Accuracy of Measuring Rebar Strain in Concrete Using a Diffractometer for Residual Stress Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Concrete Materials Used and Mix Proportion

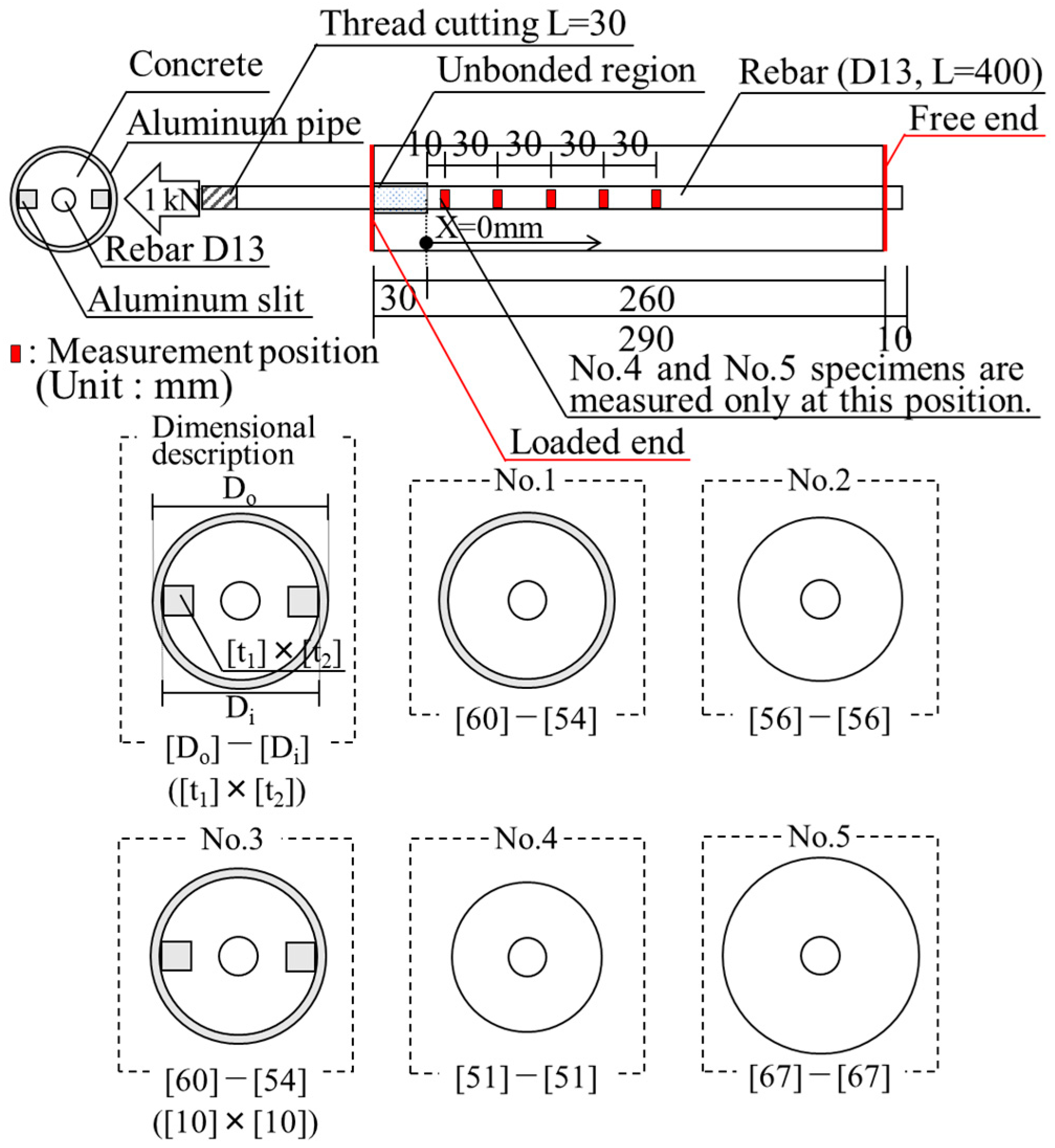

2.2. Experimental Parameters and Test Specimens

2.3. Experimental Method

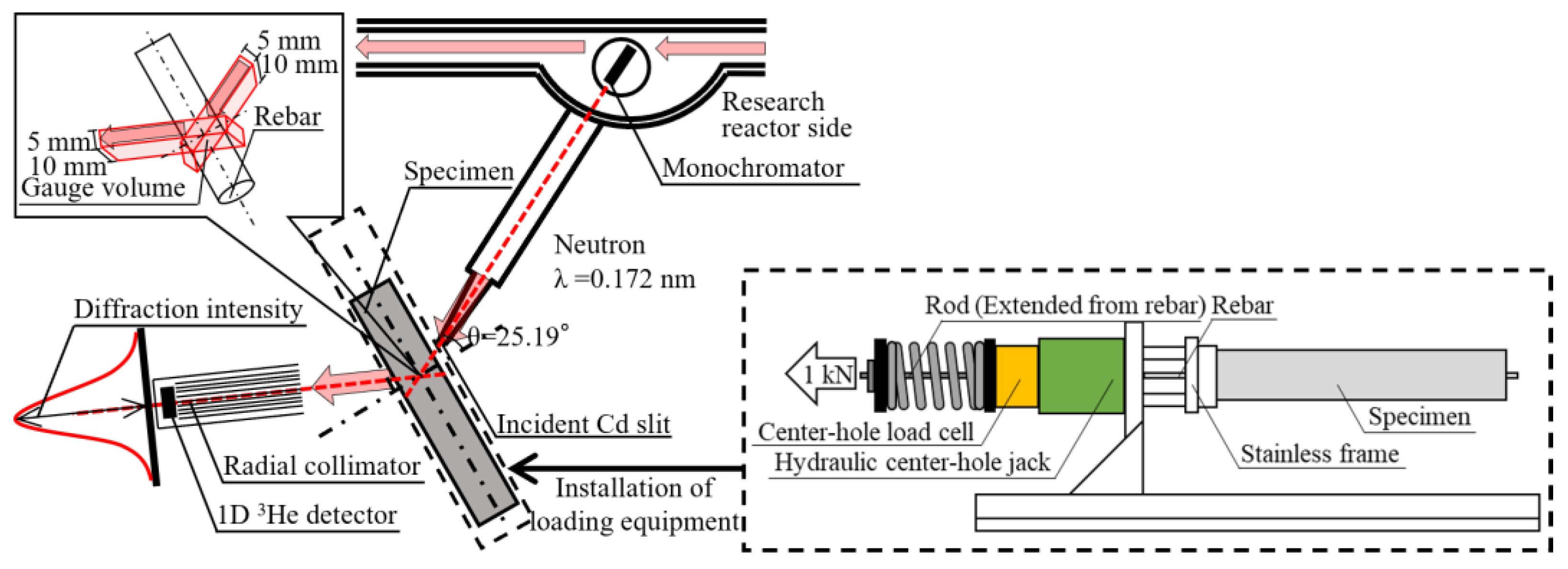

2.3.1. Overview of Measuring Rebar Strain

2.3.2. Loading Method and Measurement Position

2.4. Analysis Methods

