1. Introduction

Every year, a significant quantity of chestnuts is produced, particularly in Southern Europe [

1], and especially in various regions of Greece, where chestnut groves are cultivated. Despite the high production volume, a limited quantity of the harvested chestnuts reaches the market, mainly due to post-harvest sorting and grading procedures applied by traders and suppliers. As a result, large amounts of chestnuts that do not meet the commercial standards—mainly due to size, appearance, or minor defects—remain underutilized or are discarded as waste. The discrepancy between total yield and marketable output highlights the need to explore alternative uses for these by-products in order to reduce food waste and add value to local agricultural resources. One promising approach is the conversion of non-commercial chestnuts into chestnut flour, a gluten-free ingredient with valuable nutritional characteristics. Because of its superior nutritional and functional qualities, chestnut (

Castanea sativa M.) flour has drawn a lot of interest recently as a useful component in the creation of gluten-free products. Chestnut flour is naturally gluten-free and high in nutritional fiber, which helps to reduce the glycemic response and support digestive health. In gluten-free diets, which frequently lack protein variety, it serves as a supplemental protein source since it also offers a significant quantity of essential amino acids. Chestnut flour is also an excellent source of vitamins, especially vitamin E and those in the B-complex group, which are antioxidants and crucial cofactors in metabolic processes. It also contains vital minerals, including magnesium, phosphorus, and potassium, which are important for bone health, energy metabolism, and electrolyte balance. Several research studies have addressed the effects of adding different amounts of chestnut flour to gluten-free bread and biscuit recipes in an effort to enhance the finished goods’ nutritional profile and sensory appeal. Overall, the results have shown higher nutritional value, along with improvements in flavor, color, and texture. Thus, it has been demonstrated that using chestnut flour improves the technical and functional performance of gluten-free baked goods, as well as their acceptability by consumers and health-promoting qualities [

2,

3].

A wide range of conventional gluten-free goods are made using refined flours or starches, which are distinguished by their high carbohydrate content and their low levels of proteins, antioxidants, and other bioactive substances. The general suitability of gluten-free diets has come under scrutiny due to this nutritional imbalance, especially for individuals who depend on them over an extended period of time. To improve the nutritional value of gluten-free goods, current research and product development initiatives have concentrated on the thoughtful addition of nutrient-dense, fiber-rich ingredients. By increasing the protein content, antioxidant capacity, and dietary fiber levels of traditional gluten-free matrices, these functional additives aim to compensate for their inherent nutritional shortcomings and provide more health-promoting formulations [

4,

5]. According to previous studies, people with celiac disease could have a stronger propensity for eating foods that are high in fat and sugar, possibly as a coping mechanism for the nutritional and sensory restrictions of a gluten-free diet [

6]. Dietary management for this population may become even more challenging if this habit unintentionally leads to an uneven nutrient intake. Therefore, preserving and enhancing the nutritional profile of gluten-free products—while also resolving their functional and technological constraints—continues to be a significant challenge in the development of gluten-free food formulations. Because of their extended shelf life, customer convenience, palatable sensory qualities, and adaptability to dietary and functional changes, biscuits are regarded as a viable matrix for the creation of novel gluten-free goods. Because of these qualities, they provide a perfect foundation for investigating new gluten-free formulations that seek to enhance product quality and health [

5].

The functional properties of chestnut flour, such as moisture, fat, protein, ash, total phenolics, and antioxidant activity, are crucial in determining its suitability for bio-functional food products. A recent study reported that chestnut flour exhibits high DPPH scavenging activity, markedly exceeding that of wheat flour, and these values translated into improved antioxidant levels in biscuits formulated with 10–30% chestnut flour [

7]. In cookie and biscuit applications, chestnut flour has been shown to elevate total antioxidant capacity while maintaining an acceptable macronutrient profile (moisture, fat, protein, and ash) and favorable sensory attributes [

8].

