Development of Hydrogen-Permselective Porous Membranes Using Radiation-Induced Graft Polymerization

Abstract

:1. Introduction

2. Materials and Methods

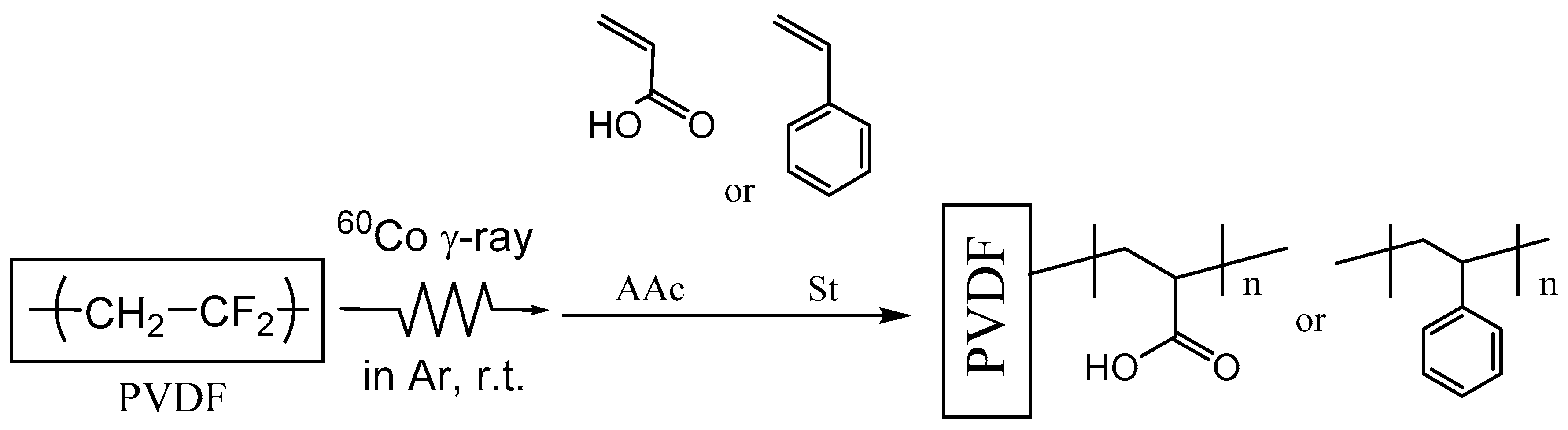

2.1. Sample Synthesis

2.2. Heat-Compression Molding

2.3. Porosity

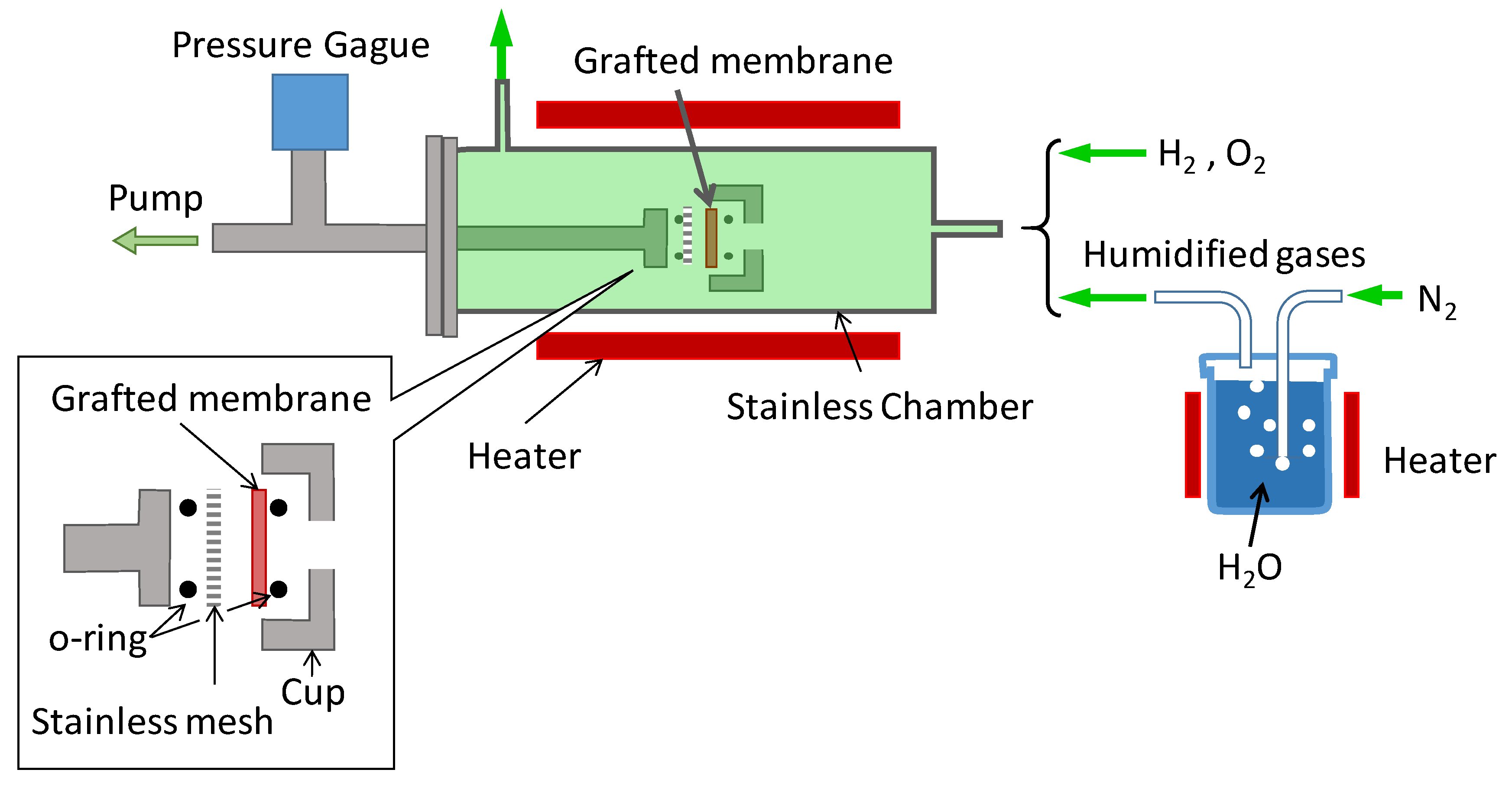

2.4. Gas Permeation Test

3. Results and Discussion

3.1. Synthesis

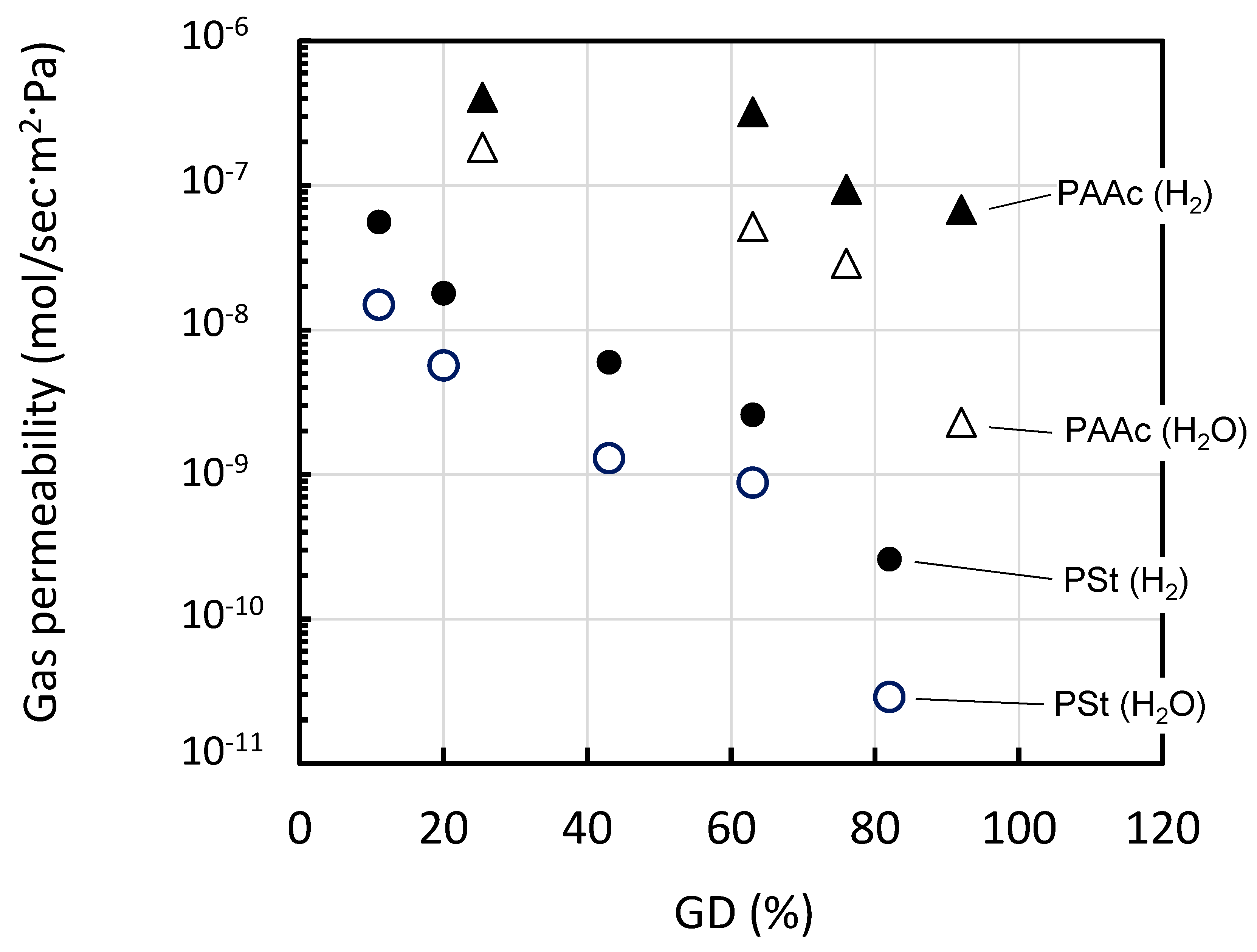

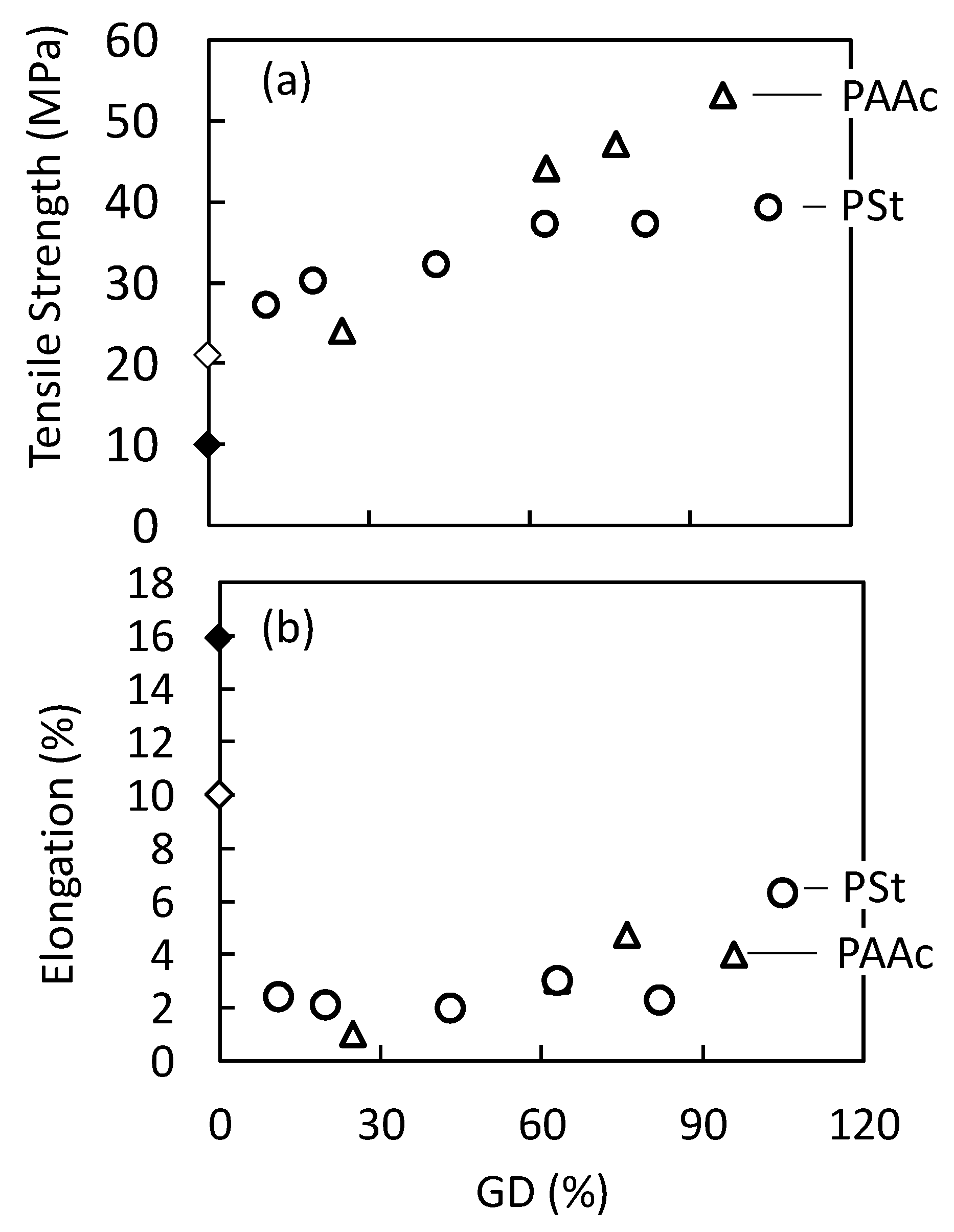

3.2. Gas Permeation Property

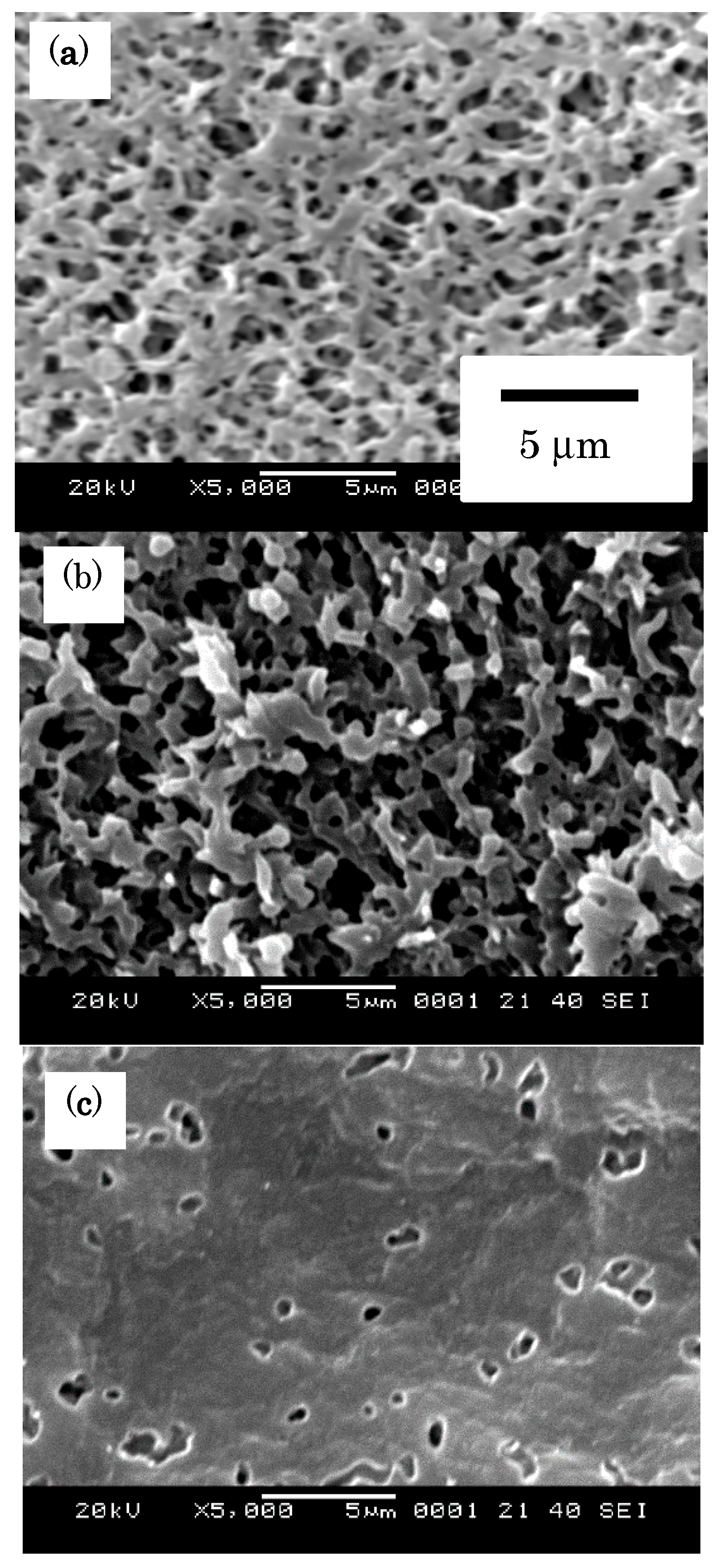

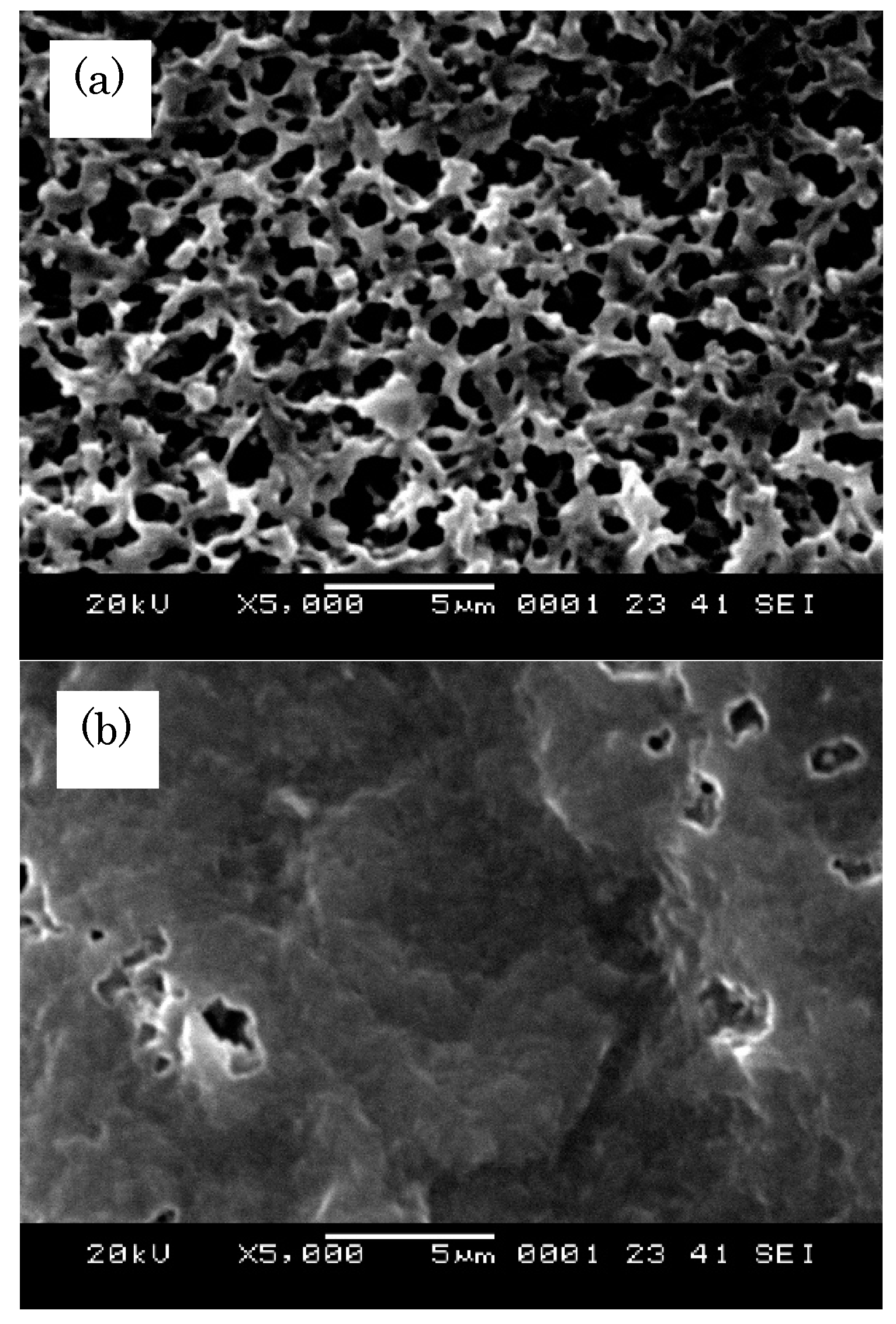

