Challenges and Opportunities in the Implementation of AI in Manufacturing: A Bibliometric Analysis

Abstract

1. Introduction

- RQ1.

- What are the underlying factors that explain the evolution in scientific production and the impact of research on the implementation of AI in manufacturing between 2019 and August 2024?

- RQ2.

- What factors explain the variation in impact and productivity of the main scientific sources in AI research applied to manufacturing?

- RQ3.

- What determinants explain the collaboration structure and academic impact of the most influential authors in AI research applied to manufacturing?

- RQ4.

- What are the determinants that influence the challenges and opportunities identified in the most cited documents on AI application in manufacturing?

- RQ5.

- How are the leading global institutions distributed in AI research applied to manufacturing, and what challenges and opportunities arise from their collaboration networks and scientific impact?

- RQ6.

- What are the most used methods and study approaches in AI research applied to manufacturing, and what challenges and opportunities arise from their application?

- RQ7.

- How is global scientific production on AI in manufacturing distributed, and what are the implications?

- RQ8.

- How are the topics developed within the conceptual structure of AI applied to manufacturing, and what challenges and opportunities do they present for its integration and development in the industrial sector?

2. Literature Review

3. Materials and Methods

3.1. Study Design

3.2. Data Collection

3.3. Analyzed Variables and Methods of Analysis by Objective

3.4. Visualization and Interpretation

3.5. Use of AI-Assisted Technologies

4. Results and Discussion

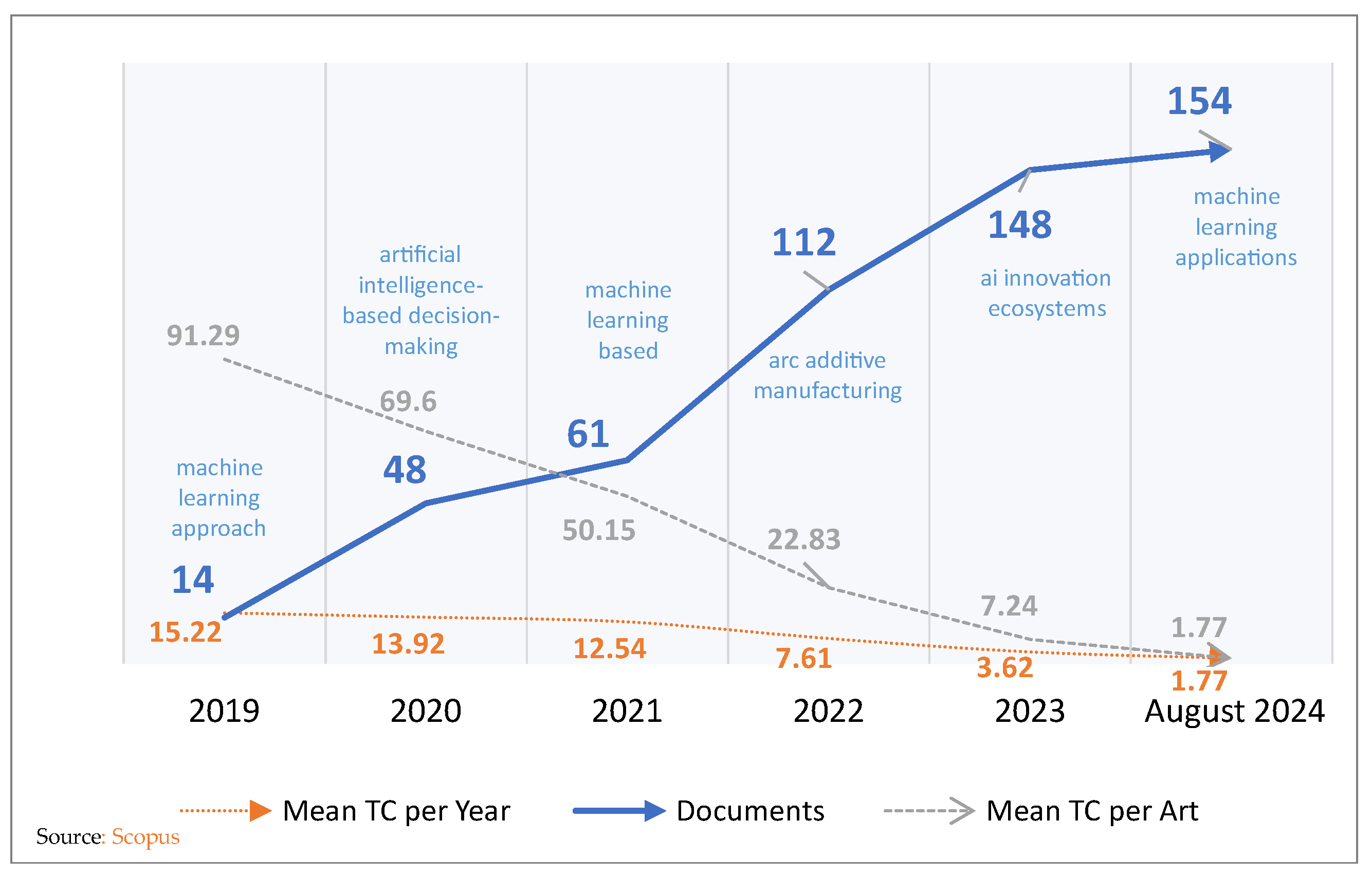

4.1. Evolution and Trends of AI Research in Manufacturing (2019–August 2024)

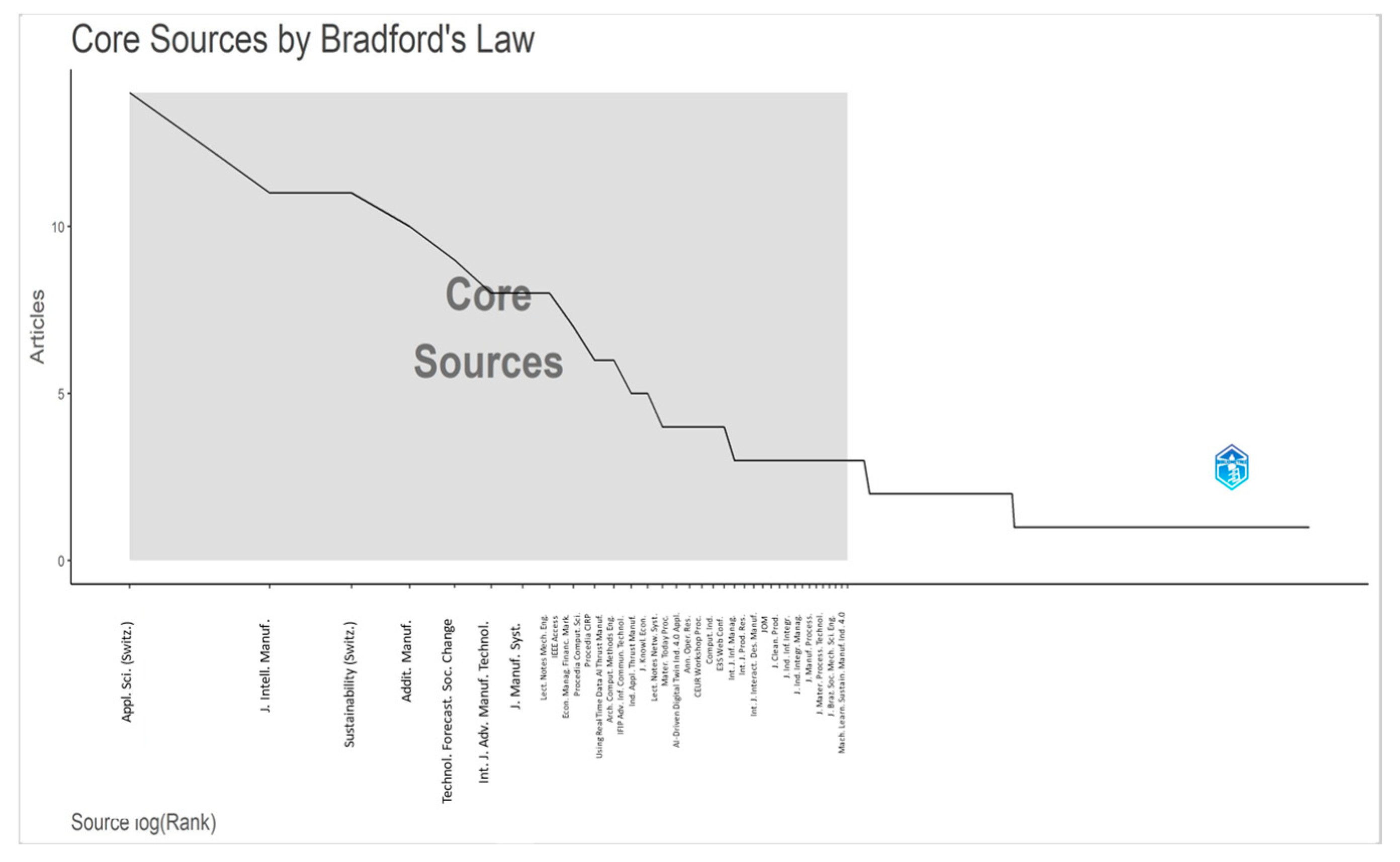

4.2. Impact and Trends of the Leading Sources

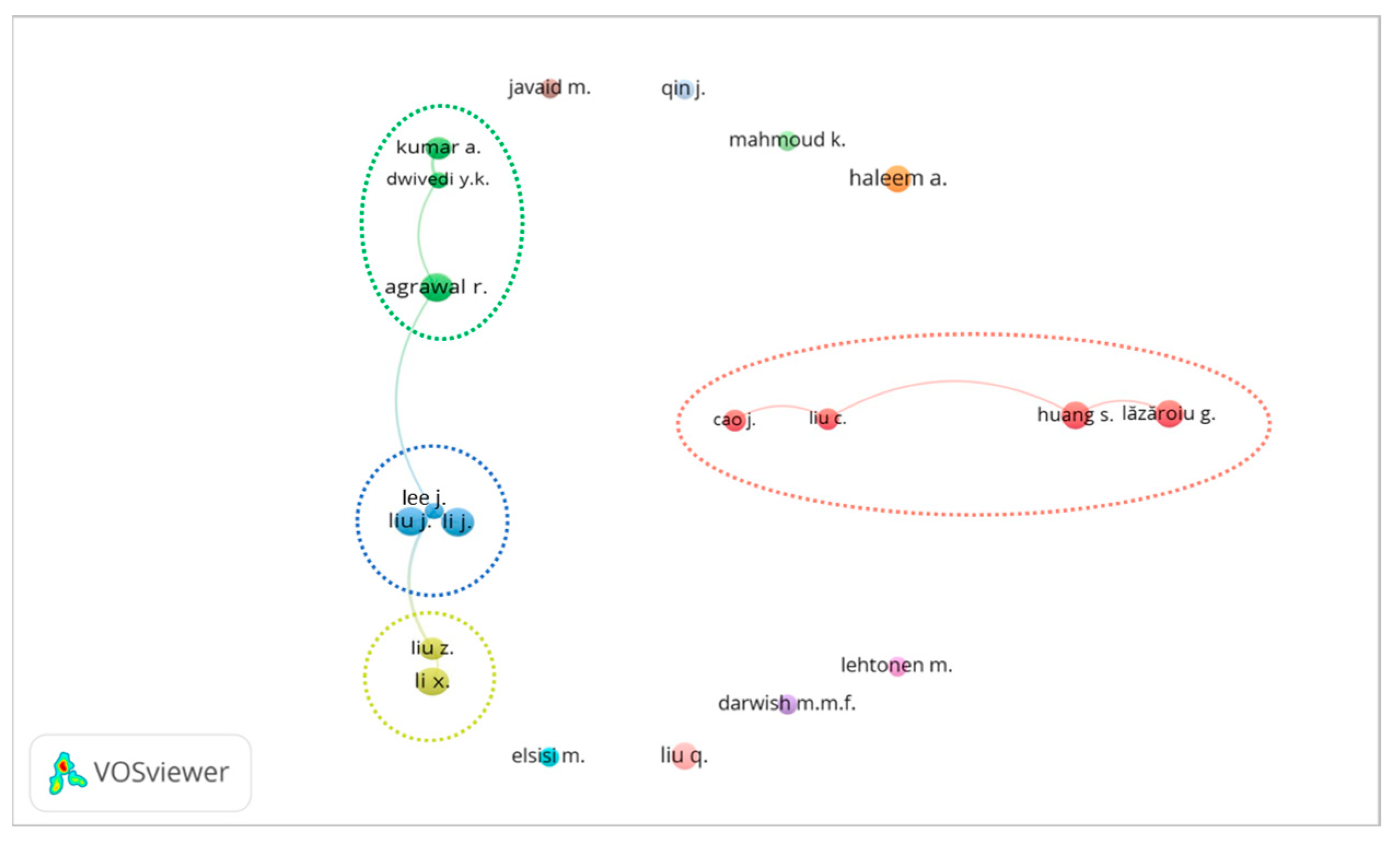

4.3. Key Authors: Influence and Trends

4.4. Most Cited Documents

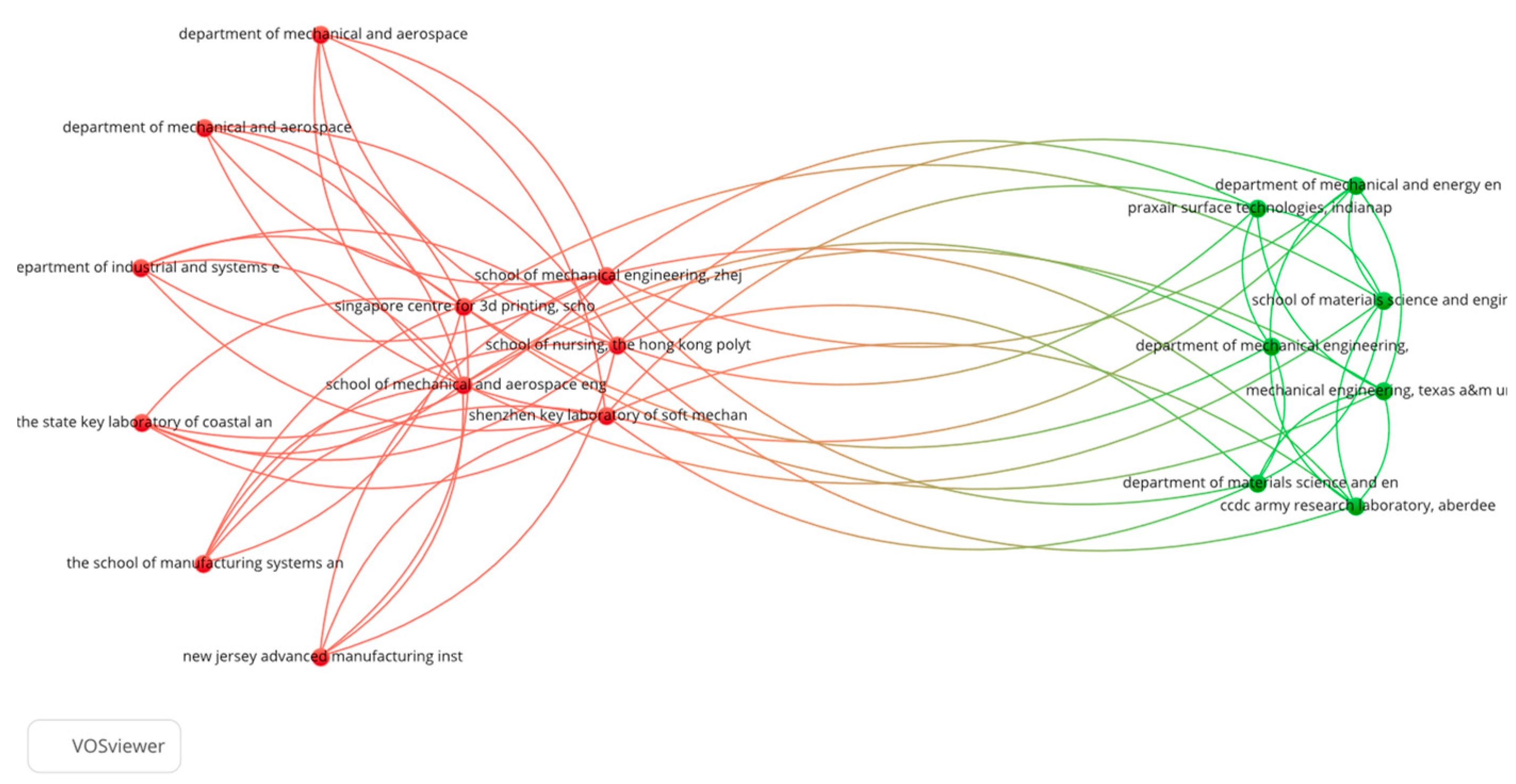

4.5. Global Analysis of Leading Institutions in AI Research Applied to Manufacturing

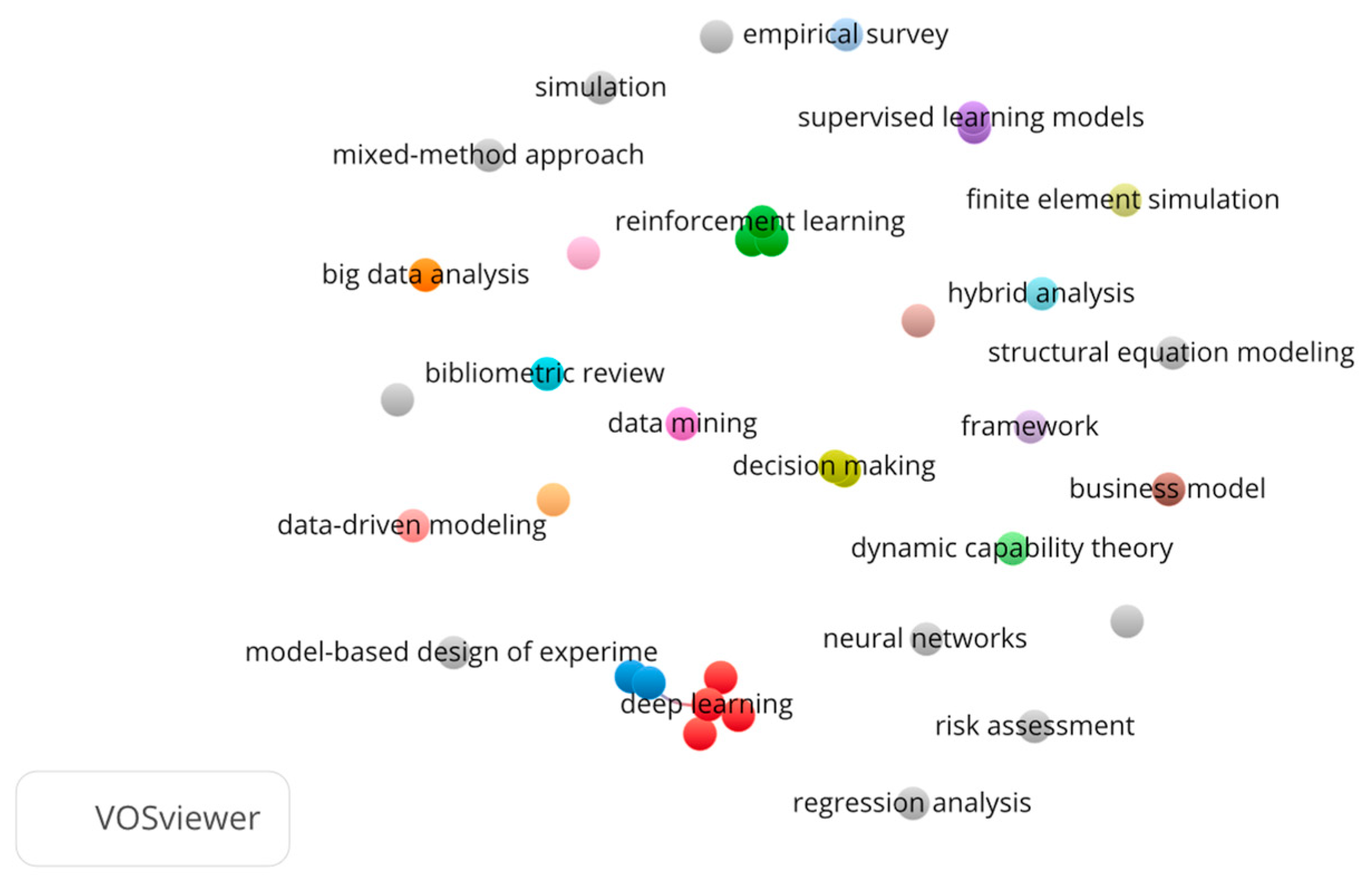

4.6. Key Methods and Approaches in AI Research in Manufacturing

- (1)

- Augmented Statistical Fatigue Life Model: A model that combines statistical methods with experimental data to predict the fatigue life of materials, improving the accuracy of estimations [120].

- (2)

- (3)

- Big Data Analysis: An approach that involves collecting, processing, and analyzing large volumes of data to extract meaningful patterns and support data-driven decision-making [13].

- (4)

- Building Information Modeling (BIM): A process that involves the generation and management of digital representations of the physical and functional characteristics of a built space, used to enhance the planning and execution of construction projects [122].

- (5)

- Business Model: A structure that defines how an organization creates, delivers, and captures value, focusing on business strategy and key operations [123].

- (6)

- (7)

- Data-Driven Models: Models that use empirical data to build mathematical or computational representations of phenomena, enabling informed predictions and decisions [126].

- (8)

- Data Mining Techniques: A set of methods used to discover patterns and relationships in large datasets, applied in areas such as marketing, biomedicine, and computer science [127].

