Applications of Microbeams Produced by Tapered Glass Capillary Optics

Abstract

1. Introduction

2. Transmission Mechanism of Ion Beams through Insulator Capillaries

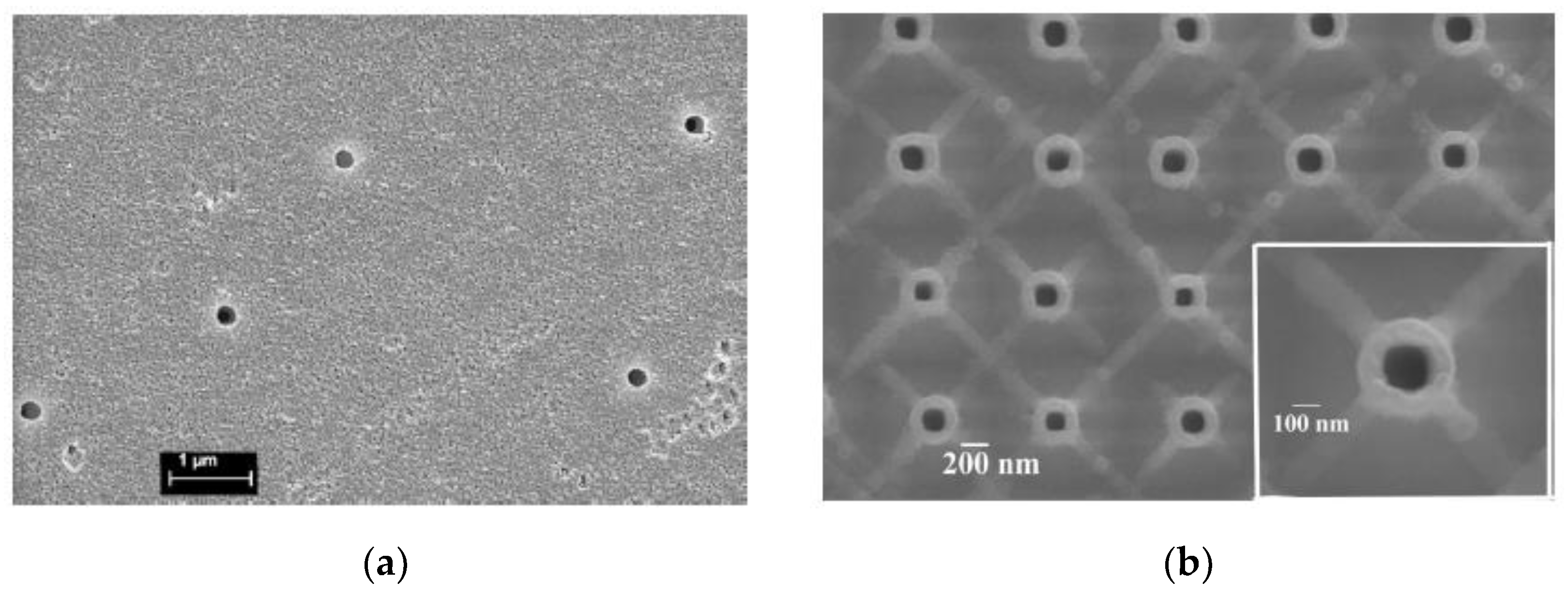

2.1. Various Capillary Shapes

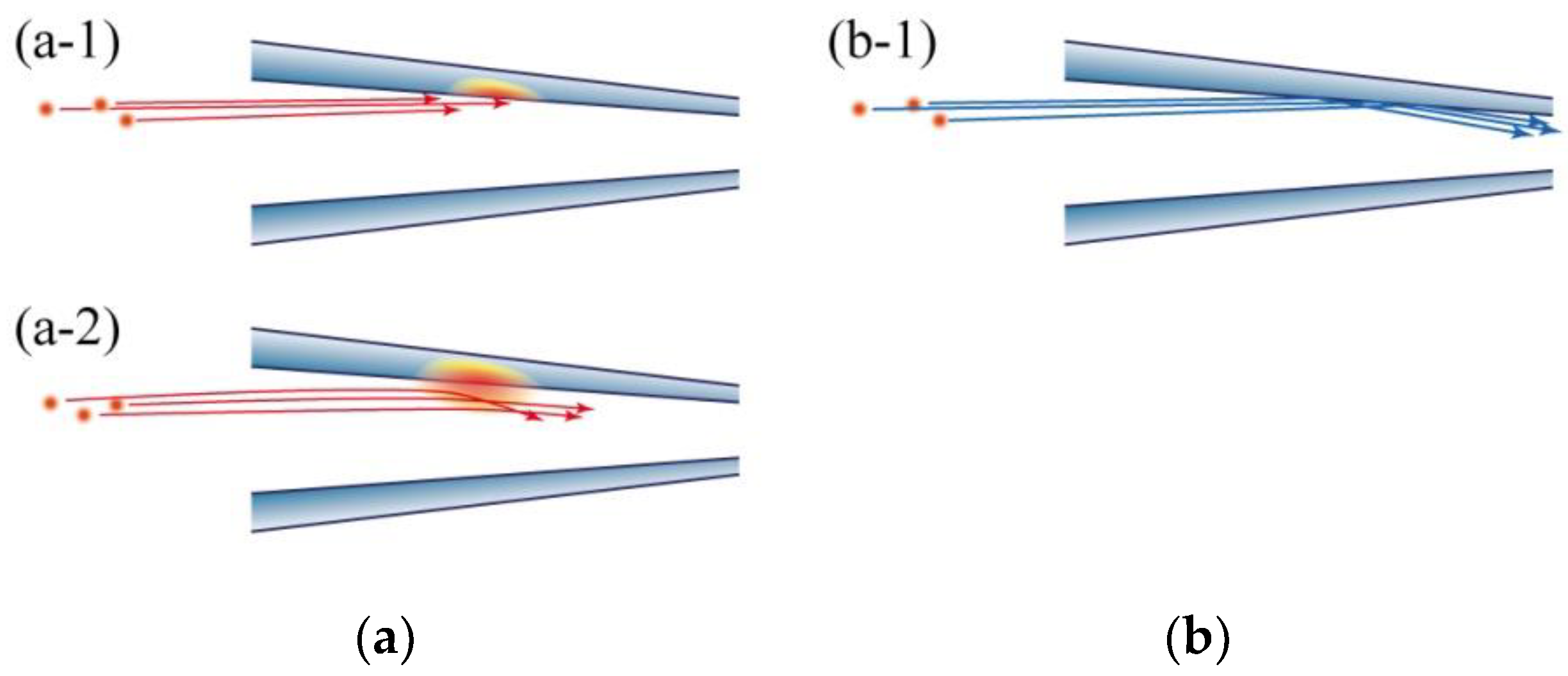

2.2. Difference in Transmission Mechanism between keV and MeV Ions

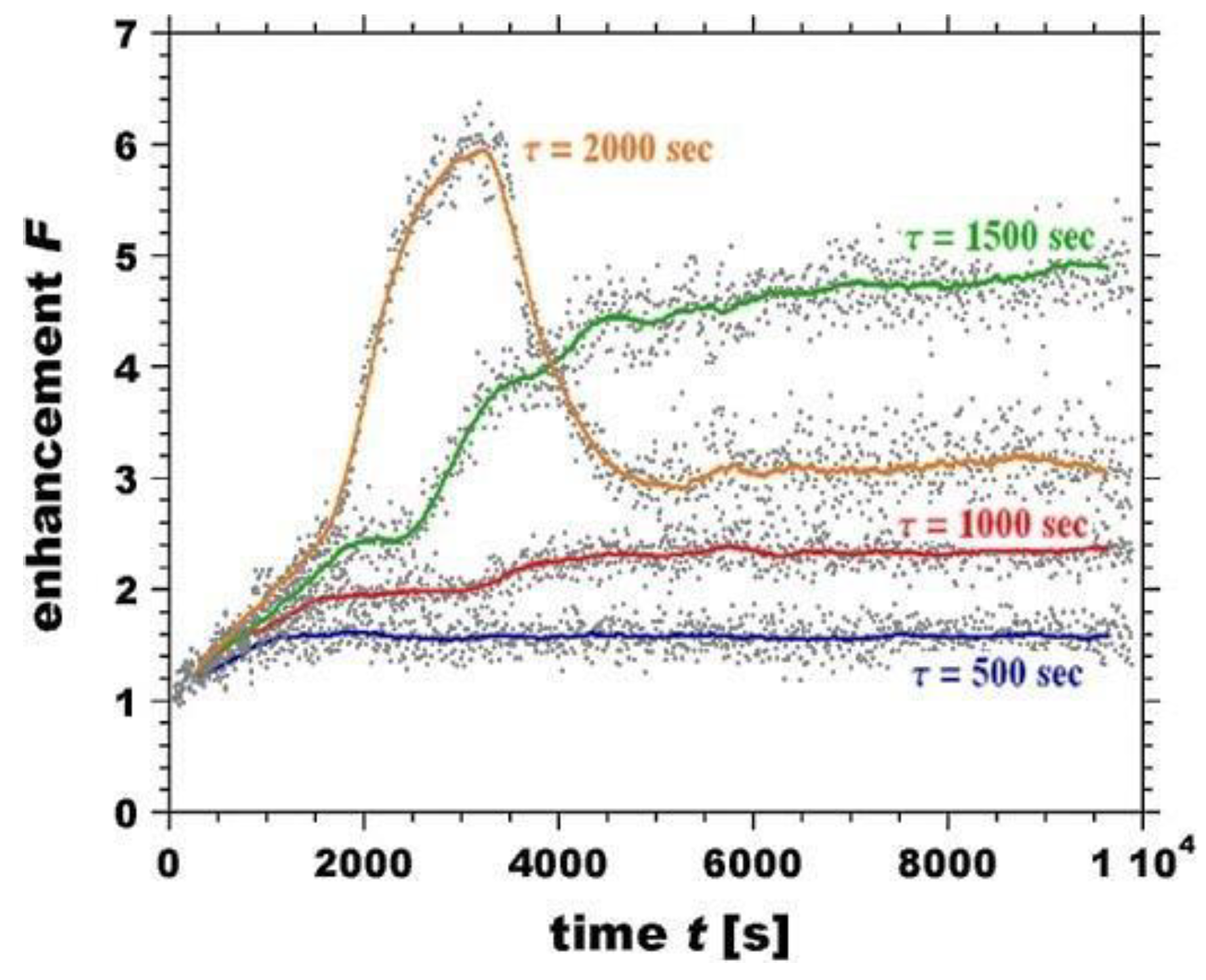

2.3. The First Report of Delayed Transmission and Beam Guiding

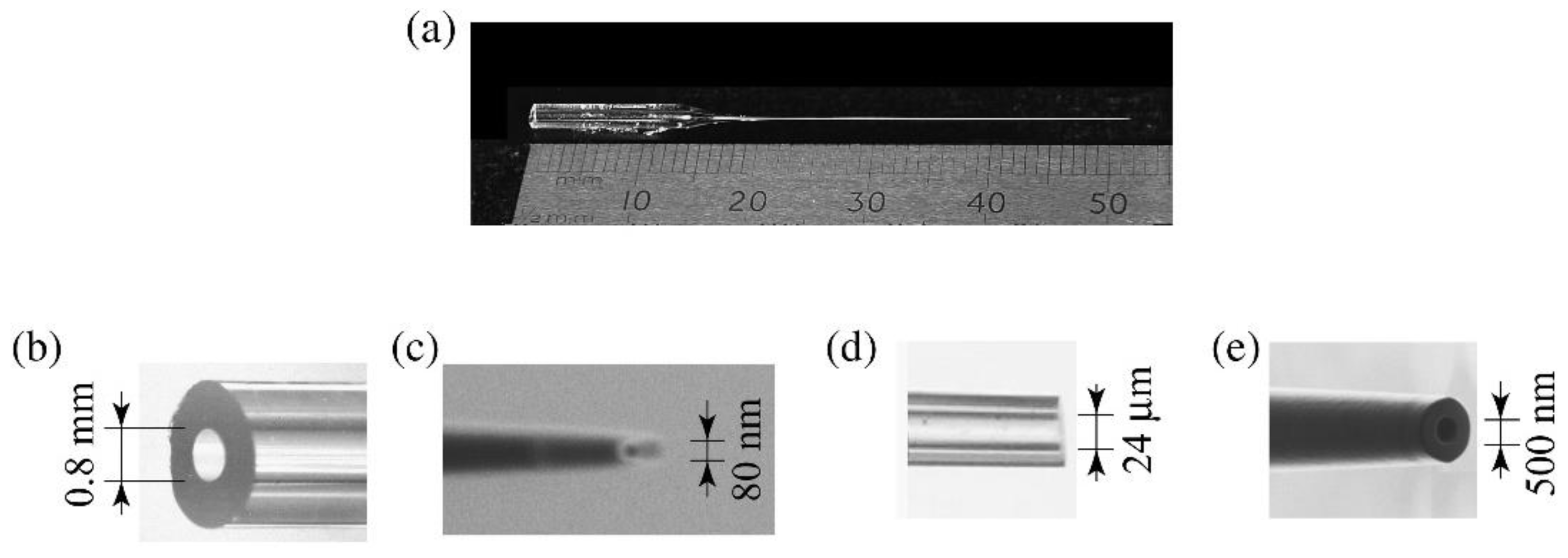

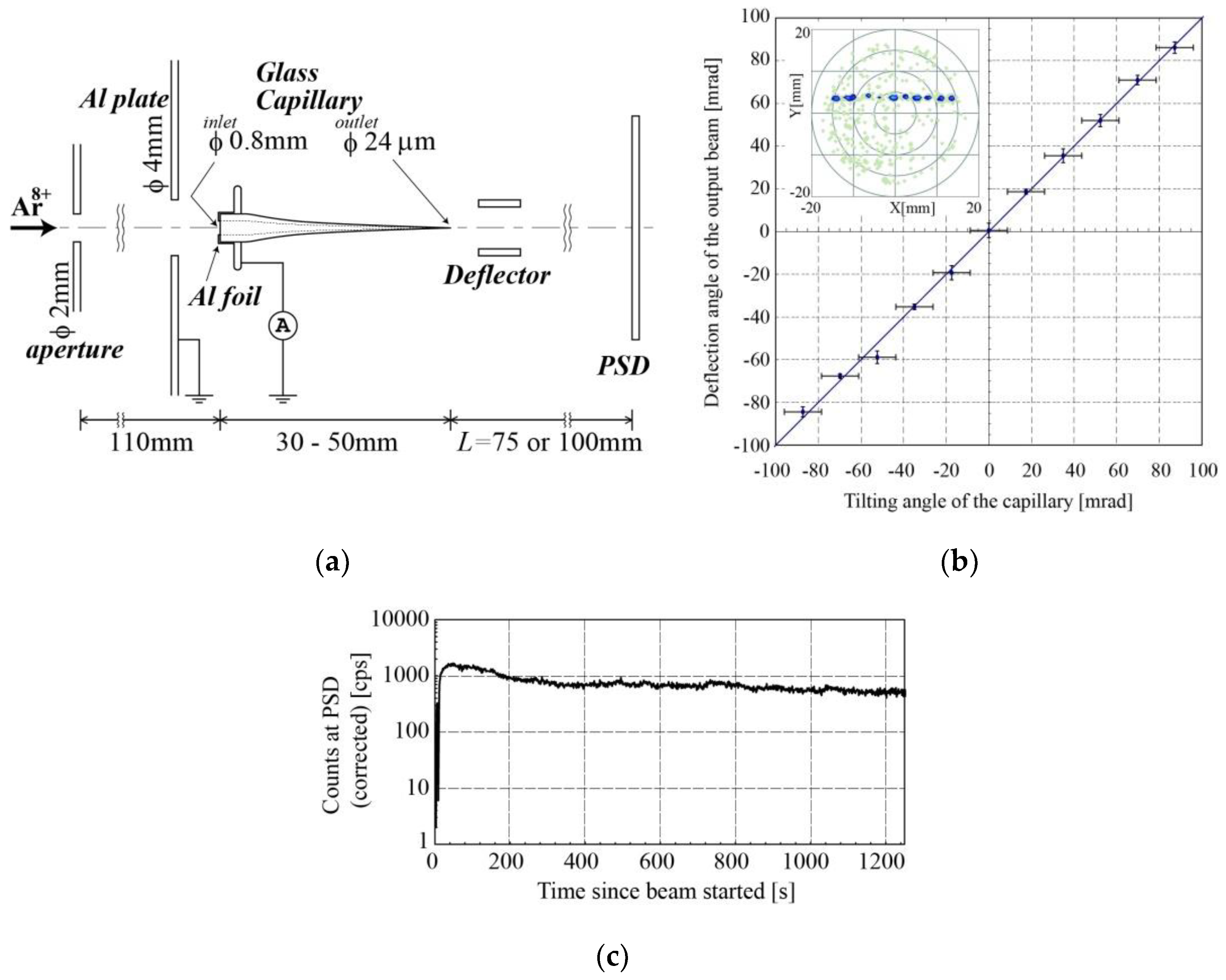

2.4. The First Demonstration of an Easy Production Method of a Microbeam

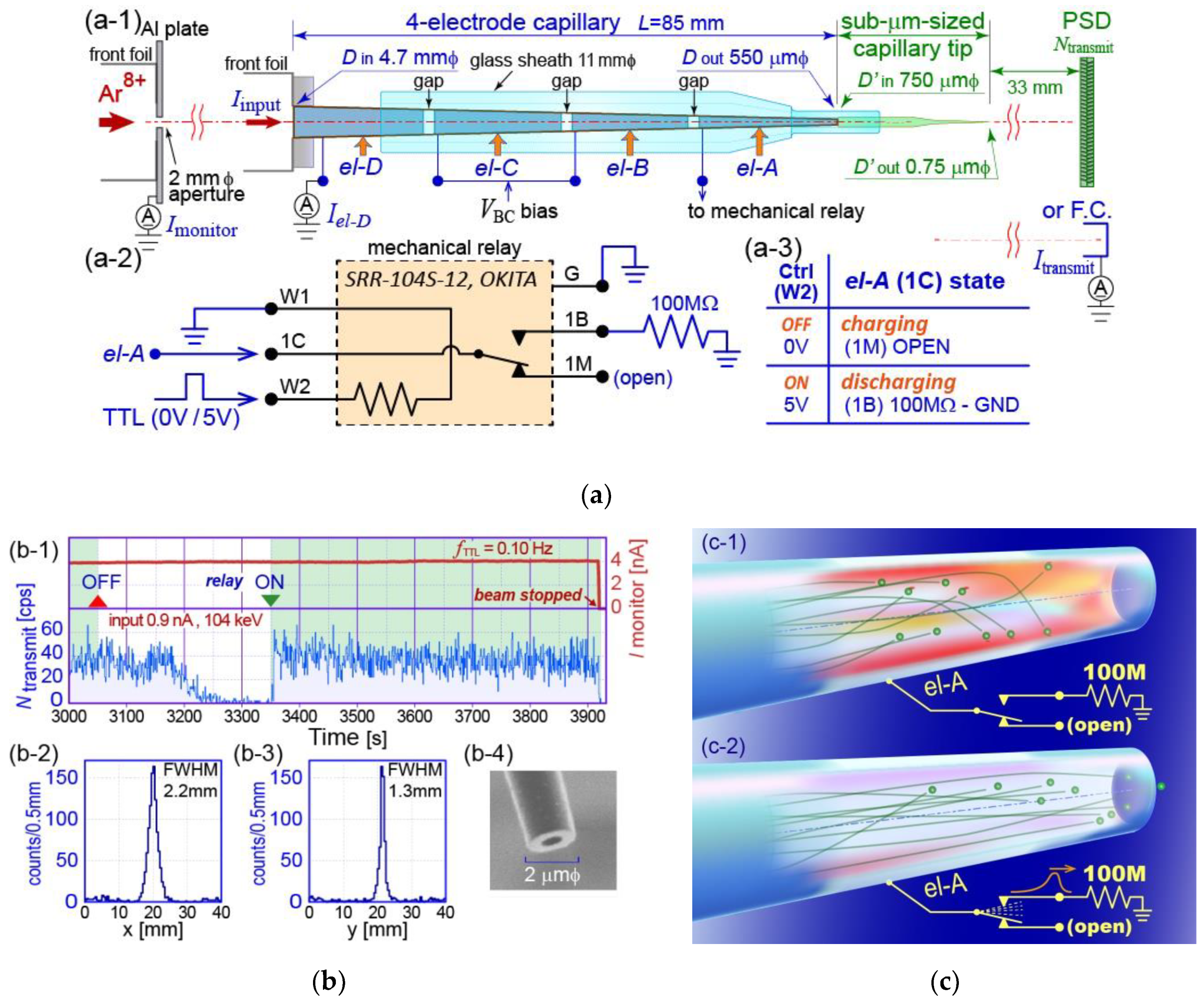

2.5. The First Microbeam of keV Ions Produced by Single Tapered Glass Capillary Optics

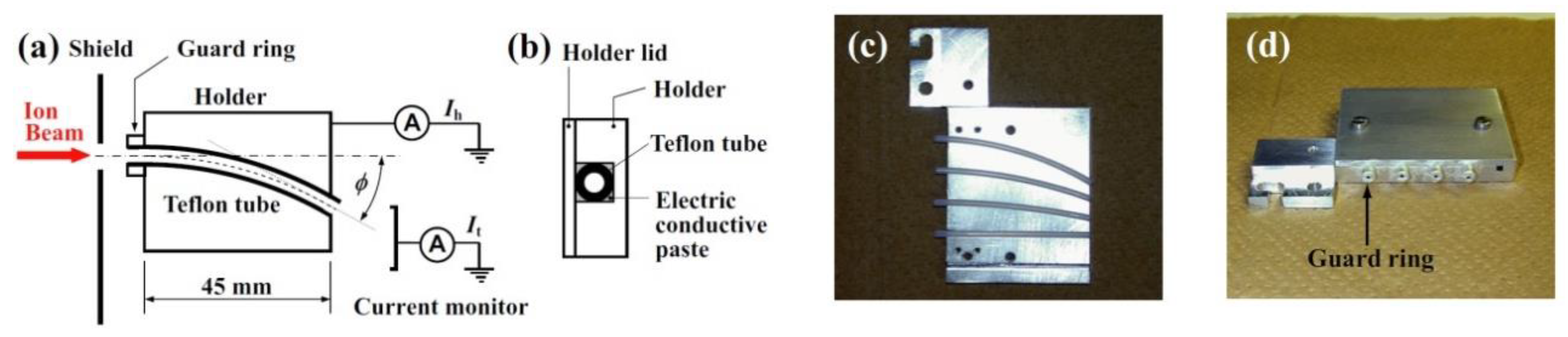

2.6. Various Shapes of Single Macro-Sized Capillary Optics for keV Ion Beams

3. Materials of Glass Capillary Optics and the Fabrication Methods