Therefore, in this study, chestnut (Castanea sativa Mill.) flour was used in a gluten-free biscuit formulation to enhance both nutritional and technological drawbacks and evaluate its potential as a functional and sustainable alternative to conventional wheat flour. This study was designed to investigate the physicochemical profile and antioxidant capacity of chestnut flours processed from chestnuts sourced from various regions of Greece, as well as chestnut-flour biscuits produced by incorporating this flour.

To achieve this aim, nutritional and bioactive markers were measured to assess the potential benefits of these products. Additionally, spectroscopic techniques were used to evaluate the antioxidant activity. The findings suggest that chestnut flour may serve as a valuable alternative to wheat flour in baked goods. Its high phytochemical content, antioxidant activity, and availability in several regions worldwide (including Europe, Asia, Australia, and the Americas) highlight its relevance for enhancing the nutritional quality of bakery products.

Laboratory analysis included measurements of moisture, fat, protein, ash, total phenolic content, and antioxidant activity in both the raw chestnut flour and the baked biscuits produced using simple, home-style recipes. This approach allowed for a direct comparison between the raw material’s properties and those of the final product, providing valuable data on the retention and functionality of health-promoting compounds post-processing. Overall, the research supports the potential for chestnut flour to be integrated into bakery applications, offering innovation and improved nutritional profiles for traditional products.

2. Materials and Methods

2.1. Plant Material and Chestnut Flour Preparation

The chestnut samples used in this study were harvested from September to November 2023 and 2024 from 5 different regions in Greece (specifically in Thessaly and Peloponnese). Chestnut samples (Castanea sativa) represent a mixture of local varieties, as no specific cultivar identification was performed. The fruits selected were non-commercial grade chestnuts, which are typically discarded due to their limited marketability and lack of alternative utilization strategies in Greece. Each of the five chestnut flour groups was prepared using an identical protocol, including drying temperature and time, peeling, grinding, and particle size standardization.

Upon collection, each chestnut was manually incised circumferentially using a pre-validated scoring method that had been previously optimized to facilitate peeling after thermal treatment. The scored fruits were then placed in a convection oven (laboratory drying oven Argolab Vacuum oven TCN 50 PLUS, 50 L, max. temp. 300 °C, natural air convection by Sozhou Being Medical Device Co., Ltd.—Kunshan, Jiangsu Province, China) and dried at 65 °C until they reached a constant weight. These temperatures and endpoints were selected to ensure moisture reduction while maintaining phytochemical integrity.

After drying, the chestnuts were removed from the oven, manually peeled to separate the pericarp and inner pellicle from the kernel, and all edible fractions were collected. The peeled kernels were subsequently milled using a traditional flour mill to obtain a fine flour. The resulting chestnut flour was stored in appropriate food-grade textile sacks under controlled conditions (20 ± 2 °C, <60% relative humidity, in a dark and dry environment) until further analysis.

2.2. Sourcing of Raw Materials and Cookie Preparation/Formulation Methodology

Wheat flour (for the control sample preparation), corn starch, butter, baking powder, raw cane sugar, eggs, chocolate chips and inulin were purchased from a local supermarket; chestnut flour was produced by the laboratories’ teams (Food of Animal Origin Laboratory, Department of Animal Science, School of Agricultural Sciences, University of Thessaly and Laboratory of Food Chemistry, Biochemistry and Food Technology, Department of Nutrition and Dietetics, School of Physical Education, Sport Science and Dietetics, University of Thessaly). For the preparation of the chestnut-based biscuits, a composite flour was used, consisting of an equal-weight mixture of the five chestnut flours obtained from the different Greek regions. The chestnut flour was sieved through a 250 μm mesh to ensure uniform and fine particle size. The resulting flour had a powdery texture, which was suitable for the biscuit formulation. The recipe was developed in-house through preliminary trials, adapting standard biscuit formulas/home-cooking recipes to highly valorize the chestnut aroma. For this reason, a recipe with a minimal addition of flavorings, sweeteners, and other ingredients was used. Specifically, the ingredients included chestnut flour (34.1%), butter (19.1%), raw cane sugar (13.6%), eggs (14.4%), corn starch (3.5%), inulin (3.5%), baking powder (1%), and chocolate chips (±10%). The percentage of each ingredient is referred to as the total weight.

