Abstract

Deteriorated facility maintenance is a critical social issue in advanced countries. Its cost increases when considering the social consequences in terms of asset value and direct maintenance costs. Data from Korea’s Ministry of Land, Infrastructure, and Transport shows that there were 3454 bridges aged 30 years or over in Korea in 2017; this number will increase to 10,961 by 2027. In thirty years, maintenance costs will be incurred for more than 32,000 old bridges in Korea. These trends are also observed in the US, Japan, and Korea. Diverse studies have been conducted to predict the residual life of old bridges via bridge performance evaluation and load-carrying capacity assessments. However, criteria for evaluating bridge performance and verifying the effect of bridge maintenance are yet to be established due to two reasons. First, most studies on performance evaluation, maintenance, and rehabilitation techniques have been performed on limited specimens from building elements or through small-scale simulations that do not reflect the deterioration factors of complex materials in diverse environments. Second, the performance evaluation of bridges is difficult compared to quantitative state evaluations. As a method of predicting the future performance of aged concrete bridges, it is effective to understand the actual aged bridges through experiments, and this study intends to propose the method.

1. Introduction

In recent years, a significant amount of capital has been invested in overcoming the problems associated with the maintenance of aging infrastructure facilities [1,2,3,4,5]. Due to these problems, research is being actively conducted to construct new facilities using new methods and materials [6,7]. In South Korea, the development of efficient maintenance methods for aging infrastructure attracted significant attention owing to the deterioration of bridges that were constructed during the period of 1970–1980 [8,9]. Similarly, most countries where several bridges were built a long time ago will face this problem in the near future. Therefore, preventive maintenance methods, which can evaluate the performance of aging bridges and facilitate maintenance of these bridges, should be developed [10].

Currently, the performance of new bridges in South Korea is investigated by conducting real-time experiments. However, for existing old bridges, it is difficult to objectively evaluate the performances or verify the effect of repair and rehabilitation on these bridges. Therefore, to date, the surface condition has been evaluated, instead of investigating the performance of bridges; in addition, the evaluations were performed through scaled-down simulation experiments. However, these methods do not accurately predict the performance of the bridges based on their deterioration level. In particular, it is difficult to detect the deterioration in the material and structural characteristics due to the aging of concrete bridges. Hence, obtaining objective data on the performance is critical. Therefore, for bridges that were constructed across the sea, concrete has been classified separately at the time of construction and monitored by reciprocally comparing the performance of the bridge over the period of time. However, most concrete bridges that are more than 40–50 years old are small bridges. Therefore, there is insufficient digital data for the analysis and prediction of performance. To ensure economic feasibility and safety in preparation for the aging of concrete bridges, it is essential to obtain digital data for preventive maintenance [11].

To procure digital data during the preparation for the aging of bridges, first, it is necessary to obtain data on the current performance of bridges. Second, data that show the performance improvement resulting from repair and rehabilitation should be procured. Moreover, a reliable evaluation method must be developed to evaluate the performance improvement data. However, there have been few studies on a method that destroys an aging concrete bridge, checks its structural performance, and then verifies the performance resulting from repair and rehabilitation based on the current performance of the aging concrete bridge. The empirical evaluation of aging bridges can provide a standard for calculating reasonable costs, which can build a foundation for the design of repair and rehabilitation and can provide a method for reducing maintenance costs. In addition, if digital data on the performance of aging bridges are constructed, the reliability of decision-making in selecting the time and construction method for bridge repair and rehabilitation will be enhanced. Furthermore, the obtained digital data can be used to improve the maintenance management system for aging bridges in the future by building a platform that can utilize new analysis techniques using AI.

This paper analyzes the state of maintenance of concrete bridges worldwide for the preventive maintenance of aging concrete bridges. In addition, this study proposes an analytical model for empirical experimental data and systematic experimental procedure.

2. State of Aging Bridges

2.1. Problem of Aging Bridges Worldwide

Bridges are considered the biggest indicator of the nation’s competitiveness in construction technology. Moreover, as regional landmarks and the foundation of the local economy, bridges are facilities that attract significant social attention. The collapse of the Mianus River Bridge in Connecticut, United States, in 1983, the collapse of the Thruway Bridge in the state of New York in 1987, and the collapse of the Minnesota Bridge in Minnesota in 2007 serve as important cases that suggest that delayed investment and decision-making in aging bridges can result in serious safety problems. However, despite these cases, the Morandi Bridge in Genoa, Italy, collapsed in 2018, as shown in Figure 1. The Morandi Bridge was 51 years old, and its collapse resulted in 43 casualties and an estimated economic loss of approximately $150 billion, according to Reuters, France 24 News. The bridge collapsed because the maintenance management system, according to the aging of the bridge, was not in place, and thus, the bridge management was outsourced to a contractor working in the private sector. Furthermore, the investment for facility maintenance cost was reduced by 63% over ten years to reduce costs.