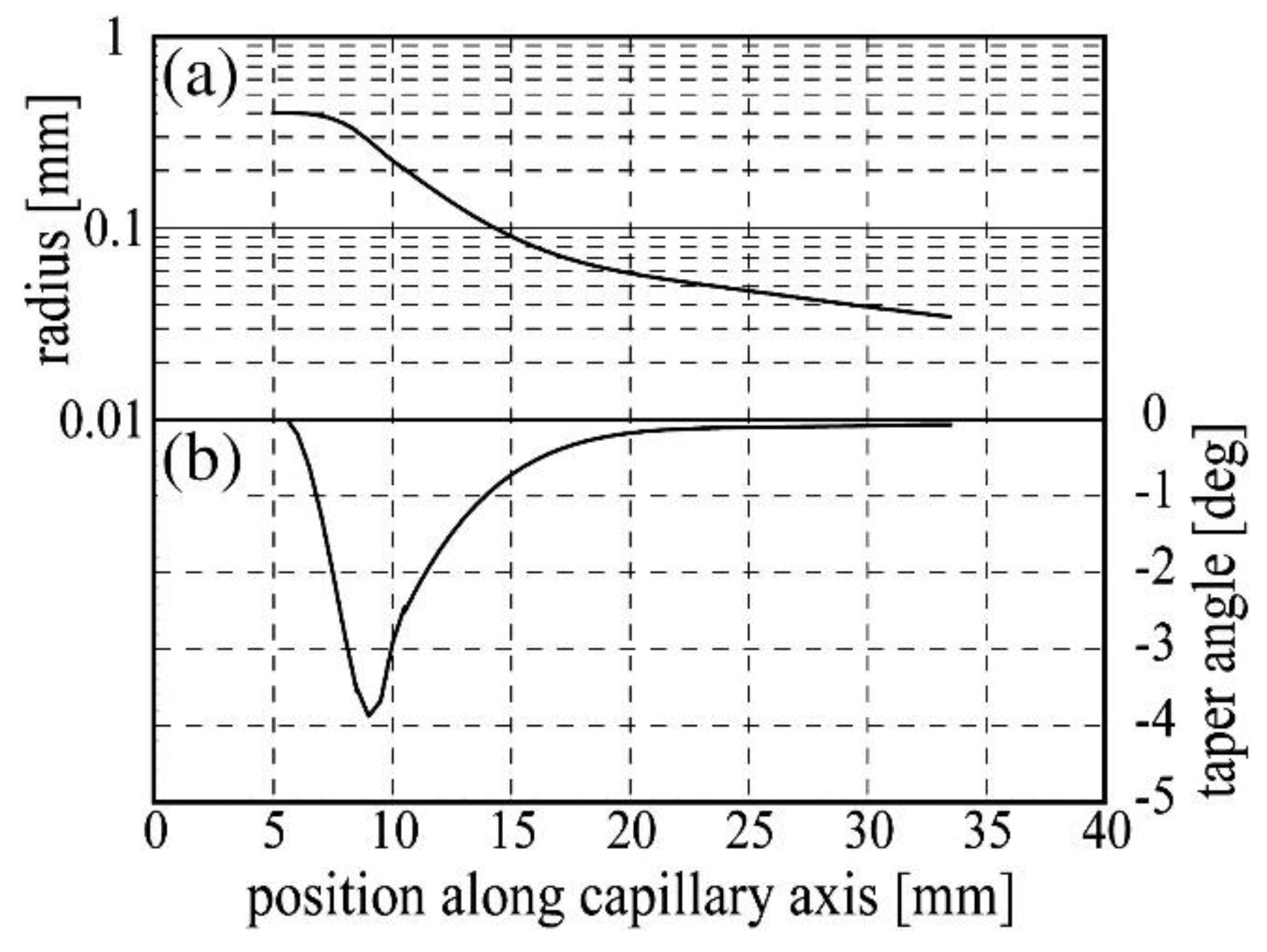

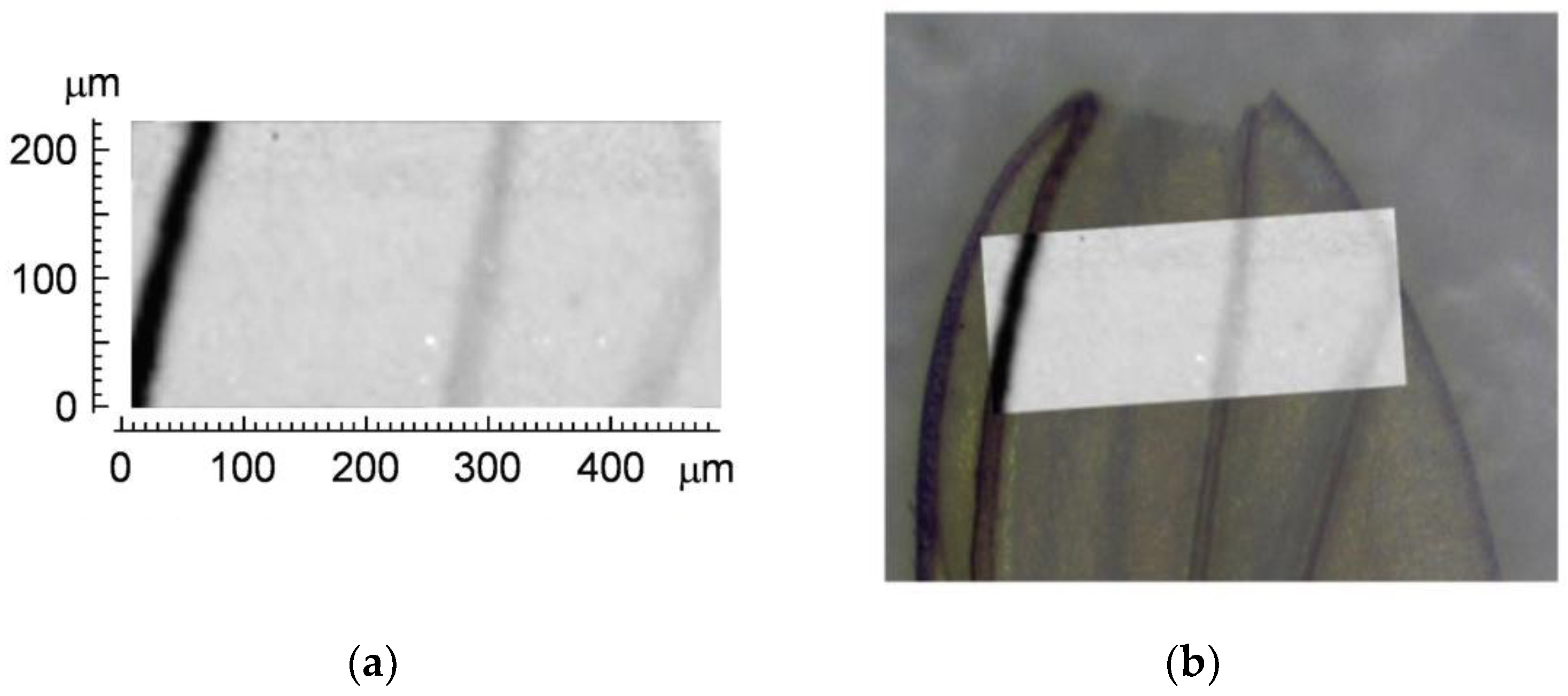

3.1. Determination of Taper Angle and Outlet Size: Puller and Microforge

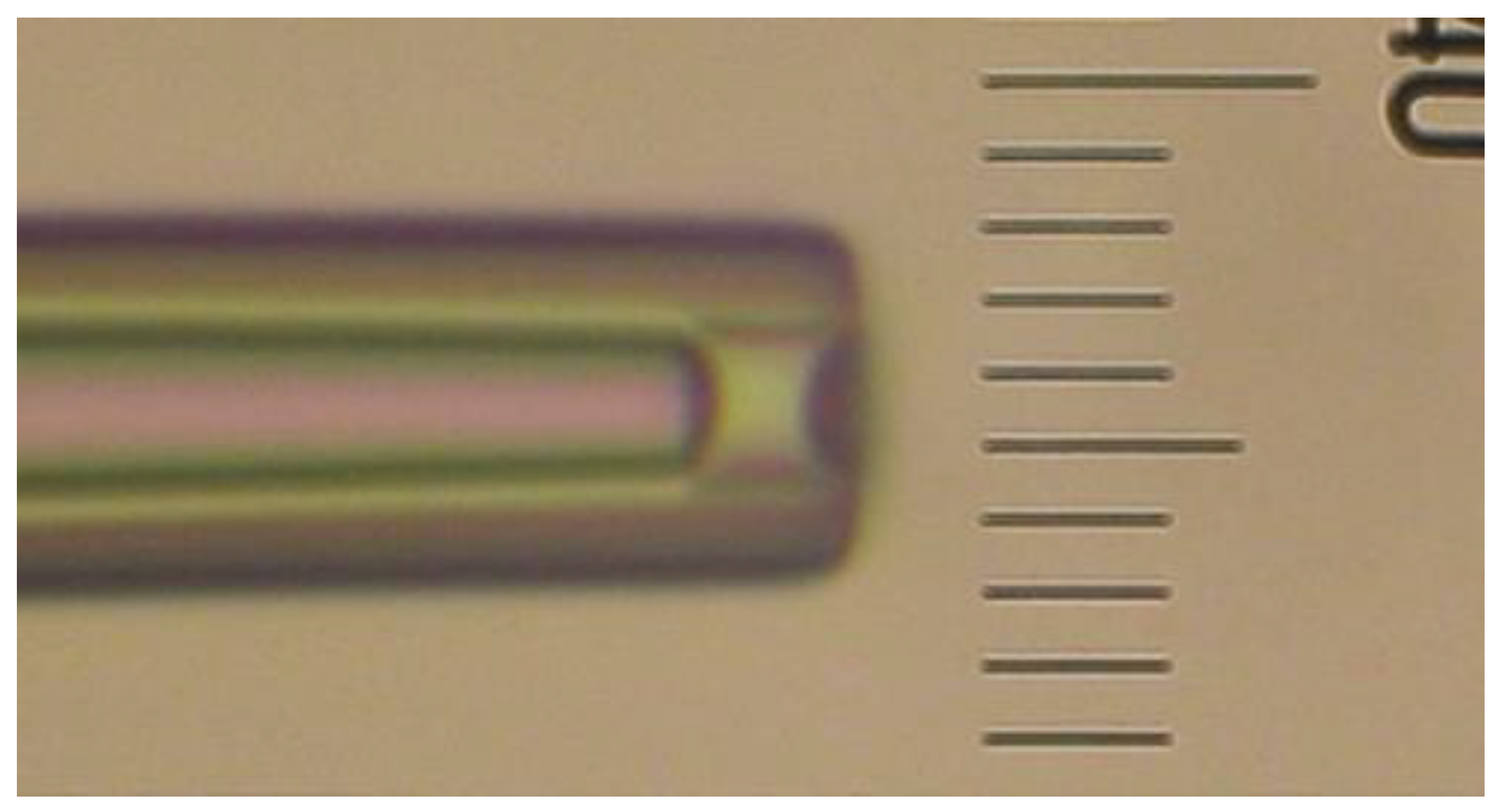

3.2. End Window at an Outlet

4. Characteristics of Microbeams Produced by Glass Capillary

4.1. Ions with keV Energy

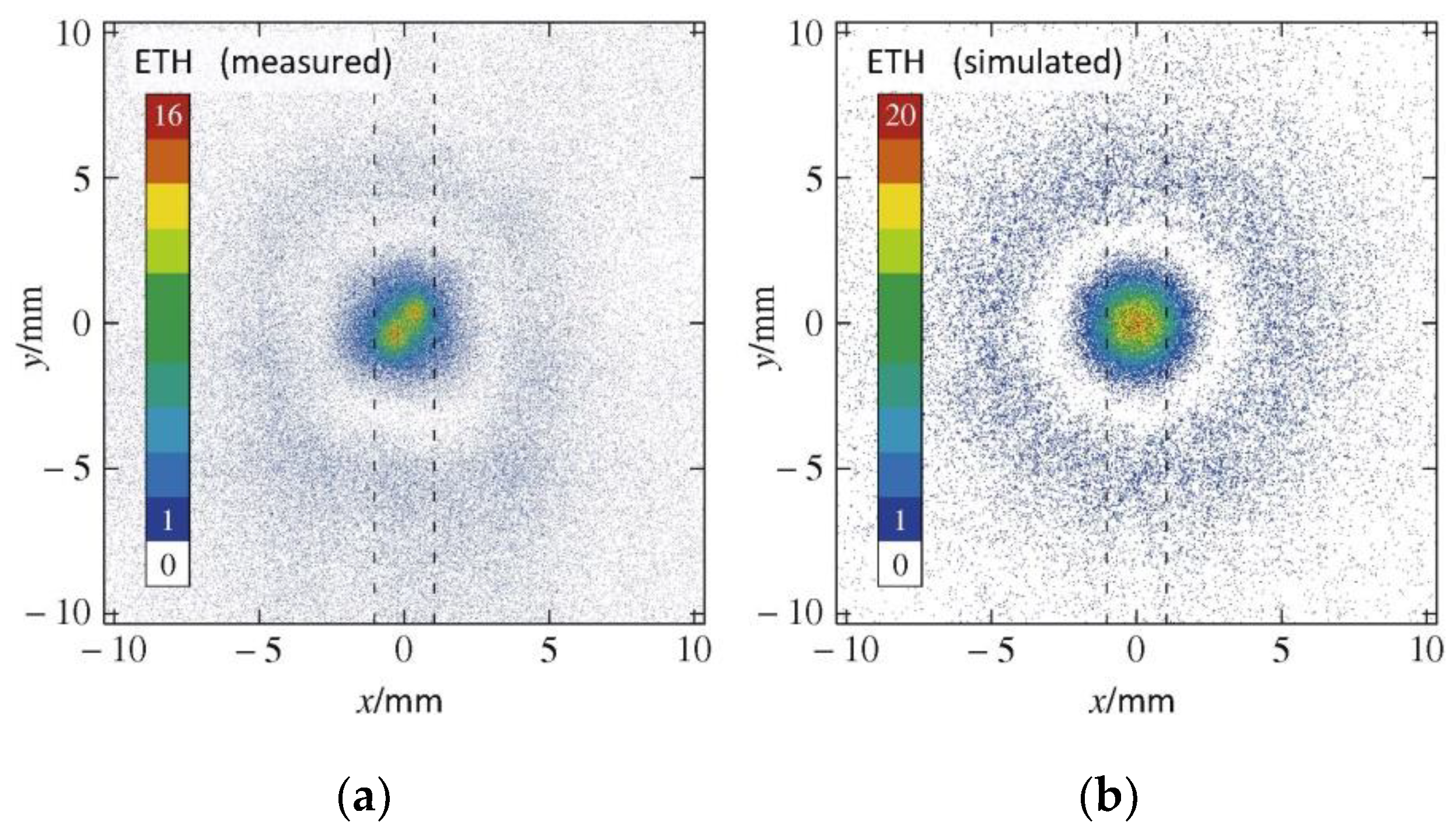

4.2. Ions with MeV Energy

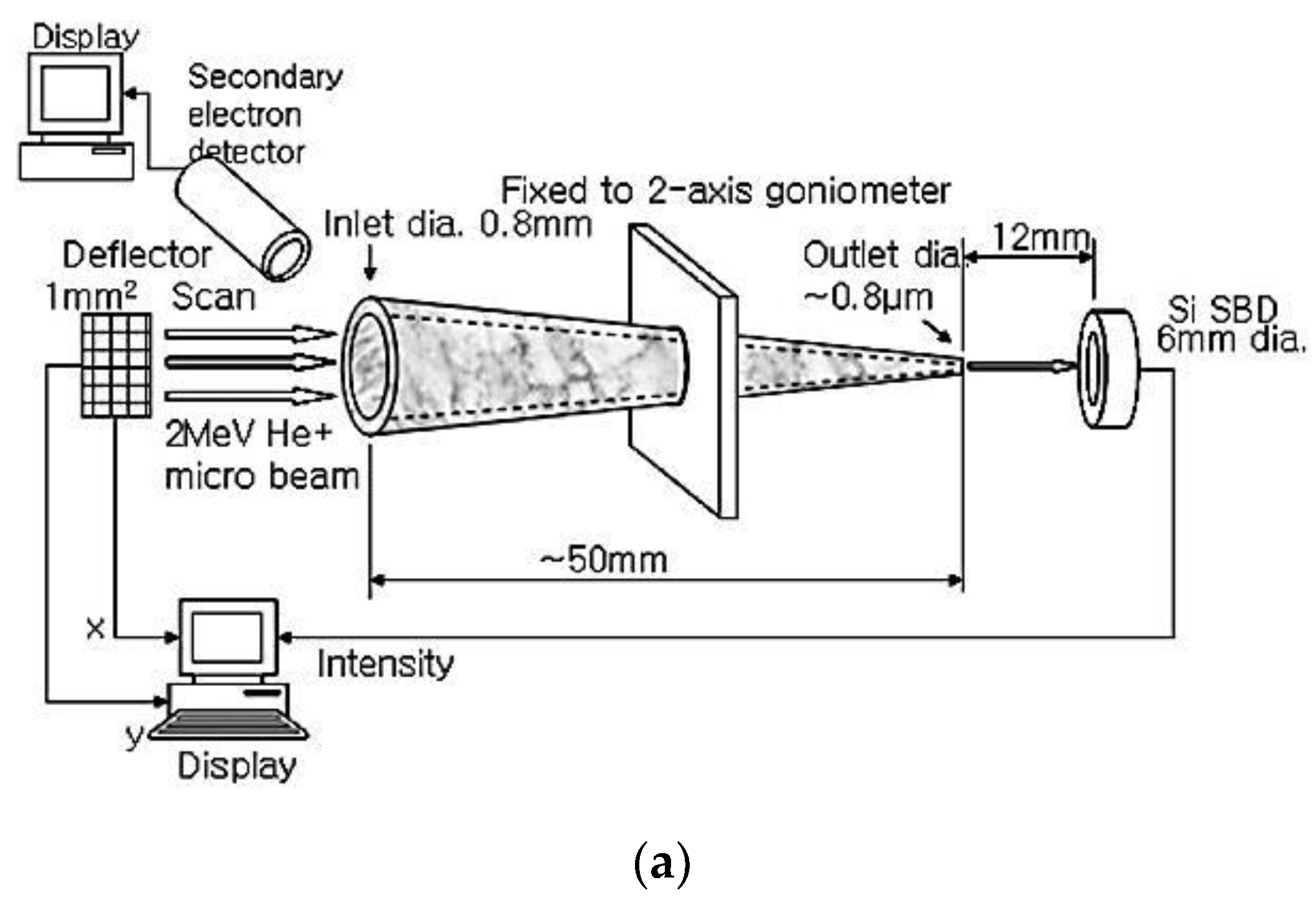

5. Applications of MeV Ion Microbeams

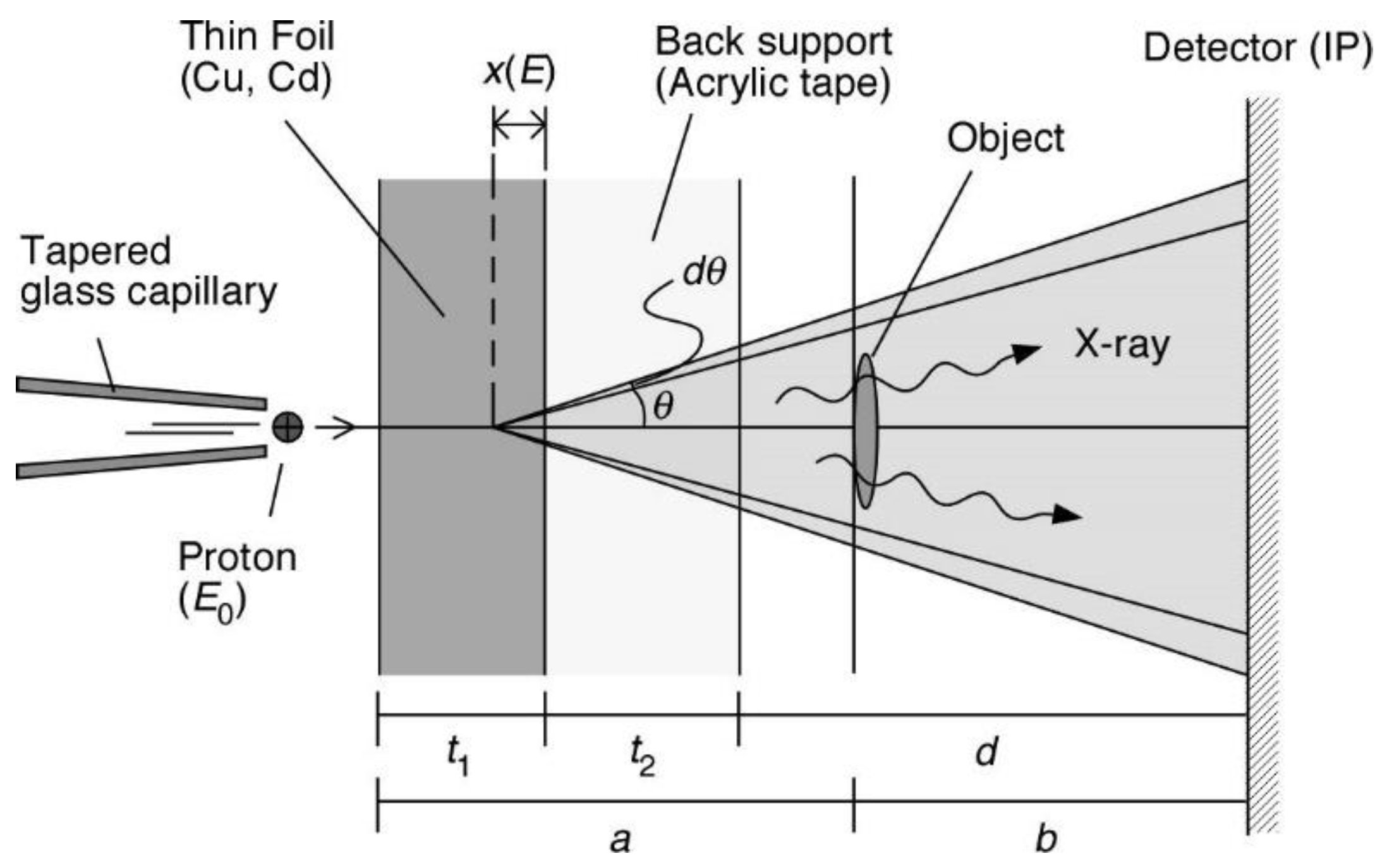

5.1. Creation of Point-Like X-Ray Source

5.2. Micro-PIXE and Other Analysis Methods

5.3. Fast Carbon Cluster and C60 Beams

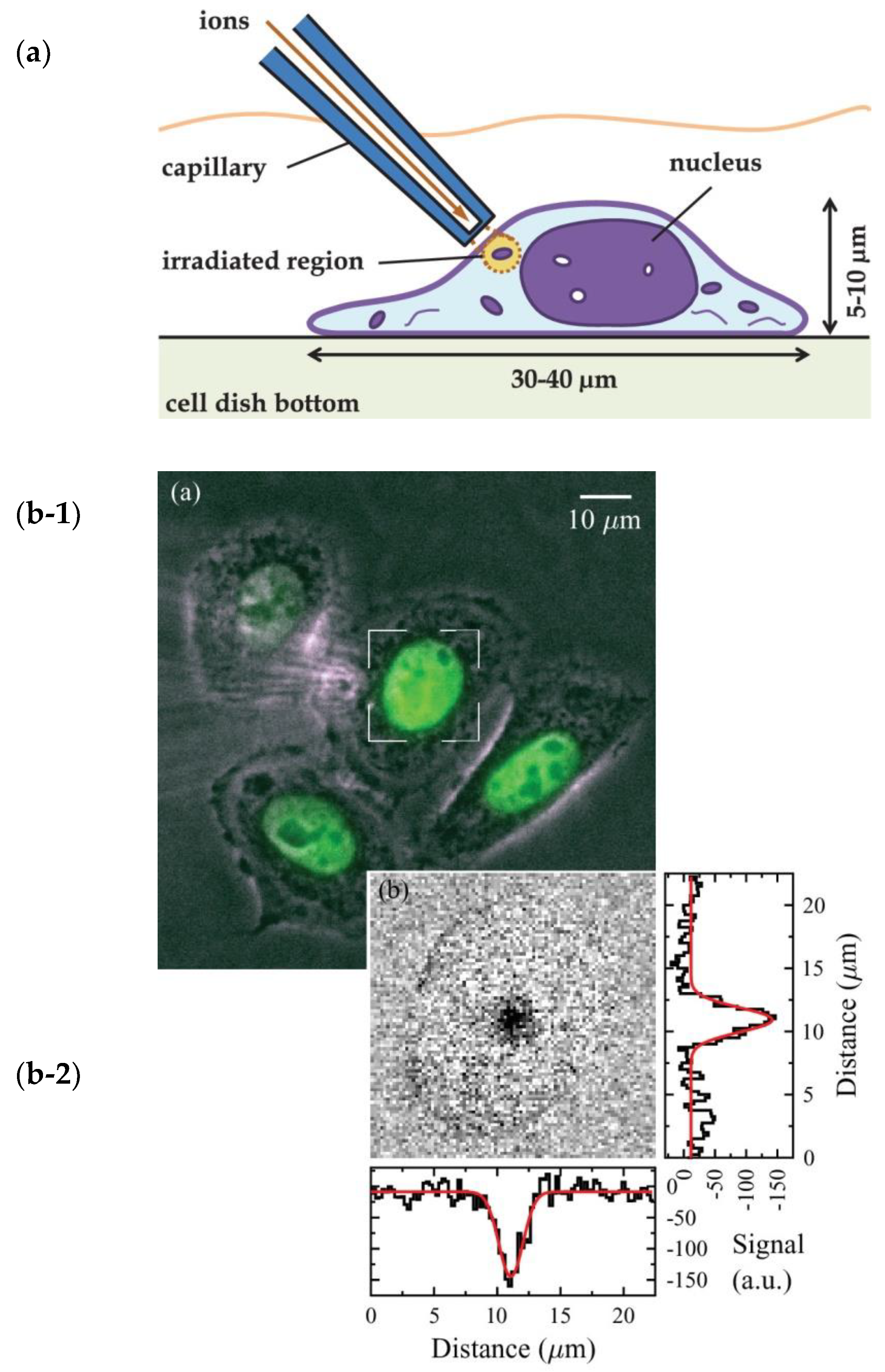

5.4. Irradiation to Mammalian Cells

5.5. Artificial DNA Damage and Its Repair Process

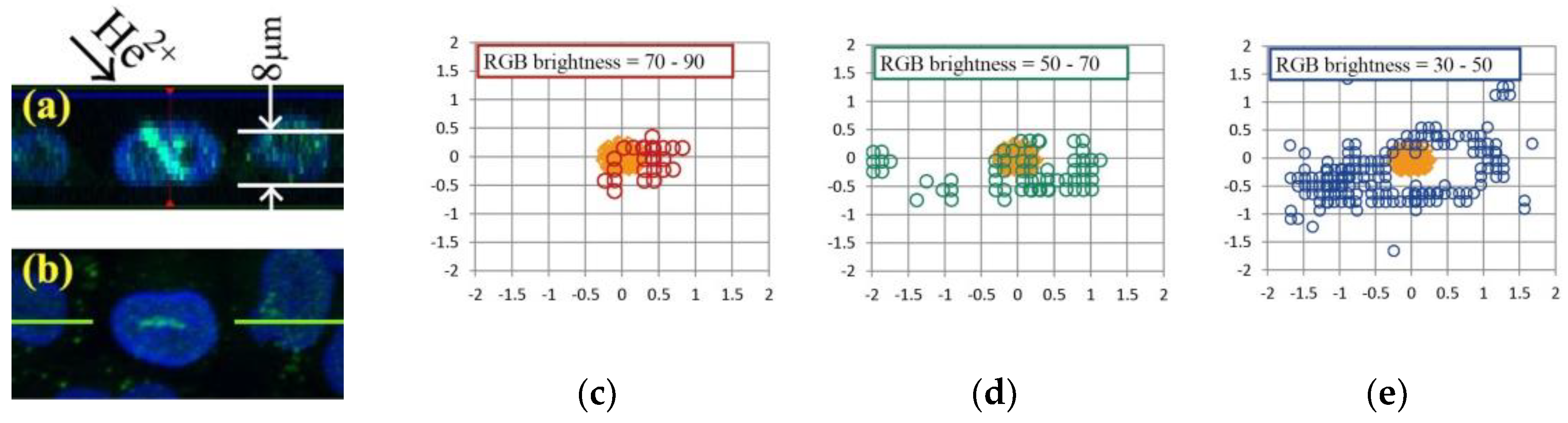

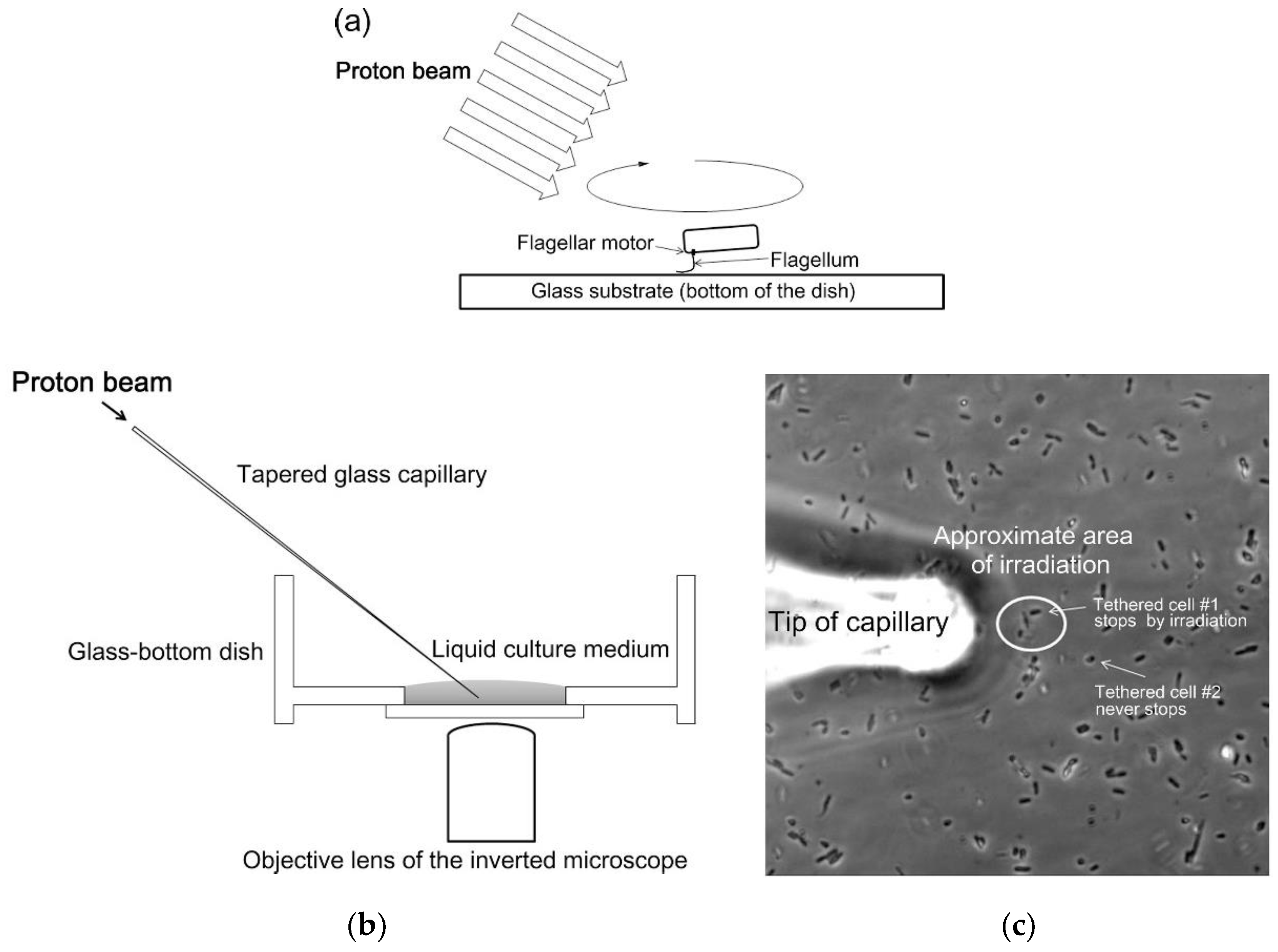

5.6. Irradiation to Bacteria

