Abstract

This study explores the feasibility of producing electrolyzed water (EW) as alternative to current chemical products used for postharvest treatment of fruits and vegetables by a new prototype generator, using tap water and NaCl as electrolyte. The EW was tested for antifungal activity, energy demand, and economic costs. In vitro tests on fungi causing spoilage as Penicillium expansum, Aspergillus niger, Botrytis cinerea, and Alternaria alternata were conducted. Furthermore, pH, chlorine concentration, electro-oxidative potential, pathogen contact time, and energy consumption were assessed. Optimal results were achieved with a pH 4.6, electro-oxidative potential 188 mV, free chlorine concentration 3.4 mg/L, and a contact time of 1–2 min. The prototype produced 10.0 L of EW in 1 h, consuming 0.11 kWh/L of electricity. Real-scale energy consumption was 11.0 kWh/m3 EW, costing 2.51 €/m3. The study concluded that optimizing EW production could reduce energy consumption, making EW a viable alternative for industrial sanitization of fresh fruits and vegetables.

1. Introduction

Fruits and vegetables constitute most of the human diet, as such the sanitization of horticultural products after harvest plays a significant role in preserving their quality, reducing wastes and ensuring consumption safety. Losses of horticultural products due to the presence of phytopathogens causing diseases after harvest are particularly relevant in terms of food security and safety, and consequently of economic losses; therefore, the interest in the search for alternative methods that might reduce losses and wastes and not causing alterations in the taste or structure is particularly high [1,2].

Washing is a critical point in the production process, aimed at removing soil and other unwanted residues and microbial contaminations. As such, the reduction of water and energy consumption, as well as wastewater disposal, represents one of the primary needs of the fresh produce industry [3]. Washing water might represent a microbiological risk associated with the accumulation of microorganisms from the surface of the washed products in the water, causing cross-contamination between lots of products through the water itself [4]. Therefore, disinfection of the washing water is necessary to reduce microbiological risks of contamination in the washing stage [5]. The use of disinfectants in process washing water is also useful to reduce contamination of the equipment.

Currently, chemical products such as sodium hypochlorite [6,7,8] and ozone [9] are used to significantly reduce the microbial load on fresh horticultural products [10,11,12]. However, chlorination systems, while seemingly economically and technologically convenient, have limitations due to the formation of harmful by-products [13,14], poor effectiveness against certain microbial species, especially viruses and protozoa [15], and the limited reusability of water, making it difficult to reduce the energy consumption required for their production. On the other hand, the food industry is known to be one of the most energy intensive [16,17].

Electrolyzed water (EW) generators, used in electrolysis systems, have been studied for industrial wastewater treatment, reducing industrial pollution from wastewater disposal [18]. The production of chlorinated compounds from saline water using an electrochemical cell offers numerous advantages over other less sustainable and ecological means [19]. Both goals can potentially be achieved through the electrochemical splitting of saline water, which has demonstrated strong antimicrobial activity in inactivating many pathogens [20,21,22,23,24,25]; moreover, it is an environmentally friendly process where electrons and water are the only reactants [26,27].

When NaCl is used as electrolyte, EW is mainly composed of hypochlorous acid (HOCl). The portion of the solution exiting the anode from the cell has strong oxidizing properties that have shown broad-spectrum inhibitory effectiveness against a wide range of bacteria, viruses, yeasts, and fungi [28,29]. For these reasons, the use of EW has been studied as an alternative to conventional chemical disinfectants in many food productions [30,31] and to mitigate fungal infections in postharvest [32].

The advantage, in terms of energy and economic costs, in using EW might be the limited quantity to be diluted in the washing water by industries requiring high hourly volumes of washing water, reducing the use of chemical products and wastewater treatment costs [26]. The effectiveness of the EW sanitizing solution is determined by the limited contact time and high available chlorine concentration, thus offering treatment flexibility for different products [29]. EW has three main physicochemical properties to be monitored: pH value, available chlorinated compounds (ACC), and electrochemical oxidation potential (EOP). The variability of these values increases or decreases the sanitizing characteristics of EW, demonstrating interaction effects among these factors [33].

Disinfection with EW is already used in various medical sanitation systems [34] and simultaneous production solutions of gaseous hydrogen (H2) for use in fuel cells are also under study [35]. However, postharvest treatment of fruit with EW needs further research to achieve results on a larger scale, aimed at industrial transfer. Furthermore, there is currently a lack of scientific literature that can demonstrate the actual energy consumption and environmental and economic convenience compared to other systems, such as the use of sodium hypochlorite.

This study examines the efficacy of a new prototype to produce EW, evaluating the effectiveness on some of the common fungal pathogens present on fruits and vegetables that cause postharvest diseases and reduce product shelf-life. EW was compared with a chlorine-based sanitizing solution commonly used on horticultural products, evaluating their performance, energy consumption, and economic viability. The research aimed to determine whether EW produced with the proposed prototype could serve as an environmentally friendly and efficient alternative for industrial sanitation processes, reducing microbial load and chemical contaminants without altering the taste or structure of the produce.