Figure 1.

Morandi Bridge, Genoa, Italy.

In addition, the FERN Hollow Bridge in Pittsburgh, United States, collapsed in January 2022, as shown in Figure 2. The bridge collapsed due to a decrease in the durability of the steel bridge. The United States ranked 13th in the World Economic Forum (WEF) infrastructure maintenance in 2019. These evaluation results confirm that since 2000, the factor for the asset value decline due to the aging of facilities is greater compared to the GDP.

Figure 2.

Fern Hollow Bridge, Pittsburgh, USA.

Cases of infrastructure facility accidents in developed countries indicate that if investment for preventive maintenance is lacking, the maintenance costs will increase rapidly and may increase significantly in the future. Therefore, several experts worldwide have continually asserted that a new understanding of the asset values of infrastructure facilities, preventive investment, and proper countermeasures is necessary [12].

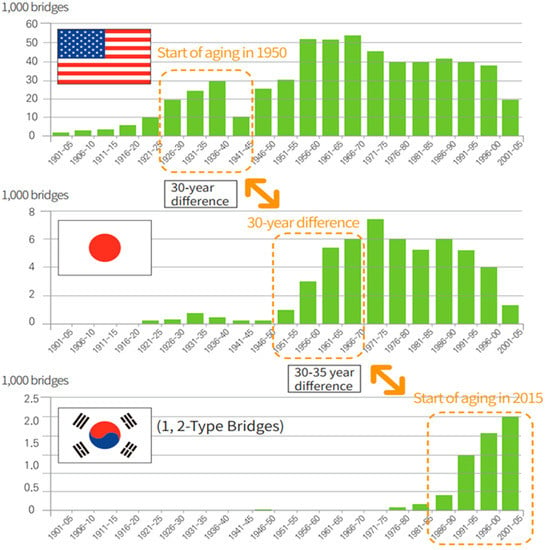

The analysis data presented in Figure 3 confirm the fact that the aging period of bridges in developed countries incurs important implications for South Korea. In the United States, bridges more than 30 years old began to emerge in 1950. In Japan, the aging of bridges began rapidly in 1980. In South Korea, many bridges were built along with the rapid growth of the economy since 1960. Hence, it can be seen that the aging of bridges began in 2015, about 35 years later, similar to that observed in the United States and Japan.

Figure 3.

Comparison of bridge completion status in South Korea, the US, and Japan.

According to a 2021 report by the United States, the repair and rehabilitation cost for aging bridges more than 30 years old was $11.5 billion in 2006; this cost increased to $18 billion in 2010. The report stated that an enormous repair and rehabilitation cost of $123 billion was required in 2021, which is about 10 times higher than that in 2006. This indicates that the maintenance cost increases by two times each year according to the aging of bridges in the United States. As of 2021, aging bridges more than 30 years old account for 66% of all bridges in the United States, and aging bridges more than 50 years old account for nearly 40% of all bridges; hence, the number of aging bridges is considerably high. The size of the country and the number of bridges in the United States are significantly larger than those in other countries. However, even if comparisons are made with one of the states, the margin of increase in bridge maintenance costs due to aging is similar.

2.2. Problem of Aging Bridges in South Korea

According to the 2016 State of Bridges Report by the Ministry of Land, Infrastructure, and Transport (as of December 2015), as of 2017, there were approximately 3500 aging bridges in South Korea that were more than 30 years old among more than 30,000 bridges that were constructed rapidly during the economic development period in the 1960s. Furthermore, it has been found that over 10,000 bridges will age rapidly after 10 years, and over 23,000 bridges will age rapidly after 20 years.

