The purpose of this paper is to propose a framework for estimating service life of a pavement. The service life of a pavement is a key input for developing LCA models for pavements. The proposed framework has been applied to a standard case wherein a penetration grade binder has been compared to a polymer modified bitumen. This approach can then be applied to various other binder materials and pavement designs, with the aim of understanding sustainability benefits associated with a specific approach.

The life cycle of a pavement can be considered as three stages, as described in

Figure 1. The whole life energy use and emissions associated with an asphalt pavement is significantly influenced by the service life of the pavement. Pavement construction results in emissions primarily associated with use of materials and energy arising from the extraction of raw materials, making asphalt, transport, and other supply chain-related emissions. Once the pavement is laid, there are emissions associated with periodic maintenance of the pavement and, finally, at the end of the pavement service life, the pavement is removed and then typically reused as recycled asphalt pavement (RAP). It is important to understand the service life of a pavement since that determines the frequency and type of maintenance required; hence, the overall emissions associated with a pavement in a cradle-to-grave, or cradle-to-cradle, approach for life cycle assessments. The design of pavements with an increased service life is one of the key levers from a sustainability perspective and also aligns with the sustainable development goals proposed by the United Nations [

1], in particular goals 9 (Industry, innovation and infrastructure), 12 (Responsible consumption and production), and 13 (Climate action), as well as long service life being a key pillar of circular economy thinking and improving resource and materials efficiency by using less materials over a period of time to perform the same function.

The service life of a pavement is affected by various factors such as the design of the pavement, climate conditions, type of binders and asphalt mixtures used, traffic and traffic growth rates, workmanship, and applied loads [

2]. There are general design guidelines that are prescribed by various highway agencies in Europe that guide the design of pavements considering these factors [

3]. Hence, pavement design tools can then help in determining specific pavement thickness aligning with such specifications. One of the primary ways in which pavement life is determined is supported by measurements of the rutting and fatigue behavior of asphalt mixtures in the laboratory [

4]. A further approach that has been adopted is to test cores from the field and fine tune pavement failure models (specifically, rutting and fatigue models) to estimate service life of pavements [

5,

6].