The specific ingredient ratios were carefully optimized through preliminary formulation trials to achieve a balance of desirable texture, structure, and sensory appeal. Chestnut flour (34.1%) was chosen as the primary flour component due to its naturally sweet flavor and fine texture, which contributes to a moist, tender crumb and a pleasant nutty taste that aligns well with consumer expectations for novel gluten-free bakery products. Butter (19.1%) enhances the mouthfeel and contributes to a soft, rich texture, while also improving flavor release. Eggs (14.4%) play a dual role as both a structural agent and emulsifier, helping to stabilize the batter and improve cohesiveness, which is especially important in gluten-free formulations. Cane sugar (13.6%) not only provides sweetness but also promotes Maillard browning, contributing to an appealing color and enhancing flavor complexity. Corn starch (3.5%) and inulin (3.5%) were included to modify the crumb structure. Corn starch promotes tenderness by reducing protein content, and inulin contributes dietary fiber while also enhancing moisture retention and improving mouthfeel. Baking powder (1%) serves as a leavening agent to ensure an appropriate rise and lightness, while chocolate chips (approximately 10%) add familiar flavor cues and visual appeal, both of which are key for consumer acceptance. The biscuit doughs were prepared by mixing the dry and wet ingredients until a homogenous mass was formed. The dough was rolled and cut into uniform round shapes (4 cm in diameter) and baked in a preheated oven at 180 °C for 15–20 min. After cooling at room temperature, the biscuits were stored in airtight containers until analysis. The wheat-based control biscuits were prepared using the same procedure and ingredient ratios, except that 100% refined wheat flour was used in place of chestnut flour.

Overall, the formulation was designed to deliver a product with optimal textural and sensory properties, guided by both functional roles of the ingredients and sensory evaluation feedback. The cookies were packaged in 250 g bags containing about 35–40 cookies.

2.3. Extraction Protocols

Refluxing 2 g of each flour and biscuit sample with 20 mL of methanol containing 1% HCl for 2 h at 60 ± 5 °C produced phenolic extracts. Total antioxidant activity (TAA) was measured by separating the supernatants after the mixtures were centrifuged for 30 min at 4500 rpm.

2.4. Total Antioxidant Activity (TAA)

The DPPH radical scavenging activity method was used to assess the biscuit extracts’ total antioxidant activity (TAA) [

9]. A total of 0.1 mL of sample extracts [chestnut flour (CF), wheat flour biscuits (WFB), and chestnut flour biscuits (CFB)] were put into a test tube that contained 0.8 mL of 80% methanol and 0.1 mL of freshly prepared DPPH solution (1 mmol/L). A negative control, consisting of DPPH solution with methanol (without sample extract), was included. No standard antioxidant was used as a reference in this assay. The tubes were then left in the dark for 30 min, and a UV/Vis spectrophotometer (Spectrophotometer XD 7000 (VIS) by Lovibond, Tintometer GmbH, Schleefstraße 8–12, Dortmund, Germany) was used to measure the sample absorbance at 517 nm. The result was expressed as the DPPH radical’s % inhibition.

2.5. Moisture Content

The moisture content of the samples was determined using a thermogravimetric method, employing a moisture analyzer (KERN DAB 100-3, KERN & SOHN GmbH, Balingen, Germany). Thermogravimetric moisture analyzers operate based on the loss on drying (LOD) principle, where the sample is heated and the weight loss due to moisture evaporation is continuously monitored until a constant mass is reached [

10]. This method is widely used in food analysis for its simplicity, speed, and accuracy in measuring moisture content [

11]. Approximately 3 g of sample was placed in the sample pan and heated at 110 °C until the weight stabilized, indicating that all free moisture had evaporated. The final moisture content was automatically calculated by the instrument and expressed as a percentage of the initial weight.

