Effect of Incorporating Cement and Olive Waste Ash on the Mechanical Properties of Rammed Earth Block

Abstract

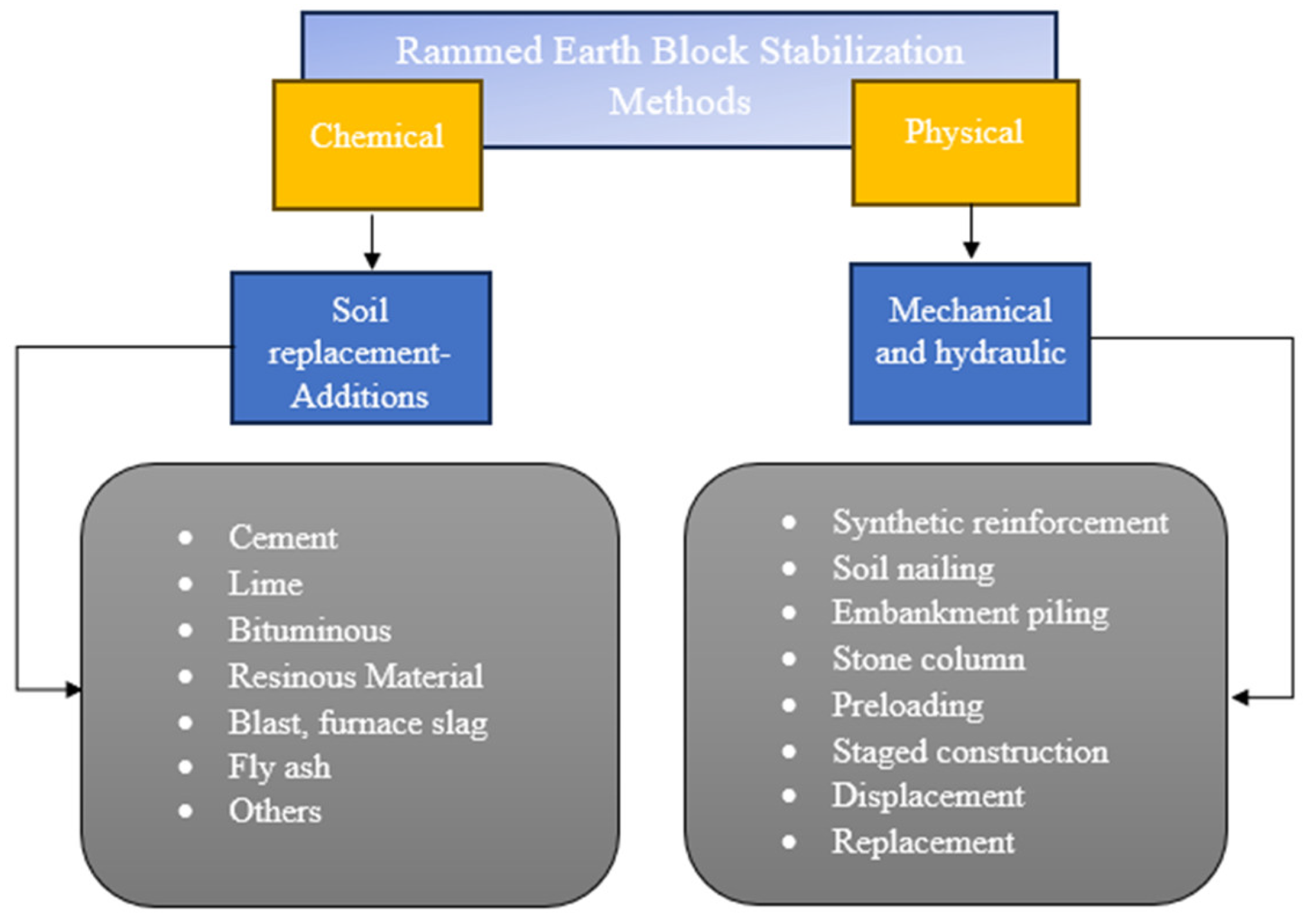

1. Introduction

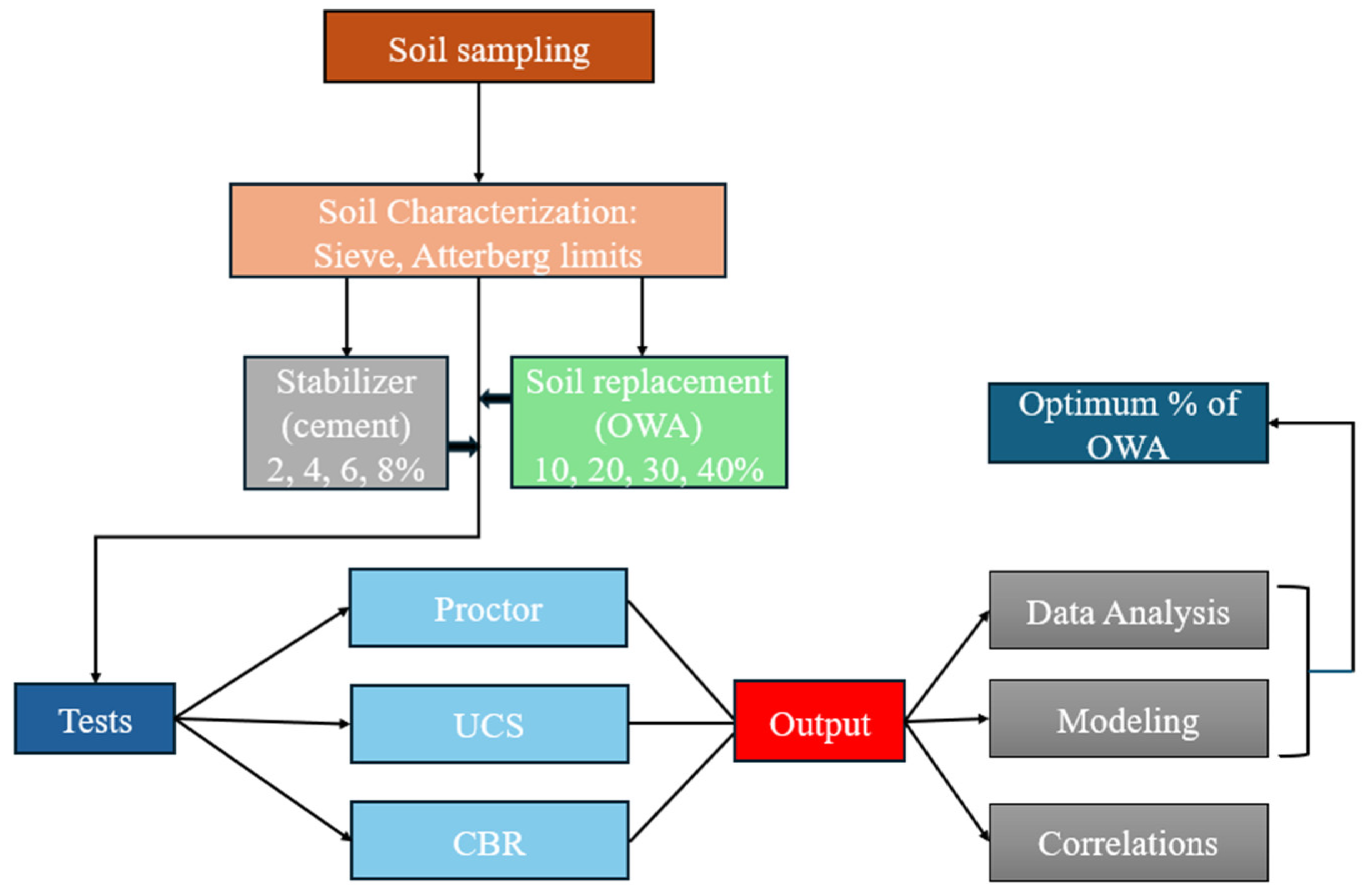

2. Experimental Program

2.1. Materials

2.1.1. Soil

2.1.2. Cement

2.1.3. Olive Waste Ash (OWA)

2.2. Mix Proportions

2.3. Sample Preparation and Testing Methods

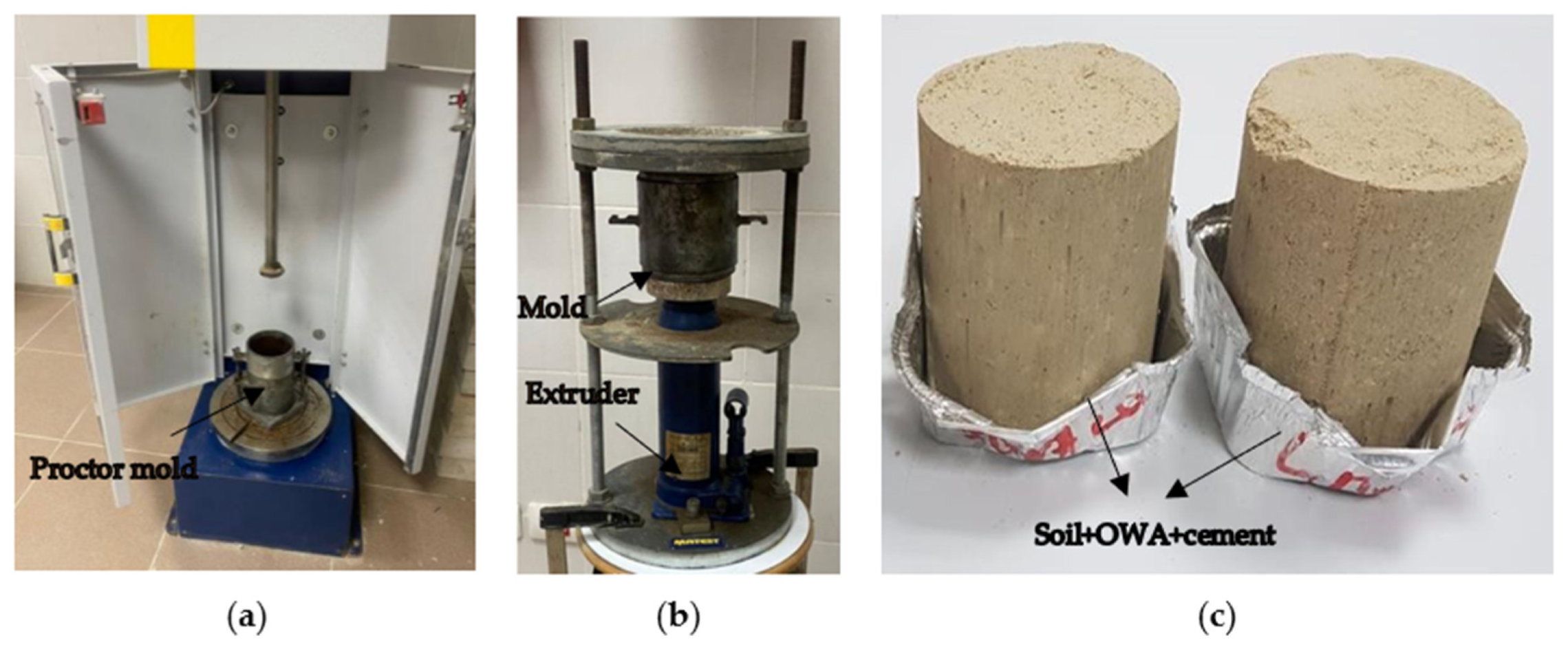

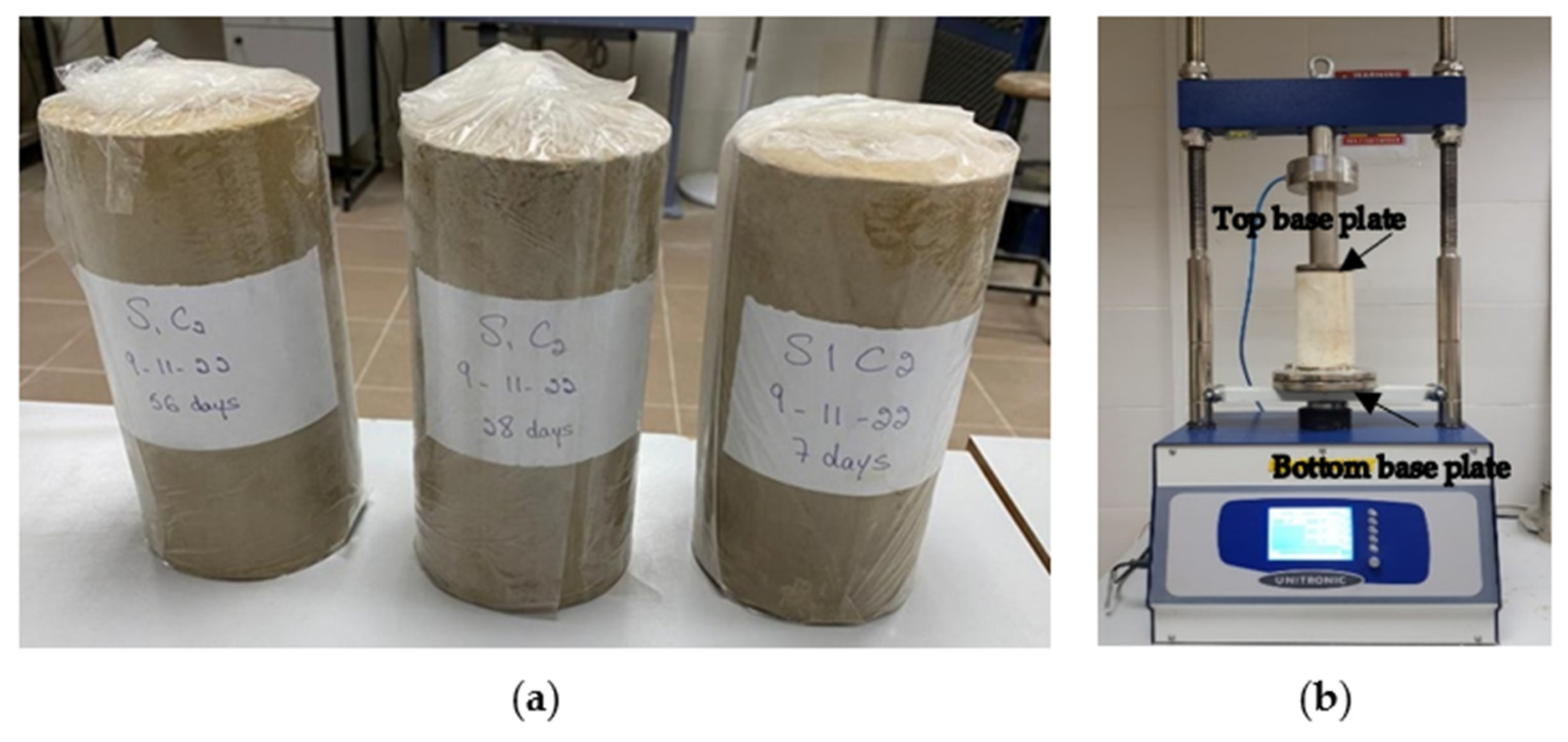

