A Path towards SDGs: Investigation of the Challenges in Adopting 3D Concrete Printing in India

Abstract

1. Introduction

- (1)

- To examine how management decisions regarding 3DCP application impact sustainability across environmental, economic, and social dimensions.

- (2)

- To explore how current institutional conditions, such as government commissioning and tendering processes, influence management incentives to invest in 3DCP.

- (3)

- To identify key challenges in implementing 3DCP and propose policy changes that could facilitate greater adoption of this technology, enhancing overall sustainability.

2. Background

2.1. Challenges and Promises of 3DCP in Construction

2.2. Research Gap

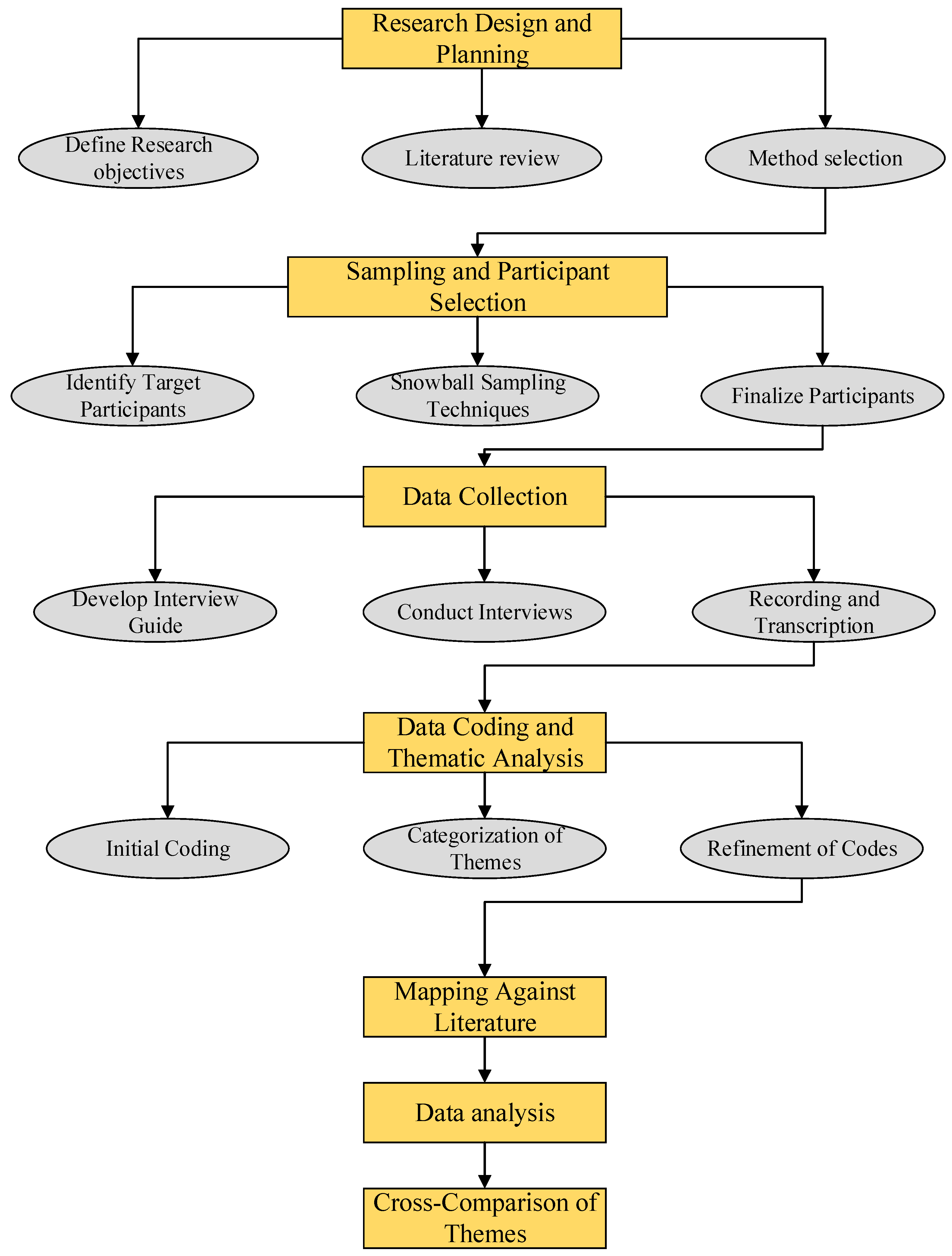

3. Methodology

3.1. Research Approach

3.2. Data Collection

3.3. Data Analysis

| Expert | Qualification | Experience | Area of Expertise | Interview Duration (mins) |

|---|---|---|---|---|

| Expert 1 | Ph.D. in Structural Engineering | 15 years | 3D Concrete Printing, Structural Design | 54 |

| Expert 2 | M.Sc. in Construction Management. | 12 years | Project Management, Sustainable Construction | 95 |

| Expert 3 | B.Eng. in Civil Engineering | 20 years | Concrete Technology, Building Materials | 74 |

| Expert 4 | M.Sc. in Environmental Engineering | 10 years | Environmental Impact Assessment, Green Building Technologies | 86 |

| Expert 5 | Ph.D. in Architecture | 18 years | Innovative Building Design, 3D Printing Applications | 46 |