- (9)

- Decision-Making Models: Systematic approaches to evaluate and select options among alternatives, optimizing outcomes based on predefined criteria [44].

- (10)

- Deep Learning Models: A subcategory of machine learning models that use deep neural networks to analyze large volumes of unstructured data, such as images or text [128].

- (11)

- Dynamic Model: A mathematical model that describes how a system evolves over time, capturing the dynamics of the processes involved [96].

- (12)

- Empirical Analysis: A research method that uses observable and measurable data to evaluate theories, testing hypotheses through experimentation and observation [129].

- (13)

- Finite Element Analysis (FEA): A computational technique that divides an object into small parts (finite elements) to analyze its behavior under various conditions, commonly used in engineering [130].

- (14)

- Fuzzy Logic Models: Models that handle uncertainty and imprecision by allowing degrees of truth instead of binary values, applied in control systems and decision-making [116].

- (15)

- Hybrid Modeling: Combines different models or methods to leverage the strengths of each, enhancing predictive accuracy and capacity in complex situations [131].

- (16)

- (17)

- (18)

- Mathematical Modeling: The creation of mathematical models to represent, analyze, and predict the behavior of real-world systems, applicable across various disciplines [75].

- (19)

- Meta-Analysis: A statistical technique that combines the results of multiple studies to derive a more robust and generalizable conclusion about a research topic [61].

- (20)

- Mixed Methods Approach: A research approach that integrates qualitative and quantitative methods to provide a more comprehensive understanding of a phenomenon [136].

- (21)

- Model-Based Systems: An approach that uses mathematical and computational models to design, analyze, and manage complex systems, optimizing their performance [137].

- (22)

- Multi-Criteria Decision Analysis (MCDA): A method that evaluates options based on multiple criteria, facilitating decision-making in complex contexts where various factors must be balanced [138].

- (23)

- Multivariate Analysis: A set of statistical techniques that analyze more than two variables simultaneously, allowing for the understanding of complex relationships between them [130].

- (24)

- Neural Networks Model: A computational model inspired by the structure of the human brain, primarily used in machine learning for tasks like pattern recognition and classification [94].

- (25)

- Optimization Models: Mathematical models that seek the best solution within a set of options, maximizing or minimizing an objective function under certain constraints [139].

- (26)

- Predictive Modeling: The use of statistical or machine learning models to make predictions about future events based on historical data [140].

- (27)

- (28)

- (29)

- Reinforcement Learning Models: A subfield of machine learning where an agent learns to make optimized decisions through trial and error, rewarded for its actions [108].

- (30)

- Risk Analysis: The process of identifying, evaluating, and prioritizing risks, using models to forecast and mitigate negative impacts on projects or systems [144].

- (31)

- Scenario Analysis: A technique used to anticipate possible future scenarios and their implications, facilitating strategic planning and decision-making in uncertain situations [145].