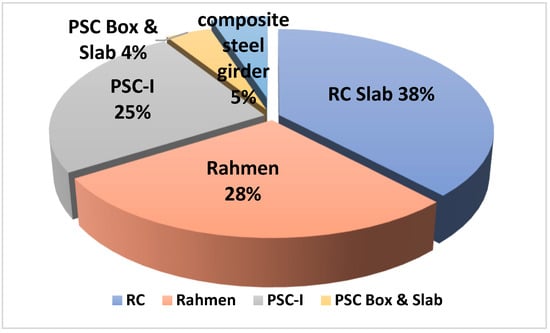

According to the “2016 State of Road, Bridges, and Tunnels Report” there are a total of 30,983 bridges, and the three most common types are RC slab, Rahmen, and PSC-I, as shown in Figure 4. These three types of bridges account for over 75% of the total bridges. Among them, the proportion of bridges over 30 years old was in the order of RC slab > Rahmen bridges > PSC-I.

Figure 4.

2017 Proportion of bridges in South Korea according to the superstructure type (service life over 30 years).

These survey results can be broadly classified for the three major types of bridges according to the aging of the domestic bridges and can be used as a criterion for determining the priority of bridges requiring maintenance in the future.

In recent years, the number of cases where steel wires deteriorate as the internal tendons of PSC-I bridges are exposed has been increasing gradually in South Korea, as shown in Figure 5. In the case of RC slab and Rahmen bridges, the most significant problem is the exposure of rebars due to the deterioration of concrete materials, excluding the deck of the bridge. For PSC bridges, the reduction of load-carrying capacity due to the deterioration of internal tendons is the most serious problem [13,14,15].

Figure 5.

Deterioration of internal tendons in a PSC bridge (2021).

2.3. Status of Countermeasures for Aging Bridges on a Global Scale

Various measures have been implemented on a global scale to overcome the issues related to aging bridges. The United States, Australia, and Canada have established a framework for asset management of infrastructure facilities to set up an asset management system with strong support from the central government. They have also prepared an information system that can perform proactive prevention and management to provide satisfactory services at an efficient cost. Moreover, the United Kingdom has established a master plan for the maintenance of national infrastructure, UK Infrastructure 2050, which involves an investment plan for aging infrastructure facilities through an integrated management system. Japan has assigned and is conducting a national research project that can manage the entire national infrastructure in an integrated manner.

The United States has recently begun investing in the maintenance of aging infrastructure facilities as a part of the economic recovery and expansionary fiscal policy; to this end, a $1 trillion investment has been performed. This policy decision is possible because the United States has recognized the gravity of the problem of aging infrastructure facilities and has created a high-quality infrastructure report card on the maintenance of aging facilities through continuous research. Furthermore, the United States has developed a rational maintenance plan, similar to that developed by the United Kingdom, and is undertaking systematic preparations to reflect the budget. Overall, many nations are dedicating extensive efforts toward the maintenance of aging infrastructure facilities because they foresee that maintenance costs will increase drastically if preventive maintenance of facilities is not carried out. In addition, they have recognized the importance of integrated maintenance.

Many countries around the world are introducing the concept of asset management into their maintenance systems as follows. Countries that have adopted advanced maintenance systems, such as the United Kingdom, the United States, and Australia, have established systems that recognize social overhead capital (SOC) as national assets and evaluate the cost-effectiveness, convenience, usability, and performance of facilities, as well as safety. In the United States, SOC maintenance is performed by FHWA (Asset Management Agency, established in 1998), which is a subsidiary of the Department of Transportation (DOT), AASHTO (Special Committee on Road Asset Management, established in 1999), and other transportation-related associations. The basic asset management system of the US FHWA consists of five stages and incorporates policy, budget, and expectations into its decision-making.

FHWA, for example, provides a framework to procedurally define the most cost-effective maintenance system focusing on road assets and to establish short- and long-term plans that allow for engineering principles and logical approaches for decision-making based on economic theory (FHWA, 1999). Recently, the SOC maintenance system in the United States has added a process of establishing preventive plans and preparing alternative measures in advance. It is also structured to continuously update the management system through a feedback loop after any actions are taken. This implies that all participants actively improve the system through their participation. For example, FHWA and AASHTO are involved in National Cooperative Highway Research Program (NCHRP) projects to prepare the research-based guidance on basic systems for asset management in transportation in 2002 and self-evaluation approach to encourage each state to participate in the improvement of the SOC maintenance system (AASHTO, 2002). In addition to the cross-state programs, each state is developing independent programs as its customized system to cater to its requirements. For instance, the Florida Department of Transportation runs its asset management for roads in five categories: roads, roadside areas, transportation services, drainage systems, and vegetation and landscape, considering mobility, economic efficiency, and sustainability for safe transportation systems.