2.3.1. Sample Preparation

2.3.2. Compaction Test

2.3.3. Unconfined Compressive Strength (UCS)

2.3.4. California Bearing Ratio (CBR)

- P = measured pressure for site soils [N/mm2]

- PS = pressure to achieve equal penetration on standard crushed stone [N/mm2]

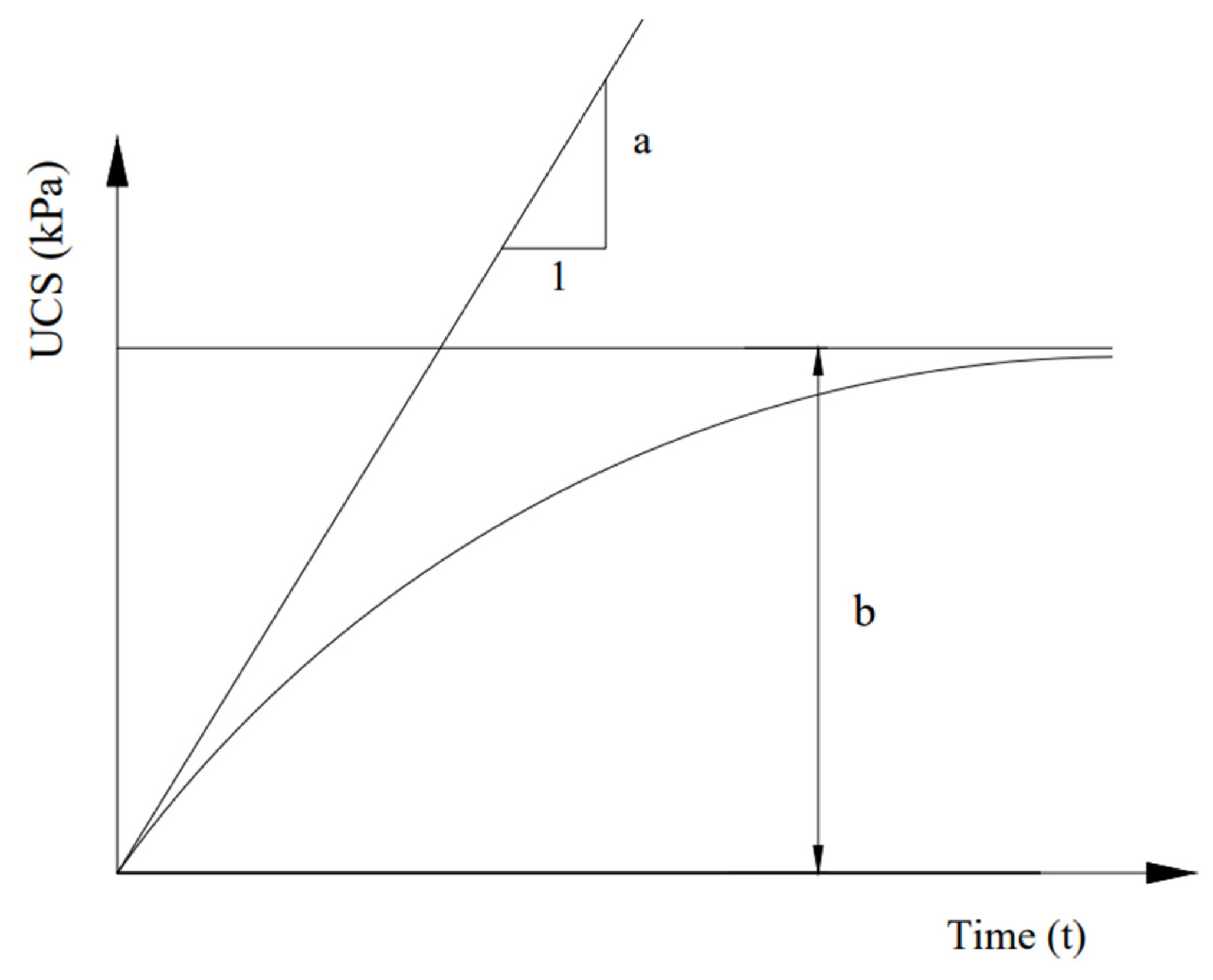

2.3.5. UCS Data Analysis for Rammed Earth Block

- UCS = unconfined compressive strength (kPa);

- T = time (days);

- a = I-UCS (kPa/day);

- b = U-UCS (kPa).

