Novel Approaches for Intensifying Negative C60 Ion Beams Using Conventional Ion Sources Installed on a Tandem Accelerator

Abstract

1. Introduction

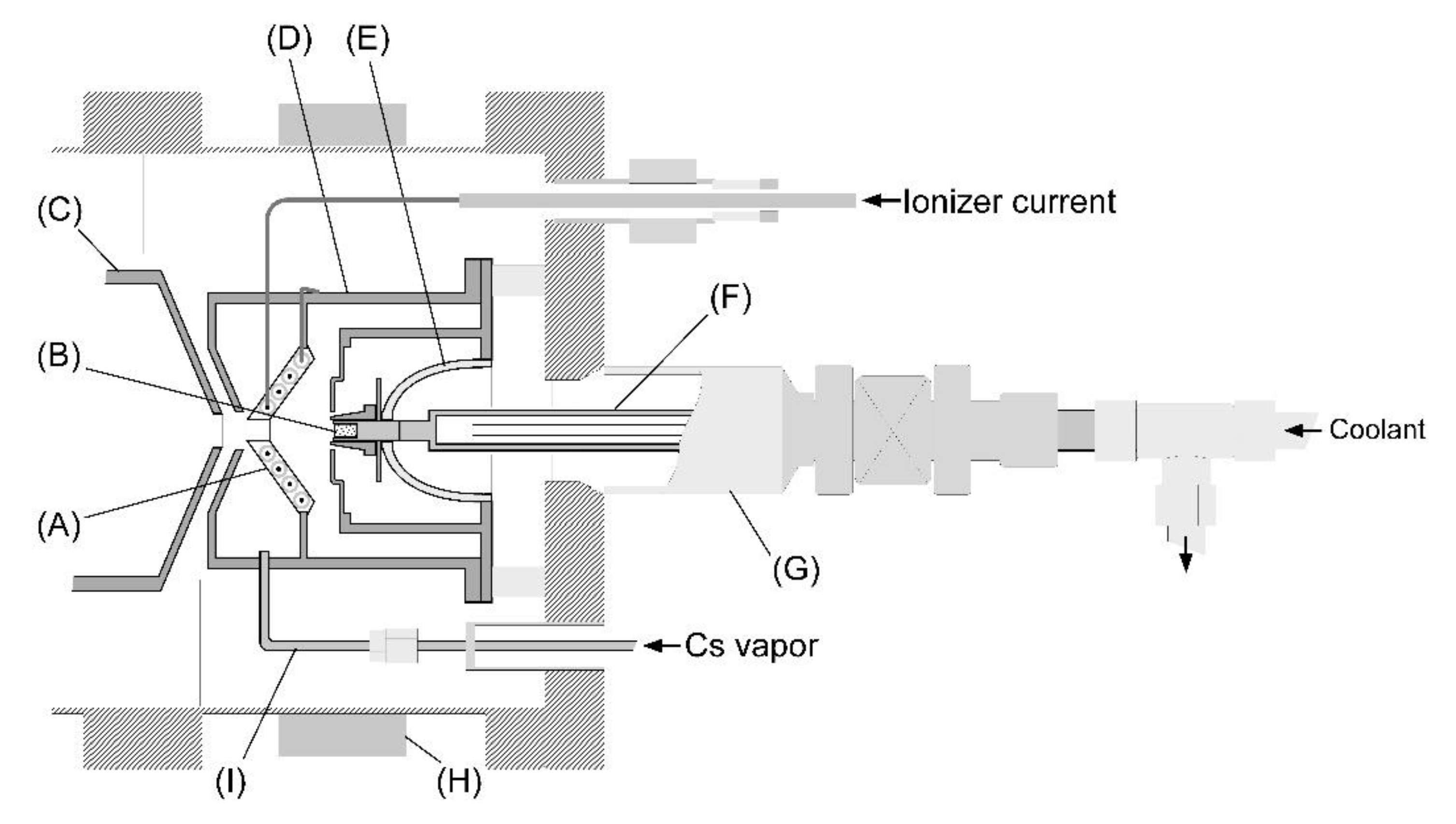

2. Conventional Method (Cs Sputter)