- (32)

- Simulation Modeling: The use of computational models to imitate the behavior of real systems, allowing for experimentation and analysis of scenarios without real risks [146].

- (33)

- Statistical Analysis: A set of techniques for collecting, reviewing, analyzing, and interpreting data, helping to uncover significant patterns and trends in research [147].

- (34)

- (35)

- Supervised Learning Models: A type of machine learning model where the algorithm learns from labeled data, improving its ability to predict or classify new data [12].

- (36)

- (37)

- Topic Modeling: A technique used to identify underlying themes in a set of documents, typically using probabilistic models that group related words [151].

- (38)

- Training Data Model Development: The process of creating and refining machine learning models using training datasets, aiming to improve their accuracy and generalization [152].

- (39)

- Unsupervised Learning Models: Machine learning models that find patterns in unlabeled data and are used for tasks such as clustering and dimensionality reduction [12].

- (40)

- Wavelet Analysis: An analysis technique that decomposes complex signals into frequency components, allowing for the study of phenomena in both the time and frequency domains simultaneously [153].

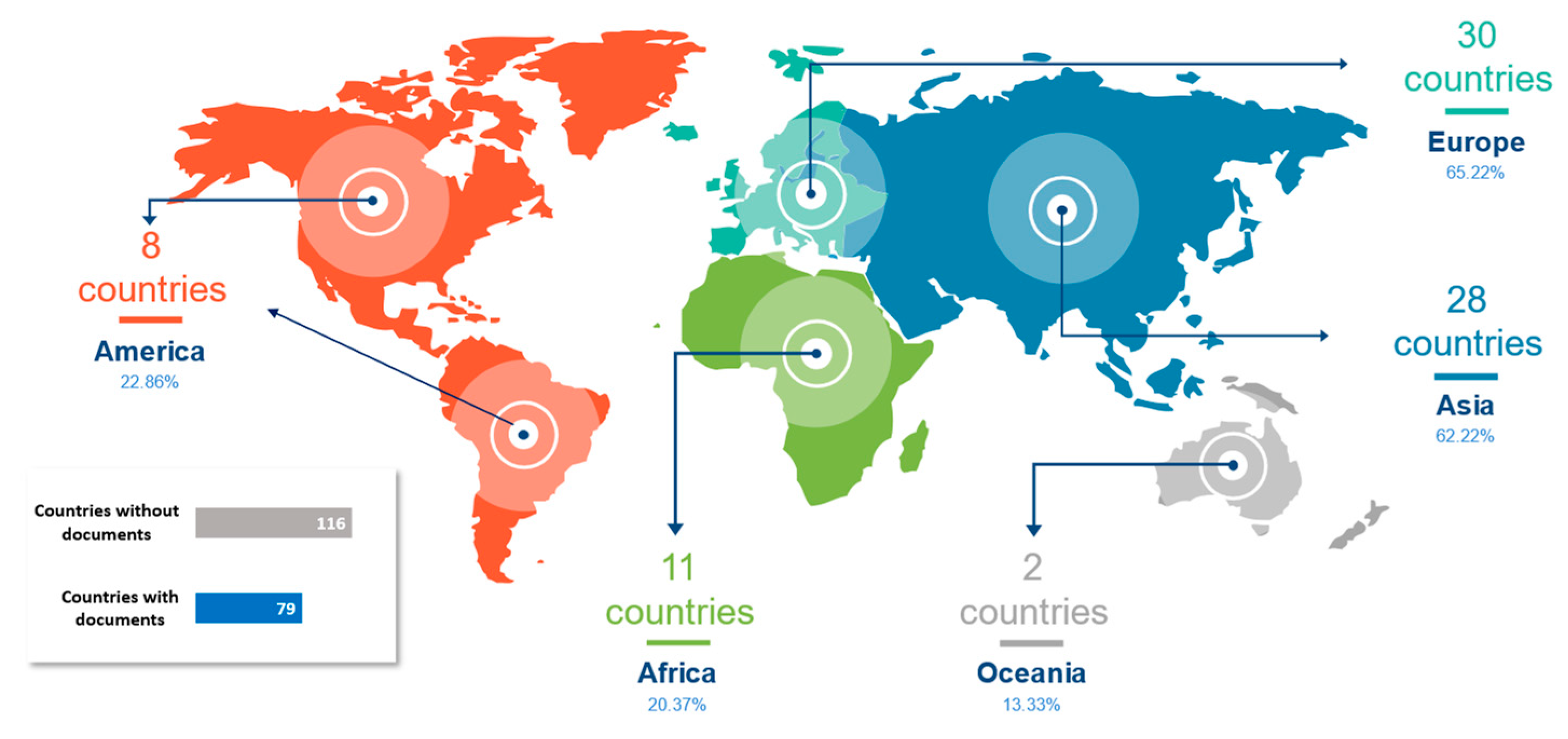

4.7. Analysis of Global Scientific Production in AI and Manufacturing

4.7.1. Scientific Production by Country

4.7.2. Continental Distribution of Scientific Production

4.7.3. Global Participation in Research

4.7.4. International Collaboration

4.7.5. Derivation of Challenges and Opportunities

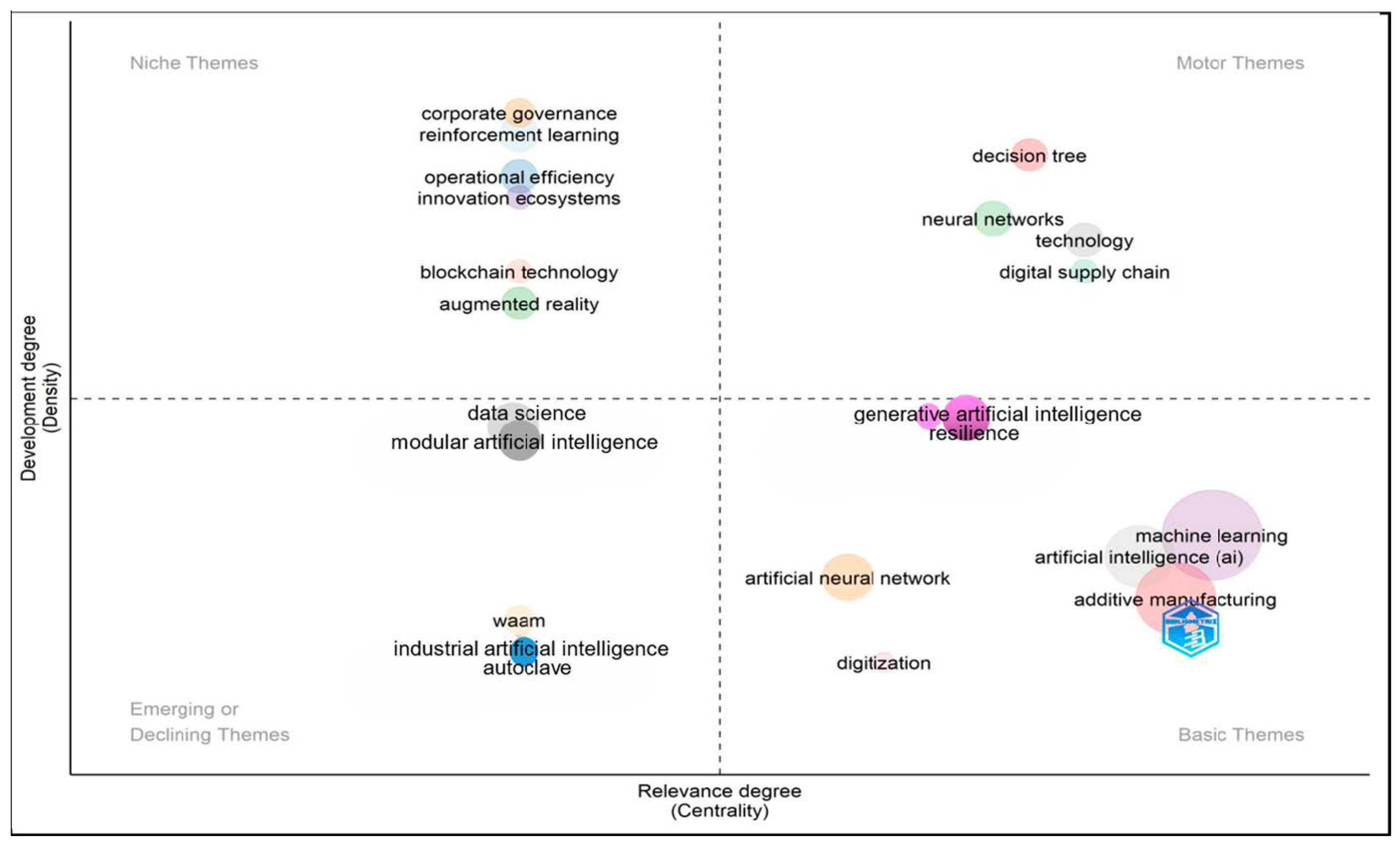

4.8. Thematic Analysis of AI in Manufacturing

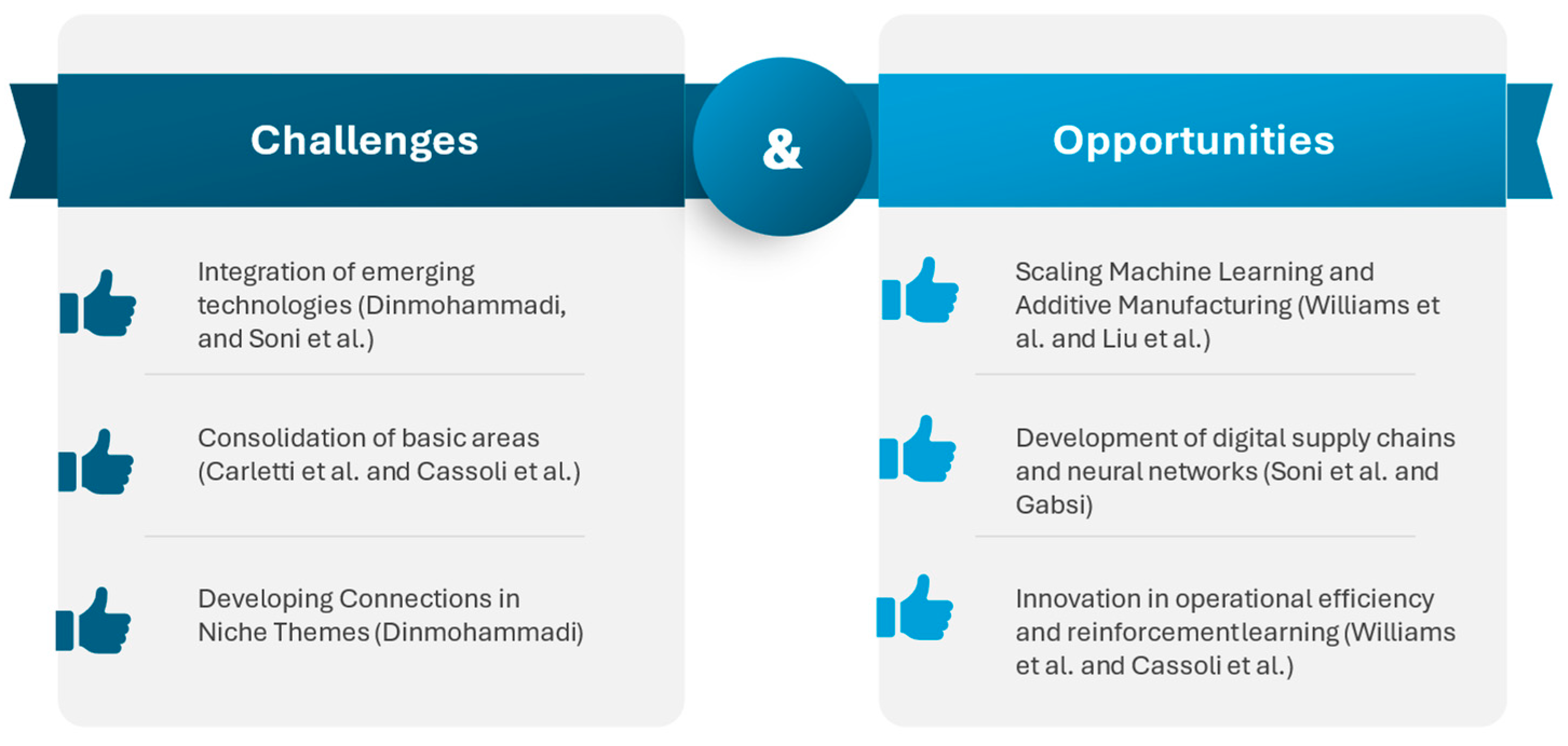

Challenges and Opportunities Derived

4.9. Limitations

4.10. Future Research Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Soumyashree, S.; Gupta, A.; Biswas, B. An Automation Designed for Industry 4.0 Using Robotics and Sensors that Based on IoT & Machine Learning. In Proceedings of the 2023 International Conference on Sustainable Technologies in Civil and Environmental Engineering, ICSTCE 2023, Pimpri, India, 15–16 June 2023; Volume 405. [Google Scholar] [CrossRef]