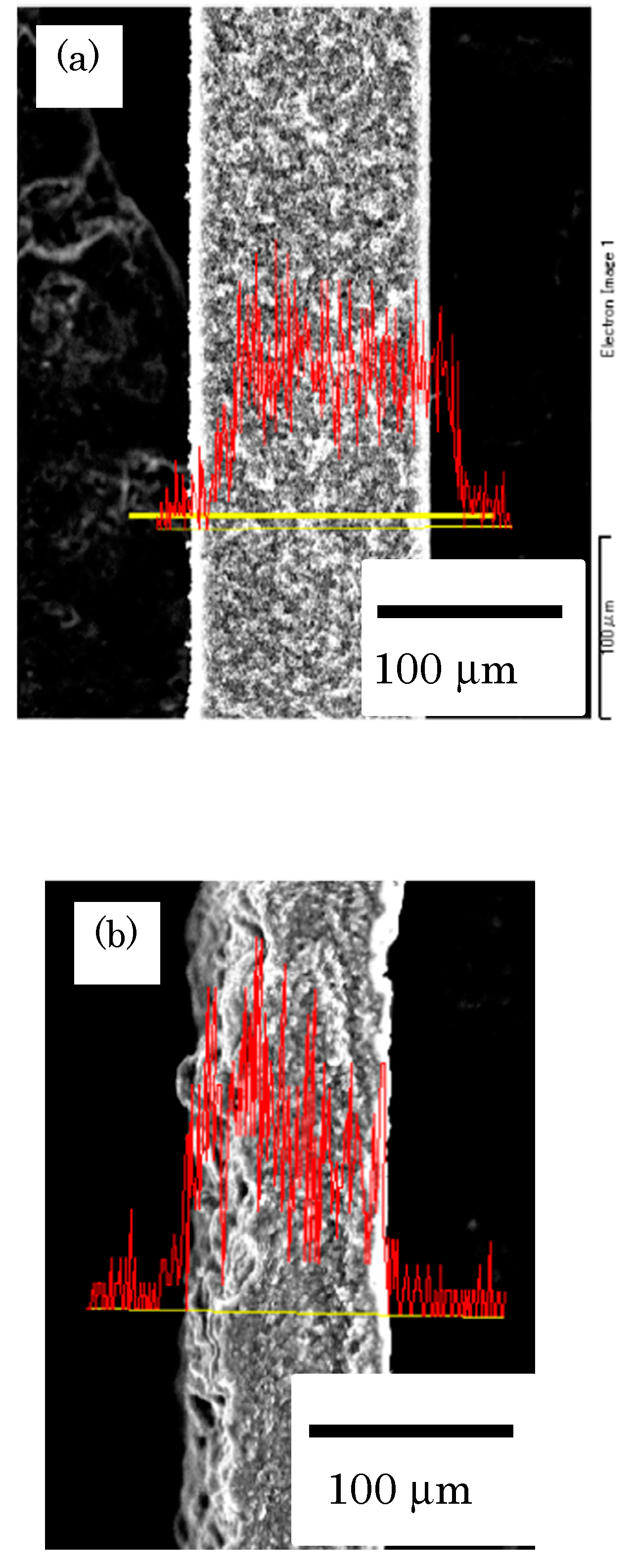

3.3. Structure and Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Prime Minister of Japan and His Cabinet. Report of Japanese Government to the IAEA Ministerial Conference on Nuclear Safety–The Accident at TEPCO’s Fukushima Nuclear Power Stations; Government of Japan: Tokyo, Japan, 2011.

- Bachellerie, F.; Arnould, F.; Auglaire, M.; Boeck, B.D.; Braillard, O.; Eckardt, B.; Ferroni, F.; Moffett, R. Generic approach for designing and implementing a passive autocatalytic recombiner PAR-system in nuclear power