2.6. Fat Content (Soxhlet Extraction Method)

The Soxhlet extraction method, a common and extensively used methodology for fat content analysis in food matrices, was used to determine the total fat content of the biscuit samples. A homogenized biscuit sample weighing around 2–5 g was placed in a cellulose thimble and extracted using petroleum ether (boiling point between 40 and 60 °C) for 6–8 h. The extracted fat was dried and weighed to determine the sample’s fat percentage after the solvent was eliminated by evaporation [

12].

2.7. Protein Content (Kjeldahl Method)

The Kjeldahl method, which evaluates the total nitrogen content and uses a conversion factor to calculate the protein content, was used to determine the protein content of biscuit samples. In order to transform organic nitrogen into ammonium sulfate, around 1 g of finely ground material was digested with concentrated sulfuric acid (H

2SO

4) in the presence of a catalyst, typically a combination of potassium sulfate and copper sulfate or selenium. Following digestion, sodium hydroxide was added to make the mixture alkaline. The ammonia that was released was then distilled and gathered in a boric acid solution. Standard hydrochloric acid was then used to titrate the ammonia that had been collected. The percentage of nitrogen was calculated and converted to protein using a factor of 6.25, which is commonly used for cereal-based products [

11]. The general conversion factor of 6.25 was applied to calculate crude protein content, in accordance with the Association of Official Analytical Collaboration (AOAC) standard methods, to ensure consistency and comparability across all flour types analyzed in this study.

2.8. Total Ash Content

The total ash content of the biscuit samples was determined according to standard gravimetric procedures. Approximately 2–3 g of ground sample was accurately weighed into a pre-weighed crucible and incinerated in a muffle furnace at 550 ± 25 °C until a constant weight was achieved. The incineration process removes all organic matter, leaving only the inorganic mineral residue (ash). After cooling in a desiccator, the crucible was reweighed, and the ash content was calculated as a percentage of the original sample weight [

12].

2.9. Statistical Analysis

All analytical measurements were performed in triplicate (three technical replicates) to ensure the reliability and reproducibility of the results. All data were analyzed using SPSS Statistics version 26.0 (IBM Corporation, Armonk, NY, USA). The normality of distribution was assessed through the Shapiro–Wilk test, and the homogeneity of variances was examined using Levene’s test. Depending on the data distribution and variance homogeneity, either parametric or non-parametric statistical tests were employed.

For the chemical characteristics of chestnut flour (i.e., moisture content, lipid content, protein content, and ash), both parametric and non-parametric tests were applied. Initial and final moisture content, as well as ash content, did not meet normality assumptions and were analyzed using the Kruskal–Wallis test, followed by post hoc pairwise comparisons using Dunn’s test (p < 0.05). The lipid and protein content met parametric assumptions and were analyzed using one-way ANOVA, followed by Tukey’s HSD test for multiple comparisons. Statistically significant differences were detected in all tested parameters among the five chestnut flour groups (p < 0.05).

For the biscuit formulations, moisture, lipid, and ash content were normally distributed with homogeneous variances and were analyzed using independent sample t-tests. The protein content did not meet the assumption of normality (Shapiro–Wilk < 0.05) and was analyzed using the non-parametric Mann–Whitney U test. Statistically significant differences were found only in protein content (U = 0.000, Z = –1.993, p = 0.046), with wheat flour biscuits presenting higher protein levels than chestnut flour biscuits. No statistically significant differences were observed in moisture, lipid, or ash content (p > 0.05 for all comparisons).

4. Discussion

The present study aimed to showcase the nutritional and functional value of chestnut flour derived from downgraded chestnuts—agricultural by-products typically excluded from the market—from five distinct Greek regions. Our results confirmed that these underutilized chestnuts can be successfully incorporated into the food chain as a value-added product: a nutritious, gluten-free biscuit with enhanced antioxidant capacity and mineral content. This finding supports the hypothesis that downgraded chestnuts can be valorized within the context of sustainable food innovation and the circular economy.