Australia formed AustRoads, an association of government agencies, in 2005 to perform integrated asset management through a life cycle approach to realize public benefits in cost-effective ways. Most of the management authority for transportation facilities is delegated to state and local governments, and the representative agencies formed by state governments include the Roads and Traffic Authority (RTA), Department of Main Roads, and Roads Corporations of Victoria (VicRoads). These agencies define asset management as a “systematic process for cost-effective maintenance, improvement, and operations of facilities,” making integrated asset management their main scope of work. They also develop long-term management strategies for efficiencies, considering the provision of clear service and performance levels and management of risks from facility damage as key elements of asset management. The RTA operates various systems including Road Asset Management System, Traffic Asset Information Management System, Bridge Information System, and Maintenance Contract Management System. Utilizing information from those systems, the RTA performs asset management with priorities including government policies for disaster and hazard mitigation measures or financial assistance, safety enhancement, and functional reliability. The key elements here are a life cycle approach, the development of a cost-effective management strategy, and the establishment of a feedback system for a virtuous circle.

Canada is establishing asset management processes for efficient and innovative financial management plans and procurement for its managed assets. The processes are composed of stages from analysis of the asset conditions (grade, location, quantity) to implementation of maintenance works. For example, the country has introduced the Capital Planning Initiative (CPI) to evaluate the status and expected performance of the assets. The CPI assigns scores ranging from 0 to 100 based on criteria including the state, use, and functionality of the asset, with 76 points allocated for soundness and safety, and the other 24 points for cost-effectiveness. Quantified evaluation from the CPI allows for optimal investment strategies in comparison with other asset categories. For example, the Alberta Department of Transportation has delegated responsibility for managing roads and public facilities within the region to Alberta Infrastructure & Transportation (AIT) and has developed the Transportation Infrastructure Management System (TIMS) as an asset management system to promote maintenance programs and manage outsourced functions. TIMS consists of 20 application software for managing bridges, roads, closed culverts, signs, signals, and other related structures and attachments. The core elements in this system are the preparation of maintenance plans for road pavements, bridges, and road networks, and the development, promotion, and evaluation of the promoted maintenance programs. The key modules in TIMS include the decision-making support module based on objective data on the current and future status of road networks and expert opinions, the planning module for determining the status, function, and maintenance strategy of bridges, and the management module for managing the list of pavements including highways, selecting maintenance and the rehabilitation works, evaluating cost-effectiveness, and making the optimal investment decisions.

Japan is making efforts to take a preventive maintenance approach for its facilities to reduce maintenance costs as it sees an increasing number of aging facilities. As an analysis showed that bridges, among aging facilities, have a cost-saving opportunity of 17.4 trillion yen over the next 50 years by applying preventive maintenance, the Japanese government pays more attention to its SOC maintenance system. For example, the simulation results of applying preventive maintenance to bridges in Tokyo showed that maintenance costs can be reduced by about 68% over the next 30 years (Tokyo Construction Department, 2009). A long-term maintenance plan for road and bridge assets including a maintenance cost plan was established considering predictions of bridge aging and social benefits. The level of bridge management was classified by reviewing the judgment criteria for future facility maintenance costs, including the current conditions of bridges, their degradation progress, changes in budgets, and changes in the surrounding environment. Japan is planning to establish a facility maintenance evaluation system that minimizes the life cycle cost while providing social benefits. To achieve proactive maintenance, a plan has been established to conduct simulations that allow for comparison with the existing maintenance system over a 30-year horizon to maximize performance relative to maintenance costs.

As such, the analysis of advanced maintenance systems for aging bridges in various countries around the world highlights the common trend of the transition to a preventive system that can make effective decisions through asset assessment.

3. Preventive Maintenance Methods for Aging Concrete Bridges

3.1. Prevent Maintenance Analysis Model for Aging Concrete Bridges

For asset evaluation of bridges for preventive maintenance of aged concrete, both past and current state information must be utilized [16]. The current state information requires the history of the bridge, i.e., the number of years the bridge has been in service and the repairs and rehabilitation made on the bridge. In addition, data are required to allow continuous monitoring of the change in the performance grade of the bridge with respect to each member based on the bridge diagnosis results. Such data play an important role in determining the functional relationship of the deterioration model in which the performance deteriorates as the concrete bridge ages. The analyzed deterioration model should be able to verify the changes that have occurred over time for each type of damage for each member. It should also be able to monitor the change in performance upon the selection of a maintenance method according to the changed state. These data serve as a guideline for predicting the changing performance of the bridge.