plant containments. Nucl. Eng. Design 2003, 221, 151–165. [Google Scholar] [CrossRef]

- Gharari, R.; Kazeminejad, H.; Kojouri, N.M.; Hedayat, A. A review on hydrogen generation, explosion, and mitigation during severe accidents in light water nuclear reactors. Int. J. Hydrog. Energy 2018, 43, 1939–1965. [Google Scholar] [CrossRef]

- Lee, C.H.; Nakagawa, Y.; Isobe, S.; Hashimoto, N.; Sugino, S.; Miyaoka, H.; Ichikawa, T. Synthesis of sodium-magnesium amidoborane by sodium amide: An investigation of functional properties for hydrogen/ammonia storage. J. Alloy. Compd. 2019, 801, 645–650. [Google Scholar] [CrossRef]

- Escolastico, S.; Solis, C.; Kjølseth, C.; Serra, J.M. Outstanding hydrogen permeation through CO2-stable dual-phase ceramic membranes. Energy Environ. Sci. 2014, 7, 3736–3746. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Tan, X.Y.; Li, K. Mixed conducting ceramics for catalytic membrane processing. Catal. Rev.-Sci. Eng. 2006, 48, 145–198. [Google Scholar] [CrossRef]

- Luo, S.J.; Stevens, K.A.; Park, J.S.; Moon, J.D.; Liu, Q.; Freeman, B.D.; Guo, R. Highly CO2-Selective Gas Separation Membranes