2. Materials and Methods

2.1. Prototype for Producing Electrolyzed Water (EW)

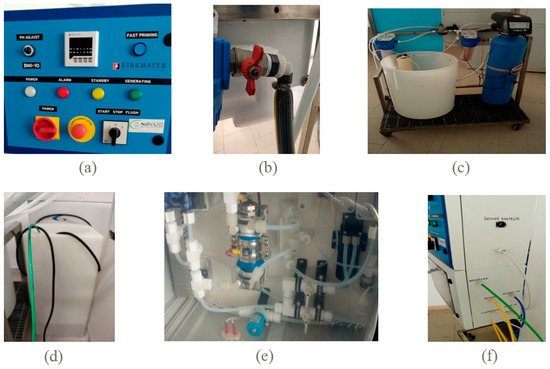

EW was produced using a prototype (Figure 1) through the electrolysis of tap water from the public water supply network of Bari (Italy), whose chemical and physical parameters are available at https://www.aqp.it/scopri-acquedotto/qualita-acqua (accessed on 26 August 2024), and a saturated solution of NaCl.

Figure 1.

The prototype of the electrolytic generator used for the production of electrolyzed water.

The prototype was equipped with the following main components:

- Control panel to manage production parameters including the pH (Figure 2a);

Figure 2. Main components of the designed prototype: (a) control panel; (b) connection to the public water supply; (c) resin filter, brine tank, and pressure gauge; (d) storage tank for electrolyzed water; (e) electrolytic cell and peristaltic pumps; (f) outlet pipes.

Figure 2. Main components of the designed prototype: (a) control panel; (b) connection to the public water supply; (c) resin filter, brine tank, and pressure gauge; (d) storage tank for electrolyzed water; (e) electrolytic cell and peristaltic pumps; (f) outlet pipes. - Connection to the public water supply (Figure 2b);

- Self-cleaning resin filter to remove impurities from the water (Figure 2c);

- Pressure gauge to manage pressure and, consequently, flow rate (Figure 2c);

- A 100 L tank for NaCl saturated solution (Figure 2c);

- Tank for the electrolyzed water with a level sensor (Figure 2d);

- Electrolytic cell with platinum electrodes (Figure 2e);

- A peristaltic pump for feeding tap water (Figure 2e);

- A peristaltic pump for feeding saturated NaCl solution (Figure 2e);

- A peristaltic pump for pH correction (Figure 2e);

- Outlet pipes for anolyte (EW), catholyte and wash water (Figure 2f).

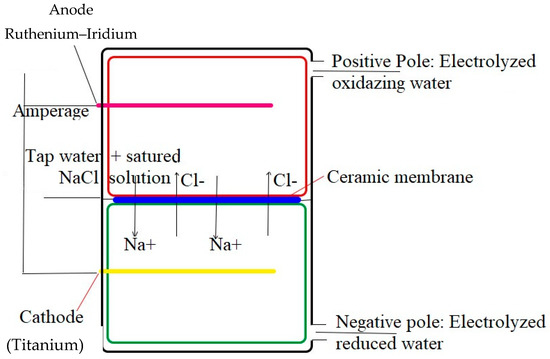

The production of EW was carried out at the Laboratory of Machinery and Plants for the Food Industries of the Department of Soil, Plant, and Food Sciences (DiSSPA) of the University of Bari Aldo Moro (Italy). The electrolytic cell consisted of an anodic electrode (ruthenium–iridium) and a cathodic electrode (titanium) separated by a ceramic septum with a mesh size of 0.2 µm. The electrodes had a total active surface area of 1.5 cm2, with an electrode thickness of 1.0 mm. The power of the electrolytic cell varied between 4 and 6.0 A, in relation to the flow pressure of the water/brine solution measured by the pressure gauge positioned downstream of the resin filter and calibrated at 1.0 atm. A schematic representation of the process realized by the electrolytic cell is shown in Figure 3.

Figure 3.

Schematic representation of the electrochemical activation process of salted water [19].

The electrolysis of tap water and saturated NaCl solution caused a dissociation of salt into sodium (Na⁺) and chloride ions (Cl−), with the formation of hydroxide ions (OH−) and hydrogen ions (H⁺) in different fractions. OH− and Cl− ions moved towards the anode where oxidation occurred with the production of HOCl, ClO−, HCl, gaseous O2 and gaseous Cl2. Na⁺ and H⁺ ions moved towards the cathode where they underwent reduction, generating sodium hydroxide (NaOH) and gaseous H2. Therefore, two types of EW were simultaneously produced: an acidic solution at the anode (anolyte) and a basic solution at the cathode (catholyte) (Figure 3). Anolyte and catholyte were conveyed into their respective outlet pipes to be collected in different containers. The pH was controlled by a switch located on the control panel; different pH values corresponded to different percentages of the catholyte fraction in the electrolyzed water (Figure 2f). The settings of the pH production management software could be modified between 0 and 11.

Since the purpose of the prototype was the production of EW for the washing of horticultural products, the cell was not equipped for the recovery of gaseous hydrogen (Figure 3, [35]). However, if needed, it could be easily achieved with a sealed system for the channeling and storage of H2 produced at the cathode.

2.2. Setup of Eletrolysed Water Parameters

The EW was produced setting the prototype pH controller at different values (1, 5, and 10) to test the characteristics of the produced EW, operating at a water pressure of 1.0 atm and at a cell power of 5.2 A. The electrolytic cell operated for 20 min. For each pH value, electrochemical oxidation potential (EOP), pH, and free and bound chlorine were determined at EW dilutions from 1 to 100%.

Free, bound, and total chlorine concentrations (mg/L) were determined using a colorimetric test (Chematest 20, SWAN Analytic Instrument, Zurich, Switzerland); pH and electrochemical oxidation potential (EOP) were determined using a benchtop pH meter (model XS PH60 DHS, GEASS S.r.l., Turin, Italy). Based on the production conditions, three categories of EW were obtained: Acidic Electrolyzed Water (AEW), Slightly Acidic Electrolyzed Water (SAEW), and Basic Electrolyzed Water (BEW) (Table 1).

