Abstract

Civil structural health monitoring (CSHM) tracks different aspects of an infrastructure system’s service and safety condition by utilizing reliably measured data and physics-based model simulations. Data and physical models are coupled with heuristic experience to proactively represent current and expected future performance. In the past two decades, more bridges and dams have been instrumented and monitored during and after construction to determine their performances and responses to various loading, material, boundary, and environmental conditions. Furthermore, bridge and dam owners increasingly utilize civionics systems to obtain essential data for developing data-driven asset management programs and addressing the state of good repair requirements.

Keywords:

civionics; SHM; CSHM; digital twin; mechanics model; sensors; data; databases; data analytics; reports 1. Introduction

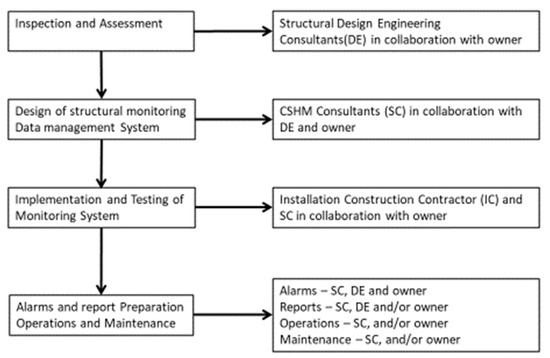

The following phases are vital to achieving an efficient, effective, and economical civil structural health monitoring (CSHM) system. These opinions have formed from our many decades of experience with the evaluation of bridges in the field for their load carrying capacity in Canada and the USA. We have studied the field work of monitoring bridges by other international practitioners and researchers. Reviews have covered some of this work, e.g., [1,2,3]. We have also studied the assignment of various tasks to owners, structural design consultants, structural health monitoring consultants, and installation construction contractors, as shown in Figure 1.

Figure 1.

Assignment of various tasks of CSHM to owners, design consulting engineers, CHSM consultants, and installation construction contractors.

- Phase 1. Inspection and Assessment

This phase should specify the qualifications of a senior engineer at an experienced consulting engineering firm. The engineering team should be able to identify failure mechanisms using the finite element method (FEM), rational mechanics models, and other physics- or heuristic-based models.

- Phase 2. Design of the CSHM System and Database Selection

This phase should specify the qualifications of CSHM system designers and their ability to select appropriate databases. Also, specifications should be given for a variety of sensors, such as accelerometers to measure accelerations, strain gauges to measure strains, displacement gauges to measure deflections, piezoelectric sensors to measure pressure, crack meters to measure crack widths, Trimble prism monitors using total station to measure movements, and tiltmeters to monitor rotations.

The selection of a data management system for the structural health monitoring (SHM) system is critical. The data management system should be able to ingest data from different types of sensors, with a reading rate of 100 Hz for transitional events and a very low rate for long-term events. The data should be able to move automatically from the site to the inspector’s office, and the data should be processed in a user-friendly language such as MATLAB or Python. Data should be exportable in CVS or equivalent formats. Operations and maintenance of data management should be secure and safe. The system should be scalable and able to integrate data from a number of sources.

- Phase 3. Implementation and Testing of the Monitoring Civionics System

The specification of the contractor should stipulate that the construction engineers and technologists are familiar with installing the required electronic and fibre optic sensors, DAQS, wiring, communication systems, solar and conventional power, and environment-proof enclosure systems at remote sites.

- Phase 4. Alarms and Report Preparation

The owner’s technical team or the SHM specialist should set thresholds to trigger the alarms. The monthly reports should be automatic and easy to read. The reports should be in a format that allows engineers to make decisions about the safety and serviceability of bridges and dams.

- Phase 5. Operations and Maintenance

Ideally, the owner should be able to replace sensors, equipment, wiring, and communication systems or assign these tasks to a construction/civionics contractor. A budget at a level of a few percent per year should be allocated to replace components lost due to wear, environmental damage, vandalism, and obsolescence.

- Damage detection and its relevance to civil structures

Structural health monitoring is defined differently depending on the context. For example, in aerospace applications, damage detection is often a central focus. In this realm where defects form, grow, and eventually require maintenance, this makes sense. In civil structures, however, owners are most often not directly interested in damage detection, but rather are concerned with the load-carrying capacity of the structure. Damage detection is not a necessary element for useful civil SHM systems. For example, when the load capacity of a structure is calculated, assumptions about the structural behaviour are often required. In the absence of quantitative load testing, worst-case assumptions need to be used for load capacity calculations. However, with instrumented load testing, the actual behaviour of the structure can be determined, and a more accurate estimate of the load capacity can be calculated [4,5]. CSHM can be used to provide ongoing verification of the structural behaviour utilizing the actual traffic loads carried by the structure and throughout the seasonal changes to the structural components and boundary conditions. Neutral axis location, girder load sharing, maximum strains for fatigue analysis, and cable tension are structural behaviours that present-day SHM is well suited to monitor. By providing ongoing quantitative information on structural behaviour, SHM can help owners more economically manage fleets of structures and identify structures most urgently in need of maintenance or replacement [6,7]. The value of CSHM is highest near the structure’s end of service life.