Based on Segmented Copolymers of Poly(Ethylene oxide) Reinforced with Pentiptycene-Containing Polyimide Hard Segments. ACS Appl. Mater. Interfaces 2016, 8, 2306–2317. [Google Scholar] [CrossRef] [PubMed]

- Takamura, H. Oxygen Permeable Ceramics. J. Surf. Finish. Soc. Jpn. 2005, 56, 491–496. [Google Scholar] [CrossRef]

- Seko, N.; Tamada, M.; Yoshii, F. Current status of adsorbent for metal ions with radiation grafting and crosslinking techniques. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms 2005, 236, 21–29. [Google Scholar] [CrossRef]

- Kavakli, P.A.; Seko, N.; Tamada, M.; Güven, O. Adsorption efficiency of a new adsorbent towards uranium and vanadium ions at low concentrations. Sep. Sci. Technol. 2004, 39, 1631–1643. [Google Scholar] [CrossRef]

- Fukaya, A.; Tateno, A.; Iimura, N.; Ohta, Y.; Takahashi, K.; Sodekoda, T.; Suzuki, K.; Takahashi, H.; Hasegawa, S.; Hiroki, A.; et al. Application of graft-type poly(ether ether ketone)-based polymer electrolyte membranes to electrochemical devices—Fuel cells and electrolytic enrichment of tritium. Int. J. Hydrog. Energy 2018, 43, 8927–8935. [Google Scholar]