| Expert 6 | B.Arch. in Architecture | 14 years | Sustainable Design, Building Information Modeling | 46 |

| Expert 7 | M.Sc. in Construction Technology | 8 years | Construction Innovation, 3DCP Implementation | 76 |

| Expert 8 | Ph.D. in Mechanical Engineering | 22 years | Robotics in Construction, Automation Technologies | 46 |

| Expert 9 | M.Sc. in Structural Engineering | 16 years | Structural Analysis, Material Science | 44 |

| Expert 10 | B.Sc. in Civil Engineering | 13 years | Infrastructure Projects, Concrete Durability | 46 |

| Expert 11 | M.Sc. in Environmental Design | 11 years | Environmental Sustainability, Circular Economy | 45 |

| Expert 12 | Ph.D. in Building Science | 17 years | Building Physics, Thermal Efficiency | 60 |

| Expert 13 | B.Eng. in Construction Engineering | 15 years | Construction Technology, Project Management | 58 |

| Expert 14 | M.Sc. in Architectural Engineering | 9 years | Sustainable Architecture, 3D Printing | 49 |

| Expert 15 | Ph.D. in Civil Engineering | 19 years | Structural Integrity, Advanced Construction Materials | 33 |

| Expert 16 | M.Sc. in Sustainability | 12 years | Sustainable Building Practices, Environmental Policy | 59 |

| Expert 17 | B.Eng. in Mechanical Engineering | 20 years | Construction Robotics, Automation Systems | 71 |

| Expert 18 | M.Sc. in Project Management | 14 years | Construction Projects, Resource Management | 43 |

| Expert 19 | Ph.D. in Environmental Science | 16 years | Eco-friendly Materials, Life Cycle Assessment | 54 |

| Expert 20 | M.Sc. in Urban Planning | 13 years | Urban Development, Sustainable Design | 87 |

4. Findings

4.1. Environmental Sustainability: Good Promise, but There Are Questions Regarding Complete Circularity

4.2. Social Sustainability: Lower Reliance on Seasonal Labor and Higher Levels of Satisfaction among Building Occupants

4.3. Sustainability Economic: High R&D Expenditures Due to the Immaturity of Technologies

4.4. Preserving Harmony between the Surroundings, People, and Business Interests

5. Discussion

5.1. Decisions That Affect the Sustainability of the 3DCP

5.2. Policy Implications

6. Conclusions and Future Scope

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aramburu, A.; Calderon-Uriszar-Aldaca, I.; Puente, I.; Castano-Alvarez, R. Effects of 3D-printing on the tensile splitting strength of concrete structures. Case Stud. Constr. Mater. 2024, 20, e03090. [Google Scholar] [CrossRef]

- Dananjaya, V.; Marimuthu, S.; Yang, R.C.; Grace, A.N.; Abeykoon, C. Synthesis, properties, applications, 3D printing and machine learning of graphene quantum dots in polymer nanocomposites. Prog. Mater. Sci. 2024, 144, 101282. [Google Scholar] [CrossRef]

- Tinoco, M.P.; de Mendonça, É.M.; Fernandez, L.I.C.; Caldas, L.R.; Reales, O.A.M.; Filho, R.D.T. Life cycle assessment (LCA) and environmental sustainability of cementitious materials for 3D concrete printing: A systematic literature review. J. Build. Eng. 2022, 52, 104456. [Google Scholar] [CrossRef]

- Rajeev, P.; Ramesh, A.; Navaratnam, S.; Sanjayan, J. Using Fibre recovered from face mask waste to improve printability in 3D concrete printing. Cem. Concr. Compos. 2023, 139, 105047. [Google Scholar] [CrossRef]

- Cuevas, K.; Weinhold, J.; Stephan, D.; Kim, J.S. Effect of printing patterns on pore-related microstructural characteristics and properties of materials for 3D concrete printing using in situ and ex situ imaging techniques. Constr. Build. Mater. 2023, 405, 133220. [Google Scholar] [CrossRef]

- Hojati, M.; Memari, A.M.; Zahabi, M.; Wu, Z.; Li, Z.; Park, K.; Nazarian, S.; Duarte, J.P. Barbed-wire reinforcement for 3D concrete printing. Autom. Constr. 2022, 141, 104438. [Google Scholar] [CrossRef]

- Haar, B.T.; Kruger, J.; van Zijl, G. Off-site construction with 3D concrete printing. Autom. Constr. 2023, 152, 104906. [Google Scholar] [CrossRef]

- Castro, B.M.; Elbadawi, M.; Ong, J.J.; Pollard, T.; Song, Z.; Gaisford, S.; Pérez, G.; Basit, A.W.; Cabalar, P.; Goyanes, A. Machine learning predicts 3D printing performance of over 900 drug delivery systems. J. Control. Release 2021, 337, 530–545. [Google Scholar] [CrossRef]

- Chang, Z.; Zhang, H.; Liang, M.; Schlangen, E.; Šavija, B. Numerical simulation of elastic buckling in 3D concrete printing using the lattice model with geometric nonlinearity. Autom. Constr. 2022, 142, 104485. [Google Scholar] [CrossRef]