- One last thought

As dams and bridges continue to age and available budgets for replacement diminish, government owners are advised to employ CSHM technologies. Over the past decade, there have been major advances in CSHM technology. CSHM should now be considered one of the essential tools for effectively monitoring and ensuring the ongoing serviceability and safety of these critical infrastructures [7,8]. To achieve this very important objective, the senior management of government organizations should employ the expertise of academics in the universities who are undertaking state-of-the-art research in the faculty of engineering specializing in CSHM. The research advice, supplementing other groups identified in Figure 1, will lead to an economical CSHM system that will achieve the objectives of keeping dams and bridges serviceable and safe.

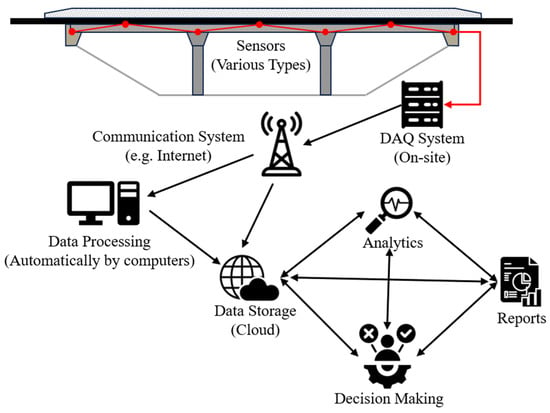

2. Civionics

The term ‘civionics’ refers to the application of electronics to civil structures for the purpose of determining the state of their health. The use of sensors to monitor the response of a structure or its model to applied loads is not new, nor is bridge evaluation by field testing, which includes both diagnostic and proof testing. What is new, however, is the use of civil structural health monitoring. The purpose of civil structural health monitoring (CSHM), according to [9,10,11,12] is to monitor the in situ behaviour of a structure accurately and efficiently to determine its health or condition. CSHM is the integration of a system of sensors, a data acquisition system, a data processing system, an archiving system, a communications system, and a damage detection and modeling system to acquire knowledge, either on demand or on a continual basis, regarding the in-service performance of structures (Figure 2).

Figure 2.

Basic components of a CSHM system, utilizing civionics.

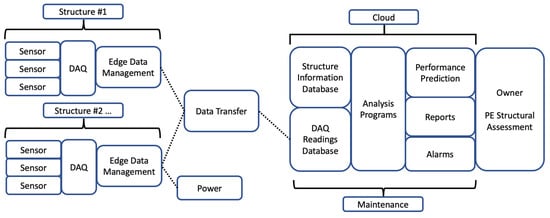

We further define civionics as a discipline concerned with the interface of the use of electronic devices, data and databases, data analytics, alarms, and reports for the monitoring of civil engineering infrastructure. The term was first coined in Canada by the Network of Centres of Excellence for Intelligent Sensing for Innovative Structures (ISIS Canada). Like the disciplines of avionics, mechatronics, and bionics, it is an interdisciplinary field founded on solving problems of an applied nature for industry. A schematic outline of an SHM system is illustrated in Figure 3. Sensor readings are digitized by the DAQ, which may actually be integrated with the sensor. Readings are analyzed and aggregated by an edge data management system. This avoids sending raw sampled data and sends preprocessed data that is in a more directly useful form. For example, the edge data management system might identify when a vehicle is passing and only send sampled data for time periods when a vehicle is passing. The data can be transferred to a cloud-based data base via ethernet, cellular, or satellite transfer. Once in the cloud, information on the structure along with sensor data can be analyzed to produce outcomes used in prediction, reports, and alarms. This information can then be used for structural assessment. Avionics, mechatronics, and bionics have made huge advances for the aircraft, automobile, and biomedical industries, respectively. It is expected that the field of civionics will play a vital role for the government and companies involved in infrastructure development.

Figure 3.

Civionics system design for CSHM.