- U-UCSi = Ultimate Strength for mix i (i = 1, 2, … 15);

- I-UCSi = Initial Strength Gain for mix i (i = 1, 2, … 15);

- %Ci = % cement in mix i (i = 1, 2, … 15);

- %OWAi = % of olive waste ash in mix i (i = 1, 2, … 15);

- a0, a1, a2, a3 = regression parameters for the ultimate strength;

- b0, b1, b2, b3 = regression parameters for the initial strength gain.

3. Results

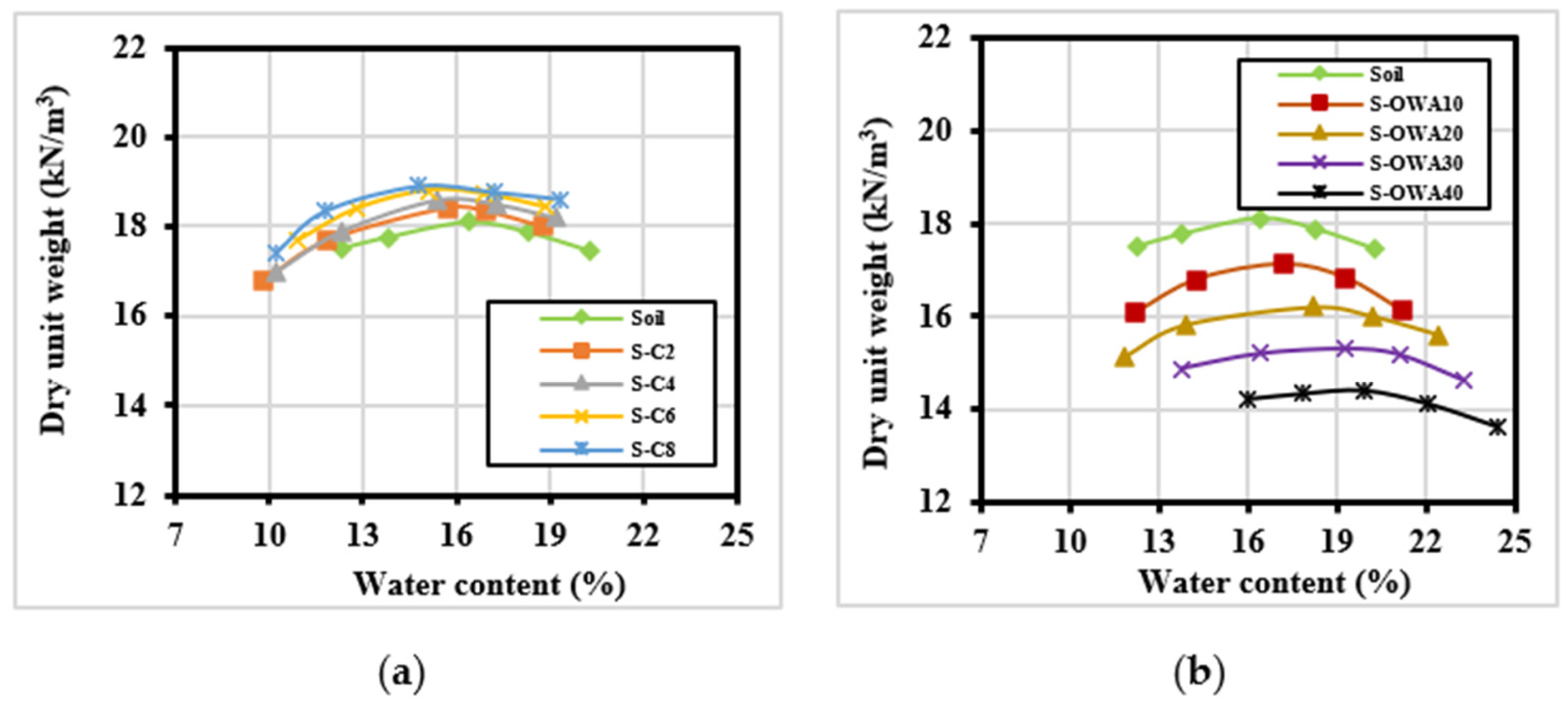

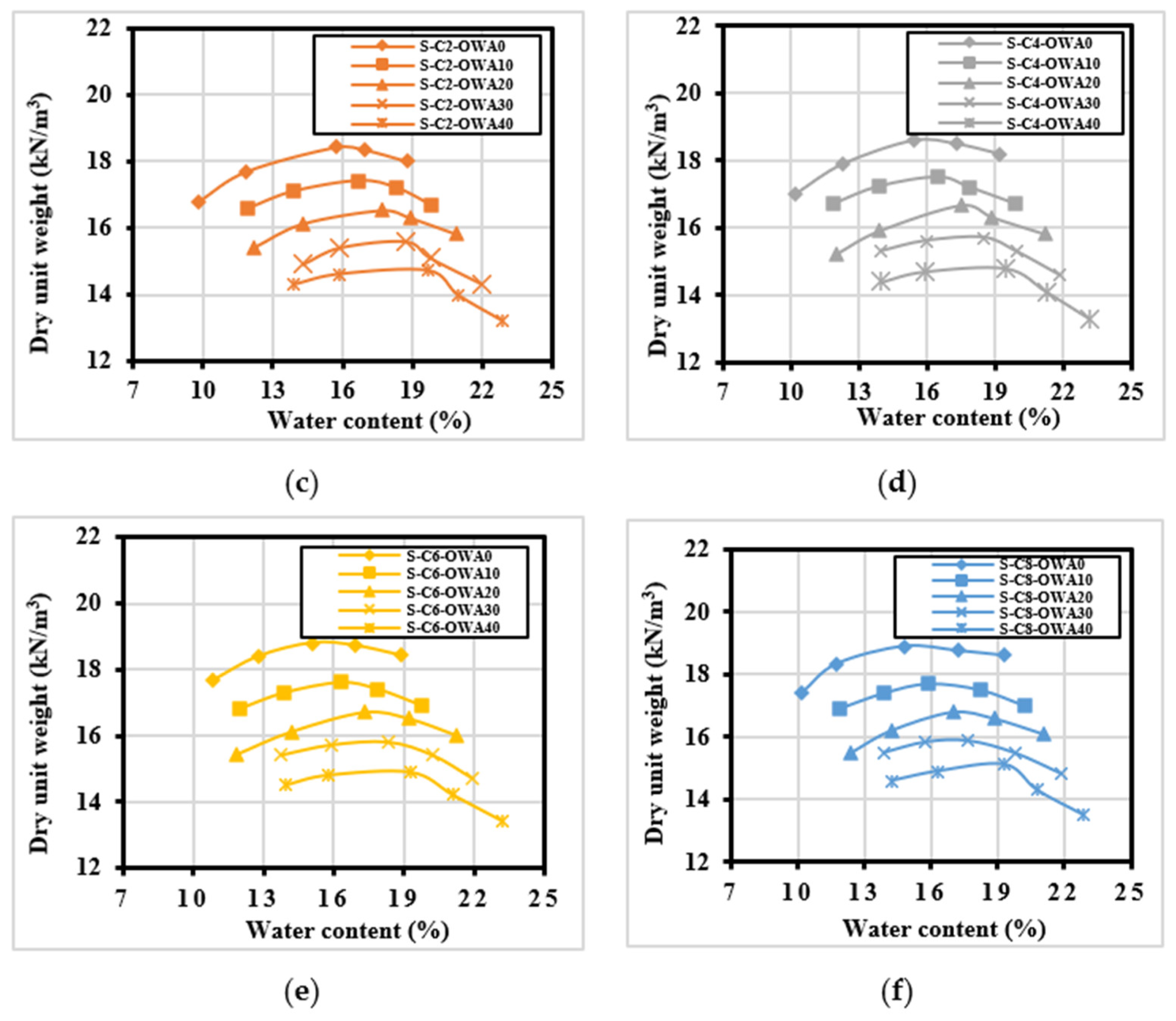

3.1. Compaction Characteristics

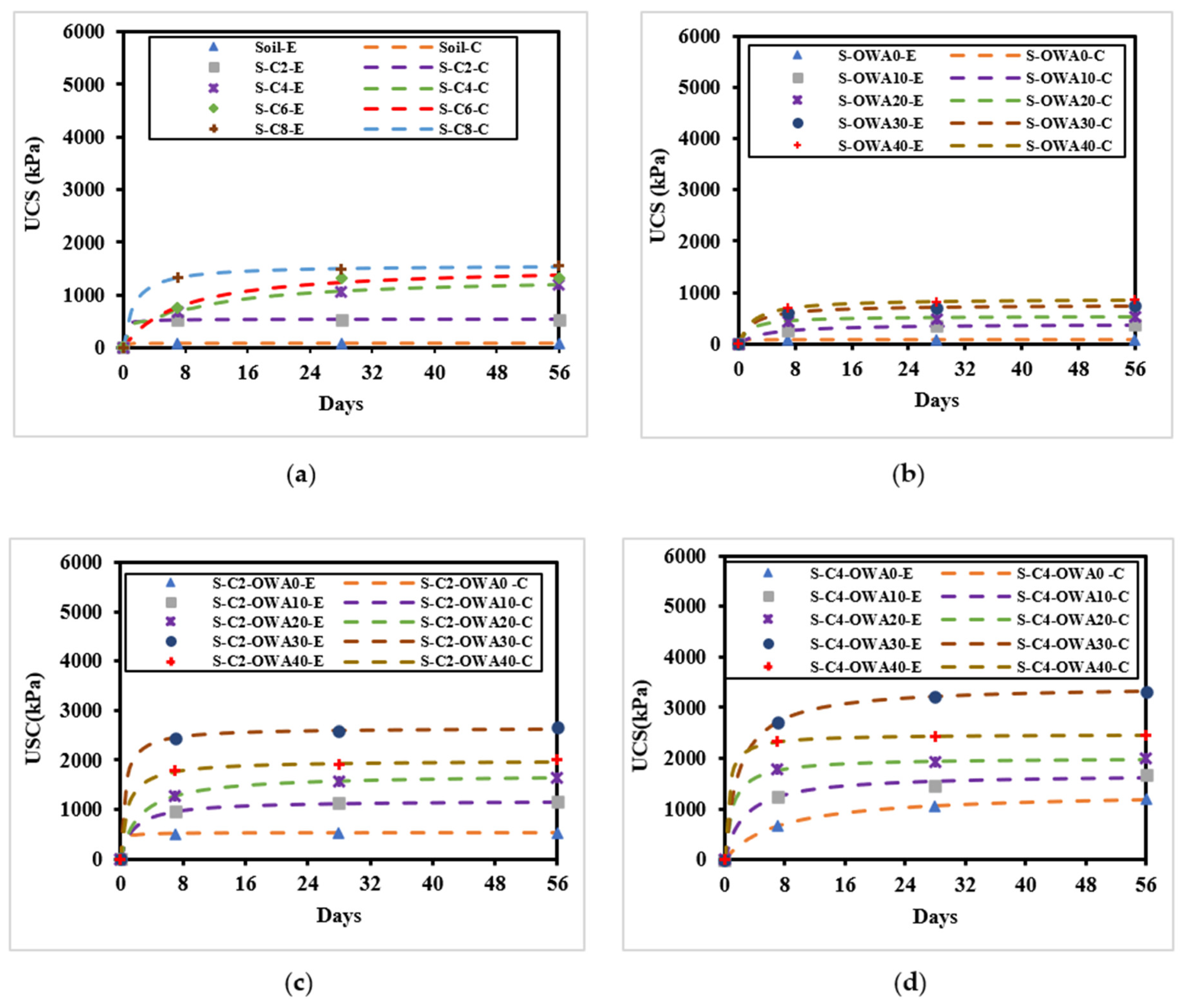

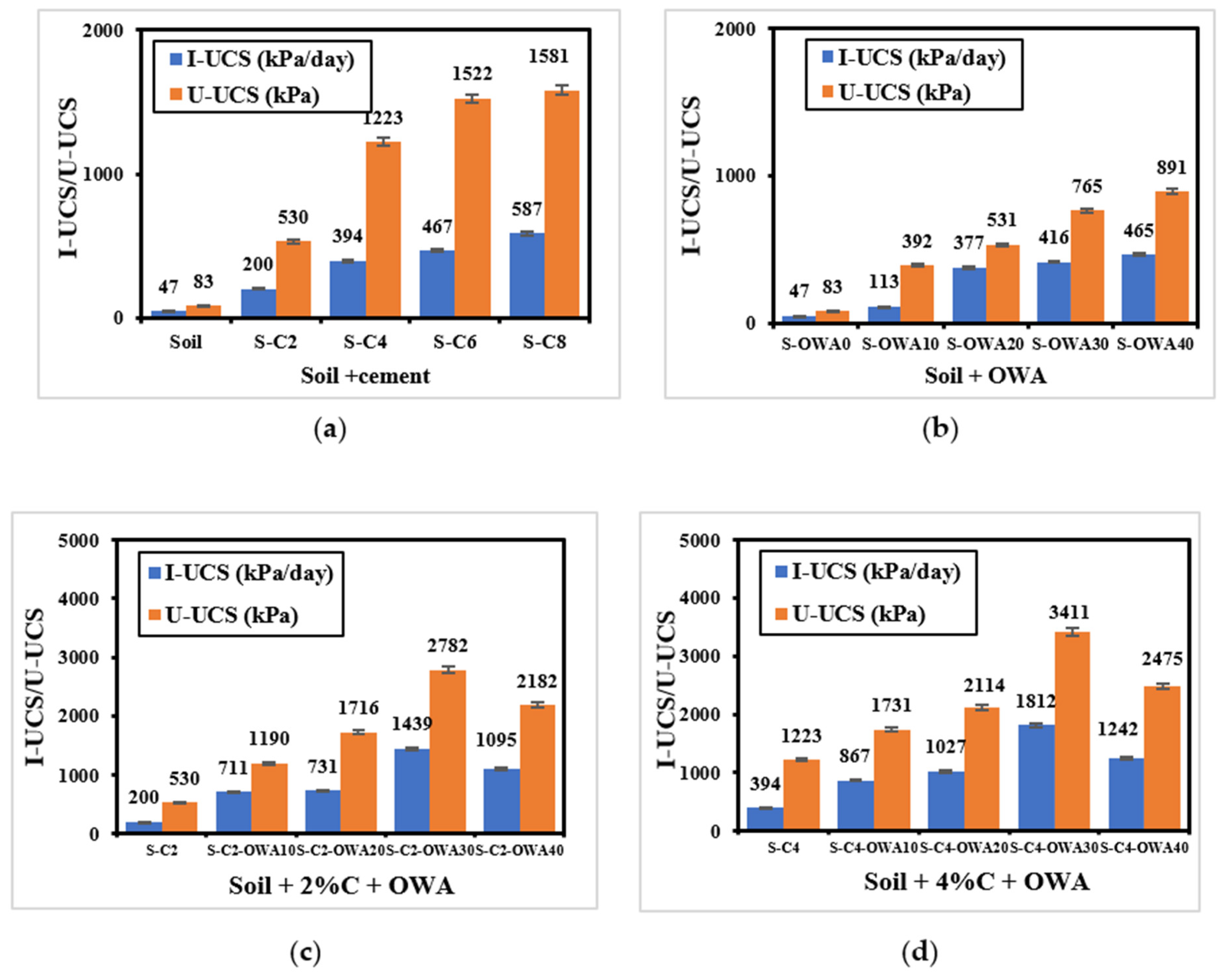

3.2. Unconfined Compressive Strength (UCS)

3.3. UCS Parameters

3.4. UCS Regression Analysis

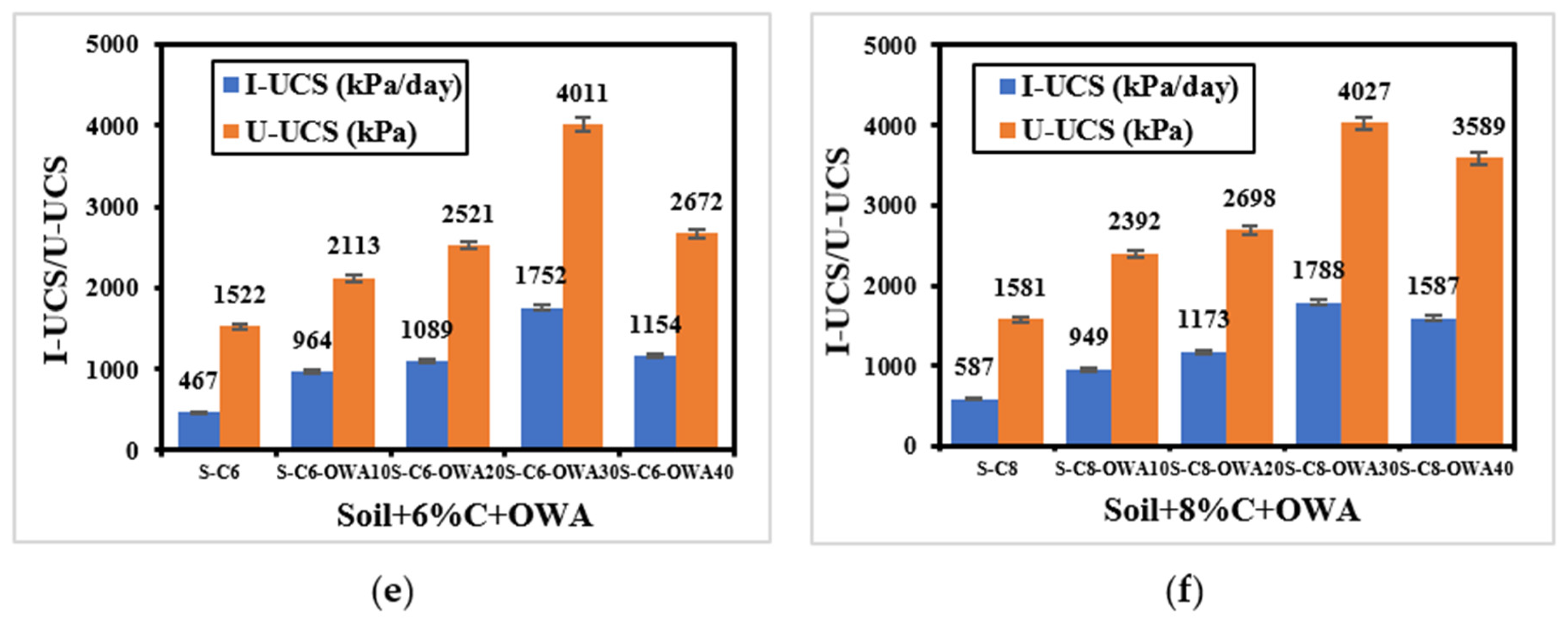

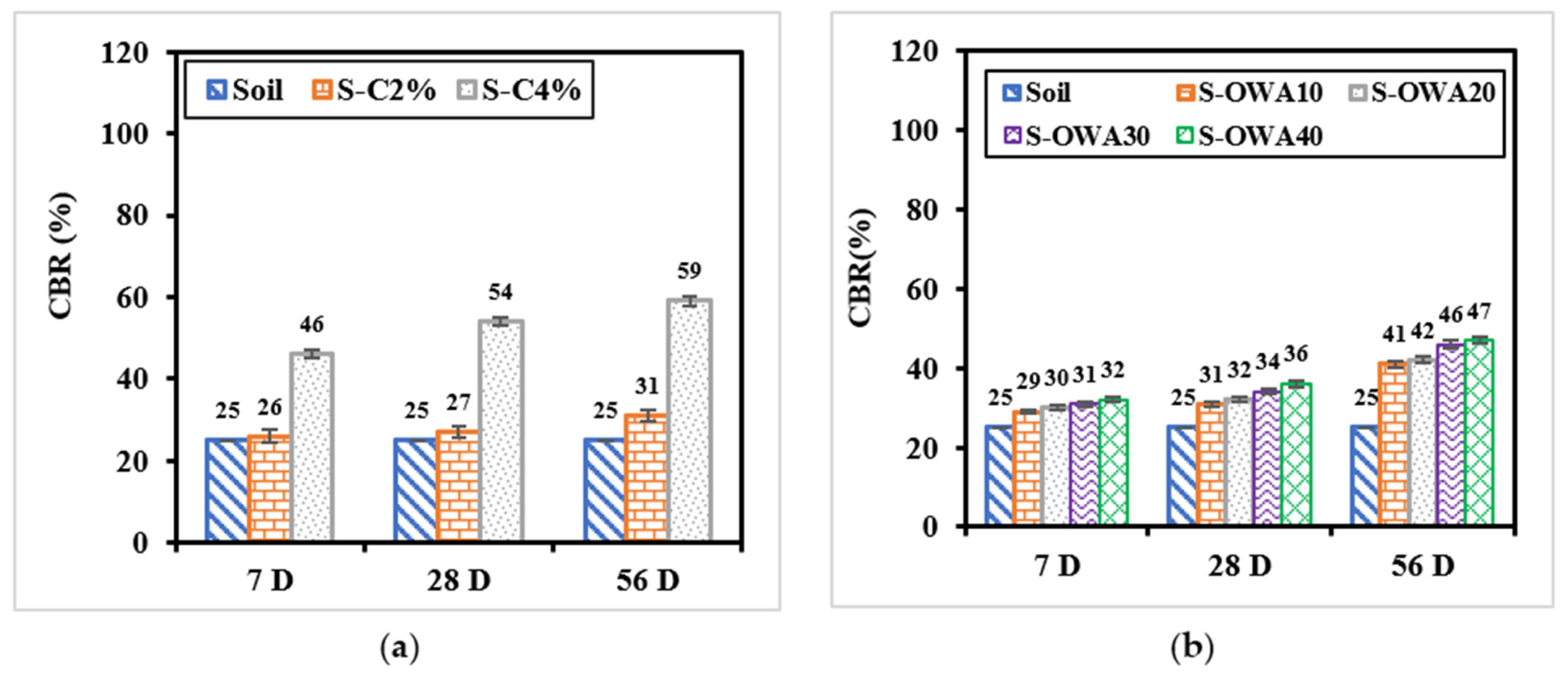

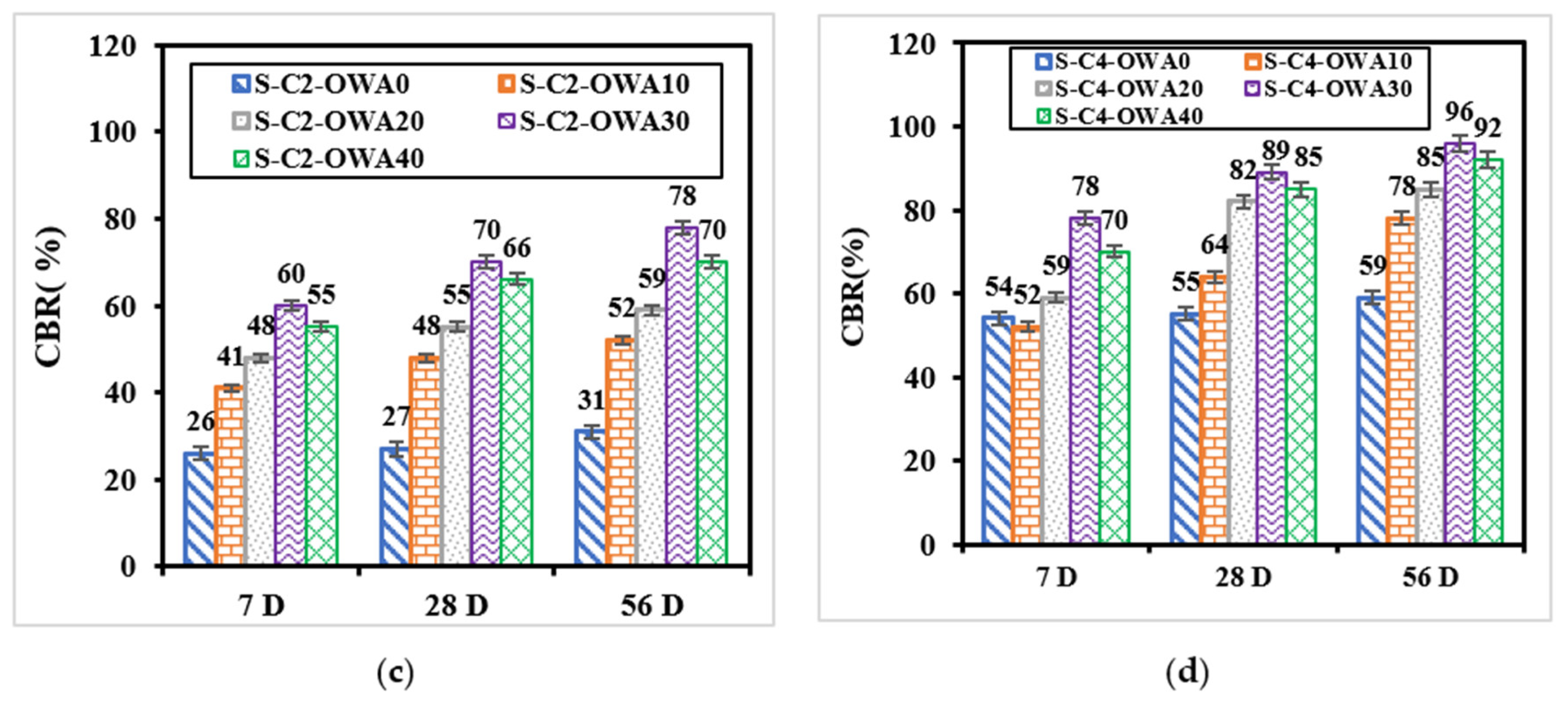

3.5. California Bearing Ratio (CBR)

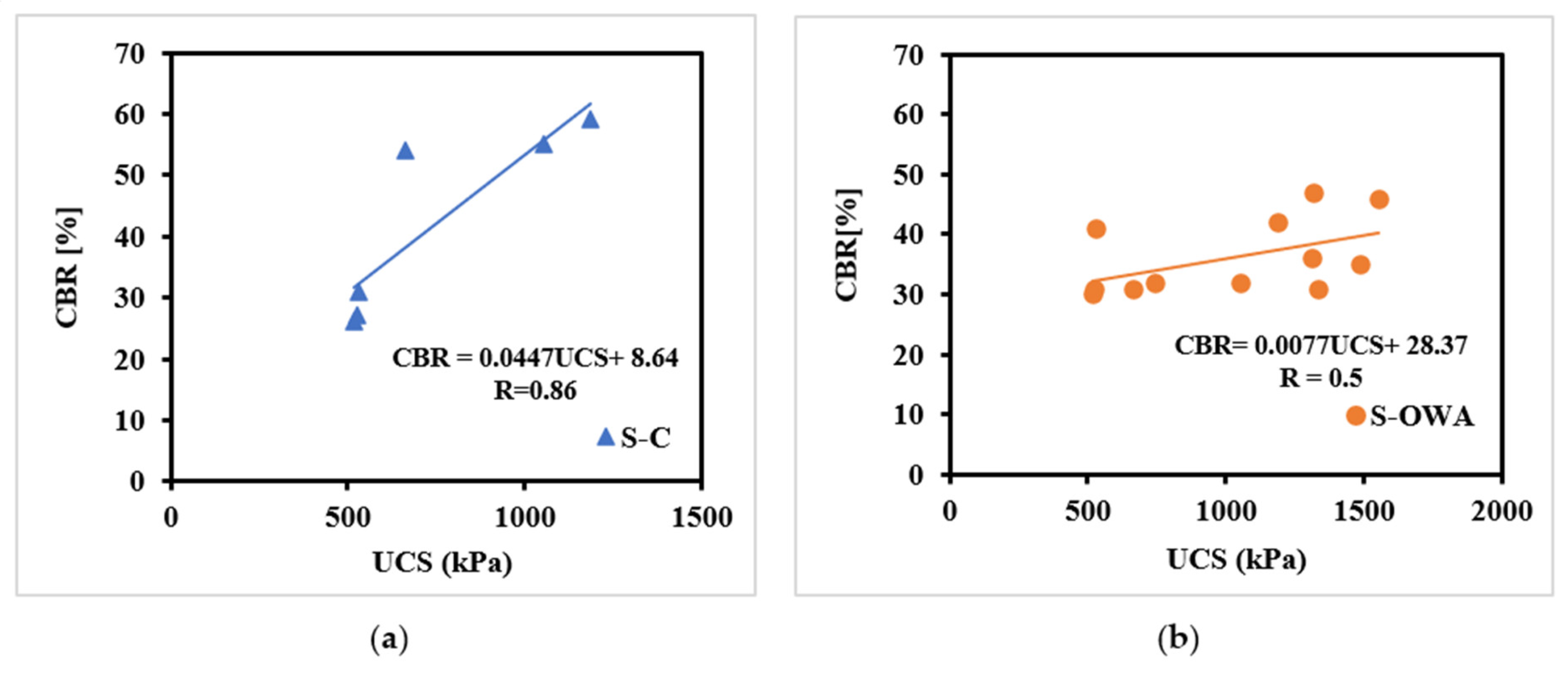

3.6. Correlations between CBR and UCS

4. Conclusions

- The presence of cement and OWA altered the compaction characteristics of the mixtures. The Proctor test results showed that replacing soil with OWA reduced the MDUW but raised the OMC moisture. However, the cement addition improved the compaction characteristics of the soil. The highest values of MDUW and OMC were recorded in the S-C8 and S-OWA40 mixes, respectively.

- Replacing soil with up to 40% OWA caused an increase in the UCS and CBR. This indicates that OWA possesses cementitious properties. Adding cement to the soil—OWA system increased the UCS and CBR by up to 30% OWA inclusion, after which there was a significant drop at 40% OWA. The rise in UCS and CBR of up to 30% OWA content may be attributed to its pozzolanic nature, facilitating binding and cohesion within the composite. However, beyond this threshold, UCS and CBR declined due to potential overfilling of voids and dilution effects.