- Su, Z.; Zhao, K.; Ye, Z.; Cao, W.; Wang, X.; Liu, K.; Wang, Y.; Yang, L.; Dai, B.; Zhu, J. Overcoming the penetration-saturation trade-off in binder jet additive manufacturing via rapid in situ curing. Addit. Manuf. 2022, 59, 103157. [Google Scholar] [CrossRef]

- Christ, J.; Perrot, A.; Ottosen, L.M.; Koss, H. Rheological characterization of temperature-sensitive biopolymer-bound 3D printing concrete. Constr. Build. Mater. 2024, 411, 134337. [Google Scholar] [CrossRef]

- Khan, S.A.; Koç, M. Numerical modelling and simulation for extrusion-based 3D concrete printing: The underlying physics, potential, and challenges. Results Mater. 2022, 16, 100337. [Google Scholar] [CrossRef]

- Liu, J.; Li, S.; Fox, K.; Tran, P. 3D concrete printing of bioinspired Bouligand structure: A study on impact resistance. Addit. Manuf. 2022, 50, 102544. [Google Scholar] [CrossRef]

- Geng, S.Y.; Luo, Q.L.; Cheng, B.Y.; Li, L.X.; Wen, D.C.; Long, W.J. Intelligent multi-objective optimization of 3D printing low-carbon concrete for multi-scenario requirements. J. Clean. Prod. 2024, 445, 141361. [Google Scholar] [CrossRef]

- Ahmed, G.H. A review of “3D concrete printing”: Materials and process characterization, economic considerations and environmental sustainability. J. Build. Eng. 2023, 66, 105863. [Google Scholar] [CrossRef]

- Dey, D.; Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Use of industrial waste materials for 3D printing of sustainable concrete: A review. J. Clean. Prod. 2022, 340, 130749. [Google Scholar] [CrossRef]

- Nasiri, H.; Dadashi, A.; Azadi, M. Machine learning for fatigue lifetime predictions in 3D-printed polylactic acid biomaterials based on interpretable extreme gradient boosting model. Mater. Today Commun. 2024, 39, 109054. [Google Scholar] [CrossRef]

- Alabbasi, M.; Agkathidis, A.; Chen, H. Robotic 3D printing of concrete building components for residential buildings in Saudi Arabia. Autom. Constr. 2023, 148, 104751. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, I.G.; Kim, J.H. Towards full automation in 3D concrete printing construction: Development of an automated and inline sensor-printer integrated instrument for in-situ assessment of structural build-up and quality of concrete. Dev. Built Environ. 2024, 17, 100344. [Google Scholar] [CrossRef]

- Lyu, Q.; Dai, P.; Chen, A. Sandwich-structured porous concrete manufactured by mortar-extrusion and aggregate-bed 3D printing. Constr. Build. Mater. 2023, 392, 131909. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, L.C.; Hu, Y.Y.; Chen, S.G.; Liu, Y. Influential factors on mechanical properties and microscopic characteristics of underwater 3D printing concrete. J. Build. Eng. 2023, 77, 107571. [Google Scholar] [CrossRef]

- Rizzieri, G.; Cremonesi, M.; Ferrara, L. A 2D numerical model of 3D concrete printing including thixotropy. Mater. Today Proc. 2023, 20, 21–29. [Google Scholar] [CrossRef]

- Yang, H.; Fang, L.; Yuan, Z.; Teng, X.; Qin, H.; He, Z.; Wan, Y.; Wu, X.; Zhang, Y.; Guan, L.; et al. Machine learning guided 3D printing of carbon microlattices with customized performance for supercapacitive energy storage. Carbon 2023, 201, 408–414. [Google Scholar] [CrossRef]

- Ma, G.; Buswell, R.; da Silva, W.R.L.; Wang, L.; Xu, J.; Jones, S.Z. Technology readiness: A global snapshot of 3D concrete printing and the frontiers for development. Cem. Concr. Res. 2022, 156, 106774. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, W.; Yin, B.; Sun, W.; Akbar, A.; Zhang, Y.; Liew, K.M. Modeling extrusion process and layer deformation in 3D concrete printing via smoothed particle hydrodynamics. Comput. Methods Appl. Mech. Eng. 2024, 420, 116761. [Google Scholar] [CrossRef]

- Geng, S.Y.; Mei, L.; Cheng, B.Y.; Luo, Q.L.; Xiong, C.; Long, W.J. Revolutionizing 3D concrete printing: Leveraging RF model for precise printability and rheological prediction. J. Build. Eng. 2024, 88, 109127. [Google Scholar] [CrossRef]

- Voydie, D.; Goupil, L.; Chanthery, E.; Travé-Massuyès, L.; Delautier, S. Machine Learning Based Fault Anticipation for 3D Printing. IFAC PapersOnLine 2023, 56, 2927–2932. [Google Scholar] [CrossRef]

- Li, S.; Nguyen-Xuan, H.; Tran, P. Digital design and parametric study of 3D concrete printing on non-planar surfaces. Autom. Constr. 2023, 145, 104624. [Google Scholar] [CrossRef]

- Lu, B.; Li, M.; Wong, T.N.; Qian, S. Spray-based 3D concrete printing with calcium and polymeric additives: A feasibility study. Mater. Today Proc. 2022, 70, 252–257. [Google Scholar] [CrossRef]