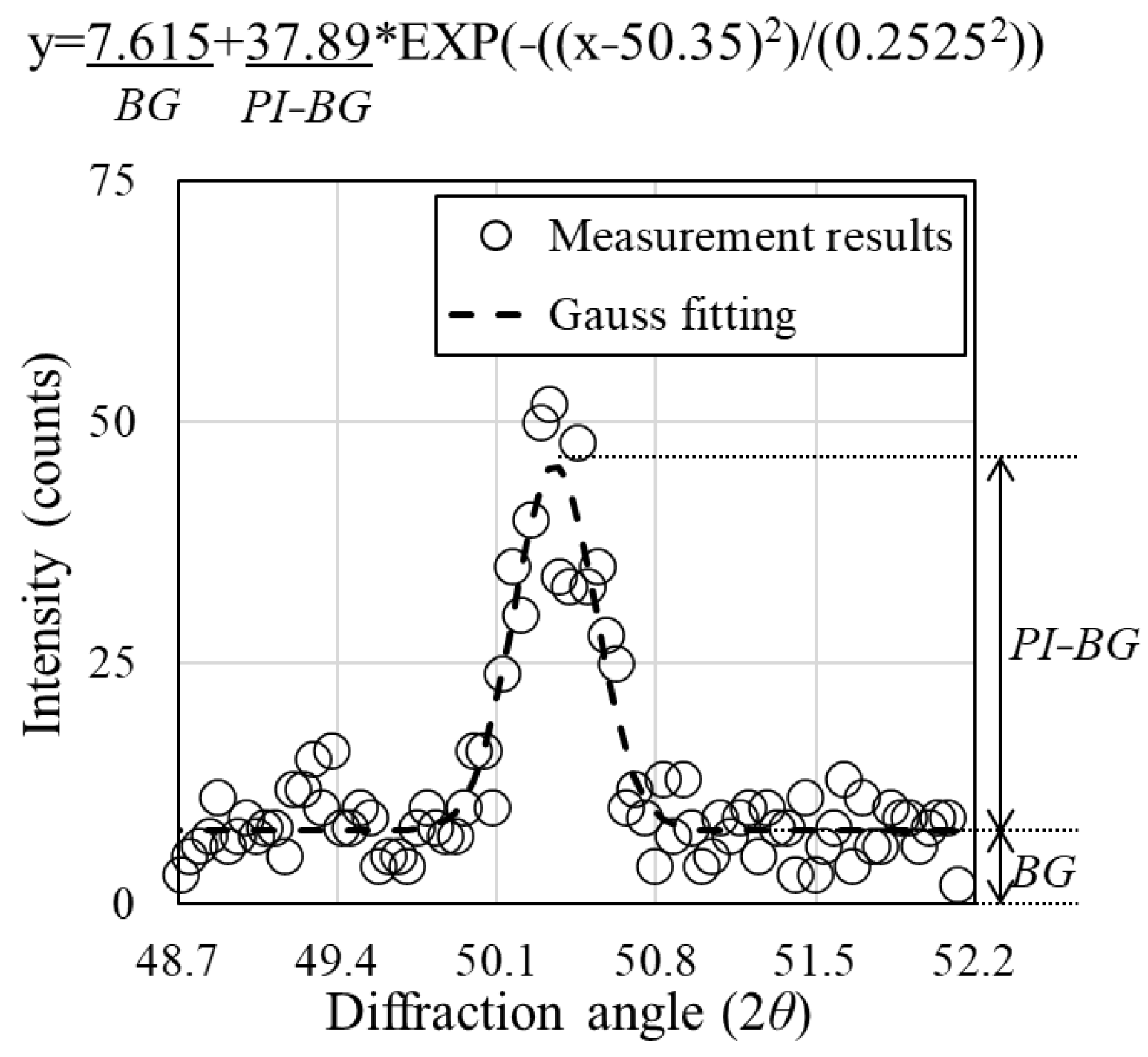

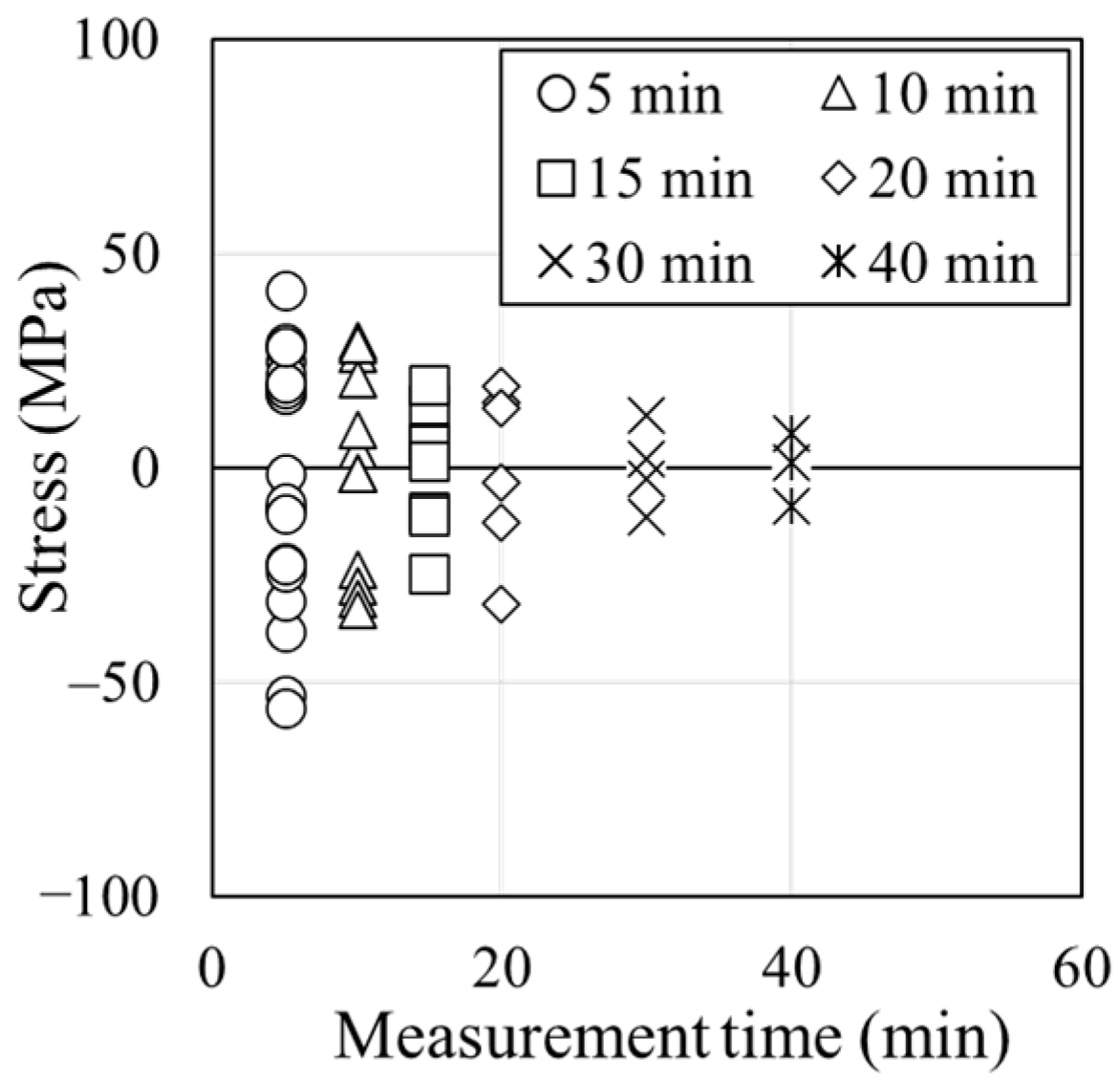

2.4.1. Variation of Rebar Stress Calculation

2.4.2. Analysis Method Sensitivity

3. Measurement Accuracy Results

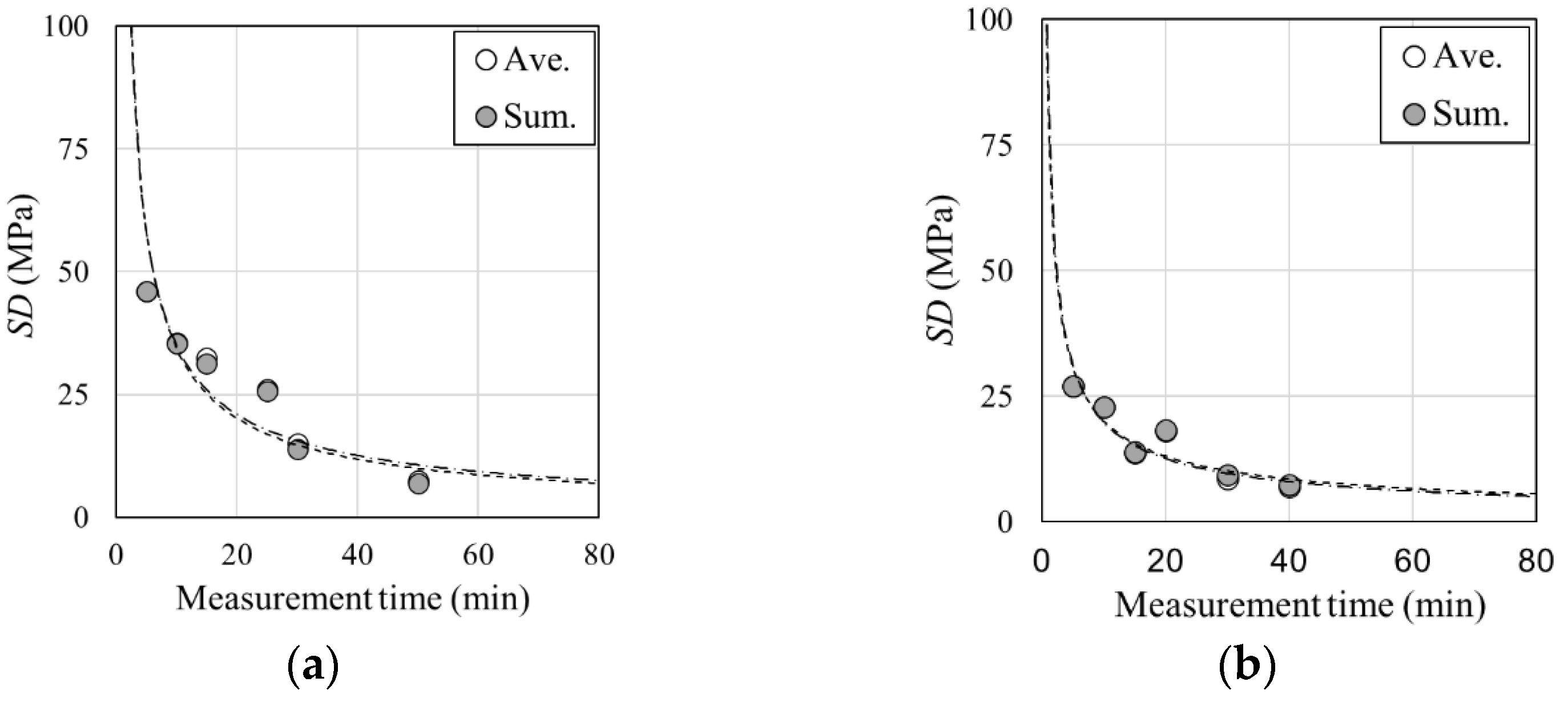

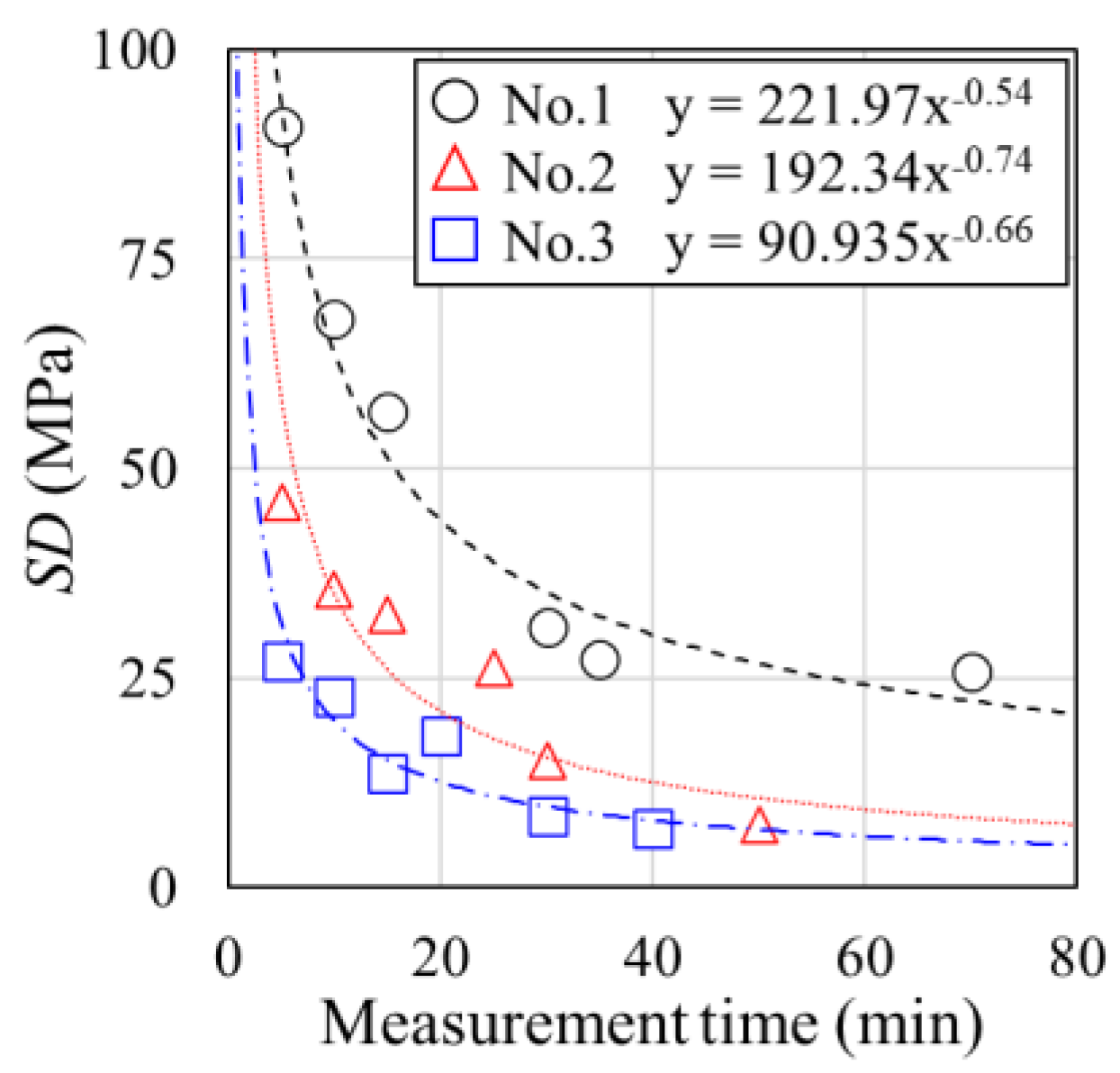

3.1. Cross-Sectional Shape Sensitivity

3.2. Sensitivity to Measurement Position

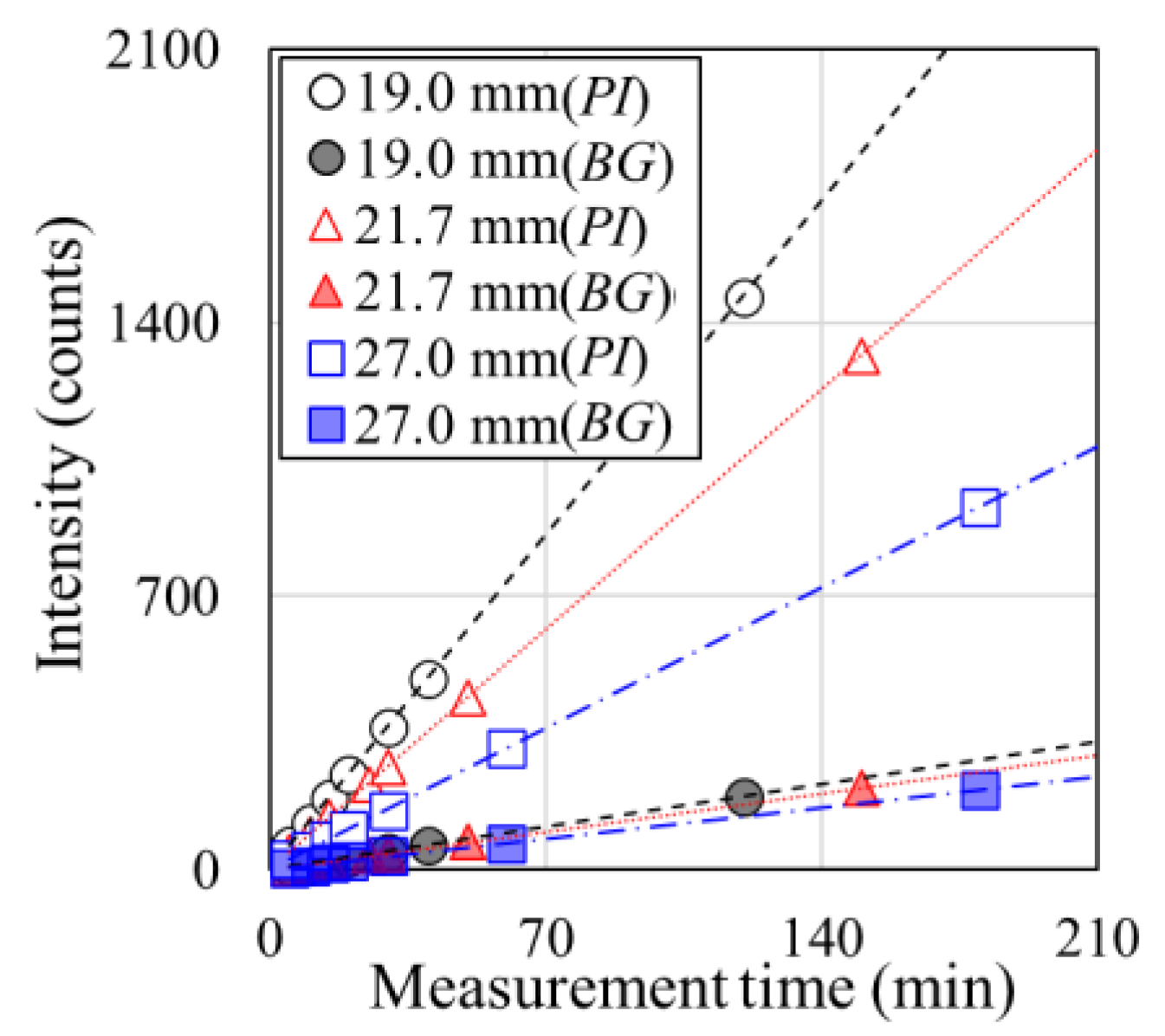

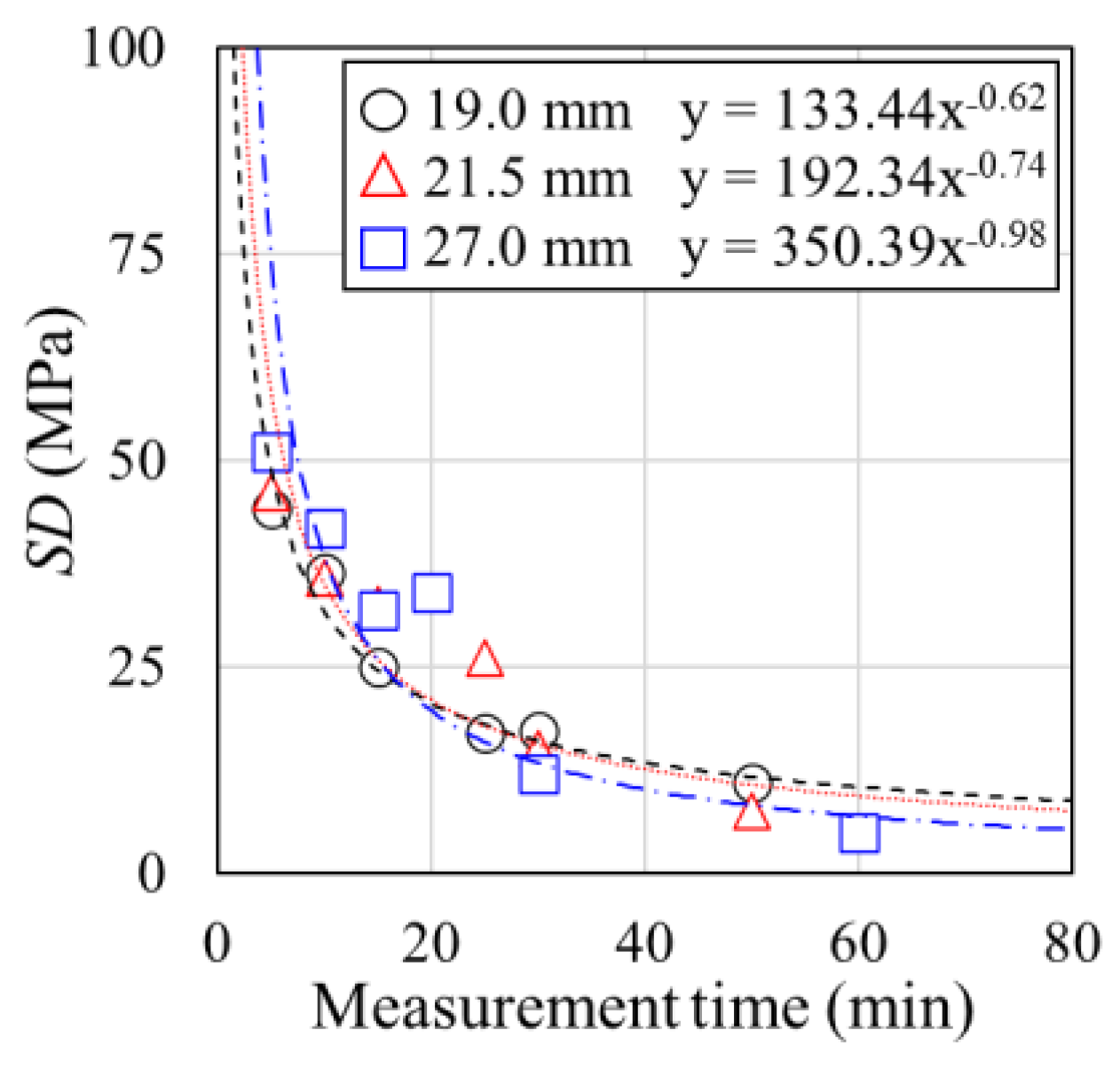