1.1. Approach to Pavement Design and Quantification of Uncertainty

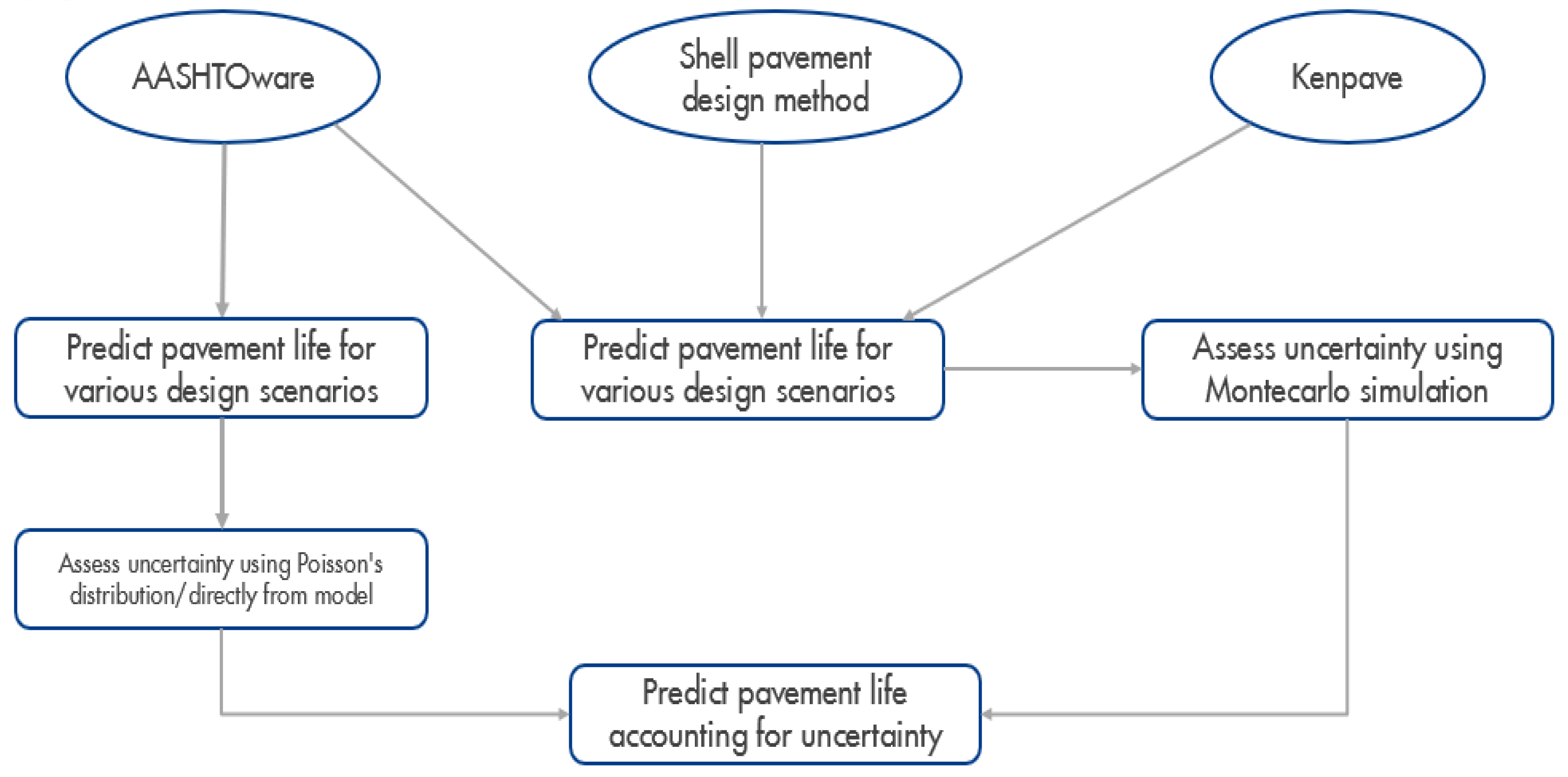

The current industrial practice for pavement design is to use pavement design software, and there are several different design tools that are currently being used in the market, as shown in

Table 1.

Most of these tools are mechanistic–empirical design tools where the stress and strain distribution in a pavement is determined by the elastic layer theory and the strain response is then further converted into pavement performance by empirical models. In addition, there are specific empirical models that are used for thermal cracking-type failure and also to determine the elastic modulus of the pavement at different temperatures. The measured dynamic modulus of an asphalt specimen is used as an input for these design tools. The preferred approach today for pavement design is to use a 2D finite element approach for strain prediction and use empirical models for pavement performance. Improving the accuracy of predicted strain, however, generally does not result in improved life prediction as discussed below.

The equation for fatigue (for example in the AASHTOware tool) is as follows

If a partial differential of this equation with respect to strain is performed, then the equation will be as below.

Nf—number of cycles, E—bulk modulus of the specimen (MPa) C, , —constants, ε—strain in the specimen.

A similar type of correlation, as given in Equation (1), will also apply to the pavement modulus. The results of a sensitivity analysis of equation 1 using partial differential method, indicates that the predicted life is more sensitive to fitting parameters rather than to strain and modulus (see

Table 2). Since the model is multiplicative in nature, the overall change in the predicted number of cycles for a 10% incremental change in strain and modulus is only 6%. This indicates that improving strain prediction accuracy may not result in an increase in the accuracy of predicted pavement life. It can also be seen in

Table 2 that although the model is more sensitive to constants, the degree of change is of the same order. This is achieved since the model has been tuned to field data; laboratory-based models may have a much higher dependency on fitting parameters. Even in the case of field models, the accuracy of the prediction when compared to observations on the field is limited (between 50% and 70%) and also has limited sensitivity, as indicated in the Mechanistic Empirical Pavement Design Guide (MEPDG), published in 2008.

In summary, predicted pavement service life is affected by many factors and, hence, is prone to inaccuracies such as the following.

- (1)

The reliability of the empirical models used for predicting pavement life depends on the nature and the quality of data used for tuning model coefficients. Empirical models that are tuned using data from the testing of field cores result in a prediction of pavement life which is lower than what is observed in the laboratory. AASHTOware uses data generated by testing cores from the field for tuning model coefficients.

- (2)

The assumption of the elastic layered theory for stress dissipation across the layers results in variations in the predicted strains [

7]

- (3)

Performance assessment of field cores requires the use of a falling weight deflectometer (FWD), traffic speed deflectometer (TSD)-type data which, when compared to laboratory techniques to determine asphalt mixture modulus, have very different accuracy levels resulting in differences in predicted pavement life.

- (4)

Growth rate assumptions for traffic and loads, plus the uncertainty in accounting for environmental events like high/low temperatures, amount of rainfall etc., may also result in inaccuracies in the predicted pavement life.

As indicated above, the pavement life determined from laboratory data and as observed in the field can differ significantly due to many reasons; hence, it is it is advisable to develop a method for uncertainty quantification associated with pavement life prediction so that a probabilistic pavement service life can then be used in life cycle estimates for pavements.