- The proposed hyperbolic model aligned well with the UCS experimental data for all mixes showing a correlation coefficient above 98%. The predicted initial strength rate (I-UCS) and ultimate strength (U-UCS) had maximum values at 30% OWA inclusion. The UCS statistical analysis showed that the combined effect of OWA and cement contributed to 90% of I-UCS and 57% of U-UCS.

- A positive correlation was determined between the UCS and CBR, especially when cement and OWA were incorporated in the mixture (S-C-OWA). The coefficient of determination R2 ranged from 0.66 to 0.99.

- All in all, this study showed that the soil, which is a primary resource, can be replaced with OWA, which is considered a waste material. If cement is added to the soil–OWA mixtures, the properties of the rammed earth blocks can be significantly improved.

- The results of this investigation are applicable to poorly graded soil with OWA acting as an up to 40% replacement. Further studies could be carried out on other types of soil (e.g., clay) and other OWA replacement percentages. Also, using fibers can improve the soil stabilization properties.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Correia da Silva, J.J.; Pereira, J.P.; Sirgado, J. Improving rammed earth wall thermal performance with added expanded granulated cork. Archit. Sci. Rev. 2015, 58, 314–323. [Google Scholar] [CrossRef]

- Giuffrida, G.; Costanzo, V.; Nocera, F.; Cuomo, M.; Caponetto, R. Natural and Recycled Stabilizers for Rammed Earth Material Optimization. In International Conference on Sustainability in Energy and Buildings; Springer Nature: Singapore, 2022; pp. 164–174. [Google Scholar] [CrossRef]