- Sawada, S.; Yasukawa, M.; Koshikawa, H.; Kitamura, A.; Higa, M.; Yamaki, T. Development of Cation and Anion Exchange Membranes for Saline Water Concentration using High-energy Heavy-ion Beams. Bull. Soc. Sea Water Sci. Jpn. 2019, 73, 208–216. [Google Scholar]

- Hasegawa, S.; Takahashi, S.; Iwase, H.; Koizumi, S.; Ohnuma, M.; Maekawa, Y. Crystal morphology-dependent graft polymerization in poly(ether ether ketone) films. Polymer 2013, 54, 2895–2900. [Google Scholar] [CrossRef]

- Nagatani, T.; Sasaki, T.; Saito, K. Production of Polyethylene-Based Ion-Exchange Membranes for Electrodialysis of Seawater by Electron Beam-Induced Graft Polymerization (I) Cation-Exchange Membranes. Bull. Soc. Sea Water Sci. 2017, 71, 300–307. [Google Scholar]

- Yamaguchi, T.; Suzuki, T.; Kai, T.; Nakao, S.I. Hollow-fiber-type pore-filling membranes made by plasma-graft polymerization for the removal of chlorinated organics from water. J. Membr. Sci. 2001, 194, 217–228. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Miyata, F.; Nakao, S.I. Pore-filling type polymer electrolyte membranes for a direct methanol fuel cell. J. Membr. Sci. 2003, 214, 283–292. [Google Scholar] [CrossRef]

- Masuelli, M.A.; Grasselli, M.; Marchese, J.; Ochoa, N.A. Preparation, structural and functional characterization of modified porous PVDF membranes by gamma-irradiation. J. Membr. Sci. 2012, 389, 91–98. [Google Scholar] [CrossRef]

- Sui, Y.; Gao, X.; Wang, Z.; Gao, C. Antifouling and antibacterial improvement of surface-functionalized poly(vinylidene fluoride) membrane prepared via dihydroxyphenylalanine-initiated atom transfer radical graft polymerizations. J. Membr. Sci. 2012, 394, 107–119. [Google Scholar] [CrossRef]

- Betz, N.; Begue, J.; Goncalves, M.; Gionnet, K.; Deleris, G.; Le Moel, A. Functionalisation of PAA radiation grafted PVDF. Nucl. Instrum. Methods Phys. Res. Sect. B-Beam Interact. Mater. Atoms 2003, 208, 434–441. [Google Scholar] [CrossRef]

- Golcuk, S.; Muftuoglu, A.E.; Celik, S.U.; Bozkurt, A. Synthesis and characterization of polymer electrolyte membranes based on PVDF and styrene via photoinduced grafting. J. Polym. Res. 2013, 20, 144. [Google Scholar] [CrossRef]

- Lin, D.J.; Lin, D.T.; Young, T.H.; Huang, F.M.; Chen, C.C.; Cheng, L.P. Immobilization of heparin on PVDF membranes with microporous structures. J. Membr. Sci. 2004, 245, 137–146. [Google Scholar] [CrossRef]

- Hegazy, E.S.A.; Ishigaki, I.; Okamoto, J. Radiation grafting of acrylic-acid onto fluorine-containing polymers. 1. Kinetic-study of pre-irradiation grafting onto poly(tetrafluoroethylene). J. Appl. Polym. Sci. 1981, 26, 3117–3124. [Google Scholar] [CrossRef]

- Ishigaki, I.; Sugo, T.; Senoo, K.; Okada, T.; Okamoto, J.; Machi, S. Graft-polymerization of acrylic-acid onto polyethylene film by pre-irradiation method. 1. Effects of pre-irradiation dose, monomer concentration, reaction temperature, and film thickness. J. Appl. Polym. Sci. 1982, 27, 1033–1041. [Google Scholar] [CrossRef]

- Wach, R.A.; Sugimoto, M.; Idesaki, A.; Yoshikawa, M. Molecular sieve SiC-based membrane for hydrogen separation produced by radiation curing of preceramic polymers. Mater. Sci. Eng. B 2007, 140, 81–89. [Google Scholar] [CrossRef]

- McNeill, I.C.; Sadeghi, S.M.T. Thermal-stability and degradation mechanisms of poly(acrylic acid) and its salts. 1. poly(acrylic acid). Polym. Degrad. Stab. 1990, 29, 233–246. [Google Scholar] [CrossRef]

- Hasegawa, S.; Takahashi, S.; Iwase, H.; Koizumi, S.; Morishita, N.; Sato, K.; Narita, T.; Ohnuma, M.; Maekawa, Y. Radiation-induced graft polymerization of functional monomer into poly(ether ether ketone) film and structure-property analysis of the grafted membrane. Polymer 2011, 52, 98–106. [Google Scholar] [CrossRef]