- Gavade, D. AI-driven process automation in manufacturing business administration: Efficiency and cost-efficiency analysis. In Proceedings of the 7th IET Smart Cities Symp SCS 2023, Bahrain, Saudi Arabia, 3–5 December 2023; pp. 677–684. [Google Scholar] [CrossRef]

- Iftikhar, N.; Nordbjerg, F.E.; Baattrup-Andersen, T.; Jeppesen, K. Industry 4.0: Sensor data analysis using machine learning. In Data Management Technologies and Applications; Springer: Cham, Switzerland, 2020; CCIS; Volume 1255, pp. 37–58. [Google Scholar] [CrossRef]

- Ekwaro-Osire, H.; Bode, D.; Thoben, K.-D.; Ohlendorf, J.-H. Identification of Machine Learning Relevant Energy and Resource Manufacturing Efficiency Levers. Sustainability 2022, 14, 15618. [Google Scholar] [CrossRef]

- Zhou, H.-R.; Yang, H.; Li, H.-Q.; Ma, Y.-C.; Yu, S.; Shi, J.; Cheng, J.-C.; Gao, P.; Yu, B.; Miao, Z.-Q.; et al. Advancements in machine learning for material design and process optimization in the field of additive manufacturing. China Foundry 2024, 21, 101–115. [Google Scholar] [CrossRef]

- Qin, J.; Hu, F.; Liu, Y.; Witherell, P.; Wang, C.C.; Rosen, D.W.; Simpson, T.W.; Lu, Y.; Tang, Q. Research and application of machine learning for additive manufacturing. Addit. Manuf. 2022, 52, 102691. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Artificial Intelligence Applications for Industry 4.0: A Literature-Based Study. J. Ind. Integr. Manag. 2021, 07, 83–111. [Google Scholar] [CrossRef]

- Jiang, X.; Lin, G.-H.; Huang, J.-C.; Hu, I.-H.; Chiu, Y.-C. Performance of Sustainable Development and Technological Innovation Based on Green Manufacturing Technology of Artificial Intelligence and Block Chain. Math. Probl. Eng. 2021, 2021, 1–11. [Google Scholar] [CrossRef]

- Bishnoi, M.M.; Ramakrishnan, S.; Suraj, S.; Dwivedi, A. Impact of AI and COVID-19 on manufacturing systems: An Asia Pacific Perspective on the two Competing exigencies. Prod. Manuf. Res. 2023, 11, 2236684. [Google Scholar] [CrossRef]

- Eklöf, J.; Snis, U.L.; Hamelryck, T.; Grima, A.; Rønning, O. AI Implementation and Capability Development in Manufacturing: An Action Research Case. In Proceedings of the 57th Annual Hawaii International Conference on System Sciences, HICSS 2024, Hawaii, HI, USA, 3 January 2024–6 January 2024; pp. 5796–5805. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85199806281&partnerID=40&md5=bf9e73a84d20cb469f8a54a199565fb5 (accessed on 2 September 2024).

- Cinar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Hector, I.; Panjanathan, R. Predictive maintenance in Industry 4.0: A survey of planning models and machine learning techniques. PeerJ Comput. Sci. 2024, 10, e2016. [Google Scholar] [CrossRef]

- Kediya, S.; Santhanam, R.; Kayande, R.A.; Sharma, A.; Sure, Y.; Disawal, V. Smart Supply Chain Management and Big Data Analysis Using Machine Learning in Industry 4. In 0. In Proceedings of the 2023 International Conference on Communication, Security and Artificial Intelligence (ICCSAI), Greater Noida, India, 23–25 November 2023; pp. 500–505. [Google Scholar] [CrossRef]

- Diez-Olivan, A.; Del Ser, J.; Galar, D.; Sierra, B. Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0. Inf. Fusion 2018, 50, 92–111. [Google Scholar] [CrossRef]

- Carletti, M.; Masiero, C.; Beghi, A.; Susto, G.A. Explainable Machine Learning in Industry 4. In 0: Evaluating Feature Importance in Anomaly Detection to Enable Root Cause Analysis. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019; IEEE: New York, NY, USA, 2019; pp. 21–26. [Google Scholar] [CrossRef]

- Antosz, K.; Pasko, L.; Gola, A. The Use of Artificial Intelligence Methods to Assess the Effectiveness of Lean Maintenance Concept Implementation in Manufacturing Enterprises. Appl. Sci. 2020, 10, 7922. [Google Scholar] [CrossRef]

- Williams, A.; Suler, P.; Vrbka, J. Business Process Optimization, Cognitive Decision-Making Algorithms, and Artificial Intelligence Data-driven Internet of Things Systems in Sustainable Smart Manufacturing. J. Self-Governance Manag. Econ. 2020, 8, 39. [Google Scholar] [CrossRef]

- Cassoli, B.B.; Hoffmann, F.; Metternich, J. Comparison of AI-Based Business Models in Manufacturing: Case Studies on Predictive Maintenance. In Proceedings of the 2nd Conference on Production Systems and Logistics, CPSL 2021, Online, 10–11 August 2021; pp. 637–647. [Google Scholar] [CrossRef]

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods 2015, 18, 429–472. [Google Scholar] [CrossRef]

- Donthu, N.; Kumar, S.; Mukherjee, D.; Pandey, N.; Lim, W.M. How to conduct a bibliometric analysis: An overview and guidelines. J. Bus. Res. 2021, 133, 285–296. [Google Scholar] [CrossRef]

- Liu, Z.; Rolston, N.; Flick, A.C.; Colburn, T.W.; Ren, Z.; Dauskardt, R.H.; Buonassisi, T. Machine learning with knowledge constraints for process optimization of open-air perovskite solar cell manufacturing. Joule 2022, 6, 834–849. [Google Scholar] [CrossRef]

- Dinmohammadi, F. Adopting Artificial Intelligence in Industry 4.0: Understanding the Drivers, Barriers and Technology Trends. In 2023 28th International Conference on Automation and Computing (ICAC), Birmingham, UK, 30 August–1 September 2023; IEEE: New York, NY, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Soni, K.; Kumar, N.; Nair, A.S.; Chourey, P.; Singh, N.J.; Agarwal, R. Artificial Intelligence. In Handbook of Metrology and Applications; Springer: Singapore, 2023; pp. 1043–1065. [Google Scholar] [CrossRef]

- Podder, I.; Fischl, T.; Bub, U. Artificial Intelligence Applications for MEMS-Based Sensors and Manufacturing Process Optimization. Telecom 2023, 4, 165–197. [Google Scholar] [CrossRef]

- TurandasjiPatil, A.; Vidhale, B.; Titarmare, A. Implementation of Artificial Intelligence in Industry 4.0, Future and Its Challenges—A Comprehensive Review. In Proceedings of the 2024 3rd International Conference for Innovation in Technology (INOCON), Bangalore, India, 1–3 March 2024; IEEE: New York, NY, USA, 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Gabsi, A.E.H. Integrating artificial intelligence in industry 4.0: Insights, challenges, and future prospects–a literature review. Ann. Oper. Res. [CrossRef]

- Todeschini, R.; Baccini, A. Handbook of Bibliometric Indicators; Wiley: Hoboken, NJ, USA, 2016. [Google Scholar] [CrossRef]

- Baas, J.; Baas, J.; Schotten, M.; Schotten, M.; Plume, A.; Plume, A.; Côté, G.; Côté, G.; Karimi, R.; Karimi, R. Scopus as a curated, high-quality bibliometric data source for academic research in quantitative science studies. Quant. Sci. Stud. 2020, 1, 377–386. [Google Scholar] [CrossRef]

- Burnham, J.F. Scopus database: A review. Biomed. Digit. Libr. 2006, 3, 1. [Google Scholar] [CrossRef]

- Kulkanjanapiban, P.; Silwattananusarn, T. Comparative analysis of Dimensions and Scopus bibliographic data sources: An approach to university research productivity. Int. J. Electr. Comput. Eng. (IJECE) 2022, 12, 706–720. [Google Scholar] [CrossRef]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Meyer, D.Z.; Avery, L.M. Excel as a Qualitative Data Analysis Tool. Field Methods 2008, 21, 91–112. [Google Scholar] [CrossRef]

- Neyeloff, J.L.; Fuchs, S.C.; Moreira, L.B. Meta-analyses and Forest plots using a microsoft excel spreadsheet: Step-by-step guide focusing on descriptive data analysis. BMC Res. Notes 2012, 5, 52. [Google Scholar] [CrossRef] [PubMed]

- Bradford, S.C. CLASSIC PAPER: Sources of Information on Specific Subjects. Collect. Manag. 1976, 1, 95–104. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- McAllister, J.T.; Lennertz, L.; Mojica, Z.A. Mapping A Discipline: A Guide to Using VOSviewer for Bibliometric and Visual Analysis. Sci. Technol. Libr. 2021, 41, 319–348. [Google Scholar] [CrossRef]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Derviş, H. Bibliometric Analysis using Bibliometrix an R Package. J. Sci. Res. 2020, 8, 156–160. [Google Scholar] [CrossRef]

- Aiza, W.S.N.; Shuib, L.; Idris, N.; Normadhi, N.B.A. Features, techniques and evaluation in predicting articles’ citations: A review from years 2010–2023. Scientometrics 2023, 129, 1–29. [Google Scholar] [CrossRef]

- Huang, C.-K.; Neylon, C.; Montgomery, L.; Hosking, R.; Diprose, J.P.; Handcock, R.N.; Wilson, K. Open access research outputs receive more diverse citations. Scientometrics 2024, 129, 825–845. [Google Scholar] [CrossRef]

- Zhang, F.; Wu, S. Predicting citation impact of academic papers across research areas using multiple models and early citations. Scientometrics 2024, 129, 4137–4166. [Google Scholar] [CrossRef]

- Razvi, S.S.; Feng, S.; Narayanan, A.; Lee, Y.-T.T.; Witherell, P. A Review of Machine Learning Applications in Additive Manufacturing. In Proceedings of the ASME 2019 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, IDETC-CIE 2019, Anaheim, CA, USA, 18–21 August 2019; Volume 1. [Google Scholar] [CrossRef]

- Paul, A.; Mozaffar, M.; Yang, Z.; Liao, W.-K.; Choudhary, A.; Cao, J.; Agrawal, A. A Real-Time Iterative Machine Learning Approach for Temperature Profile Prediction in Additive Manufacturing Processes. In Proceedings of the 6th IEEE International Conference on Data Science and Advanced Analytics, DSAA 2019, Washington, DC, USA, 5–8 October 2019; pp. 541–550. [Google Scholar] [CrossRef]

- Cavalcante, I.M.; Frazzon, E.M.; Forcellini, F.A.; Ivanov, D. A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing. Int. J. Inf. Manag. 2019, 49, 86–97. [Google Scholar] [CrossRef]

- Davidson, R. Cyber-Physical Production Networks, Artificial Intelligence-based Decision-Making Algorithms, and Big Data-driven Innovation in Industry 4.0-based Manufacturing Systems. Econ. Manag. Financial Mark. 2020, 15, 16. [Google Scholar] [CrossRef]

- Duft, G.; Durana, P. Artificial Intelligence-based Decision-Making Algorithms, Automated Production Systems, and Big Data-driven Innovation in Sustainable Industry 4.0. Econ. Manag. Financ. Mark. 2020, 15, 9. [Google Scholar] [CrossRef]

- Tran, M.-Q.; Elsisi, M.; Mahmoud, K.; Liu, M.-K.; Lehtonen, M.; Darwish, M.M.F. Experimental Setup for Online Fault Diagnosis of Induction Machines via Promising IoT and Machine Learning: Towards Industry 4.0 Empowerment. IEEE Access 2021, 9, 115429–115441. [Google Scholar] [CrossRef]

- Dib, M.A.d.S.; Ribeiro, B.; Prates, P. Federated Learning as a Privacy-Providing Machine Learning for Defect Predictions in Smart Manufacturing. Smart Sustain. Manuf. Syst. 2021, 5, 1–17. [Google Scholar] [CrossRef]

- Qin, J.; Wang, Y.; Ding, J.; Williams, S. Optimal droplet transfer mode maintenance for wire + arc additive manufacturing (WAAM) based on deep learning. J. Intell. Manuf. 2022, 33, 2179–2191. [Google Scholar] [CrossRef]

- Xiao, X.; Waddell, C.; Hamilton, C.; Xiao, H. Quality Prediction and Control in Wire Arc Additive Manufacturing via Novel Machine Learning Framework. Micromachines 2022, 13, 137. [Google Scholar] [CrossRef]

- Scepanski, E.; Schoemer, D.; Zillner, S.; Laumer, S. Navigating AI Innovation Ecosystems in Manufacturing: Shaping Factors and Their Implications. In Proceedings of the 44th International Conference on Information Systems: Rising like a Phoenix: Emerging from the Pandemic and Reshaping Human Endeavors with Digital Technologies, ICIS 2023, Hyderabad, India, 10–13 December 2023; Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85192536768&partnerID=40&md5=8c8b9cd6c6e954d8744050d405e51689 (accessed on 1 October 2024).