- Hu, R.; Liu, J. Rescuing a sustainable heritage: Prospects for traditional rammed earth housing in China today and tomorrow. In Rammed Earth Construction—Cutting Edge Research on Traditional and Modern Rammed Earth; CRC Press/Balkema: London, UK, 2015. [Google Scholar]

- Faria, P.; Silva, V.; Pereira, C.; Rocha, M. The monitoring of rammed earth experimental walls and characterization of rammed earth samples. Rammed Earth Conserv. 2012, 91–97. [Google Scholar] [CrossRef]

- Porter, H.; Blake, J.; Dhami, N.K.; Mukherjee, A. Rammed earth blocks with improved multifunctional performance. Cem. Concr. Compos. 2018, 92, 36–46. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Ciancio, D. Durability of cement-stabilised rammed earth: A case study in Western Australia. Aust. J. Civ. Eng. 2016, 14, 54–62. [Google Scholar] [CrossRef]

- Giada, G.; Caponetto, R.; Nocera, F. Hygrothermal properties of raw earth materials: A literature review. Sustainability 2019, 11, 5342. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.C.; Woloszyn, M.; Lavrik, L.; Moletti, C.; Dotelli, G.; Caruso, M. Mechanical and microstructural characterization of rammed earth stabilized with five biopolymers. Materials 2022, 15, 3136. [Google Scholar] [CrossRef]

- Liu, Z.; Du, J.; Steere, R.; Schlegel, J.P.; Khayat, K.H.; Meng, W. Cement-Based Materials with Solid–Gel Phase Change Materials for Improving Energy Efficiency of Building Envelope. J. Mater. Civ. Eng. 2023, 35, 04023425. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Q.; Miao, W.; Su, Y.; He, X.; Strnadel, B. The thermal performances of cement-based materials with different types of microencapsulated phase change materials. Constr. Build. Mater. 2022, 345, 128388. [Google Scholar] [CrossRef]