Table 1.

Analytical parameters of the EW used in the tests.

2.3. Antifungal Assays

EW was tested in vitro against some of the fungal pathogens that cause rot on fruits and vegetables during storage. Strains of Penicillium expansum (Pex04), Aspergillus niger (ASP03), Alternaria alternata (A20), and Botrytis cinerea (Bc28) from the culture collection of the laboratory of Postharvest Pathology of DiSSPA (University of Bari Aldo Moro, Italy) were cultivated on potato dextrose agar (PDA, Oxoid, Milan, Italy) for 7 days at 24 ± 1 °C. The inoculum was prepared by flooding the plates with 5 mL of 0.01% Tween 20 (Merk, Milan, Italy), gently scraping the surface of the colony using a sterile spatula and passing the suspension through two layers of sterile gauze. Conidia concentration was measured using a Thoma counting chamber (HGB Henneberg-Sander GmbH, Lutzellinden, Germany) and adjusted to the required concentration with sterile distilled water.

The effect of electrolyzed solutions on the conidia viability of the different phytopathogens was evaluated by direct contact. Briefly, the spore suspensions were put in contact with EW for a time ranging from 1 to 8 min in a final volume of 1 mL (final conidial concentration 3 × 103 conidia/mL). Sodium hypochlorite at 3% and sterile distilled water were used as controls. For each time point, an aliquot of 100 µL of that contact mix was spread on three semi-selective PDA dishes (amended with ampicillin and streptomycin, 250 mg/L each), then incubated for 2–3 days at 24 ± 1 °C before counting the Colony Forming Units (CFU)/mL.

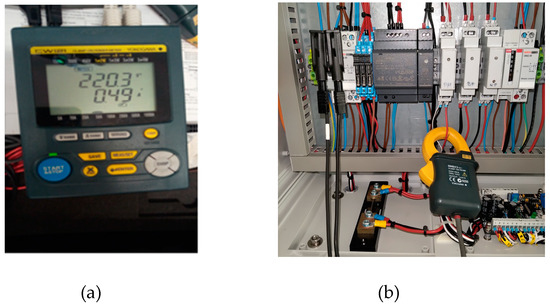

2.4. Mass Balance Evaluation

Once the optimal production parameters were established, a mass balance was performed for the input and output. The mass balance was carried out by measuring the volume of tap water input, the volume of saturated NaCl solution, and the volumes of the anolyte and catholyte fractions’ output for the different operating modes. The energy balance was performed by measuring the active electrical power absorbed by the prototype during production. An energy meter with a data logging function (CW121, Yokogawa, Tokyo, Japan) was used for the purpose; this instrument allowed measuring the energy consumption of single-phase and three-phase loads, considering the possible load imbalance on each phase. The measurements were taken by inserting the instrument’s current probes into the electrical line between the electrical panel and, respectively, the general power supply of the machine, the electrolytic cell, the feed pump of the cell, the feed pump of the saturated solution, and the discharge pump of the catholyte (Figure 4).

Figure 4.

(a) Instrument for measuring energy parameters; (b) electrical panel of the machine.

The results of the mass and energy balances were used to evaluate the production of EW with the required characteristics, comparing the energy costs related to the industrial production of sodium hypochlorite [36], currently proposed in appropriate formulations in industrial sanitation systems. Economic evaluations were made based on the specific energy costs to produce EW and 14% sodium hypochlorite, considering the current costs on the national electricity market [37].

3. Results and Discussion

3.1. Setup of Electrolyzed Water Parameters

Setting the pH value to 1 on the control panel of the prototype (Table 2), EW showed pH values ranging from 4.10 (10% dilution) to 5.20 (1% dilution), whereas a pH 3.38 was recorded for non-diluted EW; the EOP values decreased from 172 to 94.8 mV and free chlorine from 2.33 to 1.87 mg/L (Table 2). Setting the pH value to 10 on the control panel of the prototype (Table 3), EW pH values ranged from 7.90 (10% dilution) to 7.50 (1% dilution), while a pH of 8.20 was recorded for non-diluted EW; the corresponding EOP values varied from −49.5 to −43.5 mV, whereas free chlorine from 7.4 to 1.1 mg/L. Setting the pH to 5 on the control panel (Table 4), resulted in substantially comparable values of pH (swinging around 4.5), while EOP ranged from 193.9 to 186mV and free chlorine from 8 to 1.6 mg/L.

Table 2.

EW production at pH = 1 set on the control panel.

Table 3.

EW production at pH = 10 set on the control panel.

Table 4.

EW production at pH = 5 set on the control panel.

Therefore, it appears that, under extreme operating conditions of the machine (pH 1 or 10), the actual pH and electro-oxidative properties of the produced EW and its dilutions were influenced by the characteristics of the tap water, as different values were obtained from those set on the control panel. Conversely, no variations in actual pH were observed in EW and the respective dilutions when an intermediate value (pH 5) was set on the control panel of the machine. The pH values were like those obtained when the controller was set at pH 5, although a higher chlorine content was registered. At all pH values chlorine remained mostly free. Six percent dilution was selected for antifungal assays because of optimal value concerning pH, free chlorine, operational time, and costs.

In industrial production of EW plants must provide suitable control systems and standardization of parameters of the incoming tap water to ensure the exact correspondence of the set parameters with the actual parameters of the produced electrolyzed water, avoiding the need for subsequent analyses.