3. Sampling Frequency

When designing a continuous structural health monitoring system several decisions must be made, such as the types and locations of sensors, wiring scheme, data acquisition system and the sampling frequency. A higher sampling frequency will give a better representation of the actual behaviour of the bridge; however, it requires larger capacity for data storage, transmission, and handling. However, beyond a certain point higher sampling rates offer no practical advantage. A higher sampling frequency may limit the number of sensors installed if there is a limited capacity to store and handle data. The sampling frequency should therefore be chosen to minimize the amount of data generated by the structural health monitoring system, but should be high enough to accurately capture the behaviour of the structure being monitored.

The transient sampling rate is dependent on the application. The main criteria for selecting the sampling rate are to reproduce the time-varying signal, such as strain versus time, with sufficient fidelity for the end application. For example, for a truck traveling at highway speed over a typical 30 m bridge span, sampling at 100 sps will reproduce the strain versus time with less than 2% error. Determining the natural frequencies of a structure requires sampling the signals well beyond the Nyquist limit. For example, by sampling at 64 Hz, natural frequencies up to 16 Hz can be easily resolved. Corrosion can be a long-term process, and sampling more than once per day or even per month might not be needed. The suggestions with regards to sampling rate are summarized in Table 1. One additional consideration is the need to temperature-compensate readings, and sampling should be frequent enough so that reasonable temperature-compensation can be carried out.

Table 1.

Data collection frequency for various applications.

4. Selection of Database and Data Management Systems

Commercially available software/databases for the management, storage, and visualization of instrumentation data. Each database has features that include data collection, mapping/GIS functionality, data visualization, data post-processing and calculation capabilities, alarming, storage of historical data, and reporting functionality. A brief list of typical characteristics is listed in Table 2.

Table 2.

Characteristics to consider when choosing a database and data management system.

The management and timely use of data can be the difference between a usable functional system and one that is simply warehouse-sampled data that is not contributing to the management of the structures. Scalability and set-up effort can often be closely linked. Does each structure require a lot of hard or hand coding to set it up, or are there configuration tools to minimize effort to add new structures or sensors? Are the data held on a secure site with adequate backup? Cloud-based systems can reduce this risk by relying on the security resources of large organizations that manage cloud resources. Google has more than 850 personnel focused on security, for example. In terms of performance, does the system have appropriate resources to provide timely access to required data and reports? Can the alarms be set for single inputs, such as strain, or multi-inputs, such as temperature-compensated strain? Analytics may encompass simple single-input statistical analysis such as month-over-month analysis of variance (ANOVA), but in the future, statistical methods such as t-distributed stochastic neighbour embedding (t-SNE) or principle component analysis (PCA) analysis may become more common as means to identify significant structural changes. The data management system should be competent for simple analysis but have the scalability to add more advanced features in the future without massive reworking of the system. Selecting a data management system can be challenging. An objective selection criterion that uses a dual scoring system can help. Each feature or criteria can be evaluated using both a performance score and a criticality score. The performance score could range from 0 to 5 and would depend only on performance, whereas the criticality score should be either 0 or 1. If the feature or criteria is critical to the operation of the system, then the criticality score should be 1, if not the data management system should not be considered further. Using dual scoring prevents the selection of a data management system that scores well, but has fatal shortcomings that will prevent it from working. For example, it may have restrictions on data type or the number of transactions per day.

5. Graduate Studies and Training in Civionics

A civionics engineer must be familiar with the sensors and DAQ hardware and software needed to superimpose on a structure. For someone to acquire this specialized knowledge, it would seem most appropriate to do it at the graduate level. However, at the undergraduate level, students should be exposed to sensors and simple data analysis techniques so that this can start to become one of the tools used for structural management. To achieve this goal at the University of Manitoba, we have developed a Master’s program in civionics engineering. The graduate courses required for a graduate program are noted below:

Mandatory Courses

- Structural Health Monitoring (CIVL 7350)

- Sensors, Instrumentation and the IoT (ECE 7440)

- Data Structures and Algorithms (COMP 2140)

- OR the graduate alternative: Advanced Topics in Algorithms (COMP 7720)

Elective Courses

- Structural Dynamics (CIVL 4040)

- Numerical Methods in Engineering Analysis (CIVL 3590)

- Finite Element Analysis (CIVL 3710)

- Project Management (MGMT 0150)

- Databases Concepts and Usage (COMP 3380)

- Deep Learning with Convolutional Neural Networks (ECE 7650)

Research Thesis

6. Conclusions

In the past, civil engineers have gained knowledge about the integrity of civil structures largely by means of manual inspections and rarely by non-destructive evaluation (NDE) and interpretation of data using conventional technologies. The structural engineering profession has relied heavily on evaluation parameters given in codes of practice that lead to conservative and often costly conclusions about the strength of existing structures. The current practice has resulted in a North American stock of the civil structures whose health is not easy to monitor. For example, many bridges and large buildings constructed in earthquake-prone areas cannot be opened for public use immediately after a seismic event due to the time and cost involved in performing extensive safety checks. Quite often, after such extreme events, the safety of these structures cannot be ascertained with certainty, so it is difficult to know whether they should continue to stay in service.