1.2. Proposed Methods for Uncertainty Quantification

One of the ways that uncertainty quantification has been proposed for pavements is to use a statistical distribution for service life prediction; in this case, a Poisson’s distribution [

7]. Poisson’s distribution is a common method to estimate probability of occurrence of an event basis of a set of discreet independent occurrences or data points. The mathematical form of Poisson’s distribution is

α—number of events that have occurred

k—a specific event

P(k)—the probability of occurrence of the k th event.

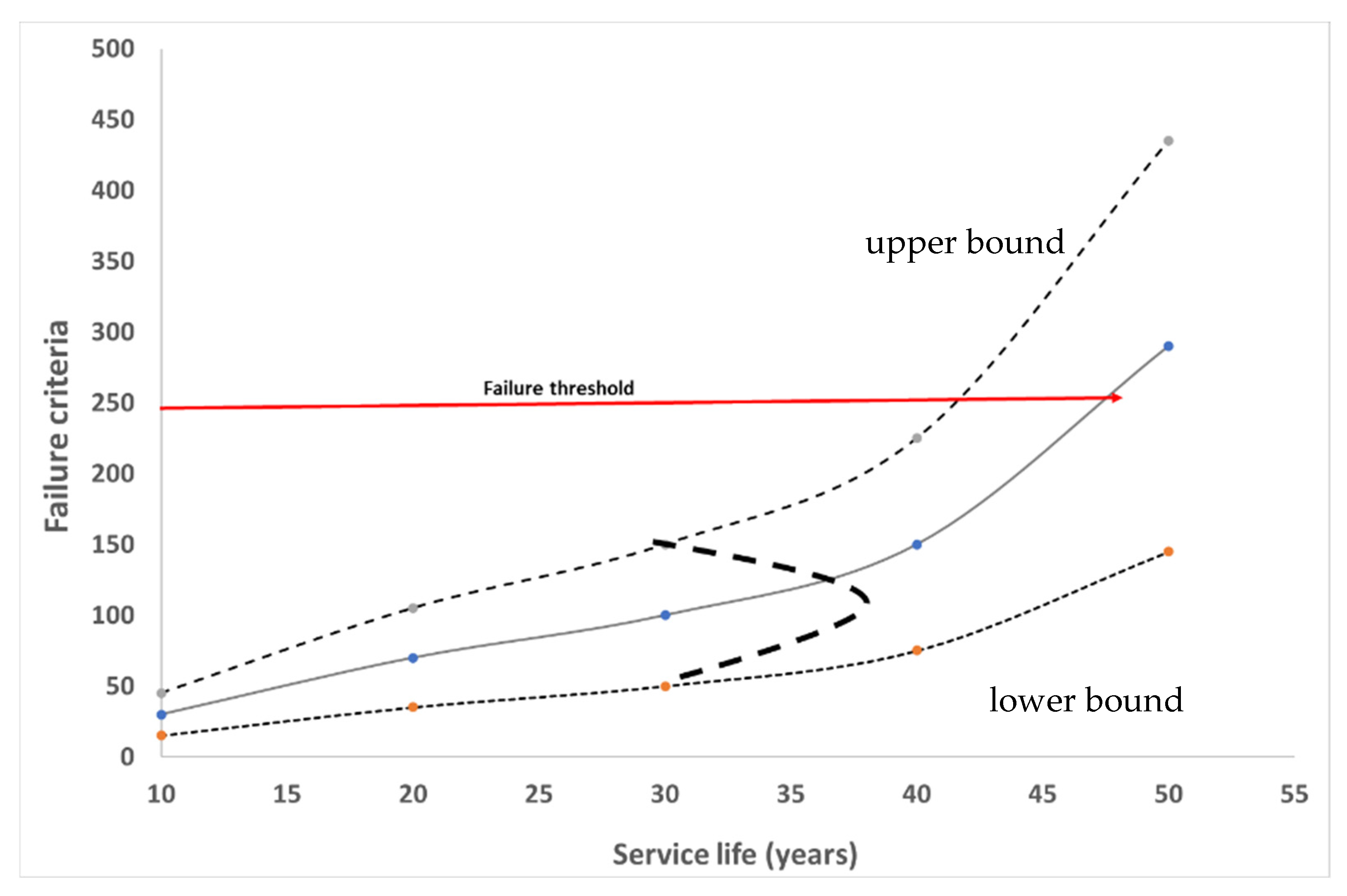

This procedure involves estimation of the pavement performance parameters at three different time points. Once this is completed, the performance parameters are then fitted to the Poisson’s distribution (See