3. Electron Attachment Method

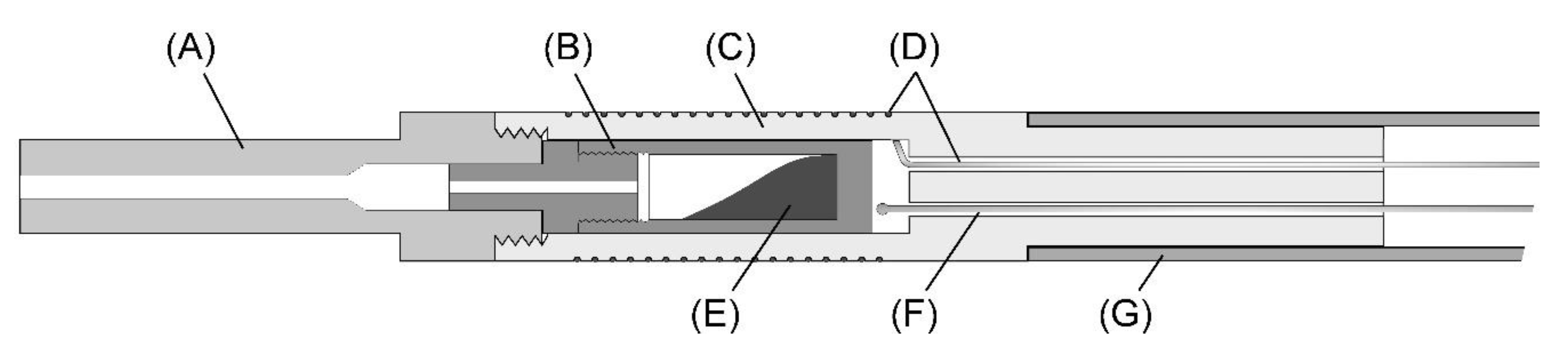

3.1. The Oven Rod

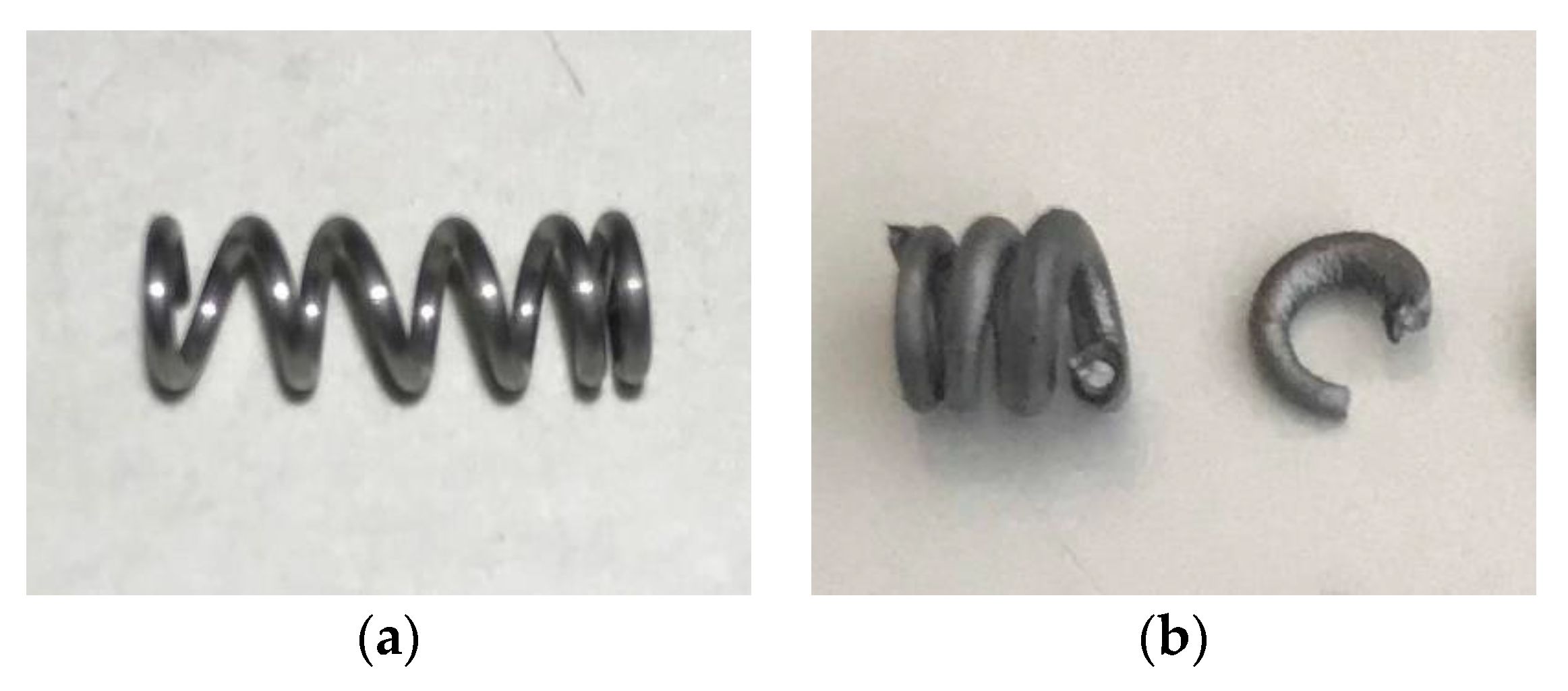

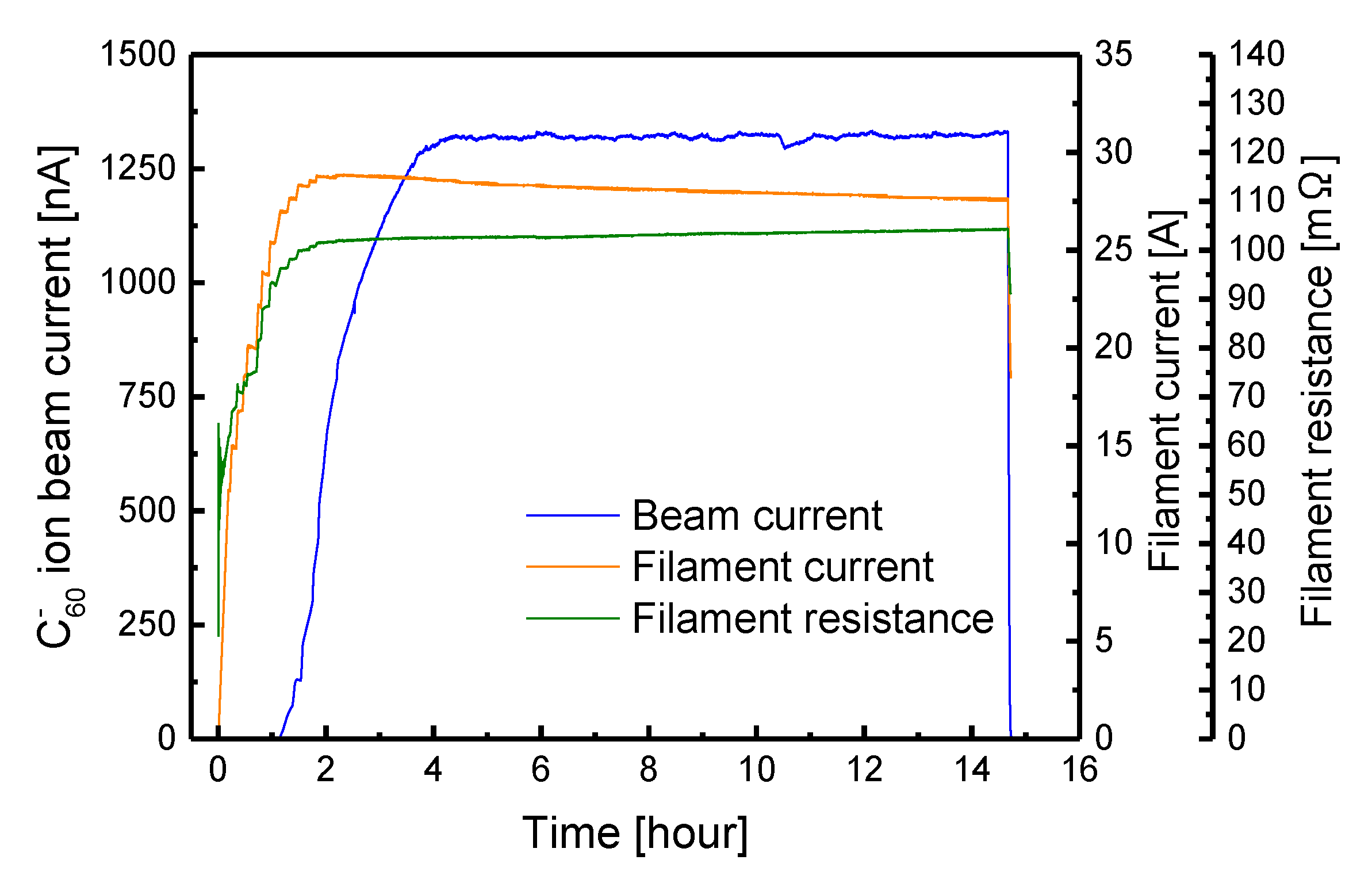

3.2. The Oven Rod with Built-In Source of Electrons

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dunlop, A.; Jaskierowicz, G.; Della-Negra, S. Latent track formation in silicon irradiation by 30 MeV fullerenes. Nucl. Instr. Meth. Phys. Res. B 1998, 146, 302–308. [Google Scholar] [CrossRef]