- Scepanski, E.; Schoemer, D.; Zillner, S.; Laumer, S. Navigating AI innovation Ecosystems in Manufacturing: Shaping Factors and Their Implications. In Proceedings of the 34th Australasian Conference on Information Systems, ACIS 2023, Wellington, New Zealand, 5–8 December 2023; Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85200104934&partnerID=40&md5=584be6b7d3bab838f08942113a3545d1 (accessed on 1 October 2024).

- Manta-Costa, A.; Araújo, S.O.; Peres, R.S.; Barata, J. Machine Learning Applications in Manufacturing—Challenges, Trends, and Future Directions. IEEE Open J. Ind. Electron. Soc. 2024, 5, 1085–1103. [Google Scholar] [CrossRef]

- Presciuttini, A.; Cantini, A.; Costa, F.; Portioli-Staudacher, A. Machine learning applications on IoT data in manufacturing operations and their interpretability implications: A systematic literature review. J. Manuf. Syst. 2024, 74, 477–486. [Google Scholar] [CrossRef]

- Egghe, L. Theory and practise of the g-index. Scientometrics 2006, 69, 131–152. [Google Scholar] [CrossRef]

- Hirsch, J.E. An index to quantify an individual’s scientific research output. Proc. Natl. Acad. Sci. USA 2005, 102, 16569–16572. [Google Scholar] [CrossRef]

- Nagy, M.; Lăzăroiu, G.; Valaskova, K. Machine Intelligence and Autonomous Robotic Technologies in the Corporate Context of SMEs: Deep Learning and Virtual Simulation Algorithms, Cyber-Physical Production Networks, and Industry 4.0-Based Manufacturing Systems. Appl. Sci. 2023, 13, 1681. [Google Scholar] [CrossRef]

- Lazaroiu, G.; Androniceanu, A.; Grecu, I.; Grecu, G.; Neguriță, O. Artificial intelligence-based decision-making algorithms, Internet of Things sensing networks, and sustainable cyber-physical management systems in big data-driven cognitive manufacturing. Oeconomia Copernic. 2022, 13, 1047–1080. [Google Scholar] [CrossRef]

- Throne, O.; Lăzăroiu, G. Internet of Things-enabled Sustainability, Industrial Big Data Analytics, and Deep Learning-assisted Smart Process Planning in Cyber-Physical Manufacturing Systems. Econ. Manag. Financial Mark. 2020, 15, 49. [Google Scholar] [CrossRef]

- Kovacova, M.; Lăzăroiu, G. Sustainable Industrial Big Data, Automated Production Processes, and Cyber-Physical System-based Manufacturing in Smart Networked Factories. Econ. Manag. Financial Mark. 2021, 16, 41–54. [Google Scholar] [CrossRef]

- Lăzăroiu, G.; Andronie, M.; Iatagan, M.; Geamănu, M.; Ștefănescu, R.; Dijmărescu, I. Deep Learning-Assisted Smart Process Planning, Robotic Wireless Sensor Networks, and Geospatial Big Data Management Algorithms in the Internet of Manufacturing Things. ISPRS Int. J. Geo-Inf. 2022, 11, 277. [Google Scholar] [CrossRef]

- Gourisaria, M.K.; Agrawal, R.; Harshvardhan, G.; Pandey, M.; Rautaray, S.S. Application of Machine Learning in Industry 4.0. In Machine Learning: Theoretical Foundations and Practical Applications; Stud Big Data; Springer: Singapore, 2021; Volume 87, pp. 57–87. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, A.; Kumar, V.; Garza-Reyes, J.A.A. Machine learning applications for sustainable manufacturing: A bibliometric-based review for future research. J. Enterp. Inf. Manag. 2021, 35, 566–596. [Google Scholar] [CrossRef]

- Agrawal, R.; Majumdar, A.; Kumar, A.; Luthra, S. Integration of artificial intelligence in sustainable manufacturing: Current status and future opportunities. Oper. Manag. Res. 2023, 16, 1720–1741. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M. Deep learning for manufacturing sustainability: Models, applications in Industry 4.0 and implications. Int. J. Inf. Manag. Data Insights 2022, 2, 100107. [Google Scholar] [CrossRef]

- Saraswat, P.; Agrawal, R. Artificial Intelligence as Key Enabler for Sustainable Maintenance in the Manufacturing Industry: Scope & Challenges. Evergreen 2023, 10, 2490–2497. [Google Scholar] [CrossRef]

- Kumar, A.; Mittal, R.K.; Haleem, A. Advances in Additive Manufacturing Artificial Intelligence, Nature-Inspired, and Biomanufacturing; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Azeem, M.; Haleem, A.; Javaid, M. Symbiotic Relationship Between Machine Learning and Industry 4.0: A Review. J. Ind. Integr. Manag. 2021, 07, 401–433. [Google Scholar] [CrossRef]

- Rizvi, A.T.; Haleem, A.; Bahl, S.; Javaid, M. Artificial Intelligence (AI) and Its Applications in Indian Manufacturing: A Review. In Current Advances in Mechanical Engineering; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; Volume 52, pp. 825–835. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A. Implementing challenges of artificial intelligence: Evidence from public manufacturing sector of an emerging economy. Gov. Inf. Q. 2021, 39, 101624. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Q.; Xu, W.; Liu, Z.; Zhou, Z.; Chen, J. Deep Learning-based Human Motion Prediction considering Context Awareness for Human-Robot Collaboration in Manufacturing. Procedia CIRP 2019, 83, 272–278. [Google Scholar] [CrossRef]

- Kundu, P.; Luo, X.; Qin, Y.; Cai, Y.; Liu, Z. A machine learning-based framework for automatic identification of process and product fingerprints for smart manufacturing systems. J. Manuf. Process. 2022, 73, 128–138. [Google Scholar] [CrossRef]

- Era, I.Z.; Farahani, M.A.; Wuest, T.; Liu, Z. Machine learning in Directed Energy Deposition (DED) additive manufacturing: A state-of-the-art review. Manuf. Lett. 2023, 35, 689–700. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, L.Z.; Xie, H.; Jiang, Y.; Zhou, J.; Wang, Y. Deep Learning-Based Robot Vision: High-End Tools for Smart Manufacturing. IEEE Instrum. Meas. Mag. 2022, 25, 27–35. [Google Scholar] [CrossRef]

- Mozaffar, M.; Liao, S.; Xie, X.; Saha, S.; Park, C.; Cao, J.; Liu, W.K.; Gan, Z. Mechanistic artificial intelligence (mechanistic-AI) for modeling, design, and control of advanced manufacturing processes: Current state and perspectives. J. Mech. Work. Technol. 2022, 302, 117485. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Z.; Cao, J.; Zhou, Y.; Guan, Y. Artificial Intelligence Empowered Laser: Research Progress of Intelligent Laser Manufacturing Equipment and Technology. Chin. J. Lasers 2023, 50, 1101005. [Google Scholar] [CrossRef]

- Karkaria, V.; Goeckner, A.; Zha, R.; Chen, J.; Zhang, J.; Zhu, Q.; Cao, J.; Gao, R.X.; Chen, W.; Karkaria, V.; et al. Towards a digital twin framework in additive manufacturing: Machine learning and bayesian optimization for time series process optimization. J. Manuf. Syst. 2024, 75, 322–332. [Google Scholar] [CrossRef]

- Elsisi, M.; Tran, M.-Q.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M.F. Deep Learning-Based Industry 4.0 and Internet of Things Towards Effective Energy Management for Smart Buildings. Sensors 2021, 21, 1038. [Google Scholar] [CrossRef]

- Elsisi, M.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M.F. Reliable Industry 4.0 Based on Machine Learning and IoT for Analyzing, Monitoring, and Securing Smart Meters. Sensors 2021, 21, 487. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rana, N.P.; Dwivedi, Y.K.; Baabdullah, A.M. Understanding AI adoption in manufacturing and production firms using an integrated TAM-TOE model. Technol. Forecast. Soc. Chang. 2021, 170, 120880. [Google Scholar] [CrossRef]

- Pillai, R.; Sivathanu, B.; Mariani, M.; Rana, N.P.; Yang, B.; Dwivedi, Y.K. Adoption of AI-empowered industrial robots in auto component manufacturing companies. Prod. Plan. Control. 2021, 33, 1517–1533. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C.; Gupta, S.; Dwivedi, Y.K. Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities. Technol. Forecast. Soc. Chang. 2020, 163, 120420. [Google Scholar] [CrossRef]

- Huang, S.; Guo, Y.; Liu, D.; Zha, S.; Fang, W. A Two-Stage Transfer Learning-Based Deep Learning Approach for Production Progress Prediction in IoT-Enabled Manufacturing. IEEE Internet Things J. 2019, 6, 10627–10638. [Google Scholar] [CrossRef]

- Chen, M.; Liu, Q.; Huang, S.; Dang, C. Environmental cost control system of manufacturing enterprises using artificial intelligence based on value chain of circular economy. Enterp. Inf. Syst. 2020, 16, 1856422. [Google Scholar] [CrossRef]

- Su, N.; Huang, S.; Su, C. Elevating Smart Manufacturing with a Unified Predictive Maintenance Platform: The Synergy between Data Warehousing, Apache Spark, and Machine Learning. Sensors 2024, 24, 4237. [Google Scholar] [CrossRef]

- Huang, S.; Wang, G.; Nie, S.; Wang, B.; Yan, Y. Part family formation method for delayed reconfigurable manufacturing system based on machine learning. J. Intell. Manuf. 2022, 34, 2849–2863. [Google Scholar] [CrossRef]

- Wang, C.; Chandra, S.; Huang, S.; Tor, S.B.; Tan, X. Unraveling process-microstructure-property correlations in powder-bed fusion additive manufacturing through information-rich surface features with deep learning. J. Mech. Work. Technol. 2023, 311, 117804. [Google Scholar] [CrossRef]

- Li, X.; Siahpour, S.; Lee, J.; Wang, Y.; Shi, J. Deep Learning-Based Intelligent Process Monitoring of Directed Energy Deposition in Additive Manufacturing with Thermal Images. Procedia Manuf. 2020, 48, 643–649. [Google Scholar] [CrossRef]

- Meng, L.; McWilliams, B.; Jarosinski, W.; Park, H.-Y.; Jung, Y.-G.; Lee, J.; Zhang, J. Machine Learning in Additive Manufacturing: A Review. JOM 2020, 72, 2363–2377. [Google Scholar] [CrossRef]

- Lee, J.; Lee, Y.C.; Kim, J.T. Fault detection based on one-class deep learning for manufacturing applications limited to an imbalanced database. J. Manuf. Syst. 2020, 57, 357–366. [Google Scholar] [CrossRef]