3.2. Data from Antifungal Assays

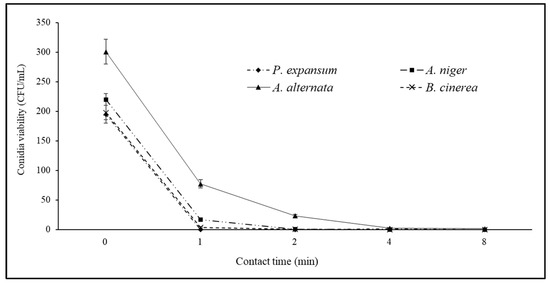

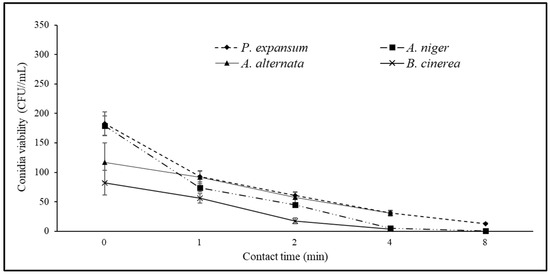

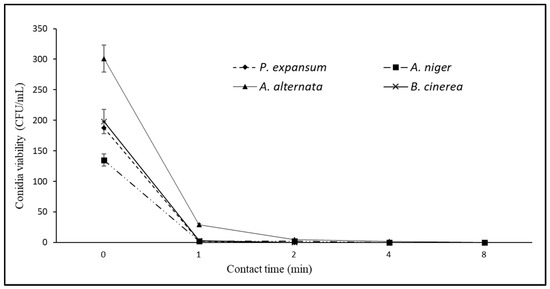

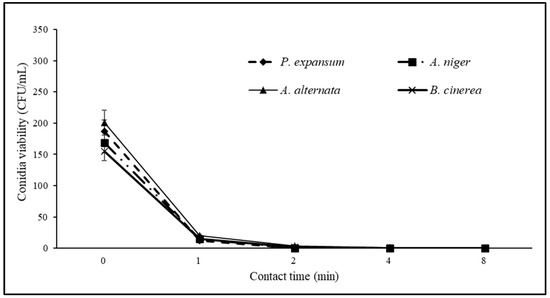

Figure 5, Figure 6 and Figure 7 refer to the best results obtained in the fungal viability tests, performed with 6% diluted EW with prototype controller set at pH 1–10, which are related to the contact times and the dilution of EW used, considering the following goals: high inhibition rates of phytopathogen viability, reduced contact times with the sanitizing solution, and minimal volumes of EW to be used in the sanitizing solution.

Figure 5.

Viability curves (CFU/mL) of Penicillium expansum, Aspergillus niger, Alternaria alternata, and Botrytis cinerea as a function of contact time (0–8 min) with 6% EW solution at pH 4.56 (see also Table 4).

Figure 6.

Viability curves (CFU/mL) of Penicillium expansum, Aspergillus niger, Alternaria alternata, and Botrytis cinerea as a function of contact time (0–8 min) with 6% EW solution at pH 7.80 (see also Table 3).

Figure 7.

Viability curves (CFU/mL) of Penicillium expansum, Aspergillus niger, Alternaria alternata and Botrytis cinerea as a function of contact time (0–8 min) with 6% EW solution at pH 4.38 (see also Table 2).

When the controller was set to pH 5, compared to the control consisting of pathogen conidia incubated in the presence of sterile distilled water, the EW diluted at 6%, corresponding to pH 4.56, EOP 188 mV, and free chlorine 3.40 mg/L (Table 4), allowed, just after 1 min of contact, a reduction in A. alternata viability of 90%, which reached 100% after 2 min of contact (Figure 5). For the other tested fungi, 1 min of contact was sufficient to completely prevent conidia germination (Figure 5).

When the controller was set to pH 10, the EW diluted at 6% with pH 7.80, EOP −41.7 mV, and free chlorine 3.86 mg/L (Table 3) provided a reduction in the pathogen viability up to 80% after 4 min of contact and up to 90% after 8 min of contact (Figure 6).

When the controller was set to pH 1, the EW diluted at 6%, with pH 4.38, EOP 155.7 mV, and free chlorine 2.29 mg/L (Table 2) provided intermediate results: reduction in the viability by 90% for P. expansum, A. niger, B. cinerea, and 74% for A. alternata after 1 min of contact, reduction of 100% after 2 min of contact for P. expansum, A. niger, B. cinerea, and 4 min for A. alternata (Figure 7).

Therefore, the best results were recorded when the controller was set at pH 5 corresponding to an actual pH of 4.56 and a free chlorine value of 3.40 mg/L.

The results may be due to the acidic pH, which caused a greater sensitivity of the cellular membranes of the pathogenic conidia, altering their physiology, hindering replication, and allowing the penetration of acidic compounds [38]. Additionally, a high EOP might influence the production of metabolic compounds such as ATP; the oxidizing compounds could damage the cellular lipid membranes, denature proteins, hinder their reproduction, and degrade DNA, thereby inhibiting enzymatic activity [39].

Therefore, although further large-scale trials are needed, the EW at 6% dilution, with pH 4.56, EOP 188 mV, and free chlorine 3.40 mg/L seems promising against phytopathogens causing rots on fresh fruits and vegetables; this could meet industrial sanitization needs for fresh fruits and vegetables and ensure continuity in washing lines, thanks to contact times ≤ 2 min. This type of EW yielded comparable results to those obtained using a sodium hypochlorite sanitizing solution at 3%; in laboratory tests, this solution proved to be effective against the studied pathogens (Figure 8) and is one of the most used sanitizing solutions in the industrial fruit and vegetable sector.