5.7. Surface Modification in Liquid

6. Other Quantum Beams

7. Summary and Outlook

Funding

Acknowledgments

Conflicts of Interest

References

- Ikeda, T.; Kanai, Y.; Kojima, T.M.; Iwai, Y.; Kambara, T.; Yamazaki, Y.; Hoshino, M.; Nebiki, T.; Narusawa, T. Production of a microbeam of slow highly charged ions with a tapered glass capillary. Appl. Phys. Lett. 2006, 89, 163502. [Google Scholar] [CrossRef]

- Stolterfoht, N.; Bremer, J.-H.; Hoffmann, V.; Hellhammer, R.; Fink, D.; Petrov, A.; Sulik, B. Transmission of 3 keV Ne7+ Ions through Nanocapillaries Etched in Polymer Foils: Evidence for Capillary Guiding. Phys. Rev. Lett. 2002, 88, 133201. [Google Scholar] [CrossRef]

- Nebiki, T.; Yamamoto, T.; Narusawa, T.; Breese, M.B.H.; Teo, E.J.; Watt, F. Focusing of MeV ion beams by means of tapered glass capillary optics. J. Vac. Sci. Technol. A 2003, 21, 1671–1674. [Google Scholar] [CrossRef]

- Japan Patent 5794501. Available online: https://www.j-platpat.inpit.go.jp/c1800/PU/JP-2011-161568/8388596826FC4AD129975A2873E22DC6AF17AEA7FF2E74738C1A523FBC1E9763/10/en (accessed on 22 May 2020).

- Lemell, C.; Burgdörfer, J.; Aumayr, F. Interaction of charged particles with insulating capillary targets—The guiding effect. Prog. Surf. Sci. 2013, 88, 237–278. [Google Scholar] [CrossRef]

- Stolterfoht, N.; Yamazaki, Y. Guiding of charged particles through capillaries in insulating materials. Phys. Rep. 2016, 629, 1–107. [Google Scholar] [CrossRef]

- Kojima, T.M. Ion guiding in macro-size insulating capillaries: Straight, tapered, and curved shapes. J. Phys. B At. Mol. Opt. Phys. 2018, 51, 042001. [Google Scholar] [CrossRef]

- Stolterfoht, N.; Hellhammer, R.; Bundesmann, J.; Fink, D.; Kanai, Y.; Hoshino, M.; Kambara, T.; Ikeda, T.; Yamazaki, Y. Guiding of slow Ne7+ ions through nanocapillaries in insulating polyethylene terephthalate: Incident current dependence. Phys. Rev. A 2007, 76, 022712. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Skog, P.; Schuch, R. Guiding of slow highly charged ions through insulating nano-capillaries. J. Phys. Conf. Ser. 2009, 163, 012092. [Google Scholar]

- Ikeda, T.; Kanai, Y.; Iwai, Y.; Kojima, T.M.; Maeshima, K.; Meissl, W.; Kobayashi, T.; Nebiki, T.; Miyamoto, S.; Pokhil, G.P.; et al. Glass capillary optics for producing nanometer sized beams and its applications. Surf. Coat. Technol. 2011, 206, 859–863. [Google Scholar] [CrossRef]

- Jin, W.-G.; Minowa, T.; Ikeda, T. Transmission of Laser Beam Through Tapered Glass Capillaries for Light Microbeams. J. Phys. Soc. Jpn. 2015, 84, 114301. [Google Scholar] [CrossRef]

- Bereczky, R.J.; Kowarik, G.; Aumayr, F.; Tőkési, K. Transmission of 4.5 keV Ar9+ ions through a single glass macro-capillary. Nucl. Instrum. Methods B 2009, 267, 317–320. [Google Scholar] [CrossRef]

- Kowarik, G.; Bereczky, R.J.; Aumayr, F.; Tőkési, K. Production of a microbeam of slow highly charged ions with a single microscopic glass capillary. Nucl. Instrum. Methods B 2009, 267, 2277–2279. [Google Scholar] [CrossRef]

- Kojima, T.M.; Ikeda, T.; Kanai, Y.; Yamazaki, Y.; Esaulov, V.A. Ion beam guiding with straight and curved Teflon tubes. J. Phys. D 2011, 44, 355201. [Google Scholar] [CrossRef]

- Zhou, C.L.; Simon, M.; Ikeda, T.; Guillous, S.; Iskandar, W.; Méry, A.; Rangama, J.; Lebius, H.; Benyagoub, A.; Grygiel, C.; et al. Transmission of slow highly charged ions through glass capillaries: Role of the capillary shape. Phys. Rev. A 2013, 88, 050901. [Google Scholar] [CrossRef]

- Narishige Group. Available online: https://narishige-group.com/ (accessed on 22 May 2020).