- Rosseau, L.R.S.; Jansen, J.T.A.; Roghair, I.; van Sint Annaland, M. Favorable trade-off between heat transfer and pressure drop in 3D printed baffled logpile catalyst structures. Chem. Eng. Res. Des. 2023, 196, 214–234. [Google Scholar] [CrossRef]

- Wan, Q.; Wang, L.; Ma, G. Continuous and adaptable printing path based on transfinite mapping for 3D concrete printing. Autom. Constr. 2022, 142, 104471. [Google Scholar] [CrossRef]

- Zhang, N.; Sanjayan, J. Mechanisms of rheological modifiers for quick mixing method in 3D concrete printing. Cem. Concr. Compos. 2023, 142, 105218. [Google Scholar] [CrossRef]

- Huang, X.; Yang, W.; Song, F.; Zou, J. Study on the mechanical properties of 3D printing concrete layers and the mechanism of influence of printing parameters. Constr. Build. Mater. 2022, 335, 127496. [Google Scholar] [CrossRef]

- Gebhard, L.; Esposito, L.; Menna, C.; Mata-Falcón, J. Inter-laboratory study on the influence of 3D concrete printing set-ups on the bond behaviour of various reinforcements. Cem. Concr. Compos. 2022, 133, 104660. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, Z.; Zhang, X.; Chen, Z. 3D printing concrete structures: State of the art, challenges, and opportunities. Constr. Build. Mater. 2023, 405, 133364. [Google Scholar] [CrossRef]

- Li, Z.; Liu, H.; Nie, P.; Cheng, X.; Zheng, G.; Jin, W.; Xiong, B. Mechanical properties of concrete reinforced with high-performance microparticles for 3D concrete printing. Constr. Build. Mater. 2024, 411, 134676. [Google Scholar] [CrossRef]

- Cipollone, D.; Yang, H.; Yang, F.; Bright, J.; Liu, B.; Winch, N.; Wu, N.; Sierros, K.A. 3D printing of an anode scaffold for lithium batteries guided by mixture design-based sequential learning. J. Mater. Process. Technol. 2021, 295, 117159. [Google Scholar] [CrossRef]

- Lu, Y.; Xiao, J.; Li, Y. 3D printing recycled concrete incorporating plant fibres: A comprehensive review. Constr. Build. Mater. 2024, 425, 135951. [Google Scholar] [CrossRef]

- Rehman, A.U.; Perrot, A.; Birru, B.M.; Kim, J.H. Recommendations for quality control in industrial 3D concrete printing construction with mono-component concrete: A critical evaluation of ten test methods and the introduction of the performance index. Dev. Built Environ. 2023, 16, 100232. [Google Scholar] [CrossRef]

- Zhao, B.; Zhang, M.; Dong, L.; Wang, D. Design of grayscale digital light processing 3D printing block by machine learning and evolutionary algorithm. Compos. Commun. 2022, 36, 101395. [Google Scholar] [CrossRef]

- Barjuei, E.S.; Courteille, E.; Rangeard, D.; Marie, F.; Perrot, A. Real-time vision-based control of industrial manipulators for layer-width setting in concrete 3D printing applications. Adv. Ind. Manuf. Eng. 2022, 5, 100094. [Google Scholar] [CrossRef]

- Ramesh, S.; Deep, A.; Tamayol, A.; Kamaraj, A.; Mahajan, C.; Madihally, S. Advancing 3D bioprinting through machine learning and artificial intelligence. Bioprinting 2024, 38, e00331. [Google Scholar] [CrossRef]

- Breseghello, L.; Hajikarimian, H.; Naboni, R. 3DLightSlab. Design to 3D concrete printing workflow for stress-driven ribbed slabs. J. Build. Eng. 2024, 91, 109573. [Google Scholar] [CrossRef]

- Pan, Z.; Si, D.; Tao, J.; Xiao, J. Compressive behavior of 3D printed concrete with different printing paths and concrete ages. Case Stud. Constr. Mater. 2023, 18, e01949. [Google Scholar] [CrossRef]

- Liu, Z.; Li, M.; Quah, T.K.N.; Wong, T.N.; Tan, M.J. Comprehensive investigations on the relationship between the 3D concrete printing failure criterion and properties of fresh-state cementitious materials. Addit. Manuf. 2023, 76, 103787. [Google Scholar] [CrossRef]

- Lowke, D.; Vandenberg, A.; Pierre, A.; Thomas, A.; Kloft, H.; Hack, N. Injection 3D concrete printing in a carrier liquid—Underlying physics and applications to lightweight space frame structures. Cem. Concr. Compos. 2021, 124, 104169. [Google Scholar] [CrossRef]

- Yuan, P.F.; Zhan, Q.; Wu, H.; Beh, H.S.; Zhang, L. Real-time toolpath planning and extrusion control (RTPEC) method for variable-width 3D concrete printing. J. Build. Eng. 2022, 46, 103716. [Google Scholar] [CrossRef]

- Rubin, A.P.; Quintanilha, L.C.; Repette, W.L. Influence of structuration rate, with hydration accelerating admixture, on the physical and mechanical properties of concrete for 3D printing. Constr. Build. Mater. 2023, 363, 129826. [Google Scholar] [CrossRef]

- Lee, K.W.; Lee, H.J.; Choi, M.S. Correlation between thixotropic behavior and buildability for 3D concrete printing. Constr. Build. Mater. 2022, 347, 128498. [Google Scholar] [CrossRef]