Figure 2). The use of Poisson’s distribution then enables the determination of the standard deviation associated with a specific performance criterion. This also enables the determination of a probabilistic pavement service life (at 90% confidence level) for a specific pavement design methodology. This approach can be applied to any pavement design tool where the standard deviations associated with a performance prediction using an empirical model is not established. The reliability of a specific pavement performance model does not account for the accuracy of the model. A very high model reliability is not indicative of high accuracy, specifically where accuracy is defined by how close the predicted numbers are with respect to field observations; hence, a statistical uncertainty quantification technique is required and applied [

7]. In this study, the following approach has been used with the AASHTOware design tool.

Since a number of different pavement design tools are used for making service life predictions, a system-level uncertainty quantification technique, such as Monte Carlo simulation, has also been used [

8].

The Monte Carlo simulation technique has been widely used in the area of pavement design. The primary application has been in the life cycle cost estimation analysis for pavements wherein the pavement life is already known [

9]. Several studies have applied the Monte Carlo simulation technique to determine the impact of variation in factors like traffic and frequency of loading, on pavement thickness from a perpetual pavement design perspective [

10,

11,

12,

13].

The current study applies the Monte Carlo simulation technique for estimating a reference pavement life, wherein the pavement life is determined using various pavement design tool. Since the pavement life is estimated using three different software systems which utilize different types of empirical performance models, this method of uncertainty quantification is considered to be a system-level approach.

The Monte Carlo simulation technique assumes discrete probabilities of occurrences of events and, hence, is not biased by assumptions of specific probability density functions. There are several factors in the pavement design process which can be considered as random in nature such as workmanship or the occurrence of extreme weather events. Completely random events cannot be modelled by continuous probability density functions and, hence, the Monte Carlo simulation technique becomes useful for making probabilistic estimates of service lives. In the case of the Monte Carlo technique, discrete probabilities of occurrence are converted to cumulative probability distributions, which are then evaluated with various random numbers generated between chosen thresholds [

9]. This scenario is described in

Figure 3.

Three different pavement design tools are considered in this paper. These three tools are representative of the approaches that are generally used in practice for making service life estimates (as shown in

Table 1). These also represent three different scenarios with regard to prediction of pavement service life as shown in

Table 3.

Empirical models used for prediction of pavement life in AASHTOware are validated using field data. In addition, since the models are empirical and tuning of the models is carried out using regression techniques, the models themselves have a specific accuracy (with an R

2 between 70% and 90%) [

5,

6,

7]. Hence, there is further reduction of the predicted service life beyond what is observed in practice. From a scenario analysis perspective, this has been considered to be pessimistic.

The shell pavement design method (SPDM) is based on laboratory data wherein all parameters affecting pavement performance can be controlled. Pavement service lives predicted using laboratory data are higher than observed in the field; hence, prediction of service life using the SPDM method has been considered to be optimistic.

There are several studies that have indicated that when SPDM is used, the thickness of a pavement for a given service life is overestimated; hence, for a specified thickness the fatigue life will be a overestimated [

14,

15,

16]. The SPDM method is based on the initial binder properties of the material only since the models are not tuned to field data; hence, does not account for ageing of the binder, resulting in overestimation of pavement life [

14,

16].

The equation used for determining pavement life using SPDM is as below.

N—number of load cycles to failure

Vb—volume of asphalt in the mixture (%) (13% assumed for the case discussed in the paper)

ε—maximum tensile asphalt concrete strain (micrometer/micrometer) (250 microstrains)

Smix—dynamic modulus of the asphalt mixture (MPa).