- Ikeda, T.; Meissl, W.; Meissl, E.; Kojima, T.M.; Kobayashi, T.; Yamazaki, Y. Development of a dose evaluation method for cell irradiation using glass capillaries with end-windows. J. Phys. Conf. Ser. 2012, 388, 142028. [Google Scholar] [CrossRef]

- Schweigler, T.; Lemell, C.; Burgdörfer, J. Simulation of transmission of slow highly charged ions through insulating tapered macro-capillaries. Nucl. Instrum. Methods B 2011, 269, 1253–1256. [Google Scholar] [CrossRef]

- Cassimi, A.; Ikeda, T.; Maunoury, L.; Zhou, C.L.; Guillous, S.; Mery, A.; Lebius, H.; Benyagoub, A.; Grygiel, C.; Khemliche, H.; et al. Dynamics of charge evolution in glass capillaries for 230-keV Xe23+ ions. Phys. Rev. A 2012, 86, 062902. [Google Scholar] [CrossRef]

- Giglio, E.; DuBois, R.D.; Cassimi, A.; Tőkési, K. Low energy ion transmission through a conical insulating capillary with macroscopic dimensions. Nucl. Instrum. Methods B 2015, 354, 82–85. [Google Scholar] [CrossRef]

- Giglio, E.; Guillous, S.; Cassimi, A.; Zhang, H.Q.; Nagy, G.U.L.; Tőkési, K. Evolution of the electric potential of an insulator under charged particle impact. Phys. Rev. A 2017, 95, 030702. [Google Scholar] [CrossRef]

- Giglio, E.; Guillous, S.; Cassimi, A. Ion-beam focusing by self-organized axis-symmetric potentials in insulating capillaries. Phys. Rev. A 2018, 98, 052704. [Google Scholar] [CrossRef]

- Giglio, E.; Tőkési, K.; DuBois, R.D. Relaxation dynamics of charge patches formed inside an insulating capillary by ion impact. Nucl. Instrum. Methods B 2019, 460, 234–239. [Google Scholar] [CrossRef]

- Chen, J.; Xue, Y.; Liu, J.; Wu, Y.; Ruan, F.; Wang, W.; Yu, D.; Cai, X. Focusing of 90 keV O6+ ions through a single tapered glass macrocapillary. Nucl. Instrum. Methods B 2012, 281, 26–29. [Google Scholar] [CrossRef]

- Bereczky, R.J.; Kowarik, G.; Tőkési, K.; Aumayr, F. Sample holder for studying temperature dependent particle guiding. Nucl. Instrum. Methods B 2012, 279, 182–185. [Google Scholar] [CrossRef]

- Gruber, E.; Kowarik, G.; Ladinig, F.; Waclawek, J.P.; Schrempf, D.; Aumayr, F.; Bereczky, R.J.; Tőkési, K.; Gunacker, P.; Schweigler, T.; et al. Temperature control of ion guiding through insulating capillaries. Phys. Rev. A 2012, 86, 062901. [Google Scholar] [CrossRef]

- Kulkarni, D.D.; Lyle, L.A.M.; Sosolik, C.E. Ion transport through macrocapillaries—Oscillations due to charge patch formation. Nucl. Instrum. Methods B 2016, 382, 54–59. [Google Scholar] [CrossRef]

- Maurya, S.K.; Barman, S.; Paul, S.; Bhattacharjee, S. Charge dissipation and self focusing limit in high current density ion beam transport through a micro glass capillary. J. Phys. D 2019, 52, 055205. [Google Scholar] [CrossRef]

- Ikeda, T.; Iwai, Y.; Kojima, T.M.; Onoda, S.; Kanai, Y.; Yamazaki, Y. Resistive switching induced on a glass plate by ion beam irradiation. Nucl. Instrum. Methods B 2012, 287, 31–34. [Google Scholar] [CrossRef]

- Ikeda, T.; Kojima, T.M.; Natsume, Y.; Kimura, J.; Abe, T. Stable transmission of slow highly charged ions through tapered glass capillary with active discharging method for sub-micron sized beams. Appl. Phys. Lett. 2016, 109, 133501. [Google Scholar] [CrossRef]

- Pan, P.; Niu, S.T.; Song, H.Y.; Chen, X.M.; Qiu, X.Y.; Shao, J.X. Transmission of keV O− ions through a single tapered glass capillary. Nucl. Instrum. Methods B 2019, 450, 332–336. [Google Scholar] [CrossRef]

- Hasegawa, J.; Jaiyen, S.; Polee, C.; Chankow, N.; Oguri, Y. Transport mechanism of MeV protons in tapered glass capillaries. J. Appl. Phys. 2011, 110, 044913. [Google Scholar] [CrossRef]

- Hespeels, F.; Tonneau, R.; Ikeda, T.; Lucas, S. Comparison of experimental and Monte-Carlo simulation of MeV particle transport through tapered/straight glass capillaries and circular collimators. Nucl. Instrum. Methods B 2015, 362, 72–79. [Google Scholar] [CrossRef]

- Simon, M.J.; Zhou, C.L.; Döbeli, M.; Cassimi, A.; Monnet, I.; Méry, A.; Grygiel, C.; Guillous, S.; Madi, T.; Benyagoub, A.; et al. Measurements and 3D Monte Carlo simulation of MeV ion transmission through conical glass capillaries. Nucl. Instrum. Methods B 2014, 330, 11–17. [Google Scholar] [CrossRef]

- Ikeda, T.; Ikekame, M.; Hikima, Y.; Mori, M.; Kawamura, S.; Minowa, T.; Jin, W.-G. Profile measurements of MeV ion microbeams in atmosphere extracted from single tapered glass capillaries with an end window. Nucl. Instrum. Methods B 2020, 470, 42–47. [Google Scholar] [CrossRef]

- Fujita, N.; Ishii, K.; Ogawa, H. Transmission properties of glass capillaries for MeV proton and alpha particles. Phys. Scr. 2011, T144, 014033. [Google Scholar] [CrossRef]

- Fujita, N.; Yamaki, A.; Ishii, K.; Ogawa, H. Measurements of an ion beam diameter extracted into air through a glass capillary. Nucl. Instrum. Methods B 2013, 315, 332–335. [Google Scholar] [CrossRef]

- Asamura, M.; Fukunaga, Y.; Ishii, K.; Ogawa, H. Inlet MeV ion beam dependence of transmission property for a glass capillary filled with He gas. Nucl. Instrum. Methods B 2019, 460, 220–223. [Google Scholar] [CrossRef]

- Nagy, G.U.L.; Rajta, I.; Bereczky, R.J.; Tőkési, K. Incident beam intensity dependence of the charge-up process of the guiding of 1 MeV proton microbeam through a Teflon microcapillary. Eur. Phys. J. D 2015, 69, 102. [Google Scholar] [CrossRef]

- Nagy, G.U.L.; Giglio, E.; Rajta, I.; Tőkési, K. Transmission dynamics of 1 MeV H+ microbeam guided through an insulating macrocapillary. Nucl. Instrum. Methods B 2019, 460, 216–219. [Google Scholar] [CrossRef]

- Hasegawa, J.; Shiba, S.; Fukuda, H.; Oguri, Y. A compact micro-beam system using a tapered glass capillary for proton-induced X-ray radiography. Nucl. Instrum. Methods B 2008, 266, 2125–2129. [Google Scholar] [CrossRef]

- Nebiki, T.; Kabir, M.H.; Narusawa, T. In-air PIXE analysis by means of glass capillary optics. Nucl. Instrum. Methods B 2006, 249, 226–229. [Google Scholar] [CrossRef]

- Hasegawa, J.; Jaiyen, S.; Polee, C.; Oguri, Y. Development of a micro-PIXE system using tapered glass capillary optics. Nucl. Instrum. Methods B 2011, 269, 3087–3090. [Google Scholar] [CrossRef]

- Singkarat, S.; Puttaraksa, N.; Unai, S.; Yu, L.D.; Singkarat, K.; Pussadee, N.; Whitlow, H.J.; Natyanum, S.; Tippawan, U. Development of economic MeV-ion microbeam technology at Chiang Mai University. Nucl. Instrum. Methods B 2017, 404, 58–64. [Google Scholar] [CrossRef]

- Simon, M.J.; Döbeli, M.; Müller, A.M.; Synal, H.-A. In-air STIM with a capillary microprobe. Nucl. Instrum. Methods B 2012, 273, 237–240. [Google Scholar] [CrossRef]

- Brajković, M.; Barac, M.; Cosic, D.; Bogdanović Radović, I.; Siketić, Z. Development of MeV TOF-SIMS capillary microprobe at the Ruđer Bošković Institute in Zagreb. Nucl. Instrum. Methods B 2019, 461, 237–242. [Google Scholar] [CrossRef]

- Sekiba, D.; Yonemura, H.; Nebiki, T.; Wilde, M.; Ogura, S.; Yamashita, H.; Matsumoto, M.; Kasagi, J.; Iwamura, Y.; Itoh, T.; et al. Development of micro-beam NRA for 3D-mapping of hydrogen distribution in solids: Application of tapered glass capillary to 6 MeV 15N ion. Nucl. Instrum. Methods B 2008, 266, 4027–4036. [Google Scholar] [CrossRef]

- Tsuchida, H.; Tomita, S.; Nishimura, K.; Murakoshi, R.; Naitoh, M.; Sasa, K.; Ishii, S.; Yogo, A.; Itoh, A. Properties of fast carbon cluster microbeams produced with a tapered capillary. Nucl. Instrum. Methods B 2012, 293, 6–10. [Google Scholar] [CrossRef][Green Version]

- Nomura, S.; Tsuchida, H.; Furuya, R.; Miyahara, K.; Majima, T.; Itoh, A. Effects of radical scavengers on aqueous solutions exposed to heavy-ion irradiation using the liquid microjet technique. Nucl. Instrum. Methods B 2015, 365, 611–615. [Google Scholar] [CrossRef]

- Nomura, S.; Tsuchida, H.; Kajiwara, A.; Yoshida, S.; Majima, T.; Saito, M. Dissociation of biomolecules in liquid environments during fast heavy-ion irradiation. J. Chem. Phys. 2017, 147, 225103. [Google Scholar] [CrossRef]

- Tsuchida, H.; Majima, T.; Tomita, S.; Sasa, K.; Narumi, K.; Saitoh, Y.; Chiba, A.; Yamada, K.; Hirata, K.; Shibata, H.; et al. Transmission properties of C60 ions through micro- and nano-capillaries. Nucl. Instrum. Methods B 2013, 315, 336–340. [Google Scholar] [CrossRef]

- Iwai, Y.; Ikeda, T.; Kojima, T.M.; Yamazaki, Y.; Maeshima, K.; Imamoto, N.; Kobayashi, T.; Nebiki, T.; Narusawa, T.; Pokhil, G.P. Ion irradiation in liquid of μm3 region for cell surgery. Appl. Phys. Lett. 2008, 92, 023509. [Google Scholar] [CrossRef]

- Mäckel, V.; Meissl, W.; Ikeda, T.; Clever, M.; Meissl, E.; Kobayashi, T.; Kojima, T.M.; Imamoto, N.; Ogiwara, K.; Yamazaki, Y. A novel facility for 3D micro-irradiation of living cells in a controlled environment by MeV ions. Rev. Sci. Instrum. 2014, 85, 014302. [Google Scholar] [CrossRef] [PubMed]

- Mäckel, V.; Puttaraksa, N.; Kobayashi, T.; Yamazaki, Y. Single proton counting at the RIKEN cell irradiation facility. Rev. Sci. Instrum. 2015, 86, 085103. [Google Scholar] [CrossRef]

- Puttaraksa, N.; Mäckel, V.; Kobayashi, T.; Kojima, T.M.; Hamagaki, M.; Imamoto, N.; Yamazaki, Y. Irradiation of Fucci-expressing HeLa cells using a tapered glass capillary microbeam. Nucl. Instrum. Methods B 2015, 348, 127–130. [Google Scholar] [CrossRef]

- Ikeda, T.; Izumi, M.; Mäckel, V.; Kobayashi, T.; Bereczky, R.J.; Hirano, T.; Yamazaki, Y.; Abe, T. Ion track observation in cell nucleus irradiated by 3 MeV He ion microbeams produced with glass capillaries. RIKEN Accel. Prog. Rept. 2015, 48, 315. Available online: http://www.nishina.riken.jp/researcher/APR/APR048/pdf/315.pdf (accessed on 22 May 2020).