The previous literature guided our formulation strategy. Studies have reported that chestnut flour is suitable for various food applications, including bread [

13], cakes [

14], pasta [

15,

16], and biscuits [

17]. Additionally, it has even been applied in meat products as a fat replacement [

18]. These insights informed our decision to explore the production of biscuits. Moreover, Meleti et al. (2024) [

19] emphasized the potential of chestnut by-products to generate high-value functional foods, offering health benefits and supporting rural sustainability. In alignment with the European Green Deal [

20], our findings highlight that downgraded chestnuts represent a promising raw material for the development of gluten-free functional biscuits, contributing to food waste reduction and nutritional enhancement.

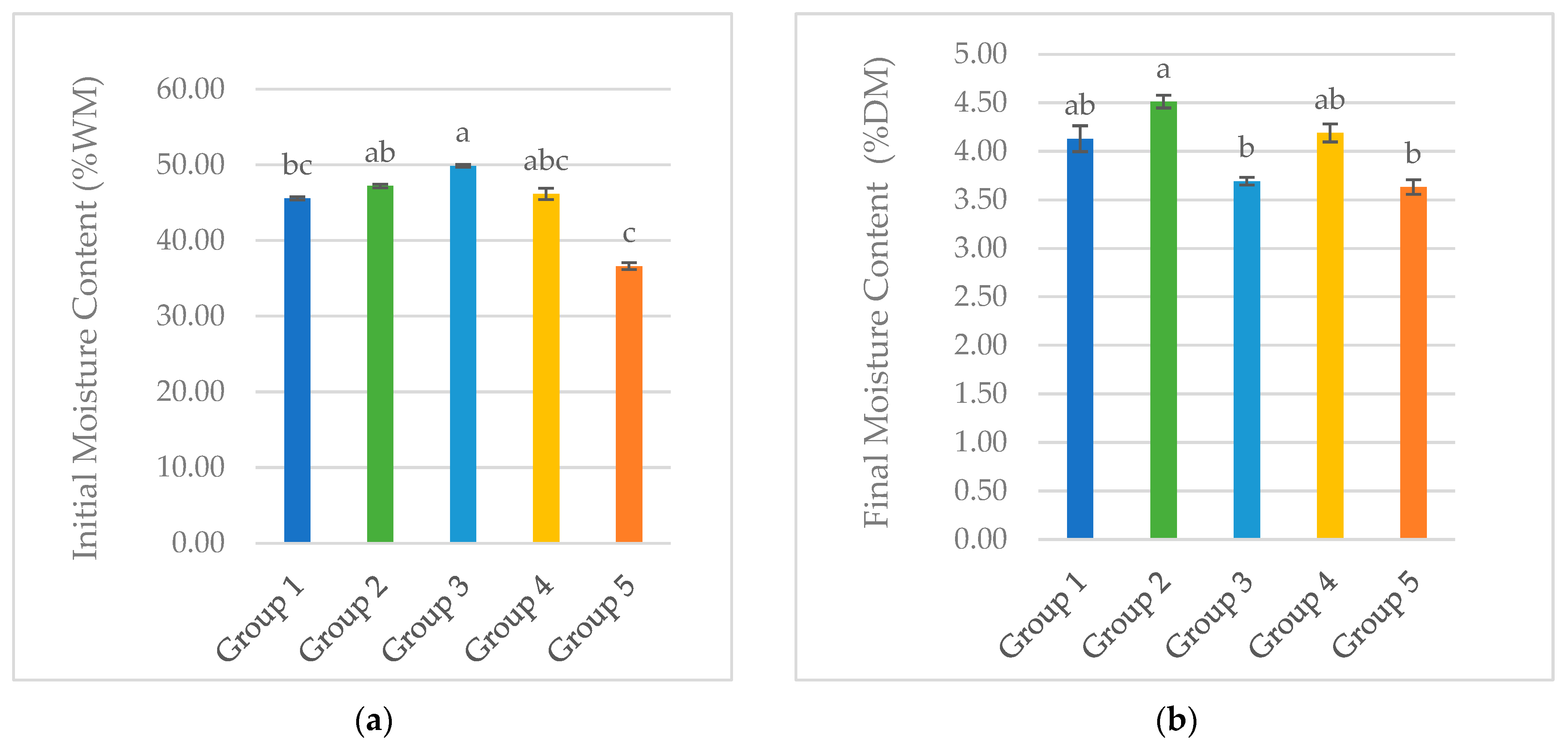

The initial moisture content (WM%) reported in this research, which ranges from 36.63% (Group 3) to 49.88% (Group 5), shows partial consistency with previously reported moisture levels for chestnuts [

21,

22,

23]. Although in Groups 1–4 the chestnuts’ initial moisture content fluctuated between 45.57% and 49.88%, aligning with the previous literature, which reports ranges of 45% to 54% [

21,

22,

23], the initial moisture content of the chestnuts in Group 5 (36.63%) fell outside the typical range. This may be attributed to environmental factors such as harvest conditions and post-harvest handling, which have been shown to influence water retention in chestnuts [

24]. Although statistically significant, the variation in moisture content among samples is relatively small and is not expected to substantially influence the flour’s performance in biscuit formulations. The highest value in our research (49.88%) is consistent with the moisture level reported by [

21] for the Portuguese PDO chestnut cultivar “Aveleira” (49.9%). Although some of the differences between groups are statistically significant, their practical impact on drying efficiency or product quality may be limited, especially when moisture values fall within an acceptable processing range.

After drying, the final moisture content (DM%) ranged from 3.63% (Group 5) to 4.51% (Group 2), which is in accordance with Erem (2020) [

23], who reported moisture contents of 3.89%, 4,04%, and 5.43% in different particle sizes of chestnut flour. Despite the variability in the chestnuts’ initial moisture content, the overall variation of the statistically significant differences in the moisture content of the chestnut flours was limited, suggesting that the applied drying process contributes to a partial standardization of moisture levels across samples.