Figure 8.

Viability curves (CFU/mL) of Penicillium expansum, Aspergillus niger, Alternaria alternata and Botrytis cinerea as a function of contact time (0–8 min) with 3% sodium hypochlorite sanitizing solution.

3.3. Mass Balance Evaluation

In Table 5 the mass balance related to the production of different types of 100% EW, setting various pH values on the control panel of the prototype is reported. In all cases, a production rate of 10 L/h was assumed.

Table 5.

Mass balance related to the production of different types of EW with different pH values on the prototype control panel.

It appeared that to produce 10 L/h of EW, decreasing volumes of saturated NaCl solution must be used depending on the level of basicity of the obtained EW; the values ranged from 0.18 L corresponding to the highest acidity levels to 0.10 L corresponding to the maximum basicity level. Indeed, to produce more acidic water, a greater quantity of chlorine is required for the formation of hydrochloric acids; consequently, the consumption of tap water tended to increase depending on the production pH (Table 5). Additionally, it is noted that decreasing acidity resulted in a larger quantity of EW (anolyte) as a greater volume of catholyte was needed to reach the set basicity; thus, the fraction of waste catholyte was reduced (Table 5). The possibility of containing waste volumes was significant when considering that, based on the obtained results (Figure 5), an amount of EW equal to 60–80 L per cubic meter of sanitizing solution could be expected, despite the absence of current industrial applications of EW in fruit and vegetable processing plants.

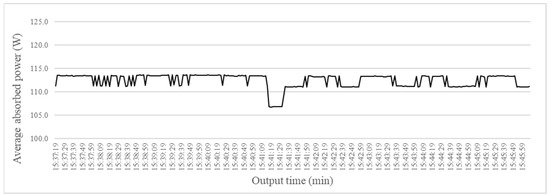

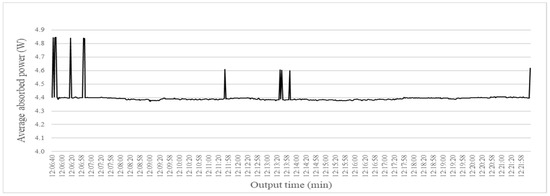

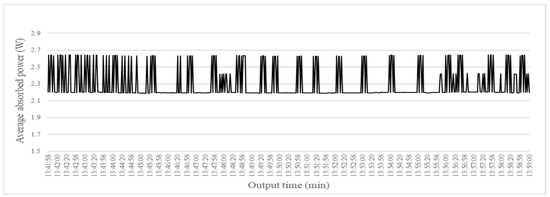

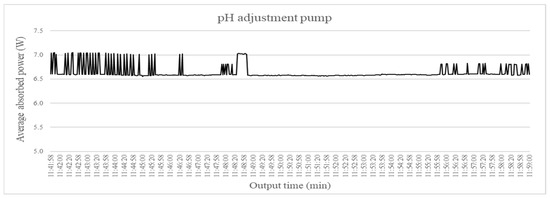

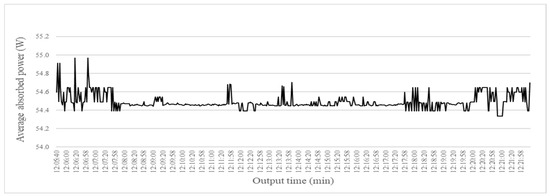

In the prototype used, the active power absorption during the production of EW might be attributed to the electrolytic cell and the three peristaltic pumps (Figure 2e): one for feeding tap water, one for feeding the saturated NaCl solution, and one for pH adjustment by appropriately mixing the discharge of catholyte into the anolyte exiting the cell. The trend over time of the machine’s active power was relatively constant (Figure 9); the tap water feeding pump averaged 4.4 W (Figure 10, Table 6), while the pumps for pH adjustment and feeding the saturated solution, had an average absorptions of 6.6 W and 2.4 W, respectively (Figure 11 and Figure 12, Table 6). The electrolytic cell had the highest absorption, with an average value of 54.5 W (Figure 13, Table 6).

Figure 9.

Global active electrical power absorption of the prototype EW generator, as a function of time.

Figure 10.

Active electrical power absorption of the main water pump.

Table 6.

Average energy parameters, distinguished for the individual components of the machine, relating to the production of 10.0 L/h of EW.

Figure 11.

Power consumption of the pump for the saturated solution.

Figure 12.

The power consumption of the pH adjustment pump.

Figure 13.

The active electrical power absorption of the electrolytic cell.

The peaks in machine absorption could be attributed to the stabilization of the set pH value through appropriate interventions by the saturated solution feeding pump and the pH correction pump. Indeed, the tap water feeding pump had a substantially constant consumption due to its continuous operation (Figure 10); however, the saturated solution pump (Figure 11) and the pump for mixing catholyte with anolyte operated in a pulsative manner to maintain the set pH value through appropriate mixing (Figure 12). The absorption peaks characterizing these latter two pumps were around 0.2–0.4 W; for the saturated solution pump, these peaks seemed due to the supply of the cell with a solution flow suitable for obtaining anolyte with the set pH value, increasing the flow rate in cases where the set value is more acidic. Similarly, the pH adjustment pump operated downstream of the cell with appropriate mixing of catholyte into EW, increasing the flow rate according to the basicity it must achieve, always based on the set values.