For the members of a bridge, data on the number of years in use, the number of spans, and the span length are required. In addition, information related to environmental factors such as structural shape, traffic volume, temperature, humidity, amount of snow removal agent, and distance between the facility and the sea is utilized. Based on these data by bridge and data by members, the deterioration rate can be calculated through regression analysis according to the design load of the bridge. The most important factor for the preventive maintenance of bridges is to continuously accumulate the above-mentioned data on an annual basis and analyze them. This analysis is critical because the performance of the bridge continues to deteriorate each year, and a decision can be made to calculate the segment with rapidly degrading performance among all segments of the bridge and carry out preventive measures to improve or maintain the performance.

To establish a preventive maintenance strategy for aging concrete bridges, the facility management authorities should first determine the most desirable target performance level for maintenance, in addition to the cost analysis from a life cycle perspective based on various management activities. The most desirable target performance level, which means a maintenance strategy that minimizes life cycle costs associated with various maintenance activities throughout the asset life cycle, can be achieved from life cycle cost simulations at different target maintenance levels. Additionally, different maintenance strategies (or scenarios) for different target levels of maintenance should be developed based on the project-level analysis of the maintenance strategy. Maintenance strategy at the road network level, similar to that at the project level, aims at minimizing the life cycle asset costs by combining project-level maintenance strategies.

Genetic Algorithm (GA) is one of the most widely used techniques for generating maintenance strategies. This approach provides criteria for scenario evaluation based on the assumption that the most superior scenario survives through the evolution of maintenance scenarios from evolutionary perspectives. Between the performance of the aging bridge and the cost determined by the performance, the maintenance scenario uses the performance as a constraint to convert a multi-purpose maintenance problem into a single-purpose maintenance problem and to derive the optimal maintenance strategy. Here, the conditions used for the asset performance are at the project management level, while the cost is evaluated from the life cycle perspective. In summary, the ultimate goal of creating a project maintenance strategy is to derive a maintenance strategy that satisfies the project management level while minimizing the life cycle cost.

The stages of establishing a maintenance strategy can be divided into scenario creation, life cycle prediction, and scenario regeneration. In the scenario creation stage, a maintenance scenario is developed to achieve the target performance of the facility. If the current performance of the facility has already reached or exceeded the target performance, a scenario can be created by estimating the trend of performance degradation of the concrete bridge without maintenance, determining the initial maintenance delay period, and setting a lower priority for maintenance. If the current performance of a structure does not meet the target performance, a maintenance scenario is developed by applying weights to the performance criteria to determine maintenance priority. For example, if concrete bridge A which was built a long time ago is located on the coast, it can be assumed that its safety and durability performance had deteriorated more than other types of bridges in different environments. In this case, it would be reasonable to propose a target performance that prioritizes safety and durability over usage performance rather than a maintenance scenario that aims to achieve the target performance. Once the maintenance scenario for the concrete bridge has been developed, the life cycle costs before and after repair and rehabilitation activities can be predicted, compared, and analyzed to create a scenario that maximizes the effectiveness of maintenance costs and safety performance of the concrete bridge.

One of the key success factors in the establishment of preventive maintenance systems for concrete bridges is the digitalization of data on the performance of current aging concrete bridges.

3.2. Proposal of Empirical Experiments to Procure Data for Preventive Maintenance of Aging Concrete Bridges

Dismantled bridges should actively be utilized for data acquisition toward the preventive maintenance of aging concrete bridges. Upon analyzing the status of dismantled bridges, it was observed that the most rational reason for dismantling a bridge is the change in traffic volume and the average annual rainfall rather than the aging of the bridge. In particular, the change in traffic volume causes various bridges to be dismantled and replaced due to the change in road routes. In general, when a concrete bridge is dismantled, the dismantled parts are either destroyed at the site and transported or transported to a nearby location and destroyed, depending on the environment of the dismantling site. It is important to obtain a part of the bridge during this process. It is very difficult to age concrete artificially. In the case of a large structure, various types of deterioration occur according to various environmental conditions. Therefore, it is important to obtain some girders and slabs separately to procure a variety of data related to aging [17,18,19].