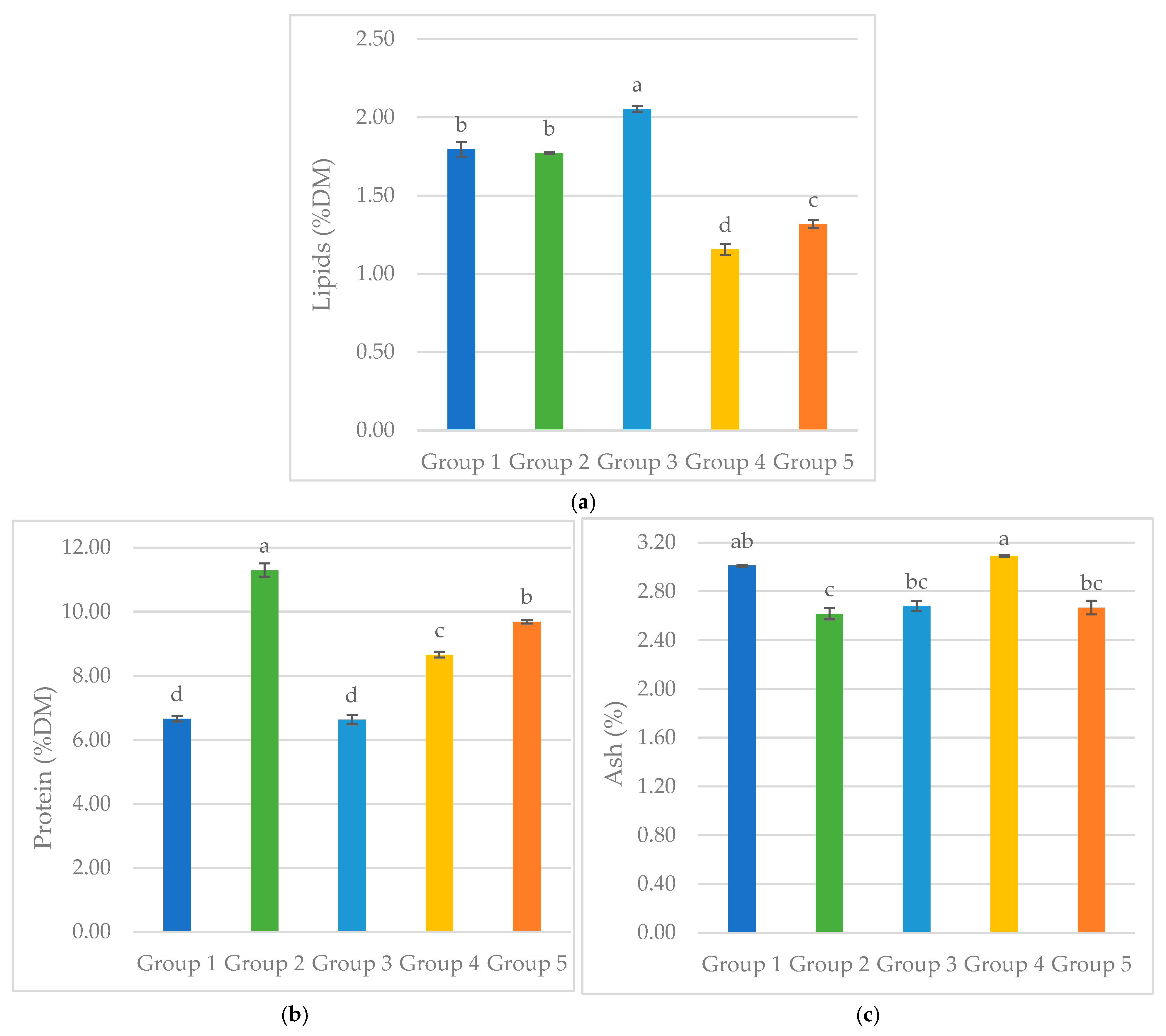

The lipid (%DM), protein (%DM), and ash (%) contents of the chestnut flour samples exhibited significant variability among the five geographical groups. The lipid content ranged from 1.16% (Group 4) to 2.05% (Group 3), which falls within the ranges previously documented for chestnut flour (1.45–3.10%) [

21,

23,

25,

26]. Group 3 exhibited the highest lipid level, potentially linked to varietal characteristics or regional agronomic factors, as chestnut fat content is known to vary significantly depending on genotype and environmental conditions [

26].

Protein content followed a similar pattern of variation, with Group 2 presenting the highest content at 11.30%, followed by Group 5 at 9.70%. All the other groups fluctuated between 8.67% and 6.63%, in accordance with the reported protein levels in chestnut flour, which typically range between 4.80% and 7.37% [

21,

23,

25,

26], suggesting a strong varietal effect on the nutritional profile of chestnuts. Ash content also differed significantly, ranging from 2.62% (Group 2) to 3.09% (Group 4). The higher ash levels in Groups 4 (3.09%) and 1 (3.01) present a richer mineral profile. These results correspond with previous studies, in which ash content, reflecting mineral composition, ranged from 1.53% to 4.70% depending on origin and processing methods [

21,

23,

25,

26].

The substitution of wheat flour with chestnut flour in biscuit formulations demonstrated not only a sustainable approach for upcycling downgraded chestnut fruits but also introduced several nutritional and functional advantages. Despite the lower protein content in CFB compared to WFB and the similar lipid content, the overall functional profile of the chestnut biscuits is enhanced due to the inherent nutritional composition of chestnut flour, which includes proteins, complex carbohydrates, dietary fiber, and bioactive phytochemicals [

3,

27]. Notably, the antioxidant capacity of the biscuits was significantly improved with the incorporation of chestnut flour, as reflected in the higher DPPH radical scavenging activity of CFB (70.83% ± 0.18) compared to WFB (61.67% ± 0.27). This effect is consistent with the antioxidant potential of pure chestnut flour, which exhibited a DPPH inhibition rate of 73%, suggesting that a substantial portion of its bioactive capacity is retained post-processing. Such enhancement of antioxidant activity highlights the functional appeal of chestnut flour in developing health-oriented bakery products. While the increase in antioxidant activity of CFB was statistically significant, its nutritional contribution relative to total daily antioxidant intake is likely to be modest. Further studies are required to assess its in vivo relevance.