- Junaid, M.F.; ur Rehman, Z.; Ijaz, N.; Farooq, R.; Khalid, U.; Ijaz, Z. Performance evaluation of cement-based composites containing phase change materials from energy management and construction standpoints. Constr. Build. Mater. 2024, 416, 135108. [Google Scholar] [CrossRef]

- Beckett, C.; Ciancio, D. Effect of compaction water content on the strength of cement-stabilized rammed earth materials. Can. Geotech. J. 2014, 51, 583–590. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, L.; Huang, J.; Law, A. Research frameworks, methodologies, and assessment methods concerning the adaptive reuse of architectural heritage: A review. Built Herit. 2021, 5, 1–19. [Google Scholar] [CrossRef]

- Vafaie, F.; Remøy, H.; Gruis, V. Adaptive reuse of heritage buildings; a systematic literature review of success factors. Habitat Int. 2023, 142, 102926. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Jalayer, F.; Prota, A.; Manfredi, G. Assessment of ecological sustainability of a building subjected to potential seismic events during its lifetime. Int. J. Life Cycle Assess. 2013, 18, 504–515. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Bournas, D.A.; Da Porto, F.; Caprino, A.; Santarsiero, G.; Triantafillou, T. Integrated seismic and energy retrofitting of existing buildings: A state-of-the-art review. J. Build. Eng. 2022, 61, 105274. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Gowthaman, S.; Nakashima, K.; Kawasaki, S. A state-of-the-art review on soil reinforcement technology using natural plant fiber materials: Past findings, present trends and future directions. Materials 2018, 11, 553. [Google Scholar] [CrossRef] [PubMed]

- Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Volume stability of cement paste containing limestone fines. Buildings 2021, 11, 366. [Google Scholar] [CrossRef]