- Seleem, S.; Hopkins, M.; Olivio, J.; Schiraldi, D.A. Comparison of Thermal Decomposition of Polystyrene Products vs. Bio-Based Polymer Aerogels. Ohio J. Sci. 2017, 117, 50–60. [Google Scholar]

- Iwata, H.; Matsuda, T. Preparation and properties of novel environment-sensitive membranes prepared by graft-polymerization onto a porous membrane. J. Membr. Sci. 1988, 38, 185–199. [Google Scholar] [CrossRef]

- Barona, G.N.B.; Cha, B.J.; Jung, B. Negatively charged poly(vinylidene fluoride) microfiltration membranes by sulfonation. J. Membr. Sci. 2007, 290, 46–54. [Google Scholar] [CrossRef]

| Graft Chains | Monomer Solutions | Dose (kGy) | Reaction Temp (°C) | Reaction Time (h) | GD (%) | Porosity (%) | Porosity after Heat Compression (%) *1 |

|---|---|---|---|---|---|---|---|

| Substrate (PVDF) | - | - | - | - | 0 | 61 | - |

| Poly (AAc) | AAc/H2O (10:90 wt%) *2 | 160 | 30 | 1 | 25 | 60 | 36 |

| AAc/H2O (20:80 wt%) *2 | 160 | 30 | 1 | 63 | 61 | 26 | |

| AAc/H2O (70:30 wt%) *2 | 160 | 30 | 0.1 | 76 | 61 | 39 | |

| AAc/H2O (70:30 wt%) *2 | 160 | 30 | 0.2 | 92 | 61 | 36 | |

| Poly (St) | St/Toluene (50:50 wt%) | 30 | 60 | 1 | 11 | 60 | 48 |

| St/Toluene (50:50 wt%) | 30 | 60 | 7 | 20 | 58 | 44 | |

| St/Toluene (90:10 wt%) | 30 | 50 | 1 | 43 | 53 | 33 | |

| St/Toluene (50:50 wt%) | 30 | 60 | 4 | 63 | 54 | 44 | |

| St/Toluene (50:50 wt%) | 30 | 60 | 4 | 82 | 54 | 44 |

| Grafted Chains | GD (%) | Porosity (%) | Gas Permeability (×10−8 mol/sec·m2·Pa) | R(H2/N2) | R(H2/H2O) | ||

|---|---|---|---|---|---|---|---|

| H2 | N2 | H2O | |||||

| AAc | 25 | 36 | 41 | 20 | 18 | 2.1 | 2.3 |

| 63 | 26 | 32 | 15 | 5.2 | 2.1 | 6.2 | |

| 76 | 39 | 9.4 | 3.2 | 2.9 | 2.9 | 3.2 | |

| 92 | 36 | 6.8 | 2.3 | 0.2 | 3.0 | 34 | |

| St | 11 | 48 | 5.6 | 3.7 | 1.5 | 2.5 | 3.7 |

| 20 | 44 | 1.8 | 0.55 | 0.6 | 3.3 | 3.0 | |

| 43 | 33 | 0.6 | 0.13 | 0.1 | 4.6 | 6.0 | |

| 63 | 44 | 0.3 | 0.14 | 0.09 | 2.1 | 3.0 | |

| 82 | 44 | 0.03 | 0.40 | 0.003 | 2.5 | 9.0 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hasegawa, S.; Sawada, S.; Azami, S.; Hagiwara, T.; Hiroki, A.; Maekawa, Y. Development of Hydrogen-Permselective Porous Membranes Using Radiation-Induced Graft Polymerization. Quantum Beam Sci. 2020, 4, 23. https://doi.org/10.3390/qubs4020023

Hasegawa S, Sawada S, Azami S, Hagiwara T, Hiroki A, Maekawa Y. Development of Hydrogen-Permselective Porous Membranes Using Radiation-Induced Graft Polymerization. Quantum Beam Science. 2020; 4(2):23. https://doi.org/10.3390/qubs4020023

Chicago/Turabian StyleHasegawa, Shin, Shinichi Sawada, Shinya Azami, Tokio Hagiwara, Akihiro Hiroki, and Yasunari Maekawa. 2020. "Development of Hydrogen-Permselective Porous Membranes Using Radiation-Induced Graft Polymerization" Quantum Beam Science 4, no. 2: 23. https://doi.org/10.3390/qubs4020023

APA StyleHasegawa, S., Sawada, S., Azami, S., Hagiwara, T., Hiroki, A., & Maekawa, Y. (2020). Development of Hydrogen-Permselective Porous Membranes Using Radiation-Induced Graft Polymerization. Quantum Beam Science, 4(2), 23. https://doi.org/10.3390/qubs4020023