- Yu, Q.; Zhang, M.; Mujumdar, A.S.; Li, J. AI-based additive manufacturing for future food: Potential applications, challenges and possible solutions. Innov. Food Sci. Emerg. Technol. 2024, 92, 103599. [Google Scholar] [CrossRef]

- Huang, Z.; Shen, Y.; Li, J.; Fey, M.; Brecher, C. A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics. Sensors 2021, 21, 6340. [Google Scholar] [CrossRef] [PubMed]

- Tan, D.; Suvarna, M.; Tan, Y.S.; Li, J.; Wang, X. A three-step machine learning framework for energy profiling, activity state prediction and production estimation in smart process manufacturing. Appl. Energy 2021, 291, 116808. [Google Scholar] [CrossRef]

- Yu, C.; Li, L.; Li, J.; Qin, P.; Zhang, B. The evaluation of enterprise supply chain intelligent manufacturing system for agricultural interconnection data based on machine learning. Expert Syst. 2023, 41, e13259. [Google Scholar] [CrossRef]

- Zhang, Y.; Safdar, M.; Xie, J.; Li, J.; Sage, M.; Zhao, Y.F. A systematic review on data of additive manufacturing for machine learning applications: The data quality, type, preprocessing, and management. J. Intell. Manuf. 2022, 34, 3305–3340. [Google Scholar] [CrossRef]

- Wan, J.; Li, X.; Dai, H.-N.; Kusiak, A.; Martinez-Garcia, M.; Li, D. Artificial-Intelligence-Driven Customized Manufacturing Factory: Key Technologies, Applications, and Challenges. Proc. IEEE 2020, 109, 377–398. [Google Scholar] [CrossRef]

- Li, X.; Ma, C.; Lv, Y. Environmental Cost Control of Manufacturing Enterprises via Machine Learning under Data Warehouse. Sustainability 2022, 14, 11571. [Google Scholar] [CrossRef]

- He, P.; Liu, Q.; Kruzic, J.J.; Li, X. Machine-learning assisted additive manufacturing of a TiCN reinforced AlSi10Mg composite with tailorable mechanical properties. Mater. Lett. 2021, 307, 131018. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, W.; Yakubov, V.; Kruzic, J.J.; Wang, C.H.; Li, X. Interpretable machine learning approach for exploring process-structure-property relationships in metal additive manufacturing. Addit. Manuf. 2024, 85, 104187. [Google Scholar] [CrossRef]

- Liu, C.; Tian, W.; Kan, C. When AI meets additive manufacturing: Challenges and emerging opportunities for human-centered products development. J. Manuf. Syst. 2022, 64, 648–656. [Google Scholar] [CrossRef]

- Duquesnoy, M.; Liu, C.; Kumar, V.; Ayerbe, E.; Franco, A.A. Toward high-performance energy and power battery cells with machine learning-based optimization of electrode manufacturing. J. Power Sources 2024, 590, 233674. [Google Scholar] [CrossRef]

- Chen, W.; Liu, C.; Xing, F.; Peng, G.; Yang, X. Establishment of a maturity model to assess the development of industrial AI in smart manufacturing. J. Enterp. Inf. Manag. 2021, 35, 701–728. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, H.; Tang, D.; Nie, Q.; Zhou, T.; Wang, L.; Song, Y. Probing an intelligent predictive maintenance approach with deep learning and augmented reality for machine tools in IoT-enabled manufacturing. Robot. Comput. Manuf. 2022, 77, 102357. [Google Scholar] [CrossRef]

- Liu, J.; Chang, H.; Forrest, J.Y.-L.; Yang, B. Influence of artificial intelligence on technological innovation: Evidence from the panel data of China’s manufacturing sectors. Technol. Forecast. Soc. Chang. 2020, 158, 120142. [Google Scholar] [CrossRef]

- Liu, J.; Ye, J.; Izquierdo, D.S.; Vinel, A.; Shamsaei, N.; Shao, S. A review of machine learning techniques for process and performance optimization in laser beam powder bed fusion additive manufacturing. J. Intell. Manuf. 2022, 34, 3249–3275. [Google Scholar] [CrossRef]

- Liu, J.; Qian, Y.; Yang, Y.; Yang, Z. Can Artificial Intelligence Improve the Energy Efficiency of Manufacturing Companies? Evidence from China. Int. J. Environ. Res. Public Health 2022, 19, 2091. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.; Shi, M.; Yang, Y. Impact of Artificial Intelligence on Manufacturing Industry Global Value Chain Position. Sustainability 2024, 16, 1341. [Google Scholar] [CrossRef]

- Xing, Y.; Hou, D.; Liu, J.; Yuan, H.; Verma, A.; Shi, W. Deep Learning and Game Theory for AI-Enabled Human-Robot Collaboration System Design in Industry 4.0. In Proceedings of the 2024 IEEE 14th Annual Computing and Communication Workshop and Conference, CCWC 2024, Las Vegas, NV, USA, 8–10 January 2024; pp. 8–13. [Google Scholar] [CrossRef]

- Qin, J.; Liu, Y.; Grosvenor, R.; Lacan, F.; Jiang, Z. Deep learning-driven particle swarm optimisation for additive manufacturing energy optimisation. J. Clean. Prod. 2019, 245, 118702. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.; Tor, S.; Lim, C. Machine learning in additive manufacturing: State-of-the-art and perspectives. Addit. Manuf. 2020, 36, 101538. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Bryde, D.J.; Giannakis, M.; Foropon, C.; Roubaud, D.; Hazen, B.T. Big data analytics and artificial intelligence pathway to operational performance under the effects of entrepreneurial orientation and environmental dynamism: A study of manufacturing organisations. Int. J. Prod. Econ. 2019, 226, 107599. [Google Scholar] [CrossRef]

- Mhlanga, D. Industry 4.0 in Finance: The Impact of Artificial Intelligence (AI) on Digital Financial Inclusion. Int. J. Financial Stud. 2020, 8, 45. [Google Scholar] [CrossRef]

- Zhan, Z.; Li, H. Machine learning based fatigue life prediction with effects of additive manufacturing process parameters for printed SS 316L. Int. J. Fatigue 2020, 142, 105941. [Google Scholar] [CrossRef]

- Johnson, N.; Vulimiri, P.; To, A.; Zhang, X.; Brice, C.; Kappes, B.; Stebner, A. Invited review: Machine learning for materials developments in metals additive manufacturing. Addit. Manuf. 2020, 36, 101641. [Google Scholar] [CrossRef]

- Sahu, C.K.; Young, C.; Rai, R. Artificial intelligence (AI) in augmented reality (AR)-assisted manufacturing applications: A review. Int. J. Prod. Res. 2020, 59, 4903–4959. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhu, H.; Zhang, D.; Tariq, R.; Bassam, A.; Ullah, F.; AlGhamdi, A.S.; Alshamrani, S.S. Energetics Systems and artificial intelligence: Applications of industry 4.0. Energy Rep. 2022, 8, 334–361. [Google Scholar] [CrossRef]

- Sing, S.L.; Kuo, C.N.; Shih, C.T.; Ho, C.C.; Chua, C.K. Perspectives of using machine learning in laser powder bed fusion for metal additive manufacturing. Virtual Phys. Prototyp. 2021, 16, 372–386. [Google Scholar] [CrossRef]

- Pratap, A.; Pandey, A.; Sardana, N. Machine learning and additive manufacturing: A case study for quality control and monitoring. In Modern Materials and Manufacturing Techniques; CRC Press: Boca Raton, FL, USA, 2024; pp. 211–234. [Google Scholar] [CrossRef]

- Altarazi, F. Optimizing Waste Reduction in Manufacturing Processes Utilizing IoT Data with Machine Learning Approach for Sustainable Production. Scalable Comput. Pract. Exp. 2024, 25, 4192–4204. [Google Scholar] [CrossRef]

- Steingrimsson, B.; Fan, X.; Kulkarni, A.; Gao, M.C.; Liaw, P.K. Machine learning and data analytics for design and manufacturing of high-entropy materials exhibiting mechanical or fatigue properties of interest. In High-Entropy Materials: Theory, Experiments, and Applications; Springer: Cham, Switzerland, 2022; pp. 115–238. [Google Scholar] [CrossRef]

- de Oliveira Igarashi, J.S.; de Magalhães, J.L. Artificial intelligence applied to project management in the Industry 4.0 concept: An overview of the bibliometric analysis using the scopus database. In Perspectives on Artificial Intelligence in Times of Turbulence: Theoretical Background to Applications; IGI Global: Hershey, PA, USA, 2023; pp. 45–60. [Google Scholar] [CrossRef]

- Pracucci, A. Designing Digital Twin with IoT and AI in Warehouse to Support Optimization and Safety in Engineer-to-Order Manufacturing Process for Prefabricated Building Products. Appl. Sci. 2024, 14, 6835. [Google Scholar] [CrossRef]

- von Garrel, J.; Jahn, C. Design Framework for the Implementation of AI-based (Service) Business Models for Small and Medium-sized Manufacturing Enterprises. J. Knowl. Econ. 2022, 14, 3551–3569. [Google Scholar] [CrossRef]

- Wachnik, B. Analysis of the use of artificial intelligence in the management of Industry 4.0 projects. The perspective of Polish industry. Prod. Eng. Arch. 2022, 28, 56–63. [Google Scholar] [CrossRef]

- Jalayer, R.; Jalayer, M.; Orsenigo, C.; Vercellis, C. A Conceptual Framework for Localization of Active Sound Sources in Manufacturing Environment Based on Artificial Intelligence. In Flexible Automation and Intelligent Manufacturing: Establishing Bridges for More Sustainable Manufacturing Systems; Springer: Cham, Switzerland, 2024; pp. 699–707. [Google Scholar] [CrossRef]

- Alon, A.S.; Alon, H.D.; Reyes, M.C.; Reyes, R.; Evangelista, R.S.; Melegrito, M.; Rivera, R.P.L.; Pelayo, E.L.B. Deep Learning-based Machine Vision for Casting Defect Detection: Data-Driven Quality Assurance in Casting Manufacturing. In Proceedings of the 2nd International Engineering Conference on Electrical, Energy, and Artificial Intelligence, EICEEAI 2023, Zarqa, Jordan, 27–28 December 2023. [Google Scholar] [CrossRef]

- Gordan, M.; Sabbagh-Yazdi, S.-R.; Ghaedi, K.; Ismail, Z. A Damage Detection Approach in the Era of Industry 4.0 Using the Relationship between Circular Economy, Data Mining, and Artificial Intelligence. Adv. Civ. Eng. 2023, 2023, 1–17. [Google Scholar] [CrossRef]

- Raparthi, E.A.M. Predictive Maintenance in Manufacturing: Deep Learning for Fault Detection in Mechanical Systems. Dandao Xuebao/J. Ballist. 2023, 35, 59–66. [Google Scholar] [CrossRef]

- Kazbekova, G.; Ismagulova, Z.; Zhussipbek, B.; Abdrazakh, Y.; Iskendirova, G.; Toilybayeva, N. Machine Learning Enhanced Framework for Big Data Modeling with Application in Industry 4.0. Int. J. Adv. Comput. Sci. Appl. 2024, 15. [Google Scholar] [CrossRef]

- Mujtaba, A.; Islam, F.; Kaeding, P.; Lindemann, T.; Prusty, B.G. Machine-learning based process monitoring for automated composites manufacturing. J. Intell. Manuf. 2023, 1–16. [Google Scholar] [CrossRef]

- Kapusuzoglu, B.; Mahadevan, S. Physics-Informed and Hybrid Machine Learning in Additive Manufacturing: Application to Fused Filament Fabrication. JOM 2020, 72, 4695–4705. [Google Scholar] [CrossRef]

- Acerbi, F.; Forterre, D.A.; Taisch, M. Role of Artificial Intelligence in Circular Manufacturing: A Systematic Literature Review. IFAC-PapersOnLine 2021, 54, 367–372. [Google Scholar] [CrossRef]

- Breitenbach, J.; Seidenspinner, F.; Vural, F.; Beisswanger, P.; Buettner, R. A Systematic Literature Review of Machine Learning Approaches for Optimization in Additive Manufacturing. In Proceedings of the 46th IEEE Annual Computers, Software, and Applications Conference, COMPSAC 2022, Los Alamitos, CA, USA, 27 June 2022–1 July 2022; pp. 1147–1152. [Google Scholar] [CrossRef]