- Dammak, H.; Dunlop, A.; Lesueur, D.; Brunelle, A.; Della-Negra, S.; Le Beyec, Y. Tracks in metals by MeV fullerenes. Phys. Rev. Lett. 1995, 74, 1135–1138. [Google Scholar] [CrossRef] [PubMed]

- Barlo Daya, D.D.N.; Hallén, A.; Eriksson, J.; Kopniczky, J.; Papaléo, R.; Reimann, C.T.; Håkansson, P.; Sundqvist, B.U.R.; Brunelle, A.; Della-Negra, S. Radiation damage features on mica and L-valine probed by scanning force microscopy. Nucl. Instr. Meth. Phys. Res. B 1995, 106, 38–42. [Google Scholar] [CrossRef]

- Fink, D.; Vacik, J.; Klett, R.; Chadderton, L.T.; Hnatowicz, V. Doping of 20 MeV fullerene ion tracks in polyimide. Nucl. Instr. Meth. Phys. Res. B 1996, 119, 591–595. [Google Scholar] [CrossRef]

- Döbeli, M.; Ames, F.; Musil, C.R.; Scandella, L.; Suter, M.; Synal, H.A. Surface tracks by MeV C60 impacts on mica and PMMA. Nucl. Instr. Meth. Phys. Res. B 1998, 143, 503–512. [Google Scholar] [CrossRef]

- Dhamodaran, S.; Pathak, A.P.; Dunlop, A.; Jaskierowicz, G.; Della Negra, S. Energetic cluster irradiation of InP. Nucl. Instr. Meth. Phys. Res. B 2007, 256, 229–232. [Google Scholar] [CrossRef]

- El-Said, A.S. Tracks of 30-MeV C60 clusters in yttrium iron garnet studied by scanning force microscopy. Nucl. Instr. Meth. Phys. Res. B 2009, 267, 953–956. [Google Scholar] [CrossRef][Green Version]

- Della-Negra, S.; Brunelle, A.; Le Beyec, Y.; Curaudeau, J.M.; Mouffron, J.P.; Waast, B.; Håkansson, P.; Sundqvist, B.U.R.; Parilis, E. Acceleration of C60n+ molecules to high energy. Nucl. Instr. Meth. Phys. Res. B 1993, 74, 453–456. [Google Scholar] [CrossRef]

- Ames, F.; Döbeli, M.; Musil, C.R.; Nebiker, P.W.; Scandella, L.; Suter, M.; Synal, H.A. Acceleration of clusters, collision induced charge exchange at MeV energies and applications for materials science. Nucl. Instr. Meth. Phys. Res. B 1996, 112, 64–67. [Google Scholar] [CrossRef]

- Tomaschko, C.; Kügler, R.; Schurr, M.; Voit, H. MeV cluster ions from the Erlangen tandem accelerator. Nucl. Instr. Meth. Phys. Res. B 1996, 117, 199–204. [Google Scholar] [CrossRef]

- Weibel, D.; Wong, S.; Lockyer, N.; Blenkinsopp, P.; Hill, R.; Vickerman, J.C. A C60 primary ion beam system for time of flight secondary ion mass spectrometry: Its development and secondary ion yield characteristics. Anal. Chem. 2003, 75, 1754–1764. [Google Scholar] [CrossRef] [PubMed]

- Sun, S.; Szakal, C.; Roll, T.; Mazarov, P.; Wucher, A.; Winograd, N. Use of C60 cluster projectiles for sputter depth profiling of polycrystalline metals. Surf. Interface Anal. 2004, 36, 1367–1372. [Google Scholar] [CrossRef]

- Fahey, A.J.; Gillen, G.; Chi, P.; Mahoney, C.M. Performance of a C60+ ion source on a dynamic SIMS instrument. Appl. Surf. Sci. 2006, 252, 7312–7314. [Google Scholar] [CrossRef]

- Toyoda, N.; Matsuo, J.; Aoki, T.; Yamada, I.; Fenner, D.B. Secondary ion mass spectrometry with gas cluster ion beams. Appl. Surf. Sci. 2003, 203–304, 214–218. [Google Scholar] [CrossRef]