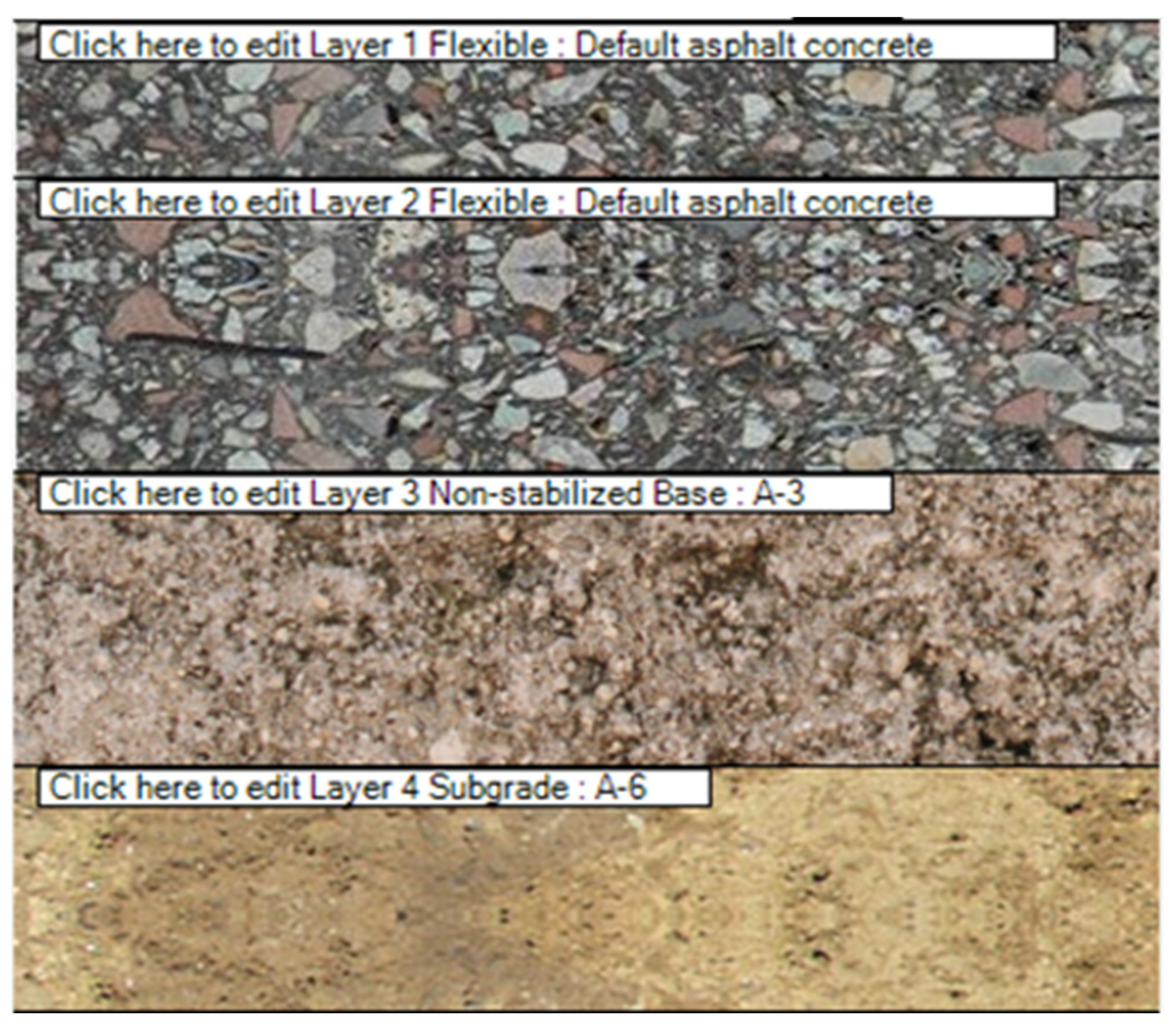

In addition to the above model, the fatigue life of an asphalt specimen was determined as as per the pavement design and gradation in

Table 4 and

Table 5 respectively, and the parameters k and n were determined for both PG64-22 and PG76-22. A design ESAL of 1000/day was used in the SPDM model. The Kenpave simulation was performed using the same inputs as used in the SPDM with a difference that a viscoelastic interface was selected while calculating the strain levels in the specimen.

Kenpave is a design tool that is partially based on laboratory data and partially based on published field testing data since it uses generic equations proposed by the Asphalt Institute, which are field tested but not calibrated to the extend as performed for AASHTOware. In addition, Kenpave assumes a viscoelastic interface between pavement layers and, hence, accounts for field behavior and simulates the rheological nature of the asphalt layers more closely; hence, it is considered to be a neutral scenario in terms of service life prediction [

17].

Some of the empirical performance models used in the AASHTOware approach have reported standard deviations, which can then be used for estimating uncertainty of predictions for point estimates. Hence, this method of uncertainty quantification can also be used for making probabilistic estimates, but this information is limited to very few tools and also to very few types of performance parameters; hence, is not a procedure that can always be used for quantifying uncertainty. In addition, even if this information is available for all the design tools and performance parameters, each predicted probabilistic service life will then require application of Monte Carlo simulations to estimate system-level uncertainties and also a unique pavement service life for a specific design. Hence, in this paper, only two different techniques have been evaluated. The methodology adopted in prediction of pavement service life accounting for uncertainty is shown in

Figure 4.