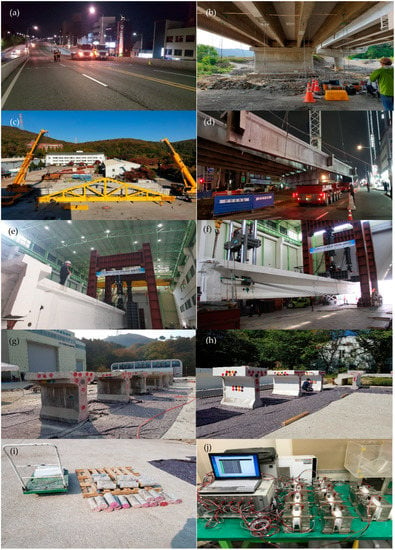

The procedure for the empirical experiment of an aging concrete bridge must first start with analyzing the performance of the bridge immediately before dismantling it, as shown in Figure 6a,b. The empirical experiment that can be conducted before dismantling the bridge is as follows: The basic condition of the bridge is evaluated. In addition, the load-carrying capacity and the behavioral characteristics according to the damage can be verified through vehicle load testing. If it is difficult to transport a dismantled section to the laboratory or transport the dismantled section, it is important to prepare equipment so that the performance can be verified before destroying the dismantled section at the site, as shown in Figure 6c. Most concrete bridges are first cut and not destroyed at once by their own weight. In this process, the specimens are cut into a girder and a slab is transported to the laboratory, as shown in Figure 6d. A basic structural experiment is conducted on the transported members, as shown in Figure 6e, to verify the change in the structural performance due to aging and to obtain the data for analyzing the correlation with the material experiment results [20,21,22,23]. In the case of a reinforced bridge, the rehabilitation method is directly applied to the same members, as shown in Figure 6f, and the destruction and fatigue tests are carried out to verify the effect of the rehabilitation method [24].

Figure 6.

Demonstrating the test procedure: (a) Load-carrying capacity evaluation of a bridge in public use; (b) Evaluation of the state of a bridge in public use; (c) Structural performance experiment of a bridge at the site; (d) Transporting slab and girder members of a dismantled bridge; (e) Structural (destruction) experiment for members of a dismantled bridge; (f) Experiment verifying the rehabilitation performance of a dismantled bridge member; (g) Cutting off a dismantled bridge and separating the tendons and rebars; (h) Non-destructive performance test of members of a dismantled bridge; (i) Test for mechanical properties of concrete; (j) Concrete durability test; (k) Test for mechanical properties of rebars and internal tendons.

There are various experiments for checking the performance of materials used in concrete bridges. First, the transported concrete member is cut into 1–2 m units, as shown in Figure 6g–k. Then, carbonation and non-destructive tests are performed on the cut cross-section, and specimens are collected from various parts through internal tendons, rebars, and coring. The collected specimens are used to check various mechanical properties, such as the concrete’s compressive strength, non-destructive strength, modulus of elasticity, and Poisson’s ratio. Next, durability tests, such as carbonation and sodium chloride measurements, are carried out to obtain structural and material property data. These data can be used as objective data on the performance of aging concrete bridges through various structural analyses and comparative verifications. In addition, these data become an indicator of the performance of the currently aging concrete bridge. If such data can be obtained continually, it is possible to check the segment where the performance will deteriorate rapidly after 30 years. Hence, these data can be utilized to make decisions for preventive maintenance objectively [25,26]. However, this method is not suitable for application to all bridges because of the high maintenance cost. Therefore, it is reasonable to select a representative bridge suitable for the environment and region and use it as an index for qualitative evaluation.

If the recent data analysis technology utilizing deep learning is applied to the obtained data, it will be possible to utilize diverse and efficient methods for maintenance in the future.

4. Conclusions

Performance evaluation, repair, and rehabilitation have continually been performed on aging concrete bridges through maintenance since their construction. However, systematic digital or verification data obtained through empirical experiments are not available. This problem makes it difficult to quantitatively evaluate the performance of concrete bridges because of aging and the effect of repair and rehabilitation. As a result, there is a high probability that maintenance budgets will be duplicated. In addition, it may not be possible to take proper repair and rehabilitation measures at a time when the performance degrades rapidly. Further, a problem may occur where an aging concrete bridge that should be dismantled and rebuilt is not dismantled, and instead, more budget is spent on maintaining it.