- Sun, L.; Hua, G.; Cheng, T.C.E.; Teunter, R.H.; Dong, J.; Wang, Y. Purchase or rent? Optimal pricing for 3D printing capacity sharing platforms. Eur. J. Oper. Res. 2023, 307, 1192–1205. [Google Scholar] [CrossRef]

- Jaji, M.B.; van Zijl, G.P.A.G.; Babafemi, A.J. Slag-modified metakaolin-based geopolymer for 3D concrete printing application: Evaluating fresh and hardened properties. Clean Eng. Technol. 2023, 15, 100665. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Zhang, Y.; Pang, B.; Zhang, W.; Liu, C.; Liu, Z.; Wang, D.; Sun, G. Influence of gradation on extrusion-based 3D printing concrete with coarse aggregate. Constr. Build. Mater. 2023, 403, 133135. [Google Scholar] [CrossRef]

- El Abbaoui, K.; Al Korachi, I.; El Jai, M.; Šeta, B.; Mollah, M.T. 3D concrete printing using computational fluid dynamics: Modeling of material extrusion with slip boundaries. J. Manuf. Process. 2024, 118, 448–459. [Google Scholar] [CrossRef]

- Rehman, A.U.; Birru, B.M.; Kim, J.H. Set-on-demand 3D Concrete Printing (3DCP) construction and potential outcome of shotcrete accelerators on its hardened properties. Case Stud. Constr. Mater. 2023, 18, e01955. [Google Scholar] [CrossRef]

- Mollah, M.T.; Comminal, R.; da Silva, W.R.L.; Šeta, B.; Spangenberg, J. Computational fluid dynamics modelling and experimental analysis of reinforcement bar integration in 3D concrete printing. Cem. Concr. Res. 2023, 173, 107263. [Google Scholar] [CrossRef]

- Besklubova, S.; Tan, B.Q.; Zhong, R.Y.; Spicek, N. Logistic cost analysis for 3D printing construction projects using a multi-stage network-based approach. Autom. Constr. 2023, 151, 104863. [Google Scholar] [CrossRef]

- Bai, G.; Wang, L.; Wang, F.; Ma, G. Assessing printing synergism in a dual 3D printing system for ultra-high performance concrete in-process reinforced cementitious composite. Addit. Manuf. 2023, 61, 103338. [Google Scholar] [CrossRef]

- Wang, L.; Ye, K.; Wan, Q.; Li, Z.; Ma, G. Inclined 3D concrete printing: Build-up prediction and early-age performance optimization. Addit. Manuf. 2023, 71, 103595. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Pasupathy, K.; Mechtcherine, V.; Sanjayan, J. Printhead mixing of geopolymer and OPC slurries for hybrid alkali-activated cement in 3D concrete printing. Constr. Build. Mater. 2024, 430, 136439. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P.; Dehdasht, G.; Mohandes, S.R.; Manu, P.; Rahimian, F.P. Investigating the barriers to the adoption of blockchain technology in sustainable construction projects. J. Clean. Prod. 2023, 403, 136840. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.P.; Shoaib, M.; Adebayo, T.S.; Irfan, M. A strategic roadmap to overcome blockchain technology barriers for sustainable construction: A deep learning-based dual-stage SEM-ANN approach. Technol. Forecast. Soc. Change 2023, 194, 122716. [Google Scholar] [CrossRef]

- Adaloudis, M.; Roca, J.B. Sustainability tradeoffs in the adoption of 3D Concrete Printing in the construction industry. J. Clean Prod. 2021, 307, 127201. [Google Scholar] [CrossRef]

- Naganna, S.R.; Ibrahim, H.A.; Yap, S.P.; Tan, C.G.; Mo, K.H.; El-Shafie, A. Insights into the multifaceted applications of architectural concrete: A state-of-the-art review. Arab. J. Sci. Eng. 2021, 46, 4213–4223. [Google Scholar] [CrossRef]

- Lyu, Q.; Dai, P.; Chen, A. Mechanical strengths and optical properties of translucent concrete manufactured by mortar-extrusion 3D printing with polymethyl methacrylate (PMMA) fibers. Compos. B Eng. 2024, 268, 111079. [Google Scholar] [CrossRef]

- Liu, X.; Cai, H.; Ma, G.; Hou, G. Spray-based 3D concrete printing parameter design model: Actionable insight for high printing quality. Cem. Concr. Compos. 2024, 147, 105446. [Google Scholar] [CrossRef]

- Salaimanimagudam, M.P.; Jayaprakash, J. Effect of introducing dummy layers on interlayer bonding and geometrical deformations in concrete 3D printing. Mater. Lett. 2024, 366, 136575. [Google Scholar] [CrossRef]

- Qu, Z.; Yu, Q.; Ong, G.P.; Cardinaels, R.; Ke, L.; Long, Y.; Geng, G. 3D printing concrete containing thermal responsive gelatin: Towards cold environment applications. Cem. Concr. Compos. 2023, 140, 105029. [Google Scholar] [CrossRef]

- Cheng, H.; Radlińska, A.; Hillman, M.; Liu, F.; Wang, J. Modeling concrete deposition via 3D printing using reproducing kernel particle method. Cem. Concr. Res. 2024, 181, 107526. [Google Scholar] [CrossRef]