3.3. Sensitivity to Cover Thickness

4. Discussion

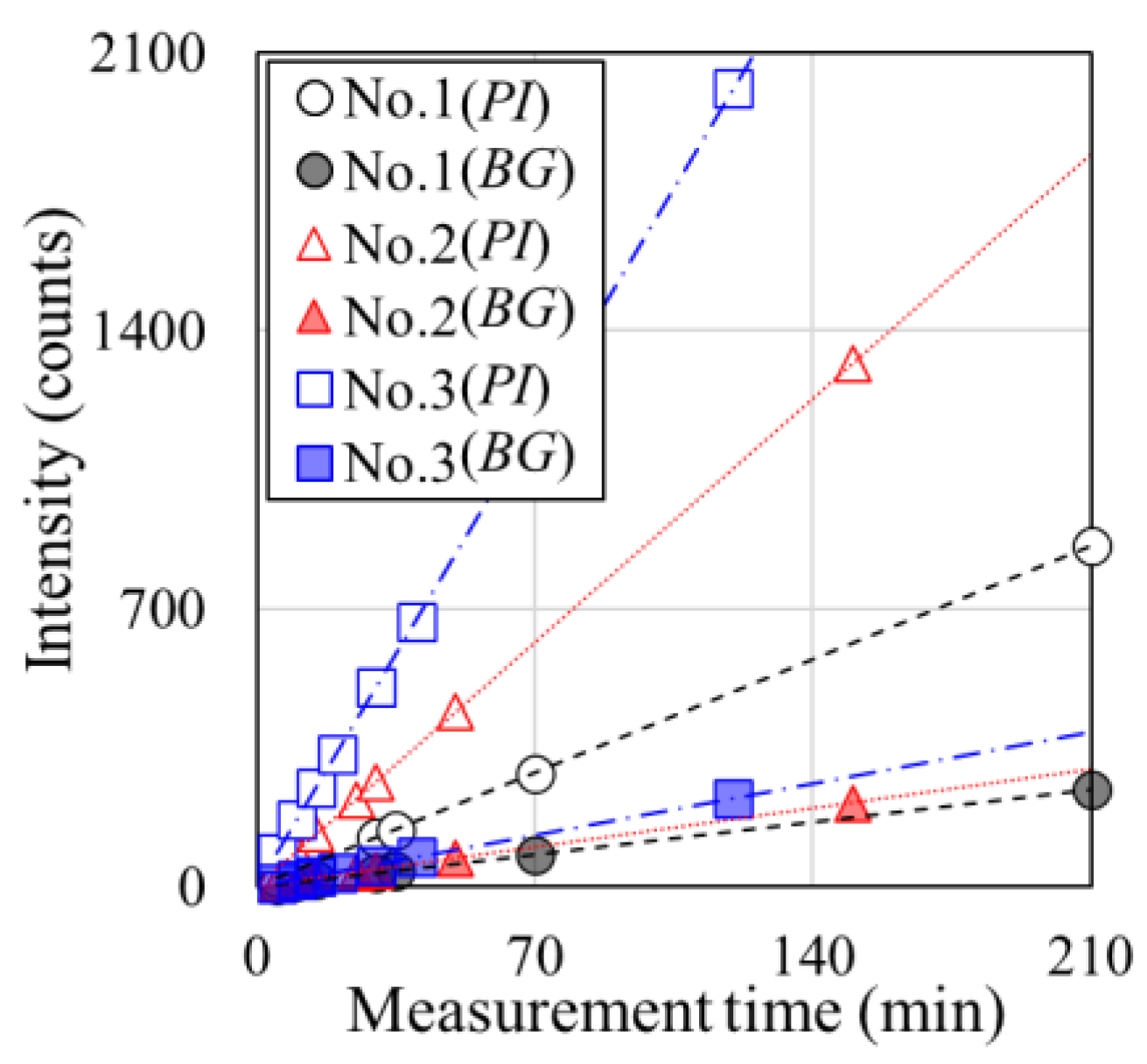

4.1. Effects of Different Factors on Diffraction Intensity

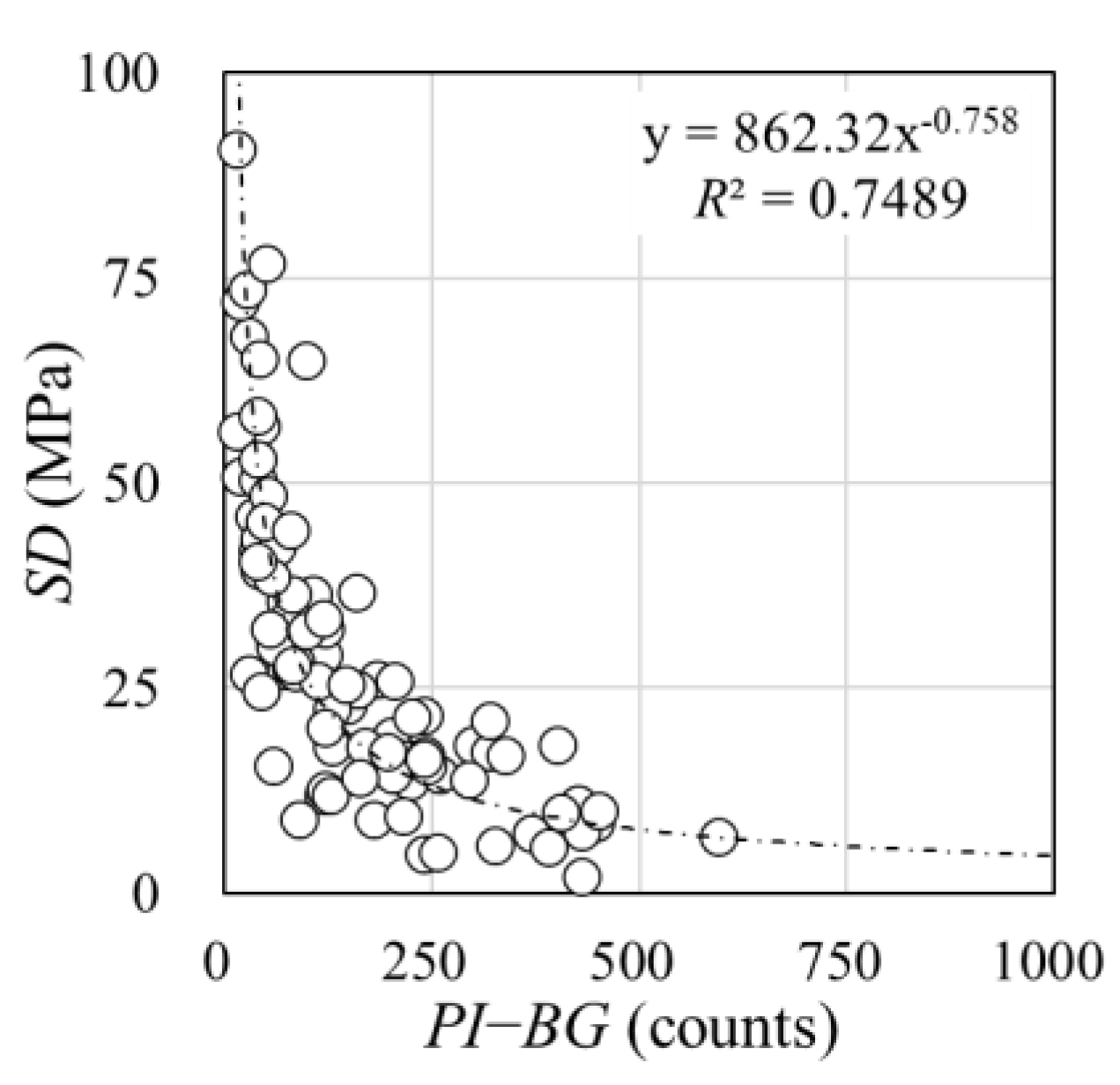

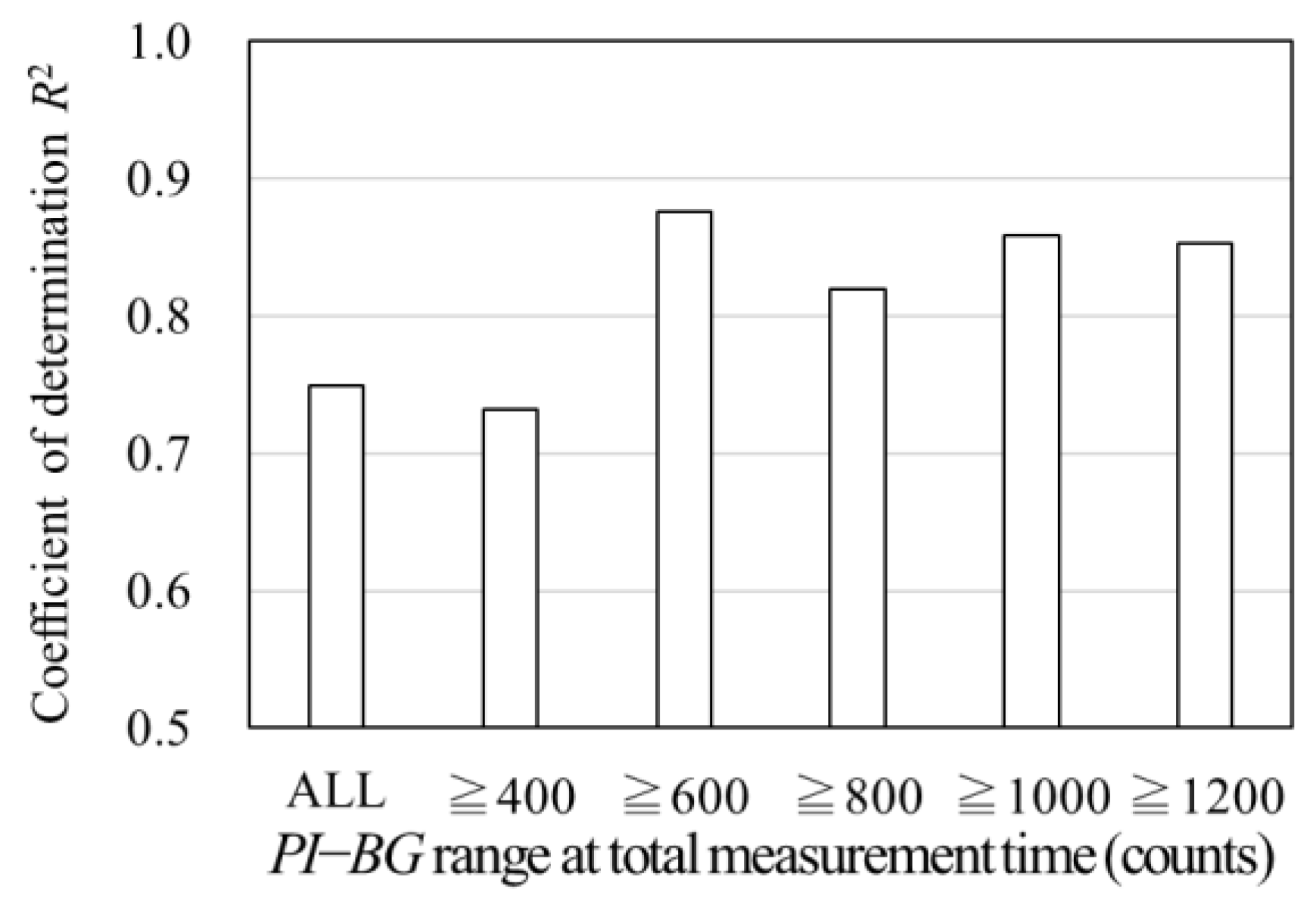

4.2. Effect of Diffraction Intensity on Accuracy

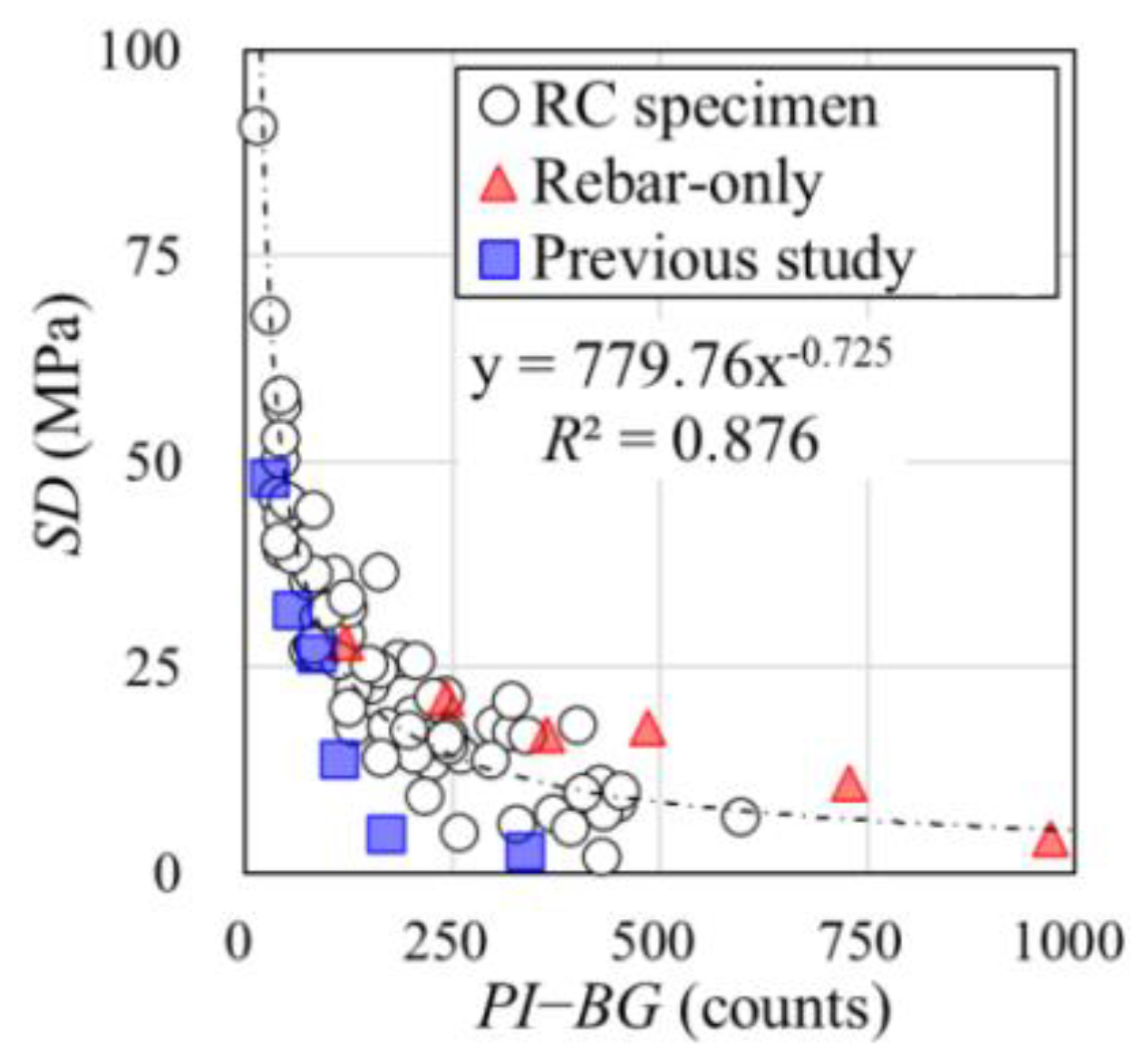

4.3. Measurement Accuracy Verification

5. Conclusions

- The increase in diffraction intensity with increasing measurement time is more significant