Thus, the efficient maintenance of deteriorated concrete bridges requires the accumulation of data that can be used for preventive maintenance of these bridges and the development of systems for obtaining such data. Previous studies had mainly focused on repairing or enhancing deteriorated infrastructure facilities. Therefore, further research should be conducted beyond the scope of existing studies to develop measures for preemptively maintaining facilities before they become deteriorated.

This study presents a method and procedure for procuring data by conducting empirical experiments on aging concrete bridges. The following conclusions can be drawn from this study:

- Maintenance data of aging concrete bridges should be procured as digital data.

- Digital data for preventive maintenance of concrete bridges must first be procured based on the current performance.

- To predict the future performance of an aging concrete bridge, it is necessary to obtain data on the deterioration state of the members—from the time the aging started—based on the current state of the bridge.

- The empirical experiment for aging concrete bridges should actively utilize dismantled bridges. It is efficient to procure the history of changes in the performance of the bridges by statistically analyzing the accumulated data on performance changes from the extent of aging.

- Various deep learning-based analysis techniques that utilize the empirical, experimental data of aging concrete bridges need to be developed. Moreover, research must be continued to determine an efficient maintenance period and calculate efficient maintenance costs.

Author Contributions

Conceptualization, Methodology and analysis H.-j.K.; Experiments and investigation, H.-j.K. and Y.-h.S.; Writing—original draft preparation, Writing—review and editing H.-j.K.; Visualization, H.-j.K. and Y.-h.S.; Supervision, J.-w.H., S.-h.K. and C.-y.K. All authors have read and agreed to the published version of the manuscript.

Funding

Korea Agency for Infrastructure Technology Advancement: (2021R1A6C101B382).

Acknowledgments

This research was supported by Korea Basic Science Institute (National Research Facilities and Equipment Center) grant funded by the Ministry of Education. (2021R1A6C101B382).

Conflicts of Interest

The authors declare no conflict of interest. The sponsors had no role in the design, execution, interpretation, or writing of the study.

References

- Chae, M.-J.; Lee, G.; Kim, J.-R.; Cho, M.-Y. Analysis of Domestic and International Infrastructure Asset Management Practices and Improvement Strategy. KJCEM 2009, 10, 55–64. [Google Scholar]

- Lee, D.H.; Kim, J.Y.; Ji, S.-G.; Lee, S.S.; Kim, J.-W. Study about the Evaluation of Bridge Asset Valuation for Maintenance. Int. J. Highw. Eng. 2012, 14, 13–23. [Google Scholar] [CrossRef]

- Kim, G.; Kim, D.-J.; Lim, J.-K.; Park, M.Y.; Lee, M.J. Basic Study on Bridge Asset Management Framework and Los for Efficient Downtown Bridge Maintenance. J. Korea Acad. -Ind. Coop. Soc. 2016, 17, 671–679. [Google Scholar] [CrossRef]

- Lee, S.-G. The SOC Must Be Healthy to Ensure the Development of the Nation. CERIK Constr. Ind. Policy 2017, 79, 127. [Google Scholar]

- Zucca, M.; Crespi, P.; Stochino, F.; Puppio, M.L.; Coni, M. Maintenance interventions period of existing RC motorway viaducts located in moderate/high seismicity zones. Structures 2023, 47, 1323–1340. [Google Scholar] [CrossRef]

- Abdal, S.; Mansour, W.; Agwa, I.; Nasr, M.; Abadel, A.; Özkılıç, Y.O.; Akeed, M.H. Application of Ultra-High-Performance Concrete in Bridge Engineering: Current Status, Limitations, Challenges, and Future Prospects. Buildings 2023, 13, 185. [Google Scholar] [CrossRef]

- Ahmed, M.; Metiche, S.; Masmoudi, R. Literature Review on External Carbon Fiber-Reinforced Polymers (CFRP) Reinforcements for Concrete Bridges. ACI Symp. Spec. Publ. 2022, 356, 203–223. [Google Scholar]

- Lee, S.-G. Legislation for Improving the Performance and Extending the Life of Aging Infrastructure in Seoul. KSCE 2016, 11, 38–41. [Google Scholar]

- Jo, J.; Go, T.; Yu, J.; Yun, S.; Yun, J.; Lee, S.; Lee, I.; Jeon, Y.; Han, S.; Hyeon, I. Seoul metro infrastructure longevity study. KSCE 2015, 76–77. [Google Scholar]