To remain competitive in today’s global economic environment, the owners of civil structures need to minimize the user costs involved with the unnecessary closing of the structures and the service disruption caused by outdated and time-consuming inspections following extreme events, such as strong-motion earthquakes, hurricanes, or flash floods. In the evaluation of any structural system, it is important to be able to assess specific performance issues related to serviceability, reliability, and durability. Effectively quantifying the system’s performance requires a means to monitor and evaluate the integrity of these large civil structures with minimal interruption of service. The SHM data, besides allowing owners to better allocate their resources towards repair, replacement, or rehabilitation of the structures, will also be useful in future projects in estimating the life cycle costs of the structural system compared to the initial cost. An efficient SHM system should be largely autonomous and capable of continuous monitoring, inspection, and damage detection of structures. Reports regarding the integrity of a structure should be automatically relayed through a local network or to a remote monitoring centre. Clearly, the development of major CSHM systems will involve many disciplines, including structures, materials, damage detection, sensors, data collection and intelligent processing, computers, and communication.

Author Contributions

A.A.M. and D.J.T. have contributed equally to all aspects of this work. All authors have read and agreed to the published version of the manuscript.

Funding

Research Manitoba and NSERC provided funding for the equipment to use in the field and laboratory testing.

Data Availability Statement

Data are contained within the article.

Acknowledgments

Baidar Bakht has provided insightful comments and guidance.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mishra, M.; Lourenço, P.B.; Ramana, G.V. Structural health monitoring of civil engineering structures by using the internet of things: A review. J. Build. Eng. 2022, 48, 03954. [Google Scholar] [CrossRef]

- Zinno, R.; Haghshenas, S.S.; Guido, G.; VItale, A. Artificial intelligence and structural health monitoring of bridges: A review of the state-of-the-art. IEEE Access 2022, 10, 88058–88078. [Google Scholar] [CrossRef]

- Tokognon, C.A.; Gao, B.; Tian, G.Y.; Yan, Y. Structural health monitoring framework based on Internet of Things: A survey. IEEE Internet Things J. 2017, 4, 619–635. [Google Scholar] [CrossRef]

- Breña, S.F.; Jeffrey, A.E.; Civjan, S.A. Evaluation of a noncomposite steel girder bridge through live-load field testing. J. Bridge Eng. 2013, 18, 690–699. [Google Scholar] [CrossRef]

- James, E.D.; Yarnold, M.T. Rapid evaluation of a steel girder bridge: Case study. J. Bridge Eng. 2017, 22, 05017013. [Google Scholar] [CrossRef]

- Thomson, D.J. The economic case for service life extension of structures using structural health monitoring based on the delayed cost of borrowing. J. Civ. Struct. Health Monit. 2013, 3, 335–340. [Google Scholar] [CrossRef]

- Bakht, B.; Mufti, A. Evaluation of one hundred and one instrumented bridges suggests a new level of inspection should be established in the bridge design codes. J. Civ. Struct. Health Monit. 2018, 8, 3. [Google Scholar] [CrossRef]

- Bakht, B.; Mufti, A. Bridges: Analysis, Design, Structural Health Monitoring, and Rehabilitation; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Mufti, A.A. Guidelines for Structural Health Monitoring. In ISIS Canada Research Network, Design Manual #2; ISIS Canada Research Network: Winnipeg, MB, Canada, 2001. [Google Scholar]

- Mufti, A.A. Integration of Sensing in Civil Engineering Structures: Development of the New Discipline of Civionics. In Proceedings of the First International Conference on Structural Health Monitoring and Intelligent Infrastructure (SHMII-1), Tokyo, Japan, 13–15 November 2003. [Google Scholar]

- Rivera, E.; Mufti, A.A.; Thomson, D. Civionics Specifications. In ISIS Canada Research Network, Design Manual #6; ISIS Canada Research Network: Winnipeg, MB, Canada, 2004. [Google Scholar]

- Mufti, A.A.; Thomson, D.; Taimur, I. CSHM Specifications. In SIMTReC Research Group, Design Manual #7; ISIS Canada Research Network: Winnipeg, MB, Canada, 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).