because of the installation of aluminum slits and decreasing cover thickness, resulting in decreased hardened cement and water contents in the neutron transmission path.

- For specimens where the increase in diffraction intensity with an increase in measurement time is significant, the measurement accuracy tends to be high in short-time measurements.

- Under the conditions of this experiment, the analytical results tend to be stable when PI−BG > 600 counts.

- The SD of the rebar stress decreases as PI−BG increases, and the relationship between the two values is expressed by a power approximation equation.

- By calculating the required measurement time from the SD of the rebar stress following the procedure in Figure 16, it is possible to ensure the reproducibility and reliability of the rebar stress even for reinforced concrete specimens with different measurement conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nilson, A.H. Internal Measurement of Bond Slip. ACI J. Proc. 1972, 69, 439–441. [Google Scholar] [CrossRef]

- McHenry, D.E.; Walker, W.T. Laboratory Measurements of Stress Distribution in Reinforcing Steel. ACI J. Proc. 1948, 44, 1041–1054. [Google Scholar] [CrossRef]

- Shima, H.; Chou, L.L.; Okamura, H. Micro and Macro Models for Bond in Reinforced Concrete. J. Fac. Eng. Univ. Tokyo 1987, 39, 133–194. [Google Scholar]

- Suzuki, H.; Kanematsu, M.; Kusunoki, K. Neutron Diffraction Studies on Strain Evaluation of Rebar in Reinforced Concrete. Powder Diffr. 2009, 24, S68–S71. [Google Scholar] [CrossRef]

- Suzuki, H.; Kusunoki, K.; Hatanaka, Y.; Mukai, T.; Tasai, A.; Kanematsu, M.; Kabayama, K.; Harjo, S. Measuring Strain and Stress Distributions Along Rebar Embedded in Concrete Using Time-of-Flight Neutron Diffraction. Meas. Sci. Technol. 2014, 25, 025602. [Google Scholar] [CrossRef]