- Lee, Y.h. An Analysis of the Aging State of Urban Infrastructure and a Proposal for Sustainable Performance Improvement and Extending the Lifespan. AJIP 2020, 9, 79–94. [Google Scholar]

- Shim, C.; Dang, S.; Lon, S.; Jeon, C. Development of a Bridge Maintenance System for PSC Bridges Using 3D Digital Twin Model. Struc. Infrastruc. Eng. 2019, 15, 1319–1332. [Google Scholar] [CrossRef]

- Santarsiero, G.; Masi, A.; Picciano, V.; Digrisolo, A. The Italian Guidelines on Risk Classification and Management of Bridges: Applications and Remarks on Large Scale Risk Assessments. Infrastructures 2021, 6, 111. [Google Scholar] [CrossRef]

- Jeon, C.-H.; Lee, J.-B.; Lon, S.; Shim, C.-S. Equivalent Material Model of Corroded Prestressing Steel Strand. J. Mater. Res. Technol. 2019, 8, 2450–2460. [Google Scholar] [CrossRef]

- Lee, J.; Lee, Y.-J.; Shim, C.-S. Probabilistic Prediction of Mechanical Characteristics of Corroded Strands. Eng. Struc. 2020, 203, 109882. [Google Scholar] [CrossRef]

- Jeon, C.-H.; Nguyen, C.D.; Shim, C.-S. Assessment of Mechanical Properties of Corroded Prestressing Strands. Appl. Sci. 2020, 10, 4055. [Google Scholar] [CrossRef]

- Jeon, C.-H.; Shim, C.-S. Flexural Behavior of Posttensioned Concrete Beams with Multiple Internal Corroded Strands. Appl. Sci. 2020, 10, 7994. [Google Scholar] [CrossRef]

- Kim, H.-J. Development of 3D Damage Management Platform for 3 Types of Local Government Facilities (Bridges). KSCE 2021, 69, 42–47. [Google Scholar] [CrossRef]

- Kim, H.-J.; Sung, Y.H.; Kwon, S.H.; Kim, C.Y.; Park, Y.S. Short-Medium Span Bridges Based on Full-Scale Experimental Verifications for Long Life Bridges. In Bridge Maintenance, Safety, Management, Life-Cycle Sustainability and Innovations, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Kim, S.-H.; Park, J.-S.; Jung, W.-T.; Kim, T.-K.; Park, H.-B. Experimental Study on Strengthening Effect Analysis of a Deteriorated Bridge Using External Prestressing Method. Appl. Sci. 2021, 11, 2478. [Google Scholar] [CrossRef]

- Kim, S.-H.; Park, J.-S.; Jung, W.-T.; Kang, J.-Y. Strengthening Effect of the External Prestressing Method That Simulated a Deterioration Bridge. Appl. Sci. 2021, 11, 2553. [Google Scholar] [CrossRef]

- Kim, T.-K.; Park, J.-S. Experimental Evaluation of the Durability of Concrete Repair Materials. Appl. Sci. 2021, 11, 2303. [Google Scholar] [CrossRef]

- Jeon, C.-H.; Sim, C.; Shim, C.-S. The Effect of Wire Rupture on Flexural Behavior of 45-Year-Old Posttensioned Concrete Bridge Girders. Eng. Struc. 2021, 245, 112842. [Google Scholar] [CrossRef]

- Lee, J.; Lee, Y.-J.; Shim, C.-S. A Multi-Scale Framework for Probabilistic Structural Analysis of PSC Girders Considering Pit Corrosion of Prestressing Wires. Eng. Struc. 2021, 244, 112745. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, Y.-J.; Shin, D.H.; Sim, S.-H. Automated Real-Time Assessment of Stay-Cable Serviceability Using Smart Sensors. Appl. Sci. 2019, 9, 4469. [Google Scholar] [CrossRef]

- Shin, S.; Lee, H.; Lee, J.-H. Effects of Prestressing Force on Natural Frequency of Prestressed Concrete Beams Considering Self-Weight. Struc. Eng. Mech. 2020, 74, 495–502. [Google Scholar]

- Lee, K.; Jeong, S.; Sim, S.-H.; Shin, D.H. Field experiment on a PSC-I bridge for convolutional autoencoder-based damage detection. Struc. Health Monit. 2020, 20, 1627–1643. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).