- Khatib, J.M.; Ramadan, R.; Ghanem, H.; Elkordi, A.; Baalbaki, O.; Kırgız, M. Chemical shrinkage of paste and mortar containing limestone fines. Mater. Today Proc. 2022, 61, 530–536. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; ElKordi, A. Effect of using limestone fines on the chemical shrinkage of pastes and mortars. Environ. Sci. Pollut. Res. 2023, 30, 25287–25298. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.G.; Zhang, R.H.; Han, L.; Goh, A.T.C. Engineering properties of the Bukit Timah Granitic residual soil in Singapore. Undergr. Space 2019, 4, 98–108. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, W.; Zhou, D.; Zhang, R.; Goh, A.T.C.; Hou, Z. Influence of groundwater drawdown on excavation responses—A case history in Bukit Timah granitic residual soils. J. Rock Mech. Geotech. Eng. 2018, 10, 856–864. [Google Scholar] [CrossRef]

- Abbaspour, M.; Aflaki, E.; Nejad, F.M. Reuse of waste tire textile fibers as soil reinforcement. J. Clean. Prod. 2019, 207, 1059–1071. [Google Scholar] [CrossRef]

- Vincevica-Gaile, Z.; Teppand, T.; Kriipsalu, M.; Krievans, M.; Jani, Y.; Klavins, M.; Hendroko Setyobudi, R.; Grinfelde, I.; Rudovica, V.; Tamm, T.; et al. Towards sustainable soil stabilization in peatlands: Secondary raw materials as an alternative. Sustainability 2021, 13, 6726. [Google Scholar] [CrossRef]

- Ramadan, R.; Ghanem, H.; Khatib, J.M.; ElKordi, A.M. Effect of Plant-based natural fibers on the mechanical properties and volume change of cement paste. Int. J. Build. Pathol. Adapt. 2024. [Google Scholar] [CrossRef]

- Shaheen, S.M.; Hooda, P.S.; Tsadilas, C.D. Opportunities and challenges in the use of coal fly ash for soil improvements–a review. J. Environ. Manag. 2014, 145, 249–267. [Google Scholar] [CrossRef] [PubMed]

- Cristelo, N.; Glendinning, S.; Miranda, T.; Oliveira, D.; Silva, R. Soil stabilisation using alkaline activation of fly ash for self compacting rammed earth construction. Constr. Build. Mater. 2012, 36, 727–735. [Google Scholar] [CrossRef]

- Silva, R.A.; Oliveira, D.V.; Miranda, T.; Cristelo, N.; Escobar, M.C.; Soares, E. Rammed earth construction with granitic residual soils: The case study of northern Portugal. Constr. Build. Mater. 2013, 47, 181–191. [Google Scholar] [CrossRef]

- Bernat-maso, E.; Gil, L.; Escrig, C. Textile-reinforced rammed earth: Experimental characterisation of flexural strength and thoughness. Constr. Build. Mater. 2016, 106, 470–479. [Google Scholar] [CrossRef]

- Miccoli, L.; Müller, U.; Pospíšil, S. Rammed earth walls strengthened with polyester fabric strips: Experimental analysis under in-plane cyclic loading. Constr. Build. Mater. 2017, 149, 29–36. [Google Scholar] [CrossRef]

- Liu, K.; Wang, M.; Wang, Y. Seismic retrofitting of rural rammed earth buildings using externally bonded fibers. Constr. Build. Mater. 2015, 100, 91–101. [Google Scholar] [CrossRef]

- Siddiqua, S.; Barreto, P.N.M. Chemical stabilization of rammed earth using calcium carbide residue and fly ash. Constr. Build. Mater. 2018, 169, 364–371. [Google Scholar] [CrossRef]

- Araldi, E.; Vincens, E.; Fabbri, A. Identification of the mechanical behaviour of rammed earth including water content influence. Mater. Struct. 2018, 51, 88. [Google Scholar] [CrossRef]

- Sen, B.; Saha, R. 1 g shake table study on seismic strengthening of low-cost rammed earthen houses built of silt enriched soil using natural fiber reinforcement. Structures 2024, 64, 106504. [Google Scholar] [CrossRef]

- Sen, B.; Saha, R. Experimental and numerical investigation of mechanical strength characteristics of natural fiber retrofitted rammed earth walls. Geotext. Geomembr. 2022, 50, 970–993. [Google Scholar] [CrossRef]

- Koutous, A.; Hilali, E. Reinforcing rammed earth with plant fibers: A case study. Case Stud. Constr. Mater. 2021, 14, e00514. [Google Scholar] [CrossRef]

- Ramezannia, A.; Gocer, O.; Tabrizi, T.B. The life cycle assessment of stabilized rammed earth reinforced with natural fibers in the context of Australia. Constr. Build. Mater. 2024, 416, 135034. [Google Scholar] [CrossRef]

- Sen, B.; Chanda, D.; Saha, R. Mechanical strength characterization and seismic performance of rammed earthen walls built on eco-friendly lateritic soil and sustainable stabilizing materials. Sādhanā 2024, 49, 37. [Google Scholar] [CrossRef]

- Su, Y.; Luo, B.; Luo, Z.; Xu, F.; Huang, H.; Long, Z.; Shen, C. Mechanical characteristics and solidification mechanism of slag/fly ash-based geopolymer and cement solidified organic clay: A comparative study. J. Build. Eng. 2023, 71, 106459. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Abdulwahid, M.Y. Utilisation of olive waste ash in mortar mixes. Struct. Concr. 2010, 11, 221–228. [Google Scholar] [CrossRef]

- Al-Akhras, N.M.; Al-Akhras, K.M.; Attom, M.F. Performance of olive waste ash concrete exposed to elevated temperatures. Fire Saf. J. 2009, 44, 370–375. [Google Scholar] [CrossRef]

- Zeyad, A.M.; Bayagoob, K.H.; Amin, M.; Tayeh, B.A.; Mostafa, S.A.; Agwa, I.S. Effect of olive waste ash on the properties of high-strength geopolymer concrete. Struct. Concr. 2024. [Google Scholar] [CrossRef]

- Hakeem, I.Y.; Agwa, I.S.; Tayeh, B.A.; Abd-Elrahman, M.H. Effect of using a combination of rice husk and olive waste ashes on high-strength concrete properties. Case Stud. Constr. Mater. 2022, 17, e01486. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Hadzima-Nyarko, M.; Zeyad, A.M.; Al-Harazin, S.Z. Properties and durability of concrete with olive waste ash as a partial cement replacement. Adv. Concr. Constr. 2021, 11, 59–71. [Google Scholar] [CrossRef]

- Khedaywi, T.; Al Kofahi, N.; Al-Zoubi, M. Effect of olive waste ash on properties of asphalt cement and asphalt concrete mixtures. Int. J. Pavement Res. Technol. 2020, 13, 276–285. [Google Scholar] [CrossRef]

- Al Qadi, A.N.; Khedaywi, T.S.; Haddad, M.A.; Al-Rababa’ah, O.A. Investigating the Effect of Olive Husk Ash on the Properties of Asphalt Concrete Mixture. Ann. De Chim. Sci. Des Mater. 2021, 45, 11–15. [Google Scholar] [CrossRef]

- Al-Qadi, Q.N.; Al-Qadi, A.N.; Khedaywi, T.S. Effect of oil shale ash on static creep performance of asphalt paving mixtures. Jordan J. Earth Environ. Sci. 2014, 6, 67–75. [Google Scholar]

- Dahim, M.A.; Abuaddous, M.; Al-Mattarneh, H.; Alluqmani, A.E.; Ismail, R. The use of olive waste for development sustainable rigid pavement concrete material. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1212, 012032. [Google Scholar] [CrossRef]

- Lila, K.; Belaadi, S.; Solimando, R.; Zirour, F.R. Valorisation of organic waste: Use of olive kernels and pomace for cement manufacture. J. Clean. Prod. 2020, 277, 123703. [Google Scholar] [CrossRef]

- ASTM D 2487 Designation: D 2487-00; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2000; ASTM Int 04:1-12.