- Parsazadeh, M.; Sharma, S.; Dahotre, N. Towards the next generation of machine learning models in additive manufacturing: A review of process dependent material evolution. Prog. Mater. Sci. 2023, 135, 101102. [Google Scholar] [CrossRef]

- Raffin, T.; Reichenstein, T.; Werner, J.; Kühl, A.; Franke, J. A reference architecture for the operationalization of machine learning models in manufacturing. Procedia CIRP 2022, 115, 130–135. [Google Scholar] [CrossRef]

- Zong, Z.; Guan, Y. AI-Driven Intelligent Data Analytics and Predictive Analysis in Industry 4.0: Transforming Knowledge, Innovation, and Efficiency. J. Knowl. Econ. 2024, 1–40. [Google Scholar] [CrossRef]

- Wang, K.; Zeng, M.; Wang, J.; Shang, W.; Zhang, Y.; Luo, T.; Dowling, A.W. When physics-informed data analytics outperforms black-box machine learning: A case study in thickness control for additive manufacturing. Digit. Chem. Eng. 2023, 6, 100076. [Google Scholar] [CrossRef]

- Gardas, R.; Narwane, S. An analysis of critical factors for adopting machine learning in manufacturing supply chains. Decis. Anal. J. 2024, 10, 100377. [Google Scholar] [CrossRef]

- Gao, R.X.; Krüger, J.; Merklein, M.; Möhring, H.-C.; Váncza, J. Artificial Intelligence in manufacturing: State of the art, perspectives, and future directions. CIRP Ann. 2024, 73, 723–749. [Google Scholar] [CrossRef]

- Solke, N.S.; Shah, P.; Sekhar, R.; Singh, T.P. Machine Learning-Based Predictive Modeling and Control of Lean Manufacturing in Automotive Parts Manufacturing Industry. Glob. J. Flex. Syst. Manag. 2021, 23, 89–112. [Google Scholar] [CrossRef]

- Sordan, J.E.; Andersson, R.; Antony, J.; Pimenta, M.L.; Oprime, P.C. How Industry 4.0, artificial intelligence and augmented reality can boost Digital Lean Six Sigma. Total. Qual. Manag. Bus. Excel. 2024, 35, 1542–1566. [Google Scholar] [CrossRef]

- Chou, J.-S.; Tai, Y.; Chang, L.-J. Predicting the development cost of TFT-LCD manufacturing equipment with artificial intelligence models. Int. J. Prod. Econ. 2010, 128, 339–350. [Google Scholar] [CrossRef]

- Bogoviz, A.V.; Lobova, S.V.; Karp, M.V.; Vologdin, E.V.; Alekseev, A.N. Diversification of educational services in the conditions of industry 4.0 on the basis of AI training. Horiz. 2019, 27, 206–212. [Google Scholar] [CrossRef]

- Roggo, Y.; Jelsch, M.; Heger, P.; Ensslin, S.; Krumme, M. Deep learning for continuous manufacturing of pharmaceutical solid dosage form. Eur. J. Pharm. Biopharm. 2020, 153, 95–105. [Google Scholar] [CrossRef]

- Liso, A.; Cardellicchio, A.; Patruno, C.; Nitti, M.; Ardino, P.; Stella, E.; Renò, V. A Review of Deep Learning-Based Anomaly Detection Strategies in Industry 4.0 Focused on Application Fields, Sensing Equipment, and Algorithms. IEEE Access 2024, 12, 93911–93923. [Google Scholar] [CrossRef]

- Valaskova, K.; Nagy, M.; Grecu, G. Digital twin simulation modeling, artificial intelligence-based Internet of Manufacturing Things systems, and virtual machine and cognitive computing algorithms in the Industry 4.0-based Slovak labor market. Oeconomia Copernic. 2024, 15, 95–143. [Google Scholar] [CrossRef]

- Hasan, H.H.; Majeed, A.H.; Abdulaziz, R.A.S.A. The Role of Artificial Intelligence Applications in Developing Manufacturing System Case study on Al Waha soft drinks. In Proceedings of the 2nd Information Technology to Enhance E-Learning and Other Application Conference, IT-ELA 2021, Baghdad, Iraq, 28–29 December 2021; pp. 23–28. [Google Scholar] [CrossRef]

- Panigrahi, R.R.; Shrivastava, A.K.; Qureshi, K.M.; Mewada, B.G.; Alghamdi, S.Y.; Almakayeel, N.; Almuflih, A.S.; Qureshi, M.R.N. AI Chatbot Adoption in SMEs for Sustainable Manufacturing Supply Chain Performance: A Mediational Research in an Emerging Country. Sustainability 2023, 15, 13743. [Google Scholar] [CrossRef]

- Ciccone, F.; Bacciaglia, A.; Ceruti, A. Optimization with artificial intelligence in additive manufacturing: A systematic review. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 303. [Google Scholar] [CrossRef]

- Jan, Z.; Ahamed, F.; Mayer, W.; Patel, N.; Grossmann, G.; Stumptner, M.; Kuusk, A. Artificial intelligence for industry 4.0: Systematic review of applications, challenges, and opportunities. Expert Syst. Appl. 2023, 216, 119456. [Google Scholar] [CrossRef]

- Shahidzadeh, M.H.; Shokouhyar, S.; Safari, A.; Tirkolaee, E.B.; Shokoohyar, S. Discovering the secret behind managing WEEE: Deep learning method in the industry 4.0. Ann. Oper. Res. 2023, 1–36. [Google Scholar] [CrossRef]

- Seneviratne, W.; Tomblin, J.; Palliyaguru, U. Machine-Learning for Automated Fiber Placement for Manufacturing Efficiency and Process Optimization. In Proceedings of the SAMPE 2021 Conference and Exhibition, Online, 29 June–1 July 2021; Volume 2021-June, pp. 671–685. Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85118789835&partnerID=40&md5=3ca4ea925bc250d43f53beac9053d3fe (accessed on 1 October 2024).

- Yazdi, R.M.; Imani, F.; Yang, H. A hybrid deep learning model of process-build interactions in additive manufacturing. J. Manuf. Syst. 2020, 57, 460–468. [Google Scholar] [CrossRef]

- Nationsonline. Nations Online. Nations Online Project. Published 2014. Available online: https://nationsonline.org/oneworld/sitemap.htm (accessed on 3 September 2024).

- Jin, L.; Zhai, X.; Wang, K.; Zhang, K.; Wu, D.; Nazir, A.; Jiang, J.; Liao, W.-H. Big data, machine learning, and digital twin assisted additive manufacturing: A review. Mater. Des. 2024, 244, 113086. [Google Scholar] [CrossRef]

- Yu, Y.; Xu, J.; Zhang, J.Z.; Liu, Y.D.; Kamal, M.M.; Cao, Y. Unleashing the power of AI in manufacturing: Enhancing resilience and performance through cognitive insights, process automation, and cognitive engagement. Int. J. Prod. Econ. 2024, 270, 109175. [Google Scholar] [CrossRef]

- Yan, Y.; Ren, J.; Sun, H.; Williams, R. Nondestructive Quantitative Measurement for Precision Quality Control in Additive Manufacturing Using Hyperspectral Imagery and Machine Learning. IEEE Trans. Ind. Inform. 2024, 20, 9963–9975. [Google Scholar] [CrossRef]

- Su, J.; Chen, L.; Tan, C.; Zhou, Y.; Wong, F.; Yao, X.; Jiang, F.; Teng, J. Progress in Machine-Learning-Assisted Process Optimization and Novel Material Development in Additive Manufacturing. Chin. J. Lasers 2022, 49, 1402101. [Google Scholar] [CrossRef]

- Zhu, W.; Huo, W.; Wang, S.; Kurpaska, Ł.; Fang, F.; Papanikolaou, S.; Kim, H.S.; Jiang, J. Machine Learning-Based Hardness Prediction of High-Entropy Alloys for Laser Additive Manufacturing. JOM 2023, 75, 5537–5548. [Google Scholar] [CrossRef]

- Manoharan, G.; Ashtikar, S.P.; Nivedha, M. Harnessing the power of artificial intelligence in reinventing the manufacturing sector. In Using Real-Time Data and AI for Thrust Manufacturing; IGI Global: Hershey, PA, USA, 2024; pp. 113–137. [Google Scholar]

- Khayyam, H.; Naebe, M.; Milani, A.S.; Fakhrhoseini, S.M.; Date, A.; Shabani, B.; Atkiss, S.; Ramakrishna, S.; Fox, B.; Jazar, R.N. Improving energy efficiency of carbon fiber manufacturing through waste heat recovery: A circular economy approach with machine learning. Energy 2021, 225, 120113. [Google Scholar] [CrossRef]

| Source | h Index | g Index | m Index | TC | NP | PY Start | Q | SJR 2023 |

|---|---|---|---|---|---|---|---|---|

| Applied Sciences (Switzerland) | 9 | 14 | 1.800 | 289 | 14 | 2020 | Q2 | 0.51 |

| Additive Manufacturing | 8 | 10 | 1.600 | 941 | 10 | 2020 | Q1 | 2.84 |

| Technological Forecasting and Social Change | 8 | 9 | 1.600 | 1194 | 9 | 2020 | Q1 | 3.12 |

| Journal of Intelligent Manufacturing | 7 | 11 | 2.333 | 237 | 11 | 2022 | Q1 | 2.07 |

| Sustainability (Switzerland) | 7 | 11 | 1.400 | 525 | 11 | 2020 | Q1 | 0.67 |

| Economics, Management, and Financial Markets | 6 | 6 | 1.200 | 211 | 6 | 2020 | N/A | N/A |

| IEEE Access | 5 | 7 | 1.000 | 181 | 7 | 2020 | Q1 | 0.96 |

| International Journal of Advanced Manufacturing Technology | 5 | 8 | 0.833 | 146 | 8 | 2019 | Q2 | 0.7 |

| Journal of Manufacturing Systems | 5 | 8 | 1.000 | 260 | 8 | 2020 | Q1 | 3.17 |

| Archives of Computational Methods in Engineering | 4 | 4 | 1.000 | 77 | 4 | 2021 | Q1 | 1.8 |

| Materials Today: Proceedings | 4 | 4 | 0.800 | 110 | 4 | 2020 | N/A | 0.47 |

| IFIP Advances in Information and Communication Technology | 3 | 3 | 0.600 | 12 | 4 | 2020 | Q3 | 0.24 |

| International Journal of Production Research | 3 | 3 | 0.750 | 166 | 3 | 2021 | Q1 | 2.67 |

| JOM | 3 | 3 | 0.600 | 345 | 3 | 2020 | Q2 | 0.55 |

| Journal of Cleaner Production | 3 | 3 | 0.600 | 157 | 3 | 2020 | Q1 | 2.06 |

| Journal of Industrial Integration and Management | 3 | 3 | 1.000 | 204 | 3 | 2022 | Q1 | 1.14 |

| Journal of Manufacturing Processes | 3 | 3 | 0.600 | 113 | 3 | 2020 | Q1 | 1.39 |

| Journal of Materials Processing Technology | 3 | 3 | 1.000 | 69 | 3 | 2022 | Q1 | 1.58 |

| Procedia CIRP | 3 | 5 | 0.500 | 82 | 5 | 2019 | N/A | 0.56 |

| Robotics and Computer-Integrated Manufacturing | 3 | 3 | 1.000 | 139 | 3 | 2022 | Q1 | 2.91 |