- Li, H.; Alkahtani, M.E.; Basit, A.W.; Elbadawi, M.; Gaisford, S. Optimizing environmental sustainability in pharmaceutical 3D printing through machine learning. Int. J. Pharm. 2023, 648, 123561. [Google Scholar] [CrossRef]

- Zhu, J.; Ren, X.; Cervera, M. Buildability modeling of 3D-printed concrete including printing deviation: A stochastic analysis. Constr. Build. Mater. 2023, 403, 133076. [Google Scholar] [CrossRef]

- Li, L.; Hao, L.; Li, X.; Xiao, J.; Zhang, S.; Poon, C.S. Development of CO2-integrated 3D printing concrete. Constr. Build. Mater. 2023, 409, 134233. [Google Scholar] [CrossRef]

- Ma, G.; Hu, T.; Wang, F.; Liu, X.; Li, Z. Magnesium phosphate cement for powder-based 3D concrete printing: Systematic evaluation and optimization of printability and printing quality. Cem. Concr. Compos. 2023, 139, 105000. [Google Scholar] [CrossRef]

- Zhao, Z.; Ji, C.; Xiao, J.; Yao, L.; Lin, C.; Ding, T.; Ye, T. A critical review on reducing the environmental impact of 3D printing concrete: Material preparation, construction process and structure level. Constr. Build. Mater. 2023, 409, 133887. [Google Scholar] [CrossRef]

- Chang, Z.; Chen, Y.; Schlangen, E.; Šavija, B. A review of methods on buildability quantification of extrusion-based 3D concrete printing: From analytical modelling to numerical simulation. Dev. Built Environ. 2023, 16, 100241. [Google Scholar] [CrossRef]

- Lyu, Q.; Wang, Y.; Dai, P. Multilayered plant-growing concrete manufactured by aggregate-bed 3D concrete printing. Constr. Build. Mater. 2024, 430, 136453. [Google Scholar] [CrossRef]

- Zhang, R.C.; Wang, L.; Xue, X.; Ma, G.W. Environmental profile of 3D concrete printing technology in desert areas via life cycle assessment. J. Clean. Prod. 2023, 396, 136412. [Google Scholar] [CrossRef]

- Yang, W.; Wang, L.; Ma, G.; Feng, P. An integrated method of topological optimization and path design for 3D concrete printing. Eng. Struct. 2023, 291, 116435. [Google Scholar] [CrossRef]

- Nguyen-Van, V.; Nguyen-Xuan, H.; Panda, B.; Tran, P. 3D concrete printing modelling of thin-walled structures. Structures 2022, 39, 496–511. [Google Scholar] [CrossRef]

- Yin, Y.; Huang, J.; Wang, T.; Yang, R.; Hu, H.; Manuka, M.; Zhou, F.; Min, J.; Wan, H.; Yuan, D.; et al. Effect of Hydroxypropyl methyl cellulose (HPMC) on rheology and printability of the first printed layer of cement activated slag-based 3D printing concrete. Constr. Build. Mater. 2023, 405, 133347. [Google Scholar] [CrossRef]

- Westphal, E.; Seitz, H. Machine learning for the intelligent analysis of 3D printing conditions using environmental sensor data to support quality assurance. Addit. Manuf. 2022, 50, 102535. [Google Scholar] [CrossRef]

- Bi, M.; Tran, P.; Xia, L.; Ma, G.; Xie, Y.M. Topology optimization for 3D concrete printing with various manufacturing constraints. Addit. Manuf. 2022, 57, 102982. [Google Scholar] [CrossRef]

- Jia, Z.; Kong, L.; Jia, L.; Ma, L.; Chen, Y.; Zhang, Y. Printability and mechanical properties of 3D printing ultra-high performance concrete incorporating limestone powder. Constr. Build. Mater. 2024, 426, 136195. [Google Scholar] [CrossRef]

- Wei, Y.; Han, S.; Chen, Z.; Lu, J.; Li, Z.; Yu, S.; Cheng, W.; An, M.; Yan, P. Numerical simulation of 3D concrete printing derived from printer head and printing process. J. Build. Eng. 2024, 88, 109241. [Google Scholar] [CrossRef]

- An, D.; Zhang, Y.X.; Yang, R.C. Numerical modelling of 3D concrete printing: Material models, boundary conditions and failure identification. Eng. Struct. 2024, 299, 117104. [Google Scholar] [CrossRef]

- Krishna, D.V.; Sankar, M.R. Machine learning-assisted extrusion-based 3D bioprinting for tissue regeneration applications. Ann. 3D Print. Med. 2023, 12, 100132. [Google Scholar] [CrossRef]

- Gao, H.; Chen, Y.; Chen, Q.; Yu, Q. Thermal and mechanical performance of 3D printing functionally graded concrete: The role of SAC on the rheology and phase evolution of 3DPC. Constr. Build. Mater. 2023, 409, 133830. [Google Scholar] [CrossRef]

- Duan, Z.; Deng, Q.; Xiao, J.; Lv, Z.; Hu, B. Experimental realization on stress distribution monitoring during 3D concrete printing. Mater. Lett. 2024, 358, 135878. [Google Scholar] [CrossRef]

