E-Waste Monitor 2020: Quantities, Flows and the Circular Economy Potential; United Nations University (UNU)/United Nations Institute for Training and Research (UNITAR)—Co-Hosted SCYCLE Programme: Geneva, Switzerland; International Telecommunication Union (ITU): Geneva, Switzerland; International Solid Waste Association (ISWA): Rotterdam, The Netherlands, 2020. [Google Scholar]

- Gollmann, M.; Silva, M.; Masuero, A.; Santos, J. Stabilization and solidification of Pb in cement matrices. J. Hazard. Mater. 2010, 179, 507–514. [Google Scholar] [CrossRef] [PubMed]

- Kara, P. Performance of lamp glass waste powder (LGWP) as supplementary cementitious material (SCM)—Viscosity and electrical conductivity. J. Silic. Based Compos. Mater. 2015, 67, 12–18. [Google Scholar] [CrossRef]

- Ali, H.; Jaber, H.; Farid, S. Investigation of fluorescent lamp glass waste as a fluxing agent in porcelain bodies. Mater. Today Proc. 2021, 42, 2381–2386. [Google Scholar] [CrossRef]

- Novais, R.; Ascensão, G.; Seabra, M.P.; Labrincha, J.A. Waste glass from end-of-life fluorescent lamps as raw material in geopolymers. Waste Manag. 2016, 52, 245–255. [Google Scholar] [CrossRef]

- Viana, L.; Soares, A.; Guimarães, D.; Rojano, W.; Saint’Pierre, T. Fluorescent lamps: A review on environmental concerns and current recycling perspectives highlighting Hg and rare earth elements. J. Environ. Chem. Eng. 2022, 10, 108915. [Google Scholar] [CrossRef]

- Kara, P.; Korjakins, A.; Kovalenko, K. The Usage of Fluorescent Waste Glass Powder in Concrete. Constr. Sci. 2013, 13, 26–32. [Google Scholar] [CrossRef][Green Version]

- Pitarch, A.M.; Reig, L.; Gallardo, A.; Soriano, L.; Borrachero, M.V.; Rochina, S. Reutilisation of hazardous spent fluorescent lamps glass waste as supplementary cementitious material. Constr. Build. Mater. 2021, 292, 123424. [Google Scholar] [CrossRef]

- Moreira, O.; Camões, A.; Malheiro, R.; Jesus, C. High Glass Waste Incorporation towards Sustainable High-Performance Concrete. CivilEng 2024, 5, 41–64. [Google Scholar] [CrossRef]

- Guignone, G.; Calmon, J.L.; Vieira, G.; Zulcão, R.; Rebello, T.A. Life Cycle Assessment ofWaste Glass Powder Incorporation on Concrete: A Bridge Retrofit Study Case. Appl. Sci. 2022, 12, 3353. [Google Scholar] [CrossRef]

- APA—Agência Portuguesa do Ambiente—Relatório de Gestão de Resíduos. 2021. Available online: www.apambiente.pt (accessed on 15 September 2022).

- Moreira, O. High-Performance Concrete with High Glass Powder Incorporation. Master’s Degree in Sustainable Construction and Rehabilitation, University of Minho, Minho, Portugal, 2023. (In Portuguese). [Google Scholar]

- European Committee for Standardization. EN 1097-6: Tests for Mechanical and Physical Properties of—Part 6: Determination of Particle Density and Water Absorption; CEN: Brussels, Belgium, 2016. [Google Scholar]

- ASTM C618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ABNT Associação Brasileira de Normas Técnicas. NBR 12653: Materiais Pozolânicos—Requisitos; ABNT: Rio de Janeiro, Brazil, 2014. [Google Scholar]

- IEA—International Energy Agency. Direct Emissions Intensity of Cement Production in the Net Zero Scenario, 2015–2030. Available online: https://www.iea.org/energy-system/industry/cement (accessed on 2 July 2025).

- EN 1015-3; Methods of Test for Mortar for Masonry: Determination of Consistence of Fresh Mortar (by Flow Table). European Committee for Standardization, CEN: Brussels, Belgium, 1999.

- EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization, CEN: Brussels, Belgium, 1999.

- EN 450-1; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. European Committee for Standardization, CEN: Brussels, Belgium, 2012.

- Laboratório Nacional de Engenharia Civil. E 463: Coeficiente de Difusão dos Cloretos. Ensaio de Migração; LNEC: Lisboa, Portugal, 2004. [Google Scholar]

- EN 12457-4; Characterisation of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 4: One Stage Batch Test at a Liquid to Solid Ratio of 10 l/kg for Materials with Particle Size Below 10 mm (without or with Size Reduction). European Committee for Standardization, CEN: Brussels, Belgium, 2002.

- ISO 3696; Water for Analytical Laboratory Use—Specification and Test Methods. International Organization for Standardization, ISO: Geneva, Switzerland, 1987.

- Bignozzi, M.C.; Saccani, A.; Barbieri, L.; Lancellotti, I. Glass waste as supplementary cementing materials: The effects of glass chemical composition. Cem. Concr. Compos. 2015, 55, 45–52. [Google Scholar] [CrossRef]

- Kim, S.K.; Kang, S.T.; Kim, J.K.; Jang, I.Y. Effects of Particle Size and Cement Replacement of LCD Glass Powder in Concret. Adv. Mater. Sci. Eng. 2017, 3928047, 12. [Google Scholar] [CrossRef]

- Ferreira, D.L.; Oliveira, A.D.; Silva, R.; Correa, M.; Jesus, C.M.G.; Malheiro, R.L.M.C.; Camões, A. Viabilidade de incorporação de resíduos de vidros industriais na produção de argamassas sustentáveis. In Proceedings of the Congresso Luso-Brasileiro de Materiais de Construção Sustentáveis|Congresso Construção, Lisboa, Portugal, 7 November 2024; Available online: https://ceris.pt/wp-content/uploads/2024/11/CLBMCS2024_Atas.pdf (accessed on 5 May 2025).

- Dobiszewska, M.; Pichór, W.; Tracz, T.; Petrella, A.; Notarnicola, M. Effect of Glass Powder on the Cement Hydration, Microstructure and Mechanical Properties of Mortar. Mater. Proc. 2023, 13, 40. [Google Scholar] [CrossRef]

- Paul, D.; Bindhu, K.; Matos, A.M.; Delgado, J. Eco-friendly concrete with waste glass powder: A sustainable and circular solution. Constr. Build. Mater. 2022, 355, 129217. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Transport Properties of Concrete with Glass Powder as Supplementary Cementitious Material. ACI Mater. J. 2015, 112, 429–438. [Google Scholar] [CrossRef]

- Masra, W.; Sutan, S.M.; Keran, N.M.; Matudin, N.D. Electrical Resistivity of Cement Based Materials. Appl. Mech. Mater. 2016, 833, 102–107. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Pilvar, A.; Mahdikhani, M.; Moodi, F. Practical evaluation of relationship between concrete resistivity, water penetration, rapid chloride penetration and compressive strength. Constr. Build. Mater 2011, 25, 2472–2479. [Google Scholar] [CrossRef]

- Araújo, C.C.; Meira, G.R. Correlation between concrete strength properties and surface electrical resistivity. Rev. IBRACON Estrut. E Mater. 2022, 15, e15103. [Google Scholar] [CrossRef]

- Portugal. (2020, 10 de dezembro). Decreto-Lei n.º 102-D/2020: Aprova o Regime Geral da Gestão de Resíduos, o Regime Jurídico da Deposição de Resíduos em Aterro e Altera o Regime de Fluxos Específicos (Diário da República n.º 239/2020, 1.º Suplemento, Série I). Available online: https://diariodarepublica.pt/dr/detalhe/decreto-lei/102-d-2020-150908012 (accessed on 25 June 2025).

- Pavón, S.; Lapo, B.; Fortuny, A.; Sastre, A.M.; Bertau, M. Recycling of rare earths from fluorescent lamp waste by the integration of solid-state chlorination, leaching and solvent extraction processes. Sep. Purif. Technol. 2021, 272, 118879. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).