Furthermore, the significantly elevated ash content in CFB indicates a higher concentration of inorganic components, reinforcing the improved micronutrient profile of the chestnut-based formulation. This increase in mineral content enhances the nutritional benefits of chestnut flour and supports its role as a valuable ingredient in functional food development. Chestnut flour is a naturally gluten-free ingredient that is rich in essential amino acids, phenolic compounds, and antioxidants such as gallic and ellagic acid, which have been associated with health-promoting effects, including anti-inflammatory, anticancer, and cardioprotective properties [

18,

26]. Markedly, the inclusion of CF has been shown to significantly elevate total phenolic content and antioxidant capacity in biscuit matrices [

25], contributing to their functional potential. In the present study, the CF biscuits retained acceptable levels of moisture, lipids, and ash, which did not differ significantly from the control biscuits (WFB), indicating that nutritional integrity was largely preserved during baking.

Moreover, CFB may be particularly advantageous for individuals following gluten-free diets, not only due to the absence of gluten but also because chestnut flour compensates for common deficiencies found in commercial gluten-free products, such as low fiber and micronutrient content [

28]. Previous studies have shown that chestnut flour improves the oxidative stability and enhances the color and aroma profile of gluten-free baked goods, thus supporting both nutritional quality and consumer acceptability [

18]. In our case, although the protein content of CFB was lower than that of WFB, the superior antioxidant profile and phenolic composition of the chestnut flour render them a functional food candidate, capable of offering added health benefits [

28,

29], while the higher ash content in CFB, compared to the WFB, suggests a higher amount of inorganic constituents, which is beneficial for human health.

Although a detailed sensory analysis (e.g., texture, flavor, and mouthfeel) was not conducted as part of the current study, a preliminary consumer evaluation (n = 136) provided valuable insights into the overall acceptability of the chestnut flour biscuits. Specifically, almost 70% of respondents reported being “very satisfied” and ~26% reported being “satisfied” with the product. Additionally, ~65% stated they would “definitely buy” it if it were commercially available, and ~29% would “probably buy” it. These findings, although exploratory, reflect a strong consumer interest and suggest that the product has high market potential. Future studies should incorporate standardized sensory panels and hedonic testing to validate and expand upon these encouraging results.

5. Conclusions

This study demonstrates the potential of downgraded chestnuts, which are typically excluded from the commercial market, as a sustainable raw material for the production of gluten-free biscuits with improved specific functional properties, particularly in terms of antioxidant capacity and mineral content. Despite some variation in moisture, protein, and ash content across the five chestnut samples, originating from five distinct Greek regions, the drying process effectively standardized moisture levels, and the final product retained key nutritional benefits. Biscuits made with chestnut flour presented significantly improved antioxidant properties, as evidenced by the higher DPPH radical scavenging activity compared to biscuits made with wheat flour. Substituting wheat flour with chestnut flour in biscuit formulations resulted in an improved antioxidant profile rich in nutrients, suggesting that chestnut flour can serve as a functional ingredient to increase the nutritional value of baked goods. Nevertheless, this study presents certain limitations that should be addressed in future research. The biscuit formulations were developed and assessed under laboratory-scale conditions, and no industrial-scale trials have yet been conducted to confirm their feasibility in large-scale production. Moreover, aspects such as shelf-life, microbial stability, and consumer acceptance were not evaluated. Further studies should focus on validating these findings under real industrial conditions and assessing the sensory profile and market potential of chestnut flour-based products. Ultimately, these findings not only highlight the nutritional and functional potential of chestnut flour but also align with the European Green Deal’s objectives, promoting food waste reduction and circular economy practices through the upcycling of agricultural by-products into health-promoting, sustainable food alternatives.