- Nguyen-Van, V.; Li, S.; Liu, J.; Nguyen, K.; Tran, P. Modelling of 3D concrete printing process: A perspective on material and structural simulations. Addit. Manuf. 2023, 61, 103333. [Google Scholar] [CrossRef]

- Ovhal, M.M.; Kumar, N.; Lee, H.B.; Tyagi, B.; Ko, K.J.; Boud, S.; Kang, J.W. Roll-to-roll 3D printing of flexible and transparent all-solid-state supercapacitors. Cell. Rep. Phys. Sci. 2021, 2, 100562. [Google Scholar] [CrossRef]

- Liu, T.; Chen, S.; Ruan, K.; Zhang, S.; He, K.; Li, J.; Chen, M.; Yin, J.; Sun, M.; Wang, X.; et al. A handheld multifunctional smartphone platform integrated with 3D printing portable device: On-site evaluation for glutathione and azodicarbonamide with machine learning. J. Hazard. Mater. 2022, 426, 128091. [Google Scholar] [CrossRef]

- Xiong, B.; Nie, P.; Liu, H.; Li, X.; Li, Z.; Jin, W.; Cheng, X.; Zheng, G.; Wang, L. Optimization of fiber reinforced lightweight rubber concrete mix design for 3D printing. J. Build. Eng. 2024, 88, 109105. [Google Scholar] [CrossRef]

- Wei, Y.; Han, S.; Yu, S.; Chen, Z.; Li, Z.; Wang, H.; Cheng, W.; An, M. Parameter impact on 3D concrete printing from single to multi-layer stacking. Autom. Constr. 2024, 164, 105449. [Google Scholar] [CrossRef]

- Wang, Y.; Qiu, L.C.; Chen, S.G.; Liu, Y. 3D concrete printing in air and under water: A comparative study on the buildability and interlayer adhesion. Constr. Build. Mater. 2024, 411, 134403. [Google Scholar] [CrossRef]

- Rollakanti, C.R.; Prasad, C.V.S.R. Applications, performance, challenges and current progress of 3D concrete printing technologies as the future of sustainable construction—A state of the art review. Mater. Today Proc. 2022, 65, 995–1000. [Google Scholar] [CrossRef]

- Liu, S.; Lu, B.; Li, H.; Pan, Z.; Jiang, J.; Qian, S. A comparative study on environmental performance of 3D printing and conventional casting of concrete products with industrial wastes. Chemosphere 2022, 298, 134310. [Google Scholar] [CrossRef]

- Liu, X.; Sun, B. The influence of interface on the structural stability in 3D concrete printing processes. Addit. Manuf. 2021, 48, 102456. [Google Scholar] [CrossRef]

- Khan, S.A.; Ilcan, H.; Imran, R.; Aminipour, E.; Şahin, O.; Al Rashid, A.; Şahmaran, M.; Koç, M. The impact of nozzle diameter and printing speed on geopolymer-based 3D-Printed concrete structures: Numerical modeling and experimental validation. Results Eng. 2024, 21, 101864. [Google Scholar] [CrossRef]

- Zhang, N.; Sanjayan, J. Quick nozzle mixing technology for 3D printing foam concrete. J. Build. Eng. 2024, 83, 108445. [Google Scholar] [CrossRef]

- Dabbagh, S.R.; Ozcan, O.; Tasoglu, S. Machine learning-enabled optimization of extrusion-based 3D printing. Methods 2022, 206, 27–40. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, Y.; Chen, G.; Li, S.; Singh, A.; Luo, X.; Liu, C.; Gao, J.; Du, H. Development of low-carbon materials from GGBS and clay brick powder for 3D concrete printing. Constr. Build. Mater. 2023, 383, 131232. [Google Scholar] [CrossRef]

- Tu, H.; Wei, Z.; Bahrami, A.; Kahla, N.B.; Ahmad, A.; Özkılıç, Y.O. Recent advancements and future trends in 3D concrete printing using waste materials. Dev. Built Environ. 2023, 16, 100187. [Google Scholar] [CrossRef]

- Zhang, N.; Sanjayan, J. Surfactants to enable quick nozzle mixing in 3D concrete printing. Cem. Concr. Compos. 2023, 142, 105226. [Google Scholar] [CrossRef]

- Salaimanimagudam, M.P.; Jayaprakash, J. Effect of printing parameters on inter-filament voids, bonding, and geometrical deviation in concrete 3D printed structures. Mater. Lett. 2023, 349, 134815. [Google Scholar] [CrossRef]

- Dong, W.; Wang, J.; Hang, M.; Qu, S. Research on printing parameters and salt frost resistance of 3D printing concrete with ferrochrome slag and aeolian sand. J. Build. Eng. 2024, 84, 108508. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; Almujibah, H.R.; Sajjad, M.; Deifalla, A.; Shafiq, N.; Azab, M.; Qureshi, A.H. Overcoming implementation barriers in 3D printing for gaining positive influence considering PEST environment. Ain Shams Eng. J. 2024, 15, 102517. [Google Scholar] [CrossRef]

- Pott, U.; Jakob, C.; Dorn, T.; Stephan, D. Investigation of a shotcrete accelerator for targeted control of material properties for 3D concrete printing injection method. Cem. Concr. Res. 2023, 173, 107264. [Google Scholar] [CrossRef]