| Author | h-Index | g-Index | m-Index | TC | NP | PY-Start |

|---|---|---|---|---|---|---|

| Lăzăroiu G [57,58,59,60,61] | 5 | 5 | 1.000 | 391 | 5 | 2020 |

| Agrawal R [62,63,64,65,66] | 4 | 5 | 1.000 | 112 | 5 | 2021 |

| Haleem A [7,67,68,69] | 4 | 4 | 1.000 | 255 | 4 | 2021 |

| Kumar A [63,64,67,70] | 4 | 4 | 1.333 | 122 | 4 | 2022 |

| Liu Z [21,71,72,73,74] | 4 | 5 | 0.667 | 233 | 5 | 2019 |

| Cao J [43,75,76,77] | 3 | 4 | 0.500 | 99 | 4 | 2019 |

| Darwish MMF [47,78,79] | 3 | 3 | 0.750 | 298 | 3 | 2021 |

| Dwivedi YK [80,81,82] | 3 | 3 | 0.750 | 737 | 3 | 2021 |

| Elsisi M [47,78,79] | 3 | 3 | 0.750 | 298 | 3 | 2021 |

| Huang S [83,84,85,86,87] | 3 | 5 | 0.500 | 134 | 5 | 2019 |

| Javaid M [7,68,69] | 3 | 3 | 0.750 | 229 | 3 | 2021 |

| Lee J [88,89,90] | 3 | 3 | 0.600 | 409 | 3 | 2020 |

| Lehtonen M [47,78,79] | 3 | 3 | 0.750 | 298 | 3 | 2021 |

| Li J [91,92,93,94,95] | 3 | 5 | 0.750 | 197 | 5 | 2021 |

| Li X [88,96,97,98,99] | 3 | 5 | 0.600 | 207 | 5 | 2020 |

| Liu C [100,101,102,103] | 3 | 4 | 1.000 | 108 | 4 | 2022 |

| Liu J [104,105,106,107,108] | 3 | 5 | 0.600 | 280 | 5 | 2020 |

| Liu Q [71,84,98,99] | 3 | 4 | 0.500 | 169 | 4 | 2019 |

| Mahmoud K [47,78,79] | 3 | 3 | 0.750 | 298 | 3 | 2021 |

| Qin J [6,49,109] | 3 | 3 | 0.600 | 216 | 3 | 2020 |

| Author | Paper | Total Citations | TC per Year | Normalized TC |

|---|---|---|---|---|

| Wang et al. [110] | “Machine learning in additive manufacturing: State-of-the-art and perspectives” | 450 | 90.00 | 6.47 |

| Diez-Olivan et al. [14] | “Data fusion and machine learning for industrial prognosis: Trends and perspectives towards Industry 4.0” | 441 | 73.50 | 4.83 |

| Bag et al. [82] | “Role of institutional pressures and resources in the adoption of big data analytics powered artificial intelligence, sustainable manufacturing practices and circular economy capabilities” | 426 | 106.50 | 8.49 |

| Dubey et al. [111] | “Big data analytics and artificial intelligence pathway to operational performance under the effects of entrepreneurial orientation and environmental dynamism: A study of manufacturing organisations” | 409 | 81.80 | 5.88 |

| Çinar et al. [11] | “Machine Learning in Predictive Maintenance towards Sustainable Smart Manufacturing in Industry 4.0” | 350 | 70.00 | 5.03 |

| Cavalcante et al. [44] | “A supervised machine learning approach to data-driven simulation of resilient supplier selection in digital manufacturing” | 325 | 54.17 | 3.56 |

| Meng et al. [89] | “Machine Learning in Additive Manufacturing: A Review” | 294 | 58.80 | 4.22 |

| Chatterjee et al. [80] | “Understanding AI adoption in manufacturing and production firms using an integrated TAM-TOE model” | 250 | 62.50 | 4.99 |

| Liu et al. [104] | “Influence of artificial intelligence on technological innovation: Evidence from the panel data of China’s manufacturing sectors” | 231 | 46.20 | 3.32 |

| Mhlanga [112] | “Industry 4.0 in Finance: The Impact of Artificial Intelligence (AI) on Digital Financial Inclusion” | 212 | 42.40 | 3.05 |

| Zhan and Li [113] | “Machine learning based fatigue life prediction with effects of additive manufacturing process parameters for printed SS 316L” | 172 | 43.00 | 3.43 |

| Javaid et al. [7] | “Artificial Intelligence Applications for Industry 4.0: A Literature-Based Study” | 170 | 56.67 | 7.45 |

| Qin et al. [6] | “Research and application of machine learning for additive manufacturing” | 160 | 53.33 | 7.01 |

| Johnson et al. [114] | “Invited review: Machine learning for materials developments in metals additive manufacturing” | 154 | 30.80 | 2.21 |

| Huang et al. [92] | “A Survey on AI-Driven Digital Twins in Industry 4.0: Smart Manufacturing and Advanced Robotics” | 131 | 32.75 | 2.61 |

| Sahu et al. [115] | “Artificial intelligence (AI) in augmented reality (AR)-assisted manufacturing applications: A review” | 130 | 32.50 | 2.59 |

| Ahmad et al. [116] | “Energetics Systems and artificial intelligence: Applications of industry 4.0” | 127 | 42.33 | 5.56 |

| Wan et al. [96] | “Artificial-Intelligence-Driven Customized Manufacturing Factory: Key Technologies, Applications, and Challenges” | 127 | 31.75 | 2.53 |

| Elsisi et al. [78] | “Deep Learning-Based Industry 4.0 and Internet of Things towards Effective Energy Management for Smart Buildings” | 126 | 31.50 | 2.51 |

| Sing et al. [117] | “Perspectives of using machine learning in laser powder bed fusion for metal additive manufacturing” | 125 | 31.25 | 2.49 |

| Institution | City/Country | Citations | Total Link Strength |

|---|---|---|---|

| School of Mechanical and Aerospace Engineering, Nanyang Technological University | Singapore | 450 | 9 |

| Singapore Centre for 3D Printing, School of Mechanical and Aerospace Engineering, Nanyang Technological University | Singapore | 450 | 9 |

| CCDC Army Research Laboratory | Aberdeen, MD, United States | 294 | 6 |

| Department of Materials Science and Engineering, Changwon National University | Changwon, South Korea | 294 | 6 |

| Department of Mechanical and Energy Engineering, Indiana University-Purdue University Indianapolis | Indianapolis, IN, United States | 294 | 6 |

| Praxair Surface Technologies | Indianapolis, IN, United States | 294 | 6 |

| Department of Industrial and Systems Engineering, Rutgers University-New Brunswick | Piscataway, NJ, United States | 108 | 5 |

| Department of Mechanical and Aerospace Engineering, Case Western Reserve University | Cleveland, OH, United States | 108 | 5 |

| Department of Mechanical and Aerospace Engineering, Rutgers University-New Brunswick | Piscataway, NJ, United States | 108 | 5 |

| New Jersey Advanced Manufacturing Institute, Rutgers University-New Brunswick | Piscataway, NJ, United States | 108 | 5 |

| The School of Manufacturing Systems and Networks, Arizona State University | Mesa, AZ, United States | 108 | 5 |

| The State Key Laboratory of Coastal and Offshore Engineering, Dalian University of Technology | Dalian, China | 108 | 5 |

| Department of Business and Economics, School of Business and Information Systems, York College, CUNY | Jamaica, NY, United States | 11 | 0 |

| Department of Mechanical Engineering, CVR College of Engineering | Hyderabad, Telangana, India | 4 | 6 |

| Mechanical Engineering, Texas A&M University College Station | College Station, TX, United States | 4 | 6 |

| School of Materials Science and Engineering, Gyeongsang National University | Jinju, South Korea | 4 | 6 |

| School of Mechanical Engineering, Zhejiang University | Hangzhou, China | 3 | 10 |

| School of Nursing, The Hong Kong Polytechnic University | Hong Kong | 3 | 10 |

| Shenzhen Key Laboratory of Soft Mechanics & Smart Manufacturing, Southern University of Science and Technology | Shenzhen, China | 3 | 10 |

| Department of Mechanical and Production Engineering, Guru Nanak Dev Engineering College | Ludhiana, Punjab, India | 1 | 0 |

| Country | TD | Total Citations | Average Article Citations |

|---|---|---|---|

| United States | 113 | 1553 | 29.9 |

| United Kingdom | 42 | 1245 | 69.2 |

| China | 73 | 1070 | 18.1 |

| Germany | 52 | 760 | 29.2 |

| Singapore | 11 | 735 | 105 |

| India | 111 | 703 | 12.6 |

| Spain | 16 | 499 | 83.2 |

| France | 9 | 480 | 120 |

| South Korea | 22 | 453 | 28.3 |

| Italy | 22 | 329 | 21.9 |

| Malaysia | 14 | 105 | 17.5 |

| Australia | 22 | 102 | 11.3 |

| Canada | 17 | 89 | 14.8 |

| Greece | 12 | 76 | 8.4 |

| Poland | 11 | 71 | 11.8 |

| Turkey | 11 | 38 | 6.3 |

| Saudi Arabia | 11 | 33 | 16.5 |

| Taiwan | 12 | 13 | 6.5 |

| Pakistan | 9 | 8 | 8 |

| Mexico | 9 | 6 | 2 |

| Cluster | Callon Centrality | Callon Density | Rank Centrality | Rank Density | Cluster Frequency |

|---|---|---|---|---|---|

| machine learning | 4.69 | 48.742 | 28 | 8 | 937 |

| additive manufacturing | 3.89 | 45.312 | 27 | 5 | 208 |

| artificial intelligence (ai) | 1.817 | 47.988 | 26 | 7 | 95 |

| technology | 0.75 | 66.667 | 24.5 | 22 | 9 |

| digital supply chain | 0.75 | 62.5 | 24.5 | 20.5 | 4 |

| decision tree | 0.5 | 87.5 | 23 | 26 | 8 |

| neural networks | 0.458 | 71.875 | 22 | 23 | 10 |

| resilience | 0.333 | 50 | 21 | 13.5 | 5 |

| generative artificial intelligence | 0.25 | 50 | 20 | 13.5 | 2 |

| digitization | 0.222 | 33.333 | 19 | 2 | 3 |

| artificial neural network | 0.214 | 47.718 | 18 | 6 | 25 |

| applications | 0 | 50 | 9 | 13.5 | 5 |

| 3D printing | 0 | 50 | 9 | 13.5 | 2 |

| surrogate model | 0 | 50 | 9 | 13.5 | 5 |

| blockchain technology | 0 | 62.5 | 9 | 20.5 | 4 |

| structural equation modeling | 0 | 33.333 | 9 | 2 | 3 |

| manufacturing sector | 0 | 50 | 9 | 13.5 | 5 |

| critical success factors | 0 | 50 | 9 | 13.5 | 2 |

| reinforcement learning | 0 | 90 | 9 | 27 | 11 |

| operational efficiency | 0 | 77.083 | 9 | 25 | 9 |

| data science | 0 | 50 | 9 | 13.5 | 5 |

| augmented reality | 0 | 53.704 | 9 | 19 | 8 |

| waam | 0 | 43.75 | 9 | 4 | 6 |

| corporate governance | 0 | 100 | 9 | 28 | 6 |

| innovation ecosystems | 0 | 75 | 9 | 24 | 4 |

| industrial artificial intelligence | 0 | 33.333 | 9 | 2 | 3 |

| autoclave | 0 | 50 | 9 | 13.5 | 2 |

| modular artificial intelligence | 0 | 50 | 9 | 13.5 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espina-Romero, L.; Gutiérrez Hurtado, H.; Ríos Parra, D.; Vilchez Pirela, R.A.; Talavera-Aguirre, R.; Ochoa-Díaz, A. Challenges and Opportunities in the Implementation of AI in Manufacturing: A Bibliometric Analysis. Sci 2024, 6, 60. https://doi.org/10.3390/sci6040060

Espina-Romero L, Gutiérrez Hurtado H, Ríos Parra D, Vilchez Pirela RA, Talavera-Aguirre R, Ochoa-Díaz A. Challenges and Opportunities in the Implementation of AI in Manufacturing: A Bibliometric Analysis. Sci. 2024; 6(4):60. https://doi.org/10.3390/sci6040060

Chicago/Turabian StyleEspina-Romero, Lorena, Humberto Gutiérrez Hurtado, Doile Ríos Parra, Rafael Alberto Vilchez Pirela, Rosa Talavera-Aguirre, and Angélica Ochoa-Díaz. 2024. "Challenges and Opportunities in the Implementation of AI in Manufacturing: A Bibliometric Analysis" Sci 6, no. 4: 60. https://doi.org/10.3390/sci6040060

APA StyleEspina-Romero, L., Gutiérrez Hurtado, H., Ríos Parra, D., Vilchez Pirela, R. A., Talavera-Aguirre, R., & Ochoa-Díaz, A. (2024). Challenges and Opportunities in the Implementation of AI in Manufacturing: A Bibliometric Analysis. Sci, 6(4), 60. https://doi.org/10.3390/sci6040060