Except for the startup phase of the plant, the active power absorption of the electrolytic cell did not change over time, as variations not exceeded 0.2 W (Figure 13).

Using the prototype developed, the production of 10 L of EW was carried out in 1 h (Table 6), with an average active power absorption of 109.6 W, corresponding to an electricity consumption of 0.11 kWh and a specific energy of 0.001 kWh/L EW (Table 6). Therefore, considering the substantial linearity, the measured data could be extrapolated to the production of 1 m3 of EW with the best sanitization characteristics (Table 4): a power commitment of 110 W, a total energy consumption of 11 kWh, a specific power commitment of 11 kW/m3 EW, and a specific consumption of 0.01 kWh/L EW (Table 7).

Table 7.

Energy parameters related to the production of: EW, industrial NaClO2, and NaClO2 at 14%.

In terms of energy, the industrial production of 14–15% sodium hypochlorite in a conventional industrial system involves the electrolysis of a saline solution and the direct production of Cl2 and H2 gases, as well as NaOH in aqueous solution, through chlor-alkali electrolysis (ECA). A typical ECA process involves an energy consumption of 2.1–3.0 MWh per 1.0 ton of production [27,33]; to produce 1.0 ton of Cl2, the energy cost corresponds to 51–58% of the production energy cost (Table 7), which, calculated with the maximum values, results in: 1.74 kWh/L (Table 7).

For the industrial sanitization of fruits and vegetables, a 14% aqueous solution of NaClO2 is used, with an energy cost corresponding to 244 kWh/m3 (Table 7), while the energy cost of the sanitizing solution EW at pH 4.56 is 11 kWh/m3 (Table 7). This energy comparison apparently found confirmation in the economic one: 2.51 €/m3 to produce EW and 56.05 €/m3 to produce 14% NaClO2 (Table 8). However, in the overall balance, it should be considered that industrial sodium hypochlorite production is highly energy-intensive and has a high environmental impact, as it uses mercury electrolytic cells and produces toxic purification sludge [40,41]; furthermore, the use of a sodium hypochlorite-based solution in a fruit and vegetable processing plant is limited to a few steps in the washing tanks. On the contrary, as the EW system operates discontinuously, 1.0 m3 of EW would be sufficient to ensure industrial sanitization for several days of fruit and vegetable production, thus reducing daily energy consumption to values lower than those of NaClO2. In fact, the washing water that uses EW might be filtered, removing suspended solid residues, and reused again, possibly only requiring minimal integrations to restore initial sanitization values.

Table 8.

Energy and economic parameters relating to the dilution in a sanitizing solution of 1.0 m3.

4. Conclusions

EW demonstrated strong antifungal activity, effectively inhibiting common postharvest fungal pathogens such as P. expansum, A. niger, A. alternata, and B. cinerea. With a pH of 4.56, an EOP of 188 mV, and 3.40 mg/L of free chlorine, EW achieved a 90% reduction in pathogen viability within 1 min and 100% within 2 min, showing comparable or superior efficacy to a 3% sodium hypochlorite solution and making it a viable alternative for sanitizing the fresh produce. The production of EW was found to be less energy-intensive compared to the industrial production of sodium hypochlorite, particularly with the discontinuous operation of EW systems in industrial settings. The specific energy consumption for EW production was 0.11 kWh/L, while the cost of producing EW 2.51 €/m3 compared to sodium hypochlorite 56.05 €/m3. However, the cost is offset by the potential for reusing washing water and the reduced environmental impact. Additionally, EW systems offer flexibility in sanitization processes due to their rapid action and ability to be integrated into existing washing lines. The prototype results suggest that industrial-scale EW production could meet sanitization needs efficiently with lower environmental and health impacts. For example, it could be efficiently coupled with renewable energies such as sunlight. In conclusion, EW is a promising alternative to conventional chemical disinfectants in the food industry, particularly for the postharvest treatment of fresh fruits and vegetables. Its effectiveness, coupled with environmental and potential long-term economic benefits, supports further development and adoption in industrial applications. The results of this study also provide useful insights for the design of machines for EW production, concerning energy usage, control systems, and operating parameters of the electrolytic cell and pumps.

Author Contributions

Conceptualization, S.M.S., A.I., P.C. and B.B.; Data curation, S.M.S., P.C. and G.T.; Formal analysis, S.M.S., P.C. and B.B.; Investigation, S.M.S., P.C., G.T., F.G. and B.B.; Methodology, S.M.S., A.I., P.C. and B.B.; Project administration, B.B.; Resources, S.M.S., A.I. and B.B.; Supervision, B.B.; Validation, S.M.S., A.I., G.T., F.G., P.C. and B.B.; Writing—original draft, G.T.; Writing—Review and Editing, S.M.S., A.I., P.C., F.G. and B.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No other new data were created.