- Christ, J.; Leusink, S.; Koss, H. Multi-axial 3D printing of biopolymer-based concrete composites in construction. Mater. Des. 2023, 235, 112410. [Google Scholar] [CrossRef]

- Tao, Y.; Ren, Q.; Vantyghem, G.; Lesage, K.; Van Tittelboom, K.; Yuan, Y.; De Corte, W.; De Schutter, G. Extending 3D concrete printing to hard rock tunnel linings: Adhesion of fresh cementitious materials for different surface inclinations. Autom. Constr. 2023, 149, 104787. [Google Scholar] [CrossRef]

- Kwon, S.W.; Kim, J.S.; Lee, H.M.; Lee, J.S. Physics-added neural networks: An image-based deep learning for material printing system. Addit. Manuf. 2023, 73, 103668. [Google Scholar] [CrossRef]

- Li, H.; Addai-Nimoh, A.; Kreiger, E.; Khayat, K.H. Methodology to design eco-friendly fiber-reinforced concrete for 3D printing. Cem. Concr. Compos. 2024, 147, 105415. [Google Scholar] [CrossRef]

- Wan, Q.; Yang, W.; Wang, L.; Ma, G. Global continuous path planning for 3D concrete printing multi-branched structure. Addit. Manuf. 2023, 71, 103581. [Google Scholar] [CrossRef]

- Zeng, J.J.; Yan, Z.T.; Jiang, Y.Y.; Li, P.L. 3D printing of FRP grid and bar reinforcement for reinforced concrete plates: Development and effectiveness. Compos. Struct. 2024, 335, 117946. [Google Scholar] [CrossRef]

- Wang, X.; Banthia, N.; Yoo, D.Y. Reinforcement bond performance in 3D concrete printing: Explainable ensemble learning augmented by deep generative adversarial networks. Autom. Constr. 2024, 158, 105164. [Google Scholar] [CrossRef]

- Motalebi, A.; Khondoker, M.A.H.; Kabir, G. A systematic review of life cycle assessments of 3D concrete printing. Sustain. Oper. Comput. 2024, 5, 41–50. [Google Scholar] [CrossRef]

- Ahi, O.; Ertunç, Ö.; Bundur, Z.B.; Bebek, Ö. Automated flow rate control of extrusion for 3D concrete printing incorporating rheological parameters. Autom. Constr. 2024, 160, 105319. [Google Scholar] [CrossRef]

- Zhang, N.; Sanjayan, J. Extrusion nozzle design and print parameter selections for 3D concrete printing. Cem. Concr. Compos. 2023, 137, 104939. [Google Scholar] [CrossRef]

| 3DCP Trait | Effects on Earth | Impact on Individuals | Effect on Profit |

|---|---|---|---|

| Reduction in material use | + Production of concrete and transportation help to lessen environmental effects. + Formwork is not needed, which is limited in reuse. − Still, concrete is a big and difficult substance. − There is limited material availability for 3DCP, hence longer distance travel could be necessary. | − Formwork not needed. | + Potential cost and savings in formwork. − 3DCP materials are more expensive than traditional concrete. − Costlier alternatives to concrete. |

| Geometry freedom for complex designs | + A holistic design approach can improve energy efficiency. − Holistic design could be less modular and contradict circularity. | + The designs allow one to more readily fit the requirements of particular users. + Promotes high-skilled employment. | − Since integrated designs are difficult to evaluate, 3DCP’s cost-competitiveness cannot be readily matched with conventional designs. |

| Automation in 3DCP | + A higher level of quality control results in less waste and fewer errors. | + Automation will be the only choice should future construction personnel be lacking. − With 3DCP, concrete pouring calls for less work. | + Significant savings connected to expenses related to failures. Low variability helps project managers to lessen their uncertainty. High equipment, R&D, and quality control expenses. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shivendra, B.T.; Shahaji; Sharath Chandra, S.; Singh, A.K.; Kumar, R.; Kumar, N.; Tantri, A.; Naganna, S.R. A Path towards SDGs: Investigation of the Challenges in Adopting 3D Concrete Printing in India. Infrastructures 2024, 9, 166. https://doi.org/10.3390/infrastructures9090166

Shivendra BT, Shahaji, Sharath Chandra S, Singh AK, Kumar R, Kumar N, Tantri A, Naganna SR. A Path towards SDGs: Investigation of the Challenges in Adopting 3D Concrete Printing in India. Infrastructures. 2024; 9(9):166. https://doi.org/10.3390/infrastructures9090166

Chicago/Turabian StyleShivendra, Bandoorvaragerahalli Thammannagowda, Shahaji, Sathvik Sharath Chandra, Atul Kumar Singh, Rakesh Kumar, Nitin Kumar, Adithya Tantri, and Sujay Raghavendra Naganna. 2024. "A Path towards SDGs: Investigation of the Challenges in Adopting 3D Concrete Printing in India" Infrastructures 9, no. 9: 166. https://doi.org/10.3390/infrastructures9090166

APA StyleShivendra, B. T., Shahaji, Sharath Chandra, S., Singh, A. K., Kumar, R., Kumar, N., Tantri, A., & Naganna, S. R. (2024). A Path towards SDGs: Investigation of the Challenges in Adopting 3D Concrete Printing in India. Infrastructures, 9(9), 166. https://doi.org/10.3390/infrastructures9090166