- Suzuki, H.; Kusunoki, K.; Kanematsu, M.; Tasai, A.; Hatanaka, Y.; Tsuchiya, N.; Bea, S.; Shiroishi, S.; Sakurai, S.; Kawasaki, T.; et al. Application of Neutron Stress Measurement to Reinforced Concrete Structure. In Proceedings of the 2nd International Symposium on Science at J-PARC, Ibaraki, Japan, 12–15 July 2014. [Google Scholar] [CrossRef]

- Suzuki, H.; Kusunoki, K.; Kanematsu, M.; Mukai, T.; Harjo, S. Structural Engineering Studies on Reinforced Concrete Structure Using Neutron Diffraction. In Proceedings of the International Conference on Residual Stresses (ICRS) 2016, Sydney, Australia, 3–7 July 2016. [Google Scholar] [CrossRef]

- Kobayashi, K.; Suzuki, H.; Nishio, Y.; Kanematsu, M. Evaluation of Bond Performance of Reinforced Concrete Using Hot-Dip Galvanized Rebar by Neutron Diffraction. J. Struct. Constr. Eng. AIJ 2021, 86, 1026–1035. (In Japanese) [Google Scholar] [CrossRef]

- Kusunoki, K.; Kabayama, K.; Mukai, T.; Hatanaka, Y. Experimental Study on Bonding Action with Neutron Measuring System. Proc. JCI 2009, 31, 619–624. Available online: https://data.jci-net.or.jp/data_pdf/31/031-01-2104.pdf (accessed on 8 February 2023). (In Japanese).

- Kanematsu, M.; Ota, T.; Suzuki, Y.; Noguchi, T. Neutron Diffraction Studies on Strain Evaluation of Rebar Around Cracks. Proc. JCI 2011, 33, 1853–1858. Available online: https://data.jci-net.or.jp/data_pdf/33/033-01-1303.pdf (accessed on 8 February 2023). (In Japanese).

- Lin, Y.; Leong, B.S.; Hu, Z.-T.; Yang, E.-H. Autoclaved Aerated Concrete Incorporating Waste Aluminum Dust as Foaming Agent. Constr. Build. Mater. 2017, 148, 140–147. [Google Scholar] [CrossRef]

- Tanaka, K.; Akiniwa, Y.; Hayashi, M. Neutron Diffraction Measurements of Residual Stresses in Engineering Materials and Components. Mater. Sci. Res. Int. 2002, 8, 165–174. [Google Scholar] [CrossRef] [PubMed]

- Kanematsu, M.; Maruyama, I.; Noguchi, T.; Tsuchiya, N. Quantification of Water Penetration into Concrete through Cracks by Neutron Radiography. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2009, 605, 154–158. [Google Scholar] [CrossRef]

- Perfect, E.; Cheng, C.-L.; Kang, M.; Bilheux, H.Z.; Lamanna, J.M.; Gragg, M.J.; Wright, D.M. Neutron Imaging of Hydrogen-Rich Fluids in Geomaterials and Engineered Porous Media: A review. Earth-Sci. Rev. 2014, 129, 120–135. [Google Scholar] [CrossRef]

- Kobayashi, K.; Yasue, A.; Kim, J.; Nishio, Y.; Miyazu, Y.; Mukai, T.; Kanematsu, M. The Effect on the Measurement Time of Neutron Diffraction Method on the Accuracy of Measuring Rebar Stress. In Proceedings of the Summaries of Technical Papers of Annual Meeting, AIJ, Materials and Construction, Hokkaido, Japan, 5–9 September 2022. (In Japanese). [Google Scholar]

| Materials | Types and Properties |

|---|---|

| Water (W) | Deionized water |

| Cement (C) | High early-strength Portland cement. Density: 3.14 g/cm3 |

| Fine aggregate (S) | Land sand from the Oi river. Absolute dry density: 2.58 g/cm3 |

| Coarse aggregate (G) | Crushed stone from Ome. Maximum particle size: 10 mm Absolute dry density: 2.66 g/cm3 |

| Chemical admixture (Ad) | Lignin sulfonate, oxycarboxylate, and polycarboxylic acid compounds |

| W/C (%) | Unit Weight (kg/m3) | Ad (g) | Slump * (cm) | Air (%) | fc (Test Day *) (MPa) | Ec (Test Day *) (GPa) | fc (28 Days *) (MPa) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| W | C | S | G | |||||||

| 60 | 175 | 294 | 850 | 950 | C × 1.7% | 19.6 | 4.7 | 39.4 | 23.8 | 41.1 |

| Series | Parameters |

|---|---|

| Series 1: Cross-sectional shape of the neutron path | No. 1, No. 2, No. 3 (as shown in Figure 1.) |

| Series 2: Measurement position (mm) (No. 1, No. 2, No. 3) | 10, 40, 70, 100, 130 (as shown in Figure 1.) |

| Series 3: Cover thickness (mm) | 19.0 (No. 4), 21.5 (No. 2), 27.0 (No. 5) |

| Specimen No. | Measurement Time (min) |

|---|---|

| No. 1 | 210 (5 × 42 times) [10, 40, 70, 100 mm] |

| No. 2 | 150 (5 × 30 times) [10, 40, 70, 100, 130 mm] |

| No. 3 | 120 (5 × 24 times) [10, 40, 70, 100, 130 mm] |

| No. 4 | 120 (5 × 24 times) [10 mm] |

| No. 5 | 180 (5 × 36 times) [10 mm] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yasue, A.; Kawakami, M.; Kobayashi, K.; Kim, J.; Miyazu, Y.; Nishio, Y.; Mukai, T.; Morooka, S.; Kanematsu, M. Accuracy of Measuring Rebar Strain in Concrete Using a Diffractometer for Residual Stress Analysis. Quantum Beam Sci. 2023, 7, 15. https://doi.org/10.3390/qubs7020015

Yasue A, Kawakami M, Kobayashi K, Kim J, Miyazu Y, Nishio Y, Mukai T, Morooka S, Kanematsu M. Accuracy of Measuring Rebar Strain in Concrete Using a Diffractometer for Residual Stress Analysis. Quantum Beam Science. 2023; 7(2):15. https://doi.org/10.3390/qubs7020015

Chicago/Turabian StyleYasue, Ayumu, Mayu Kawakami, Kensuke Kobayashi, Junho Kim, Yuji Miyazu, Yuhei Nishio, Tomohisa Mukai, Satoshi Morooka, and Manabu Kanematsu. 2023. "Accuracy of Measuring Rebar Strain in Concrete Using a Diffractometer for Residual Stress Analysis" Quantum Beam Science 7, no. 2: 15. https://doi.org/10.3390/qubs7020015

APA StyleYasue, A., Kawakami, M., Kobayashi, K., Kim, J., Miyazu, Y., Nishio, Y., Mukai, T., Morooka, S., & Kanematsu, M. (2023). Accuracy of Measuring Rebar Strain in Concrete Using a Diffractometer for Residual Stress Analysis. Quantum Beam Science, 7(2), 15. https://doi.org/10.3390/qubs7020015