Acknowledgments

G.T. acknowledges the project “RIPARTI-assegni di RIcerca per riPARTire con le Imprese”, founded by Regione Puglia (Scientific Coordinator: Bianchi). All authors acknowledge NOVUS s.r.l. (Via Enrico Fermi 18, Brindisi, Italy, e-mail: novus@novuscd.it) for providing some of the prototype components and collaborating to its assembly.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Rahman, S.M.E.; Khan, I.; Oh, D.H. Electrolyzed water as a novel sanitizer in the food industry: Current trends and future perspectives. Compr. Rev. Food Sci. Food Saf. 2016, 15, 471–490. [Google Scholar] [CrossRef]

- Saxena, J.; Williams, T. Electrolysed water (hypochlorous acid) generation and efficacy against food-borne pathogens. Sustain. Food Technol. 2023, 1, 603–609. [Google Scholar] [CrossRef]

- Manzocco, L.; Ignat, A.; Anese, M.; Bot, F.; Calligaris, S.; Valoppi, F.; Nicoli, M.C. Efficient management of the water resource in the fresh-cut industry: Current status and perspectives. Trends Food Sci. Technol. 2015, 46, 286–294. [Google Scholar] [CrossRef]

- Gombas, D.; Luo, Y.; Brennan, J.; Shergill, G.; Petran, R.; Walsh, R.; Hau, H.; Khurana, K.; Zomorodi, B.; Rosen, J.; et al. Guidelines to validate control of cross-contamination during washing of fresh-cut leafy vegetables. J. Food Protect. 2017, 80, 312–330. [Google Scholar] [CrossRef]

- López-Gálvez, F.; Tudela, J.A.; Gil, M.I.; Allende, A. Use of chlorine dioxide to treat recirculated process water in a commercial tomato packinghouse: Microbiological and chemical risks. Front. Sustain. Food Syst. 2020, 4, 42. [Google Scholar] [CrossRef]

- Bolin, H.R.; Stafford, A.E.; King, A.D., Jr.; Huxsoll, C.C. Factors affecting the storage stability of shredded lettuce. J. Food Sci. 1977, 42, 1319–1321. [Google Scholar] [CrossRef]

- Zhang, S.; Farber, J.M. The effects of various disinfectants against Listeria monocytogenes on fresh-cut vegetables. Food Microbiol. 1996, 13, 311–321. [Google Scholar] [CrossRef]

- Krahn, T.R. Improving the keeping quality of cut head lettuce. Acta Hortic. 1977, 62, 79–92. [Google Scholar] [CrossRef]

- Nagashima, T.; Kamoi, I. Sterilization and preservation of vegetables by ozonated water treatment. Food Preserv. Sci. 1997, 23, 127–131. [Google Scholar] [CrossRef]

- Allende, A.; McEvoy, J.; Tao, Y.; Luo, Y. Antimicrobial effect of acidified sodium chlorite, sodium chlorite, sodium hypochlorite, and citric acid on Escherichia coli O157:H7 and natural microflora of fresh-cut cilantro. Food Control 2009, 20, 230–234. [Google Scholar] [CrossRef]

- Liao, C.H. Acidified sodium chlorite as an alternative to chlorine for elimination of Salmonella on Alfalfa Seeds. J. Food Sci. 2009, 74, 159–164. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Hung, Y.-C.; Chung, D. Effects of chlorine and pH on efficacy of electrolyzed water for inactivating Escherichia coli O157:H7 and Listeria monocytogenes. Int. J. Food Microbiol. 2004, 91, 13–18. [Google Scholar] [CrossRef] [PubMed]

- Marriott, N.G.; Gravani, R.B. Attrezzature e impianti per la sanificazione. In Sanitization in the Food Industry; Springer Science & Business Media: Milano, Italy, 2008; Volume 10, pp. 205–206. [Google Scholar] [CrossRef]

- Tak, S.; Vellanki, B.P.; Ahuja, S. A review on disinfection and disinfection byproducts. In Contaminants in Our Water: Identification and Remediation Methods; ACS Publications: Washington, DC, USA, 2020; pp. 105–117. [Google Scholar]

- Nguyen-The, C.; Carlin, F. The microbiology of minimally processed fresh fruits and vegetables. Crit. Rev. Food Sci. Nutr. 1994, 34, 371–401. [Google Scholar] [CrossRef]

- Perone, C.; Bianchi, B.; Catalano, F.; Orsino, M. Experimental Evaluation of Functional and Energy Performance of Pneumatic Oenological Presses for High Quality White Wines. Sustainability 2022, 14, 8033. [Google Scholar] [CrossRef]

- Catalano, F.; Romaniello, R.; Orsino, M.; Perone, C.; Bianchi, B.; Giametta, F. Experimental Tests in Production of Ready-to-Drink Primitive Wine with Different Modes of Circulation of the Fermenting Must. Appl. Sci. 2023, 13, 5941. [Google Scholar] [CrossRef]

- Ferreira, A.P.R.A.; Oliveira, R.C.P.; Mateus, M.M.; Santos, D.M.F. A Review of the Use of Electrolytic Cells for Energy and Environmental Applications. Energies 2023, 16, 1593. [Google Scholar] [CrossRef]

- Afify, A.A.; Hassan, G.K.; Al-Hazmi, H.E.; Kamal, R.M.; Mohamed, R.M.; Drewnowski, J.; Majtacz, J.; Mąkinia, J.; El-Gawad, H.A. Electrochemical Production of Sodium Hypochlorite from Salty Wastewater Using a Flow-by Porous Graphite Electrode. Energies 2023, 16, 4754. [Google Scholar] [CrossRef]

- Rahman, S.M.; Ding, T.; Oh, D.H. Inactivation effect of newly developed low concentration electrolyzed water and other sanitizers against microorganisms on spinach. Food Control 2010, 21, 1383–1387. [Google Scholar] [CrossRef]

- Huang, Y.H.; Hung, Y.C.; Hsu, S.Y.; Huang, Y.W.; Hwang, D.F. Application of electrolyzed water in the food industry. Food Control 2008, 19, 329–345. [Google Scholar] [CrossRef]

- Fabrizio, K.A.; Cutter, C.N. Stability of electrolyzed oxidizing water and its efficacy against cell suspensions of Salmonella typhimurium and Listeria monocytogenes. J. Food Prot. 2003, 66, 1379–1384. [Google Scholar] [CrossRef]