- Ikeda, T.; Izumi, M.; Mäckel, V.; Kobayashi, T.; Ogiwara, K.; Hirano, T.; Yamazaki, Y.; Abe, T. Observation of unrepairable lesions at DNA by using 3-MeV proton microbeams produced by glass capillaries. RIKEN Accel. Prog. Rept. 2014, 47, 282. Available online: http://www.nishina.riken.jp/researcher/APR/APR047/pdf/282.pdf (accessed on 22 May 2020).

- Kato, M.; Meissl, W.; Umezawa, K.; Ikeda, T.; Yamazaki, Y. Real-time observation of Escherichia coli cells under irradiation with a 2-MeV H+ microbeam. Appl. Phys. Lett. 2012, 100, 193702. [Google Scholar] [CrossRef]

- Kobayashi, T.; Miyamoto, S.; Ikeda, T.; Kojima, T.M.; Ogiwara, K.; Yamazaki, Y. Surface modification of polymers by ion irradiation at the solid–liquid interface. Nucl. Instrum. Methods B 2012, 272, 405–408. [Google Scholar] [CrossRef]

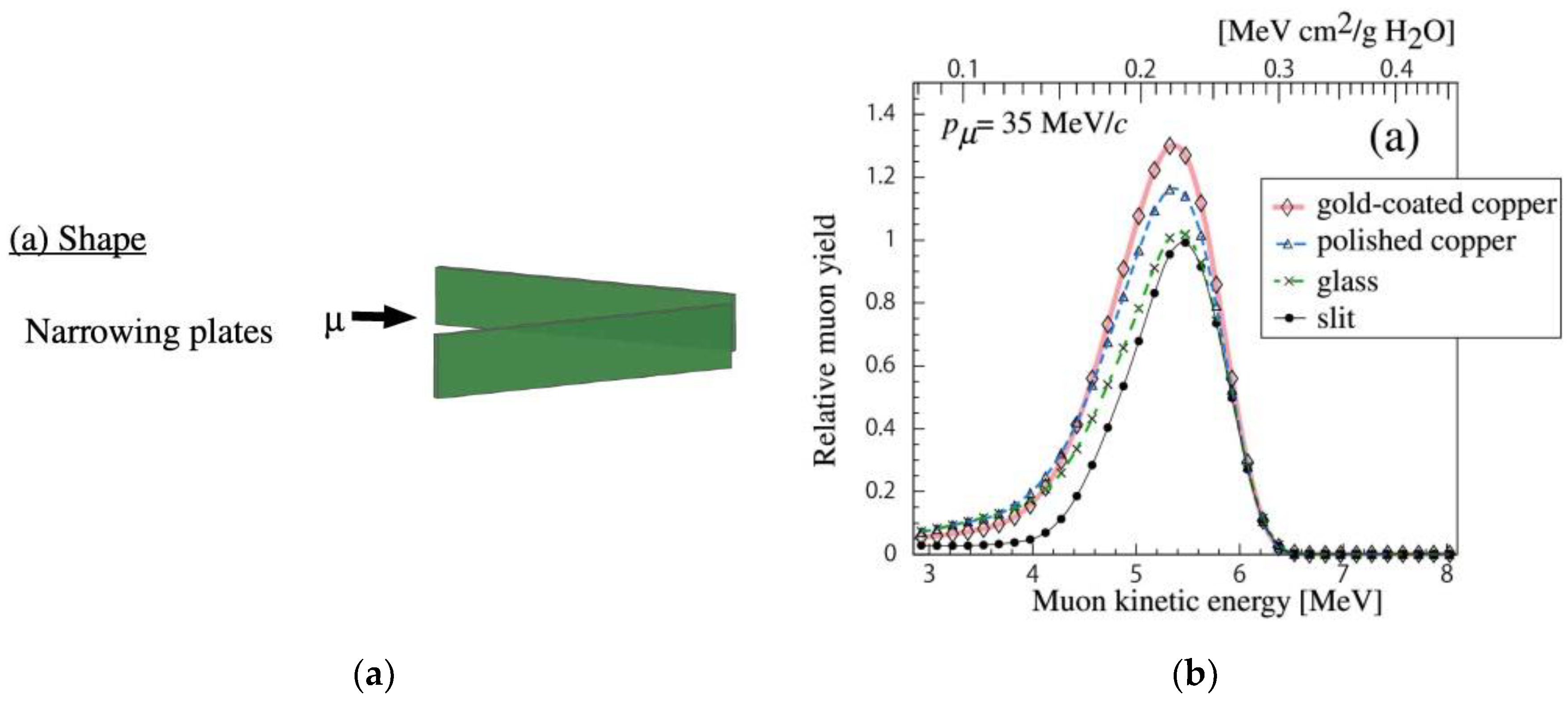

- Kojima, T.M.; Tomono, D.; Ikeda, T.; Ishida, K.; Iwai, Y.; Iwasaki, M.; Matsuda, Y.; Matsuzaki, T.; Yamazaki, Y. Density Enhancement of Muon Beams with Tapered Glass Tubes. J. Phys. Soc. Jpn. 2007, 76, 093501. [Google Scholar] [CrossRef]

- Tomono, D.; Kojima, T.M.; Ishida, K.; Ikeda, T.; Iwai, Y.; Tokuda, M.; Kanazawa, Y.; Matsuda, Y.; Matsuzaki, T.; Iwasaki, M.; et al. Focusing Effect of MeV Muon Beam with a Tapered Capillary Method. J. Phys. Soc. Jpn. 2011, 80, 044501. [Google Scholar] [CrossRef]

- Wickramarachchi, S.J.; Ikeda, T.; Dassanayake, B.S.; Keerthisinghe, D.; Tanis, J.A. Incident energy and charge deposition dependences of electron transmission through a microsized tapered glass capillary. Nucl. Instrum. Methods B 2016, 382, 60–66. [Google Scholar] [CrossRef]

- Wickramarachchi, S.J.; Ikeda, T.; Dassanayake, B.S.; Keerthisinghe, D.; Tanis, J.A. Electron-beam transmission through a micrometer-sized tapered-glass capillary: Dependence on incident energy and angular tilt angle. Phys. Rev. A 2016, 94, 022701. [Google Scholar] [CrossRef]

- Vokhmyanina, K.A.; Pokhil, G.P.; Zhukova, P.N.; Irribarra, E.; Kubankin, A.S.; Levina, V.S.; Nazhmudinov, R.M.; Oleinik, A.N.; Kishin, I.A. Guiding of a beam of 10keV electrons by micro size tapered glass capillary. Nucl. Instrum. Methods B 2015, 355, 307–310. [Google Scholar] [CrossRef]

- Oshima, N.; Iwai, Y.; Kojima, T.M.; Ikeda, T.; Kanazawa, Y.; Hoshino, M.; Suzuki, R.; Yamazaki, Y. Guiding of a Slow Positron Beam with a Glass Capillary. Mater. Sci. Forum 2009, 607, 263–265. [Google Scholar] [CrossRef]

- Mironov, B.N.; Aseyev, S.A.; Chekalin, S.V. Ion transmission through a dielectric hollow tip for scanning probe microscopy. Micron 2019, 116, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Li, Y.; Luo, H.; Ye, L.; Zhou, M.; Duan, J.; Lin, X. Study on the manufacturing process and transmission performance of a nested tapered single capillary X-ray lens. Nucl. Instrum. Methods A 2019, 947, 162762. [Google Scholar] [CrossRef]

- Koushima, M.; Ikeda, T.; Matsubara, M.; Masuyama, T.; Minowa, T.; Jin, W.-G. Development of laser target sight-on system based on multiple transmission through a tapered glass capillary for ion microbeam irradiation. J. Phys. Conf. Ser. 2017, 875, 112004. [Google Scholar] [CrossRef]

| kV Accelerated Ions | MV Accelerated Ions | Photons | |

|---|---|---|---|

| Multitude of nanocapillaries | 3 keV Ne7+: a PET foil with capillaries (100 nmϕ, 10 μmL) 1 [2] | − 2 | − 2 |

| Single capillary | 8 keV Ar8+: a tapered glass capillary (24 μmϕ outlet) [1] | 2 MeV He+: a tapered glass capillary (0.8 μmϕ outlet) [3] | laser (488, 633 nm): a tapered glass capillary (22 μmϕ outlet) [11] |

| Non-Tapered Capillary | Tapered Capillary | |||

|---|---|---|---|---|

| Straight | Curved | Funnel Type | Conical Type | |

| Single capillary | 4.5-keV Ar9+: a glass capillary (170 μmϕ, 11.4 mmL) 1 [12,13] | 8-keV Ar8+: a Teflon tube (1 mmϕ, 51 mmL, 26.7° bending) [14] | Refs [1,3,15] | 27-keV Ar9+: a glass capillary (22 μmϕ outlet) [15] |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ikeda, T. Applications of Microbeams Produced by Tapered Glass Capillary Optics. Quantum Beam Sci. 2020, 4, 22. https://doi.org/10.3390/qubs4020022

Ikeda T. Applications of Microbeams Produced by Tapered Glass Capillary Optics. Quantum Beam Science. 2020; 4(2):22. https://doi.org/10.3390/qubs4020022

Chicago/Turabian StyleIkeda, Tokihiro. 2020. "Applications of Microbeams Produced by Tapered Glass Capillary Optics" Quantum Beam Science 4, no. 2: 22. https://doi.org/10.3390/qubs4020022

APA StyleIkeda, T. (2020). Applications of Microbeams Produced by Tapered Glass Capillary Optics. Quantum Beam Science, 4(2), 22. https://doi.org/10.3390/qubs4020022