- Rickman, R.D.; Verkhoturov, S.V.; Parilis, E.S.; Schweikert, E.A. Simultaneous ejection of two molecular ions from keV gold atomic and polyatomic projectile impacts. Phys. Rev. Lett. 2004, 92, 047601. [Google Scholar] [CrossRef]

- Hirata, K.; Saitoh, Y.; Chiba, A.; Adachi, M.; Yamada, K.; Narumi, K. Development of secondary ion mass spectroscopy using medium energy C60 ion impact. Nucl. Instr. Meth. Phys. Res. B 2008, 266, 2450–2452. [Google Scholar] [CrossRef]

- Hirata, K.; Saitoh, Y.; Chiba, A.; Yamada, K. Narumi, Surface-sensitive chemical analysis of organic insulating thin films using negative secondary ions induced by medium energy C60 impacts. Appl. Phys. Expr. 2011, 4, 116202. [Google Scholar] [CrossRef]

- Middleton, R. A survey of negative ions from a cesium sputter source. Nucl. Instr. Meth. 1977, 144, 373–399. [Google Scholar] [CrossRef]

- Middleton, R. A versatile high intensity negative ion source. Nucl. Instr. Meth. 1983, 214, 139–150. [Google Scholar] [CrossRef]

- Rathmell, R.D.; Norton, G.A. Production MeV ion implanters for energies from 200 keV to 4MeV. Nucl. Instr. Meth. Phys. Res. B 1987, 21, 270–273. [Google Scholar] [CrossRef]

- Lezius, M.; Scheier, P.; Märk, T.D. Free electron attachment to C60 and C70. Chem. Phys. Lett. 1993, 203, 232–236. [Google Scholar] [CrossRef]

- Jaffke, T.; Illenberger, E.; Lezius, M.; Matejcik, S.; Smith, D.; Märk, T.D. Formation of C60− and C70− by free electron capture. Activation energy and effect of the internal energy on lifetime. Chem. Phys. Lett. 1994, 226, 213–218. [Google Scholar] [CrossRef]

- Prabhudesai, V.S.; Nandi, D.; Krishnakumar, E. Low energy electron attachment to C60. Eur. Phys. J. D 2005, 35, 261–266. [Google Scholar] [CrossRef]

- Bekkerman, A.; Tsipinyuk, B.; Kolodney, E. Thermally activated decay channels of superhot C60−: Delayed electron emission and dissociative attachment studied by hyperthermal negative surface ionization. Int. J. Mass Spectrom. 1999, 187, 773–786. [Google Scholar] [CrossRef]

- Koda, D.; Kuninaka, H.; Tsukizaki, R. Demonstration of negative fullerene ion thruster combined with positive xenon ion thruster. Trans. JSASS Aerosp. Technol. Japan 2016, 14, 203–208. [Google Scholar] [CrossRef]

- Saitoh, Y.; Chiba, A.; Narumi, K. Transmission of cluster ions through a tandem accelerator of several stripper gases. Rev. Sci. Instr. 2009, 80, 106104. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiba, A.; Usui, A.; Hirano, Y.; Yamada, K.; Narumi, K.; Saitoh, Y. Novel Approaches for Intensifying Negative C60 Ion Beams Using Conventional Ion Sources Installed on a Tandem Accelerator. Quantum Beam Sci. 2020, 4, 13. https://doi.org/10.3390/qubs4010013

Chiba A, Usui A, Hirano Y, Yamada K, Narumi K, Saitoh Y. Novel Approaches for Intensifying Negative C60 Ion Beams Using Conventional Ion Sources Installed on a Tandem Accelerator. Quantum Beam Science. 2020; 4(1):13. https://doi.org/10.3390/qubs4010013

Chicago/Turabian StyleChiba, Atsuya, Aya Usui, Yoshimi Hirano, Keisuke Yamada, Kazumasa Narumi, and Yuichi Saitoh. 2020. "Novel Approaches for Intensifying Negative C60 Ion Beams Using Conventional Ion Sources Installed on a Tandem Accelerator" Quantum Beam Science 4, no. 1: 13. https://doi.org/10.3390/qubs4010013

APA StyleChiba, A., Usui, A., Hirano, Y., Yamada, K., Narumi, K., & Saitoh, Y. (2020). Novel Approaches for Intensifying Negative C60 Ion Beams Using Conventional Ion Sources Installed on a Tandem Accelerator. Quantum Beam Science, 4(1), 13. https://doi.org/10.3390/qubs4010013