- Kim, C.; Hung, Y.C.; Brackett, R.E. Efficacy of electrolyzed oxidizing (EO) and chemically modified water on different types of foodborne pathogens. Int. J. Food Microbiol. 2000, 61, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Hung, Y.-C.; Brackett, R.E. Antimicrobial effect of electrolyzed water for inactivating Campylobacter jejuni during poultry washing. Int. J. Food Microbiol. 2002, 72, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Venkitanarayanan, K.S.; Ezeike, G.O.; Sospeso, Y.; Doyle, M.P. Efficacy of Electrolyzed Oxidizing Water for Inactivating Escherichia coli O157:H7, Salmonella enteritidis, and Listeria monocytogenes. Appl Env. Microbiol 1999, 65, 4276–4279. [Google Scholar] [CrossRef]

- Euro Chlor Communications. The Electrolysis Process and the Real Costs of Production. 2020-23. Available online: https://www.eurochlor.org/wp-content/uploads/2018/06/12-Electrolysis-production-costs-November-2023.pdf (accessed on 19 July 2024).

- Ganci, F.; Baguet, T.; Aiello, G.; Cusumano, V.; Mandin, P.; Sunseri, C.; Inguanta, R. Nanostructured Ni Based Anode and Cathode for Alkaline Water Electrolyzers. Energies 2019, 12, 3669. [Google Scholar] [CrossRef]

- Guentzel, J.L.; Lam, K.L.; Callan, M.A.; Emmons, S.A.; Dunham, V.L. Postharvest management of gray mould and brown rot on surfaces of peaches and grapes using electrolyzed oxidizing water. Int. J. Food Microbiol. 2010, 143, 54–60. [Google Scholar] [CrossRef]

- Hsu, S.Y. Effects of flow rate, temperature and salt concentration on chemical and physical properties of electrolyzed oxidizing water. J. Food Eng. 2005, 66, 171–176. [Google Scholar] [CrossRef]

- Koseki, S.; Yoshida, K.; Isobe, S.; Itoh, K. Decontamination of lettuce using acidic electrolyzed water. J. Food Prot. 2001, 64, 652–658. [Google Scholar] [CrossRef]

- Park, C.M.; Hung, Y.C.; Doyle, M.P.; Ezeike, G.O.I.; Kim, C. Pathogen reduction and quality of lettuce treated with electrolyzed oxidizing and acidified chlorinated water. J. Food Sci. 2001, 66, 1368–1372. [Google Scholar] [CrossRef]

- Koutsoumanis, K.; Alvarez, A.; Bolton, O.D.; Bover-Cid, S.; Chemaly, M.; De Cesare, A.; Friederike, L.H.; Lindqvist, R.; Nauta, M.; Nonno, R.; et al. Microbiological hazards associated with the use of water in the post-harvest handling and processing operations of fresh and frozen fruits, vegetables and herbs (ffFVHs). EFSA Panel Biol. Hazards (BIOHAZ) 2023, 21, e08332. [Google Scholar] [CrossRef]

- Roha, K.; Bréea, L.C.; Perreyb, K.; Bulanb, A.; Mitsos, A. Flexible operation of switchable chlor-alkali electrolysis for demand side management. Appl. Energy 2019, 255, 113880. [Google Scholar] [CrossRef]

- Yan, P.; Daliri, E.B.M.; Oh, D.H. New clinical applications of electrolyzed water: A review. Microorganisms 2021, 9, 136. [Google Scholar] [CrossRef] [PubMed]

- Chisholm, G.; Zhao, T.; Cronin, L. Hydrogen from water electrolysis. In Storing Energy; Elsevier: Amsterdam, The Netherlands, 2022; pp. 559–591. [Google Scholar]

- Ehyaei, M.A.; Baloochzadeh, S.; Ahmadi, A.; Abanades, S. Energy, exergy, economic, exergoenvironmental, and environmental analyses of a multigeneration system to produce electricity, cooling, potable water, hydrogen and sodium-hypochlorite. Desalination 2021, 501, 114902. [Google Scholar] [CrossRef]

- ARERA. Processing on Eurostat Data, 2021, Consumption up to 20/500 MWh for Year. Available online: https://www.arera.it/fileadmin/allegati/dati/ra21/eepcfr2.xlsx (accessed on 19 July 2024).

- Al-Haq, M.I.; Seo, Y.; Oshita, S.; Kawagoe, Y. Disinfection effects of electrolyzed oxidizing water on suppressing fruit rot of pear caused by Botryosphaeria berengeriana. Food Res. Int. 2002, 35, 657–664. [Google Scholar] [CrossRef]

- Rahman, S.M.E.; Park, J.H.; Wang, J.; Oh, D.H. Stability of low concentration electrolyzed water and its sanitization potential against food-borne pathogens. J. Food Eng. 2012, 113, 548–553. [Google Scholar] [CrossRef]

- Li, K.; Fan, Q.; Chuai, H.; Liu, H.; Zhang, S.; Ma, X. Revisiting chlor-alkali electrolyzers: From materials to devices. Trans. Tianjin Univ. 2021, 27, 202–216. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, S.; Huang, W.; Wang, F.; Fang, S.; Ge, R.; Zhang, Q.; Zhang, L.; Du, W.; Fang, F.; et al. Current status of hypochlorite technology on the wastewater treatment and sludge disposal: Performance, principals and prospects. Sci. Total Environ. 2022, 803, 150085. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).