- Elahi, T.E.; Shahriar, A.R.; Islam, M.S. Engineering characteristics of compressed earth blocks stabilized with cement and fly ash. Constr. Build. Mater. 2021, 277, 122367. [Google Scholar] [CrossRef]

- Egenti, C.; Khatib, J.; Oloke, D. High Carbon Fly ash and Soil in Shelled Compressed Earth Masonry Units. Int. J. Interdiscip. Res. Innov. 2015, 3, 61–65. [Google Scholar]

- Kariyawasam, K.K.G.K.D.; Jayasinghe, C. Cement stabilized rammed earth as a sustainable construction material. Constr. Build. Mater. 2016, 105, 519–527. [Google Scholar] [CrossRef]

- Al-Gharbawi, A.S.; Najemalden, A.M.; Fattah, M.Y. Expansive soil stabilization with lime, cement, and silica fume. Appl. Sci. 2022, 13, 436. [Google Scholar] [CrossRef]

- ASTM D698-12; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12 400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D2166/D2166M; Standard Test Method for Unconfined Compression Testing of Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D1883-07e2; Standard Test Method for CBR (California Bearing Ratio) of Laboratory Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2007. [CrossRef]

- Nawaz, M.N.; Akhtar, A.Y.; Hassan, W.; Khan, M.H.A.; Nawaz, M.M. Artificial intelligence-based prediction models of bio-treated sand strength for sustainable and green infrastructure applications. Transp. Geotech. 2024, 46, 101262. [Google Scholar] [CrossRef]

- Khan, M.H.A.; Jafri, T.H.; Ud-Din, S.; Ullah, H.S.; Nawaz, M.N. Prediction of soil compaction parameters through the development and experimental validation of Gaussian process regression models. Environ. Earth Sci. 2024, 83, 129. [Google Scholar] [CrossRef]

- Nawaz, M.N.; Chong, S.H.; Nawaz, M.M.; Haider, S.; Hassan, W.; Kim, J.S. Estimating the unconfined compression strength of low plastic clayey soils using gene-expression programming. Geomech. Eng. 2023, 33, 1. [Google Scholar] [CrossRef]

- Krishna, S.V.; Santosh, B.S.; Prasanth, B.S. Prediction of UCS and CBR of a stabilized Black-cotton soil using artificial intelligence approach: ANN. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Mahmoodzadeh, A.; Mohammadi, M.; Ibrahim, H.H.; Abdulhamid, S.N.; Salim, S.G.; Ali, H.F.H.; Majeed, M.K. Artificial intelligence forecasting models of uniaxial compressive strength. Transp. Geotech. 2021, 27, 100499. [Google Scholar] [CrossRef]

- Yu, Z.; Shi, X.-z.; Chen, X.; Zhou, J.; Qi, C.-c.; Chen, Q.-s.; Rao, D.-j. Artificial intelligence model for studying unconfined compressive performance of fiber-reinforced cemented paste backfill. Trans. Nonferrous Met. Soc. China 2021, 31, 1087–1102. [Google Scholar] [CrossRef]

- Ghanem, H.; Ramadan, R.; Khatib, J.; Elkordi, A. A Review on Chemical and Autogenous Shrinkage of Cementitious Systems. Materials 2024, 17, 283. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Effect of Adding Phragmites-Australis Fiber on the Mechanical Properties and Volume Stability of Mortar. Fibers 2024, 12, 14. [Google Scholar] [CrossRef]

- Nandhini, K.; Karthikeyan, J. The early-age prediction of concrete strength using maturity models: A review. J. Build. Pathol. Rehabil. 2021, 6, 7. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar] [CrossRef]

- Alhakim, G.; Baalbaki, O.; Jaber, L. Effects of incorporation of cement and metakaolin on the mechanical properties of poorly graded sand. Arab. J. Geosci. 2022, 15, 1777. [Google Scholar] [CrossRef]

- Fawaz, A.; Alhakim, G.; Jaber, L. The stabilisation of clayey soil by using sawdust and sawdust ash. Environ. Technol. 2024, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Cheraghalizadeh, R.; Akcaoglu, T. Utilization of olive waste ash and sea sand powder in self-compacting concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 663–672. [Google Scholar] [CrossRef]

- Al-Akhras, N.M. Performance of olive waste ash concrete exposed to alkali-silica reaction. Struct. Concr. 2012, 13, 221–226. [Google Scholar] [CrossRef]

- Fırat, S.; Dikmen, S.; Yılmaz, G.; Khatib, J.M. Characteristics of engineered waste materials used for road subbase layers. KSCE J. Civ. Eng. 2020, 24, 2643–2656. [Google Scholar] [CrossRef]

- James, R.; Kamruzzaman, A.H.M.; Haque, A.; Wilkinson, A. Behavior of lime-slag-treated clay. Proc. Inst. Civ. Eng.-Geotech. Eng. 2008, 161, 207–216. [Google Scholar] [CrossRef]

- Kalkan, E.; Akbulut, S.; Tortum, A.; Celik, S. Prediction of the unconfined compressive strength of compacted granular soils by using inference systems. Environ. Geol. 2009, 58, 1429–1440. [Google Scholar] [CrossRef]

- Bell, F.G. Engineering Properties of Soils and Rocks; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar] [CrossRef]

- Al Bitar, M.; Alhakim, G.; Jaber, L. Using fly ash-plastic mesh bags wastes mixture as a recoverable resource for soil stabilization. Int. J. Geotech. Eng. 2024, 1–16. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A.; Aisheh, Y.I.A.; Salih, M.N.A. Utilising olive-stone biomass ash and examining its effect on green concrete: A review paper. J. Mater. Res. Technol. 2023, 24, 7091–7107. [Google Scholar] [CrossRef]

- Boukhari, M.E.; Merroun, O.; Maalouf, C.; Bogard, F.; Kissi, B. Exploring the impact of partial sand replacement with olive waste on mechanical and thermal properties of sustainable concrete. Clean. Mater. 2023, 9, 100202. [Google Scholar] [CrossRef]

- Alyami, M.; Hakeem, I.Y.; Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of agricultural olive, rice husk and sugarcane leaf waste ashes on sustainable ultra-high-performance concrete. J. Build. Eng. 2023, 72, 106689. [Google Scholar] [CrossRef]

- Eme, D.B.; Nwofor, T.C.; Sule, S. Correlation between the California bearing ratio (CBR) and unconfined compressive strength (UCS) of stabilized sand-cement of the niger delta. Int. J. Civ. Eng. 2016, 3, 7–13. [Google Scholar] [CrossRef]

- Daghigh, H.; Mousavi Jahromi, S.H.; Khosrojerdi, A.; Hassanpour Darvishi, H.O.S.S.E.I.N. Effect of curing time and percentage of additive materials on unconfined compressive strength and California bearing ratio in sandy silt soil. Sādhanā 2022, 47, 22. [Google Scholar] [CrossRef]

- Ozdemir, M.A. Improvement in bearing capacity of a soft soil by addition of fly ash. Procedia Eng. 2016, 143, 498–505. [Google Scholar] [CrossRef]

| Properties | Symbol | Value |

|---|---|---|

| Optimum moisture content (%) | OMC | 16 |

| Maximum dry unit weight (kN/m3) | MDUW | 18.2 |

| Mean grain size: D60 (mm) | MGS | 0.55 |

| Coefficient of uniformity | CU | 4.58 |

| Coefficient of curvature: Cc | CC | 0.54 |

| Plasticity index (%) | PI | 0 |

| Oxide | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | K2O | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Cement (%) | 18.53 | 3.93 | 3.06 | 61.78 | 1.74 | 2.92 | 0.47 | 0.18 | 6.3 |

| OWA (%) | 24.73 | 3.41 | 3.83 | 36.13 | 2.81 | 0.03 | 9.56 | 1.42 | 14.7 |

| Parameters | ||

|---|---|---|

| Test Combinations | Cement content (%) | OWA content (%) |

| Undisturbed/Compacted soil | - | - |

| Soil + cement | 2, 4, 6, 8 | - |

| Soil + OWA | - | 10, 20, 30, 40 |

| Soil + cement + OWA | 2, 4, 6, 8 | 10, 20, 30, 40 |

| Mixes | R2 | Mixes | R2 | Mixes | R2 | Mixes | R2 | Mixes | R2 | Mixes | R2 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| S-C2 | 0.999 | S-OWA10 | 0.998 | S-C2-OWA10 | 0.999 | S-C4-OWA10 | 0.994 | S-C6-OWA10 | 0.999 | S-C8-OWA10 | 0.994 |

| S-C4 | 0.999 | S-OWA20 | 0.996 | S-C2-OWA20 | 0.999 | S-C4-OWA20 | 0.997 | S-C6-OWA20 | 0.999 | S-C8-OWA20 | 0.999 |

| S-C6 | 0.991 | S-OWA30 | 0.988 | S-C2-OWA30 | 0.996 | S-C4-OWA30 | 0.999 | S-C6-OWA30 | 0.998 | S-C8-OWA30 | 0.998 |

| S-C8 | 0.996 | S-OWA40 | 0.999 | S-C2-OWA40 | 0.999 | S-C4-OWA40 | 0.998 | S-C6-OWA40 | 0.999 | S-C8-OWA40 | 0.994 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghanem, H.; El Bouz, C.; Ramadan, R.; Trad, A.; Khatib, J.; Elkordi, A. Effect of Incorporating Cement and Olive Waste Ash on the Mechanical Properties of Rammed Earth Block. Infrastructures 2024, 9, 122. https://doi.org/10.3390/infrastructures9080122

Ghanem H, El Bouz C, Ramadan R, Trad A, Khatib J, Elkordi A. Effect of Incorporating Cement and Olive Waste Ash on the Mechanical Properties of Rammed Earth Block. Infrastructures. 2024; 9(8):122. https://doi.org/10.3390/infrastructures9080122

Chicago/Turabian StyleGhanem, Hassan, Chouk El Bouz, Rawan Ramadan, Adrien Trad, Jamal Khatib, and Adel Elkordi. 2024. "Effect of Incorporating Cement and Olive Waste Ash on the Mechanical Properties of Rammed Earth Block" Infrastructures 9, no. 8: 122. https://doi.org/10.3390/infrastructures9080122

APA StyleGhanem, H., El Bouz, C., Ramadan, R., Trad, A., Khatib, J., & Elkordi, A. (2024). Effect of Incorporating Cement and Olive Waste Ash on the Mechanical Properties of Rammed Earth Block. Infrastructures, 9(8), 122. https://doi.org/10.3390/infrastructures9080122